Patents

Literature

60results about How to "No defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

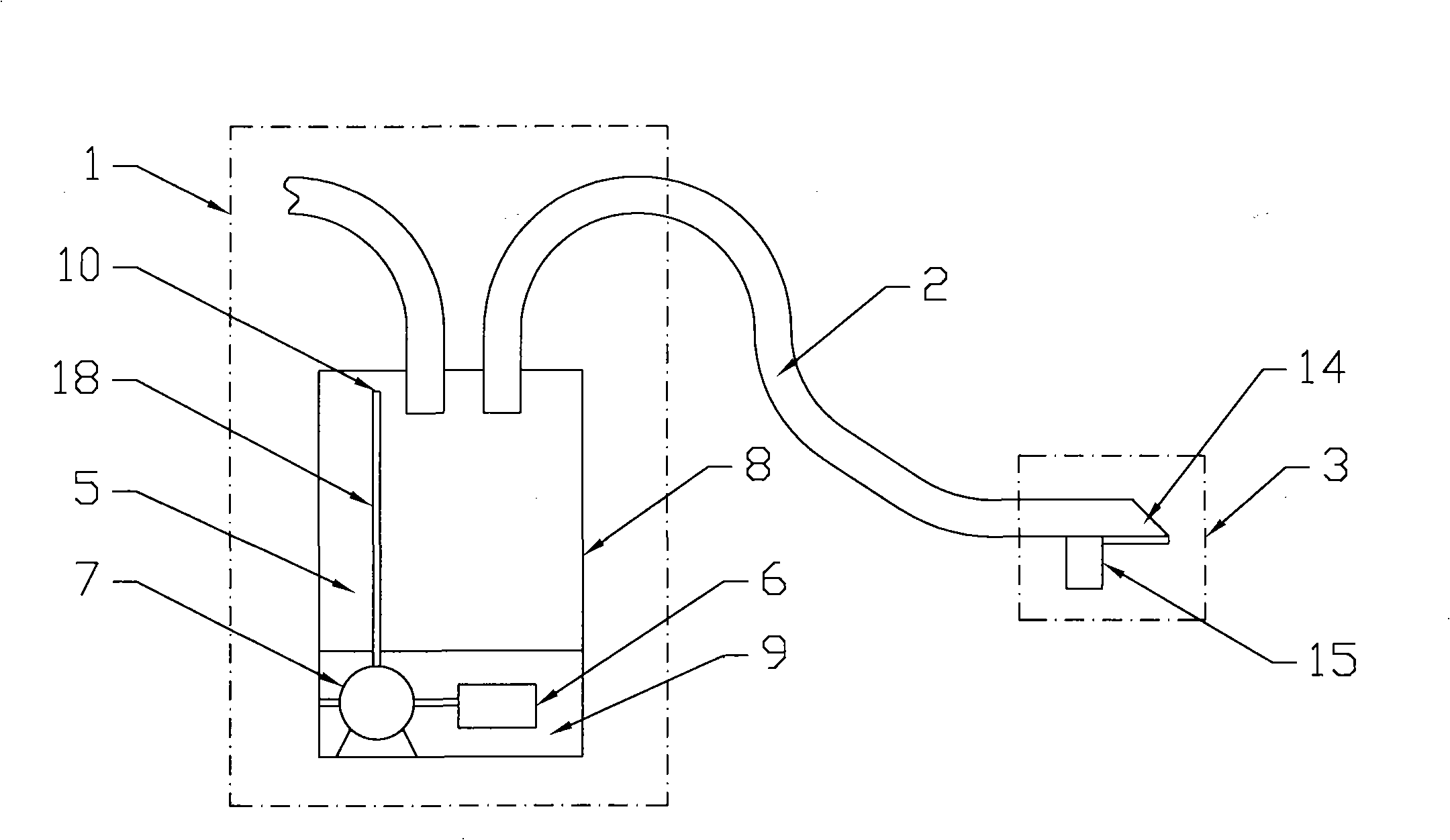

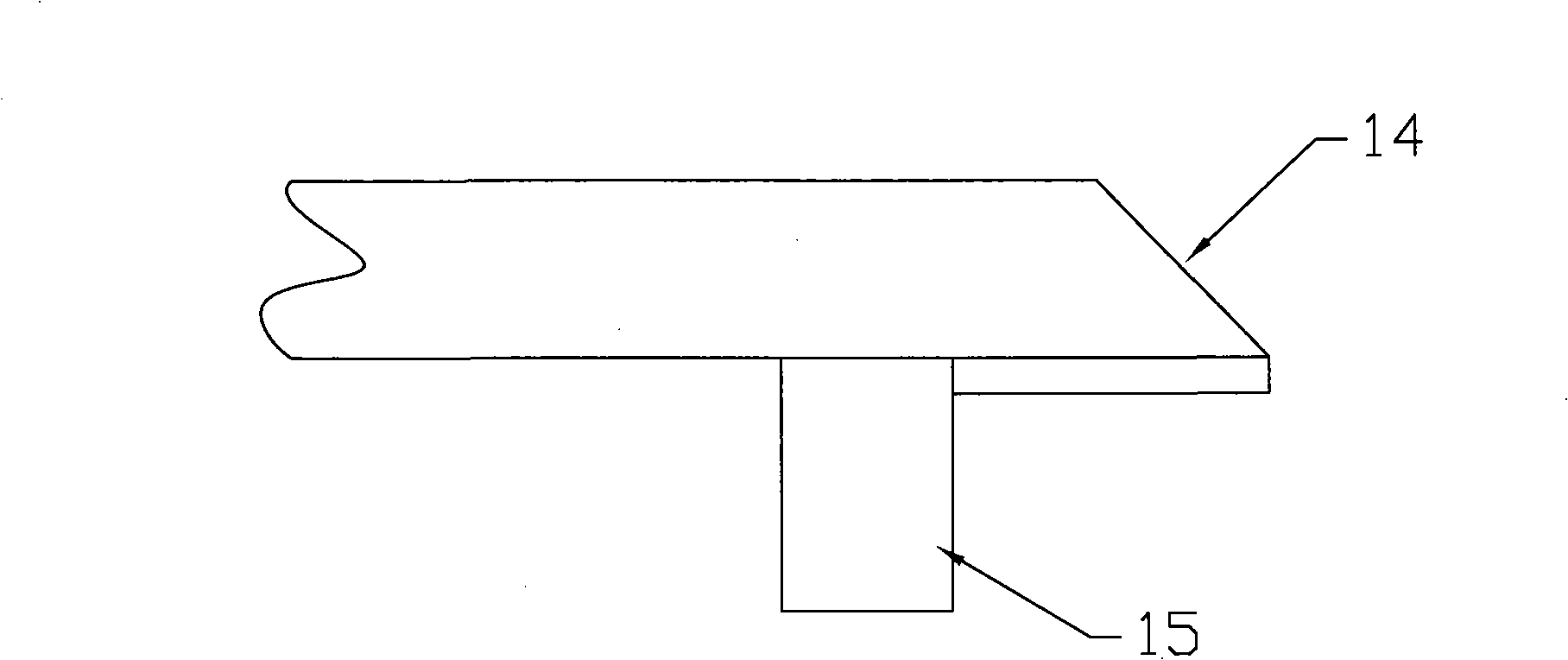

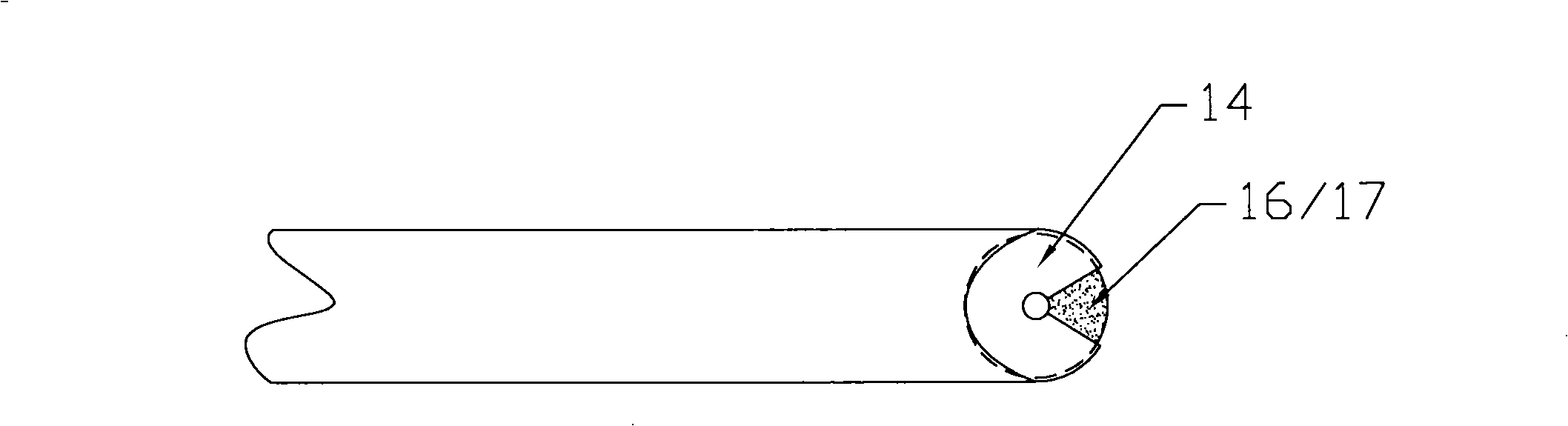

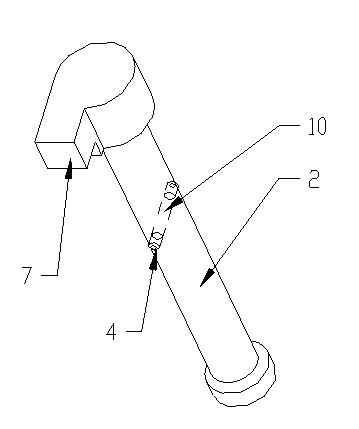

Vacuum mechanical tea picker

The invention discloses a vacuum mechanical tea plucking device and belongs to a mechanical device. The prior mechanical tea plucking device has the drawbacks of incomplete tea leaves, old and new mixed leaves, leaves mixed with stalks, etc. The vacuum mechanical tea plucking device consists of a vacuum collector and a mechanical plucker connected with the vacuum collector through a curved pipe, wherein the vacuum collector comprises a closed collection tank with a door and a power-actuated vacuum pump for producing negative pressure in the collection tank, the mechanical plucker comprises a suction mouth and a power-actuated plucking blade arranged at the suction mouth, and a flectional pipe is used to connect the collection tank and the suction mouth. When plucking tea leaves, the mechanical tea plunking device selects new leaves and tender shoots, and aims the plucking blade arranged at the suction mouth in front of the mechanical plucker at the roots of the leaves and tender shoots and makes the blade contact the roots and cut off the roots, so that the leaves and tender shoots are sucked into the collection tank from a collection opening through the flectional pipe under the action of the negative pressure. The vacuum mechanical tea plucking device overcomes the drawbacks of the prior art, and reduce product pollution by avoiding fingers, nails and so on contacting the leaves.

