Automobile dual-phase steel and machining method thereof

A processing method and dual-phase steel technology, applied in the field of iron and steel metallurgy, can solve the problems of the inability to realize the dual-phase steel segmental cooling process, air-cooling temperature, air-cooling time and coiling temperature cannot be stably controlled, and achieve stable and controllable air-cooling temperature , To ensure the effect of process temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] like Figure 1-Figure 5 As shown, the chemical composition of automotive dual-phase steel is C: 0.06wt%, Mn is 1.28wt%, Ti is 0.015wt%, Nb is 0.023wt%, Cr is 0.18wt%, Als is 0.03wt%, and the balance Fe and unavoidable impurities, the thickness of the dual-phase steel is 6mm, the preparation method of the dual-phase steel includes:

[0033] 1) Pretreatment and smelting of molten iron containing chemical components of automotive dual-phase steel;

[0034] 2) casting the smelted liquid metal to obtain a billet;

[0035] 3) heating the billet in a heating furnace, the soaking temperature of the heating furnace is 1235°C;

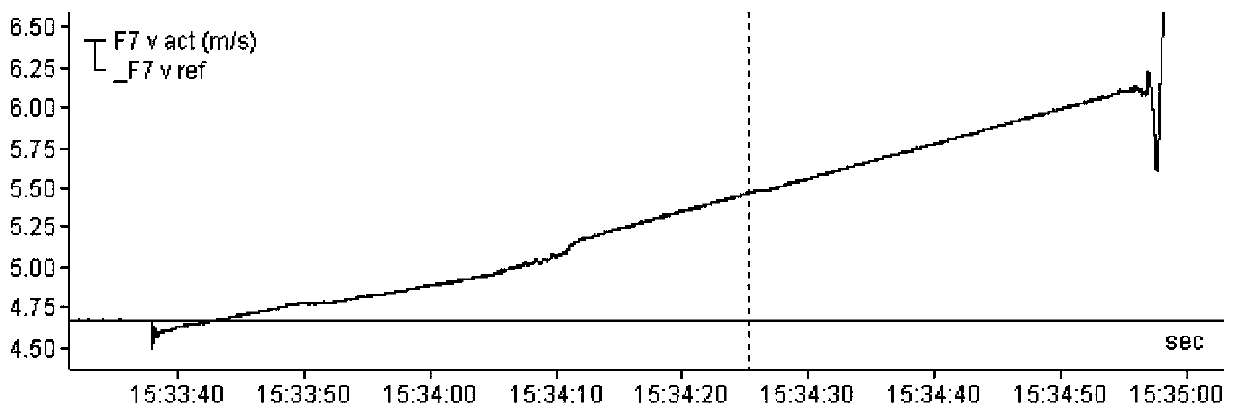

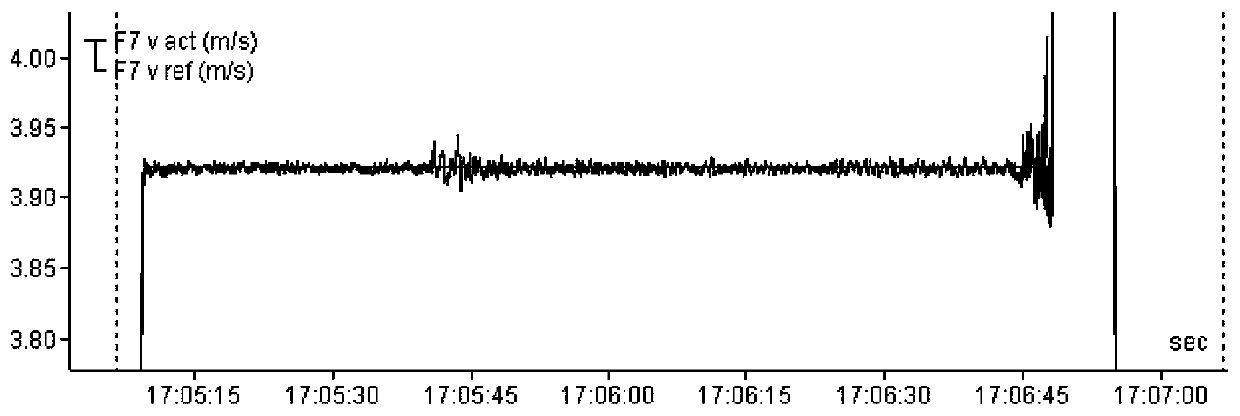

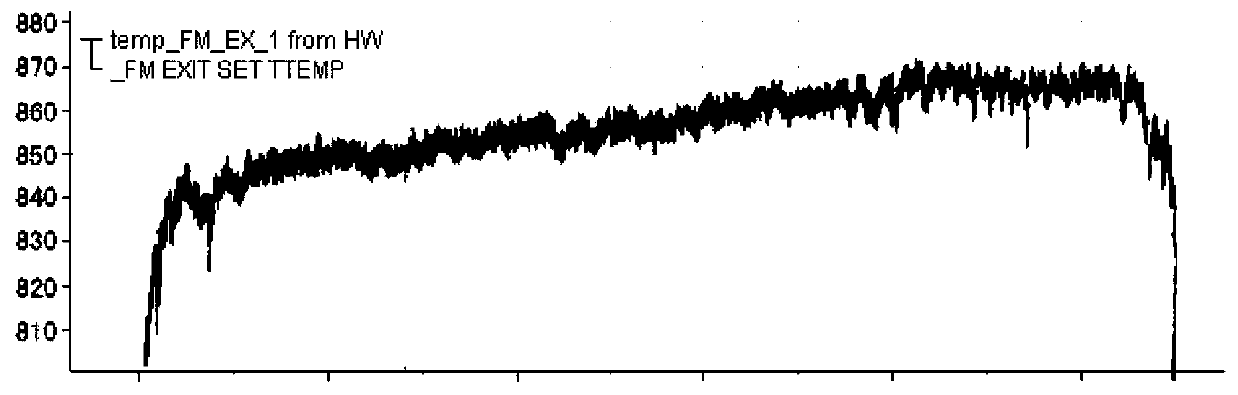

[0036] 4) Adopt two-stage rolling, control the exit temperature of rough rolling at 1025°C, limit the acceleration of rolling mill equipment through primary control, and limit the acceleration of finishing rolling temperature to 0m / s 2 , cancel the closed-loop temperature control of the secondary model, use the hot coil box to reduce the temperature de...

Embodiment 2

[0047] The chemical composition of dual-phase steel for automobiles is C: 0.05wt%, Mn: 1.33wt%, Ti: 0.020wt%, Nb: 0.028wt%, Cr: 0.22wt%, Als: 0.04wt%, and the balance is Fe and Unavoidable impurities, the thickness of the dual-phase steel is 11mm, and the preparation methods of the dual-phase steel include:

[0048] 1) Pretreatment and smelting of molten iron containing chemical components of automotive dual-phase steel;

[0049]2) casting the smelted liquid metal to obtain a billet;

[0050] 3) heating the billet in a heating furnace, the soaking temperature of the heating furnace is 1235°C;

[0051] 4) Adopt two-stage rolling, control the exit temperature of rough rolling at 1040°C, limit the acceleration of rolling mill equipment through primary control, and limit the acceleration of finishing rolling temperature to 0m / s 2 , canceled the temperature closed-loop control of the second-level model, and used the hot coil box to reduce the temperature deviation of the head and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com