Eccentric check reducer forging method

An eccentric tube, one-way technology, applied in the field of metal forging, can solve the problems of inconvenient installation, increased cost, material waste, etc., and achieves the effects of high production efficiency, qualified performance, and avoidance of rod deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by taking the forging of a unidirectional eccentric tube with a different diameter of 40Cr as an example:

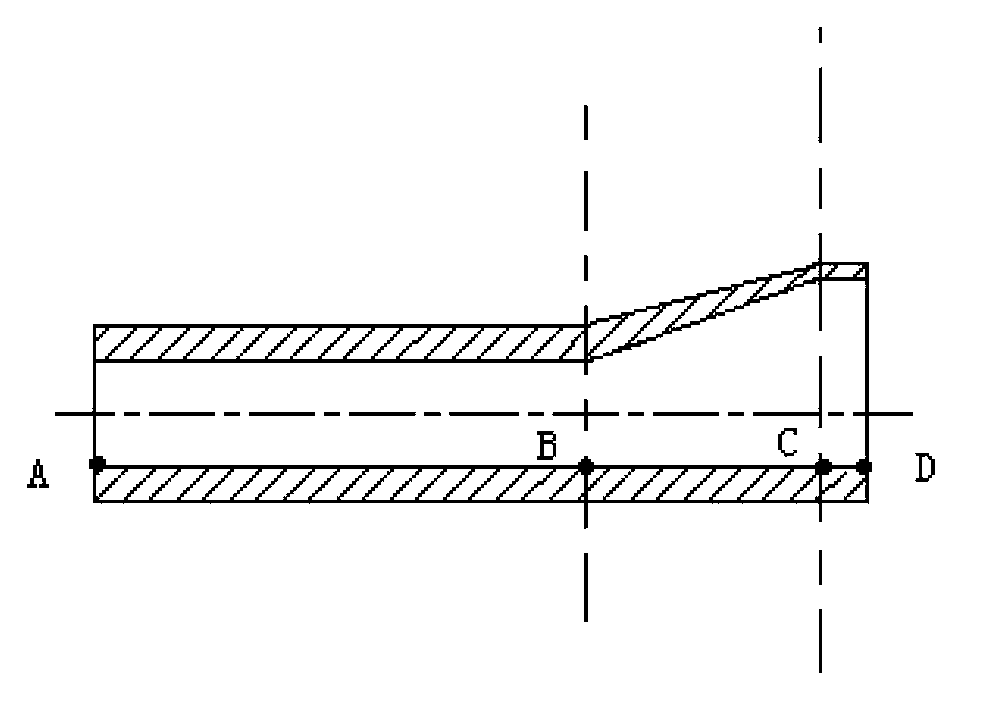

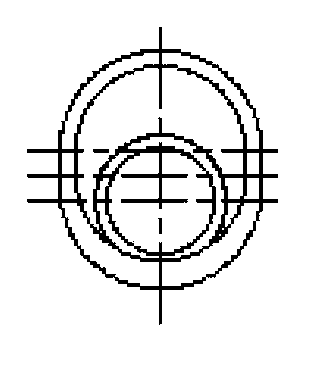

[0020] Such as figure 1 Shown: The length of the one-way eccentric tube with different diameters is AD 560MM, the forming part is BD 180MM, and the outer diameter of the rod is the inside diameter of The maximum size of the outer hole of the forming part is 178MM, and the minimum size is 109MM; the maximum size of the inner hole is 150MM, and the minimum size is 53MM.

[0021] A method for forging a one-way eccentric tube with different diameters, comprising the following steps:

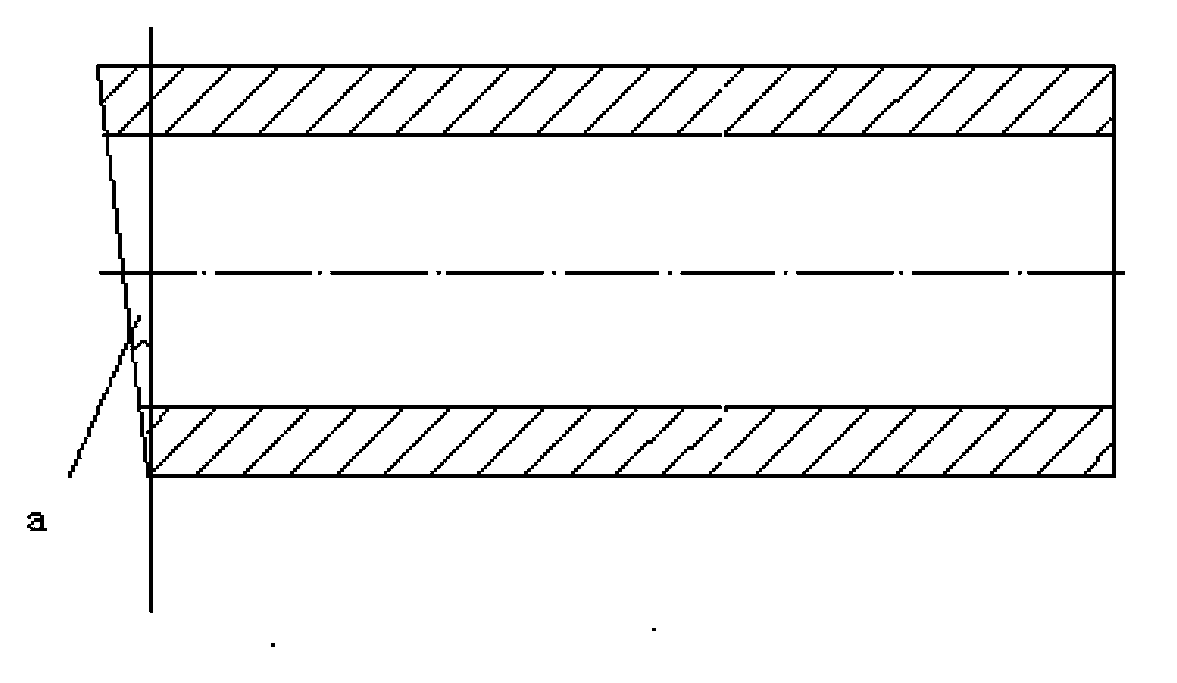

[0022] In the first step, the front end of the tube blank is turned into a slope, and the size of the slope angle a is 7°;

[0023] The second step is to apply glass lubricant to the inner hole of the tube blank, and the spraying range is to extend 20MM from the forming part and backward;

[0024] The third step is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com