Owner:何龙

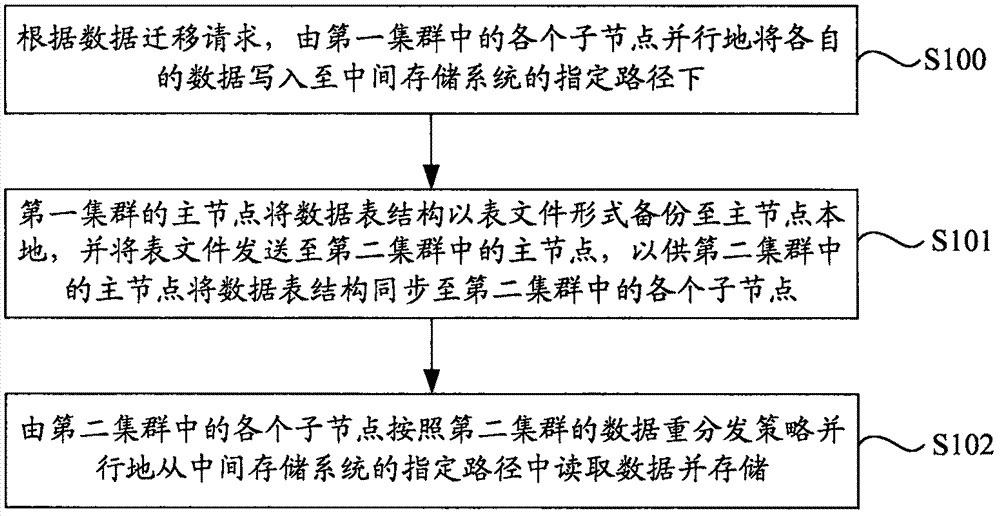

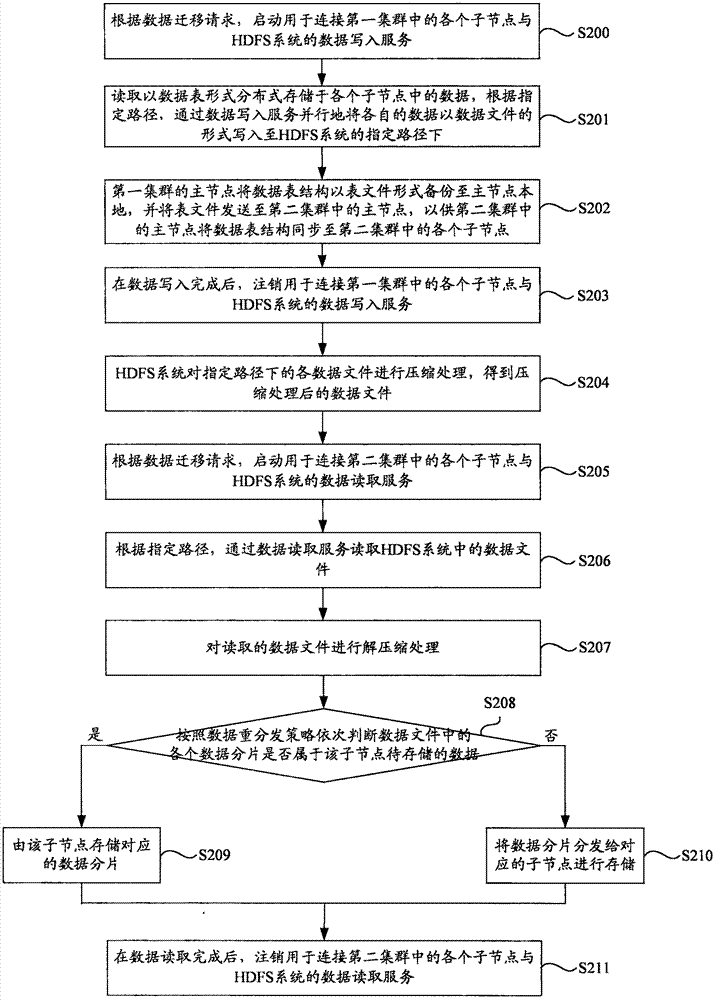

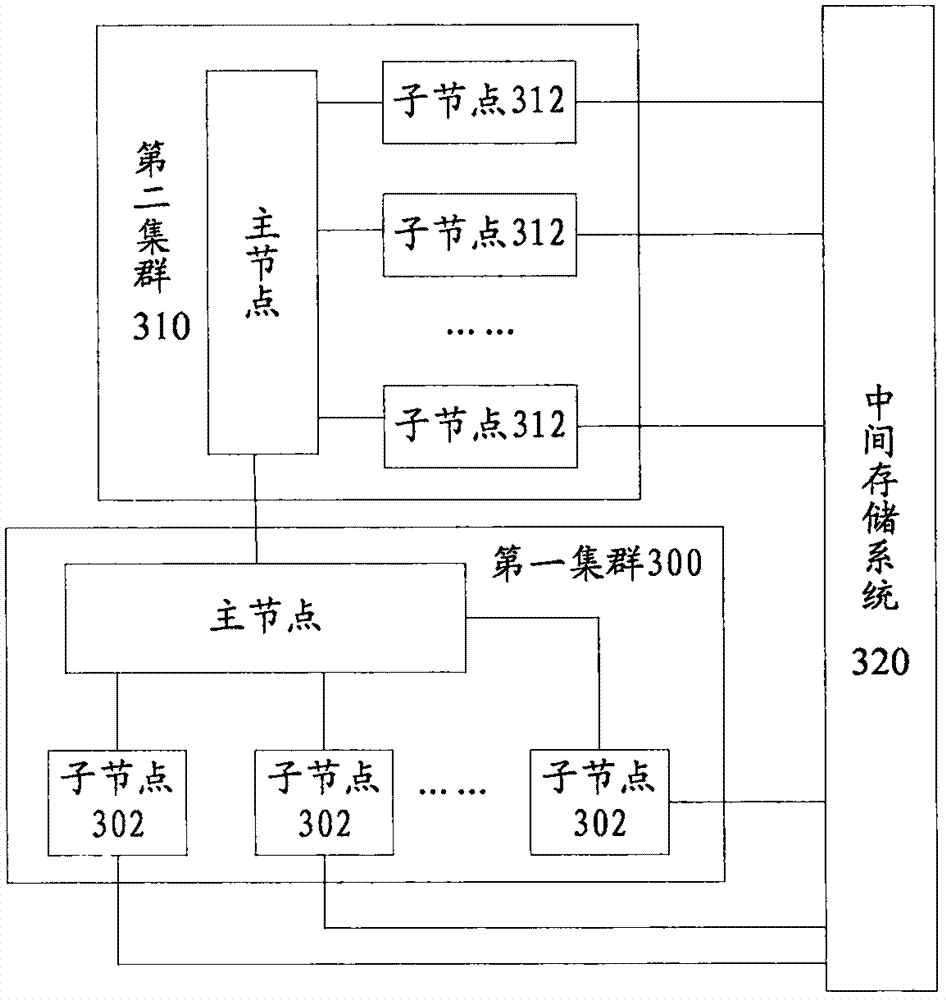

Inter-cluster data migration method and system, server and computer storage medium

ActiveCN107391629AImprove migration speedShorten the timeDatabase distribution/replicationSpecial data processing applicationsSheet structureIntermediate storage

The invention discloses an inter-cluster data migration method and system, a server and a computer storage medium. The method is used for performing data migration between a first cluster and a second cluster, and the first cluster and the second cluster each comprise a main node and at least one sub node; the method comprises the steps that according to a data migration request, data is written by the sub nodes in the first cluster concurrently into a designated path of an intermediate storage system; the main node of the first cluster backs up a data sheet structure to a main node locally in a list file mode, and sends a sheet file to the main node in the second cluster so that the main node in the second cluster can synchronize the data sheet structure to the sub nodes in the second cluster; the sub nodes in the second cluster reads and stores data from the designated path of the intermediate storage system currently according to a data redistribution strategy of the second cluster, the data migration speed is increased, and the time needed by data migration is shortened.

