A method for preparing high-strength and high-toughness aluminum alloy die forgings for aircraft wings

A high-strength, high-toughness, aluminum alloy mold technology, applied in the direction of metal processing equipment, can solve the problems that affect the safety of aircraft, increase the probability of die forging fracture, low-magnification tissue flow-through, etc., achieve high bearing capacity, qualified electrical conductivity, high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

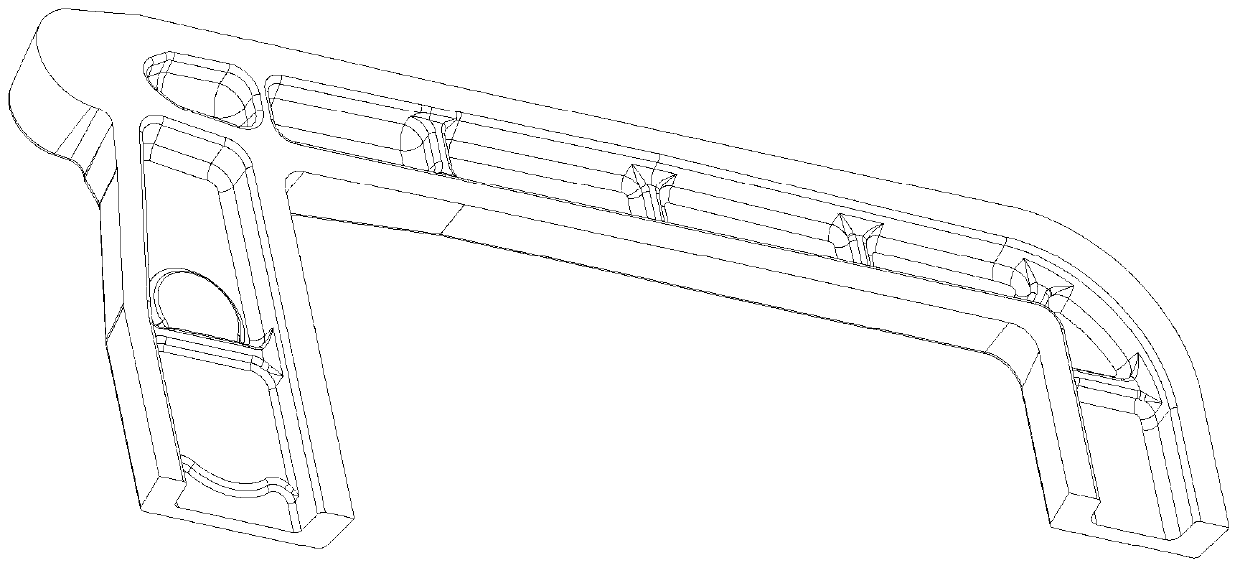

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of a kind of aircraft wing high-strength high-toughness aluminum alloy die forging of this embodiment is carried out according to the following steps:

[0021] 1. Casting 2D70 aluminum alloy ingot;

[0022] 2. Clean the thimble hole of the ingot prepared in step 1, and then heat and extrude to obtain an aluminum alloy bar blank;

[0023] 3. On the free forging hydraulic press, use a bending machine to bend the aluminum alloy bar blank prepared in step 2, and then perform heating forging to obtain the L aluminum alloy blank;

[0024] Four, on the 10,000-ton hydraulic press, use a large flat anvil to flatten the L aluminum alloy blank prepared in step 3;

[0025] 5. Put the flattened L aluminum alloy blank processed in step 4 into a mold for heating and pre-pressing to obtain a pre-pressed forging;

[0026] 6. Etching and washing the pre-pressed forging prepared in step 5;

[0027] 7. Invert the upper and lower molds of t...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that: in Step 1, the diameter of the 2D70 aluminum alloy ingot is 420 mm, and the hydrogen content is less than 1.2 mL / g. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: when heating and extruding in step two, the ingot is kept warm for 5 hours after reaching temperature, and the temperature of the pressing cylinder is controlled at 420°C to 450°C, and the extrusion speed is 1.5 m / s, the size of the aluminum alloy bar blank is Φ110mm~Φ120mm, and the length is 1700mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com