Owner:360 TECH GRP CO LTD

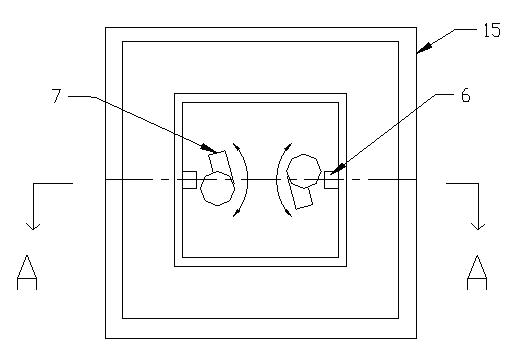

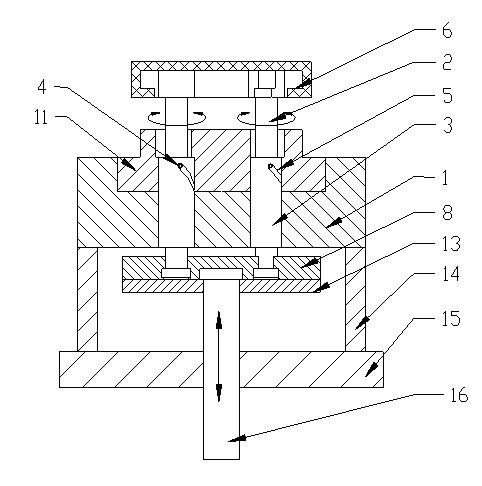

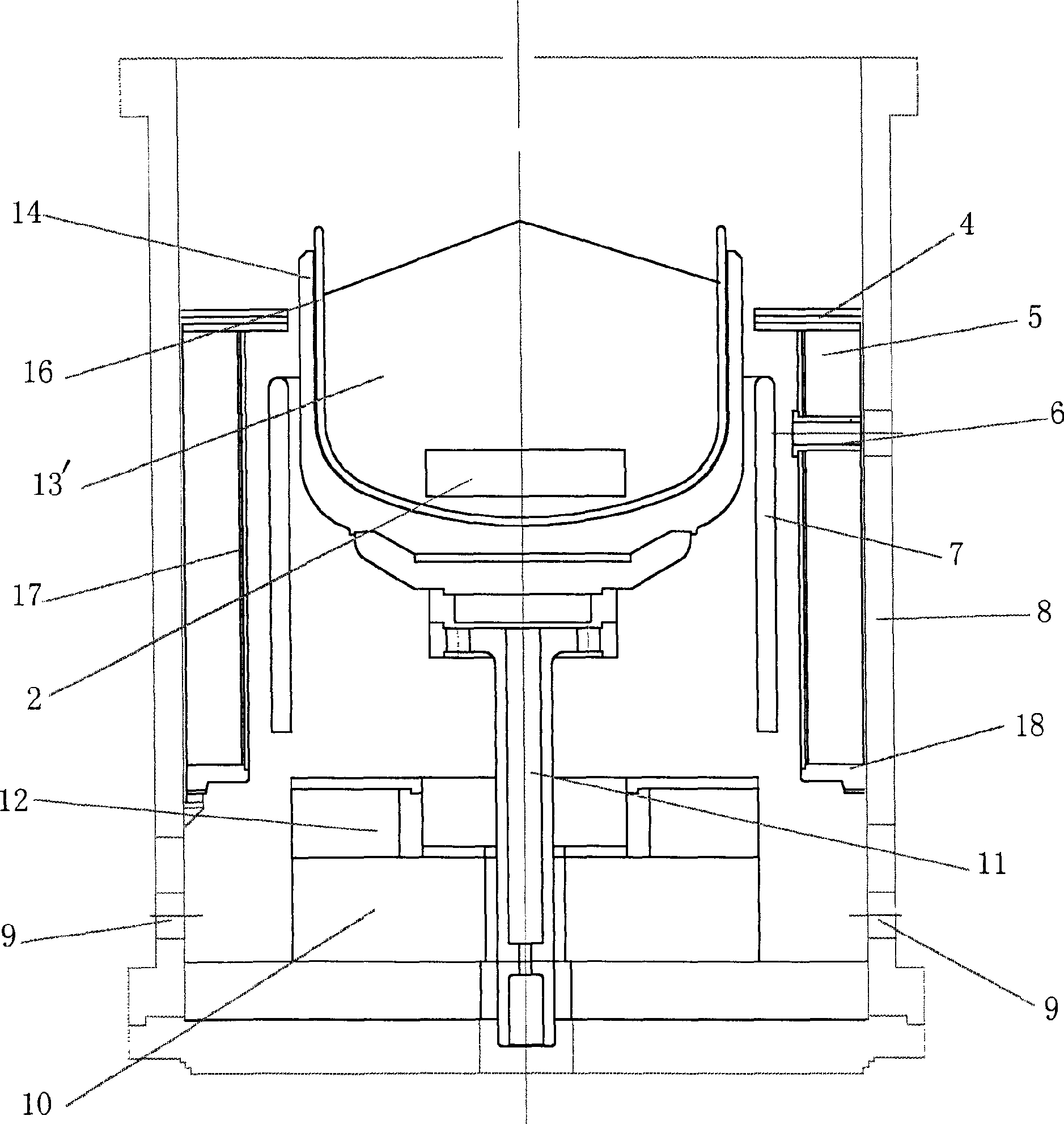

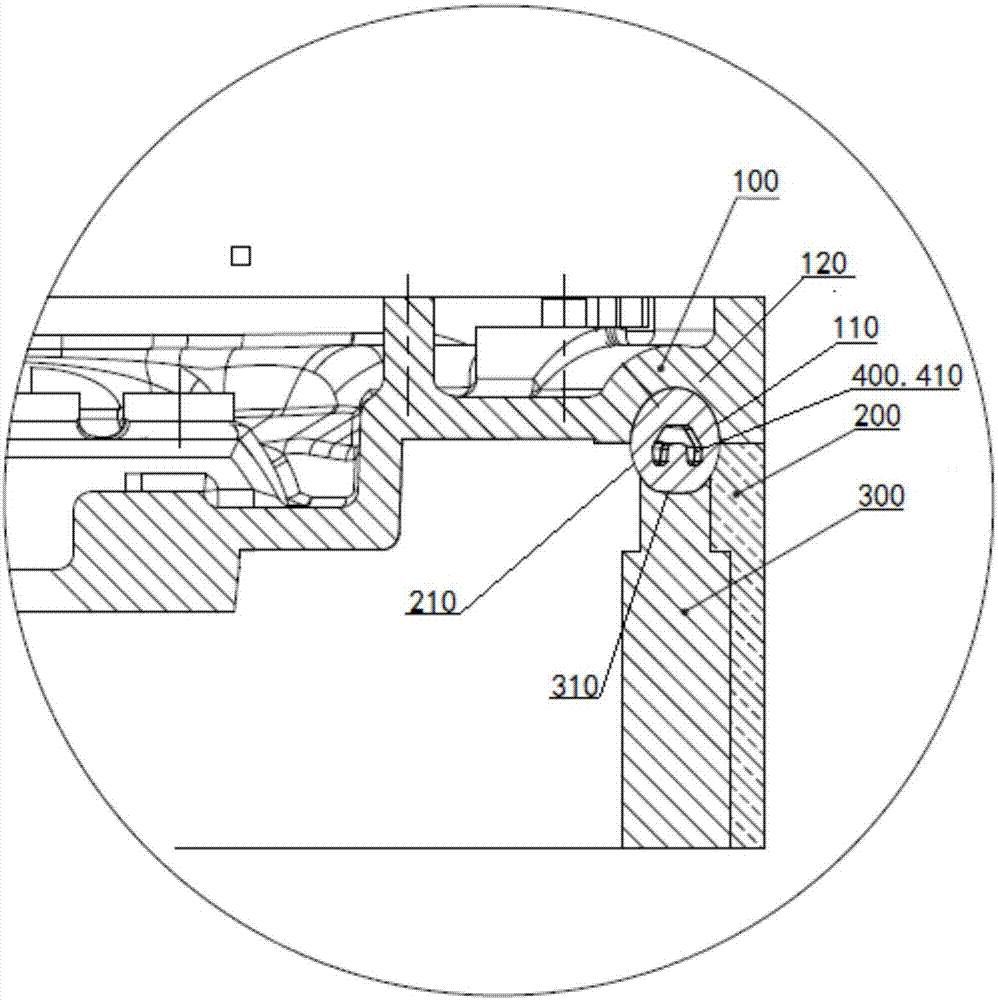

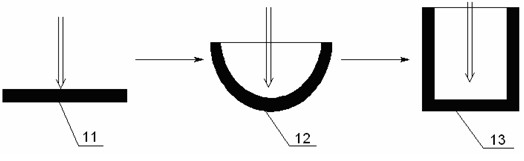

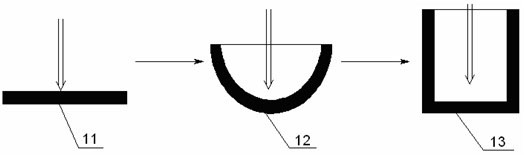

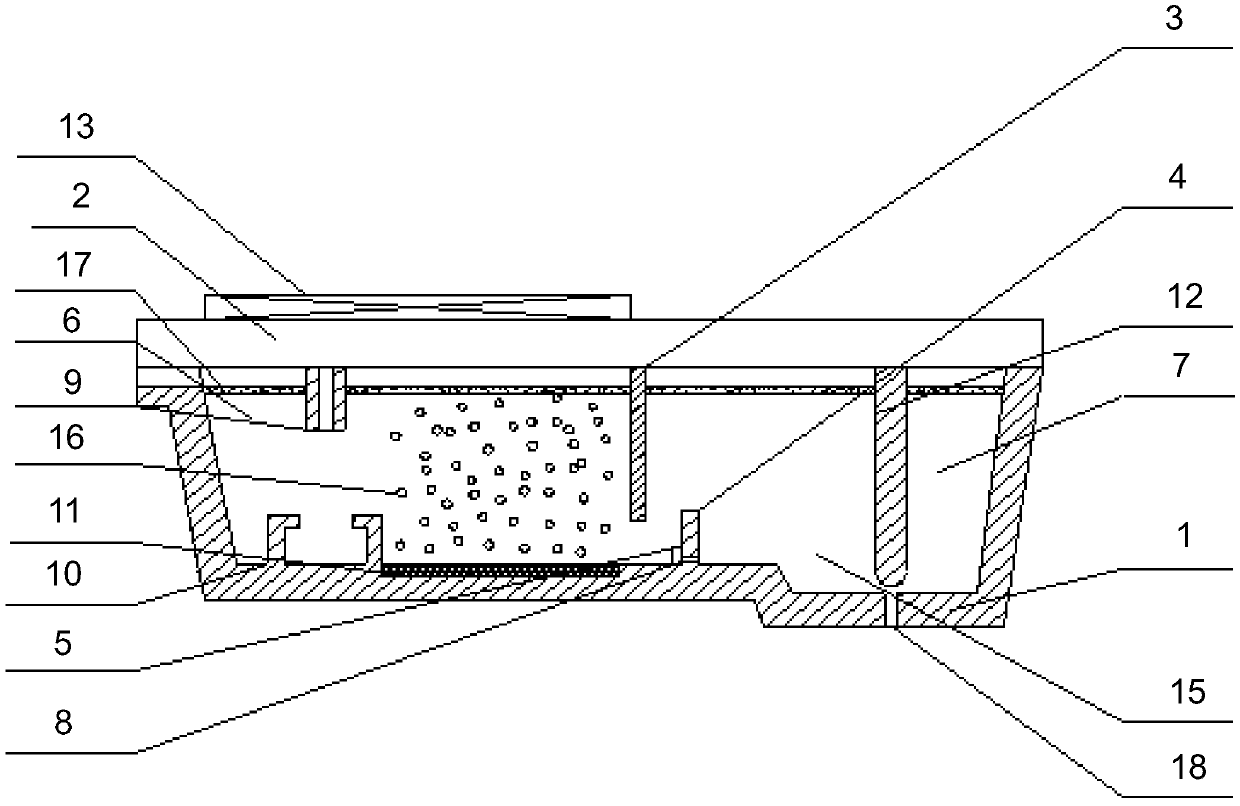

Demoulding device for barb injection molded part

The invention relates to a demoulding device for a barb injection-molded part. The demoulding device comprises a moving mould plate and a mould core, wherein a demoulding ejector rod is inserted into the moving mould plate and the mould core; sleeves are arranged between the demoulding ejector rod and the moving mould plate, and between the demoulding ejector rod and the mould core and fixedly connected with the moving mould plate; the sleeves are also provided with a spiral chute correspondingly matched with convex knobs on the two sides of the ejector rod, so that the moving mould plate forces an outward turning end embedded in a hook-shaped body of a product on the top of the demoulding ejector rod to be rotatably demoulded along with the demoulding ejector rod through the spiral chuteand the convex knobs; and the lower end of the demoulding ejector rod is rotatably connected with an ejector retainer plate. The demoulding ejector rod of the demoulding device rotatably moves upwards with small turning moment and stress on the chute is small, so that the demoulding device has the advantages of reducing friction force, reducing damage to the core structure and the mould core, greatly prolonging the service life of the barb molding structure and a mould and ensuring that the molding structure does not have the defects.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

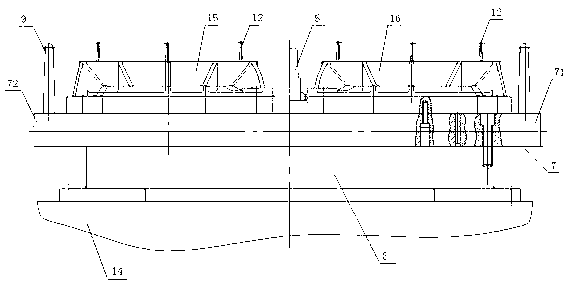

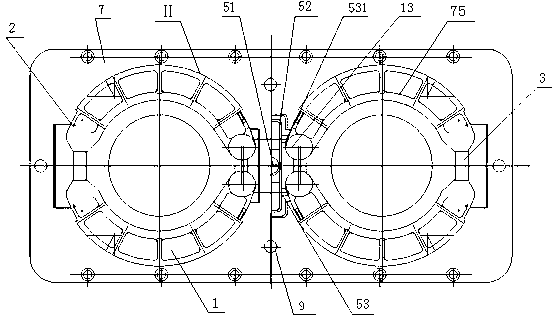

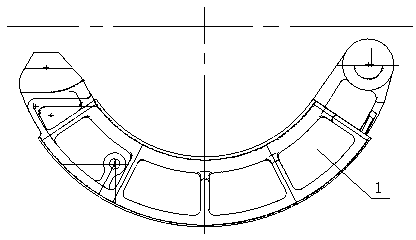

Sand lined metal mould casting brake shoe tool device and production method thereof

ActiveCN103273006AImprove casting yieldUniform materialFoundry mouldsMoulding machinesBrake shoeMetal

The invention relates to a sand lined metal mould casting brake shoe tool device and a production method thereof, and belongs to the field of sand lined metal mould casting. The sand lined metal mould casting brake shoe tool device comprises a lower casting piece and a gating system, wherein the lower casting piece and the gating system are both arranged on a mould board; the sand lined metal mould casting brake shoe tool device further comprises an upper casting piece, a single casting piece, a connection board, a loam core and a flow gate; the lower casting piece and the upper casting piece are both connected with the connection board to form the single casting piece; the loam core is arranged inside an iron mould and used for forming an inner cavity of the single casting piece, a sprue base and the lower part of a cross gate; the inner flow gate is arranged in an inner pouring gate; and one end of the flow gate is connected with the cross gate, and the other end of the flow gate is connected with the single casting piece. According to the invention, the lower casting piece and the upper casting piece are connected into a circle to form the single casting piece, the inner cavity of the single casting piece is formed by the loam core, and the production method of the sand lined metal mould casting brake shoe tool device has simple operation and high efficiency, so that the yield of the casting piece is increased, the production efficiency is improved, and the produced casting piece of the brake shoe is smooth and clean in surface and accurate in size.

Owner:浙江省机电设计研究院有限公司

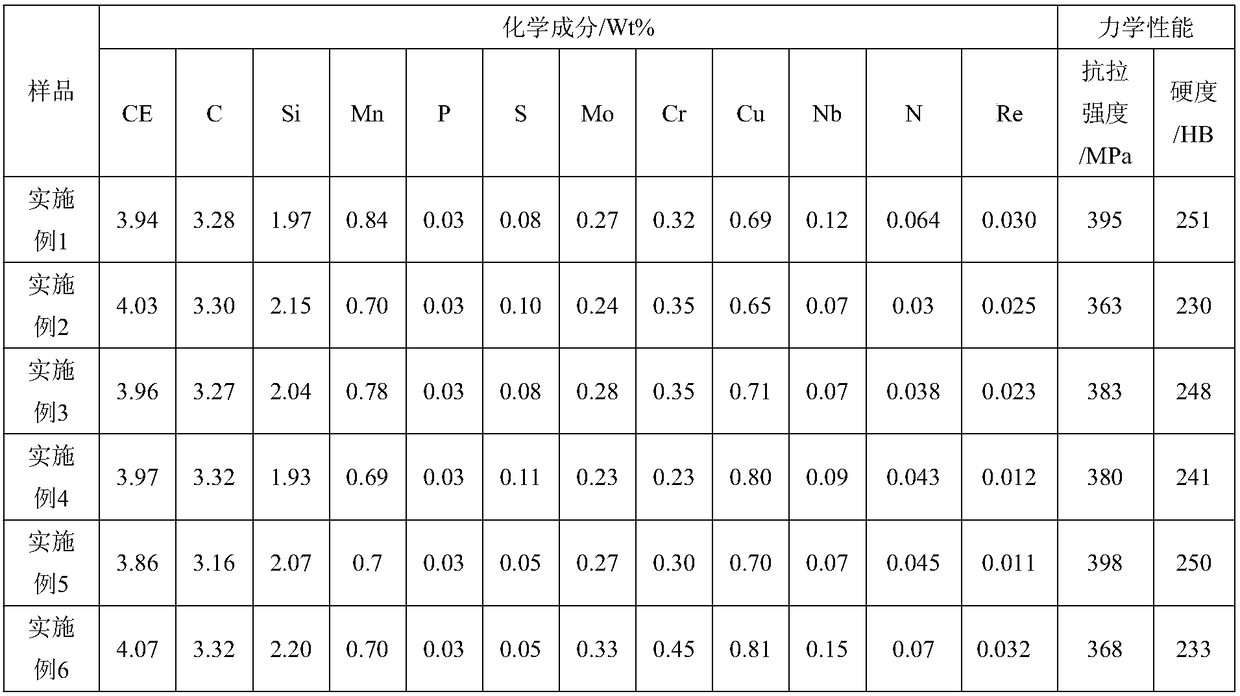

High-carbon equivalent and high-strength gray cast iron and preparation method thereof

The invention discloses a high-carbon equivalent and high-strength gray cast iron and a preparation method thereof, and belongs to the field of gray cast iron materials. The high-carbon equivalent andhigh-strength gray cast iron mainly comprises, by weight, 3.1-3.5 % of C, 1.7-2.3% of Si, 0.04-0.2% of Nb, 0.03-0.1% of N, 0.5-1.0% of Mn, 0.03-0.15% of S, 0.06% or less of P, 0.65-0.9% of Cu, 0.31-0.5% of Cr, 0.1-0.4% of Mo, 0.01-0.04% of Re, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: alloy melting, inoculating treatment and casting. Routine chemical elements are optimized, and Nb and N elements are compounded and added, so a technical problem that gray cast iron parts cannot simultaneously meet the requirements of high carbon equivalent, high strength and few casting defects is solved, and the problem of cracking of the high-carbon equivalent gray cast iron parts, caused by low strength, is solved.

Owner:DONGFENG COMML VEHICLE CO LTD

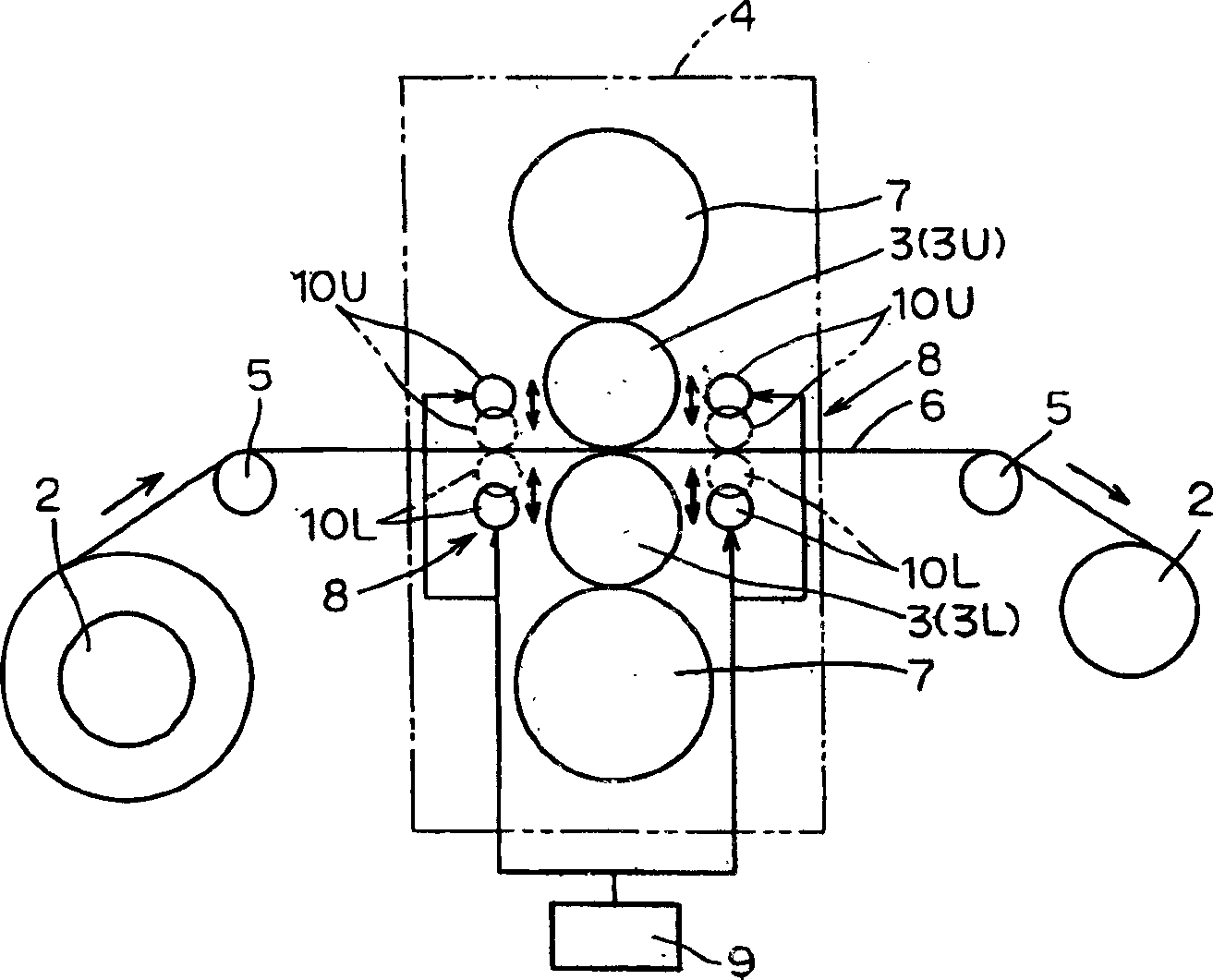

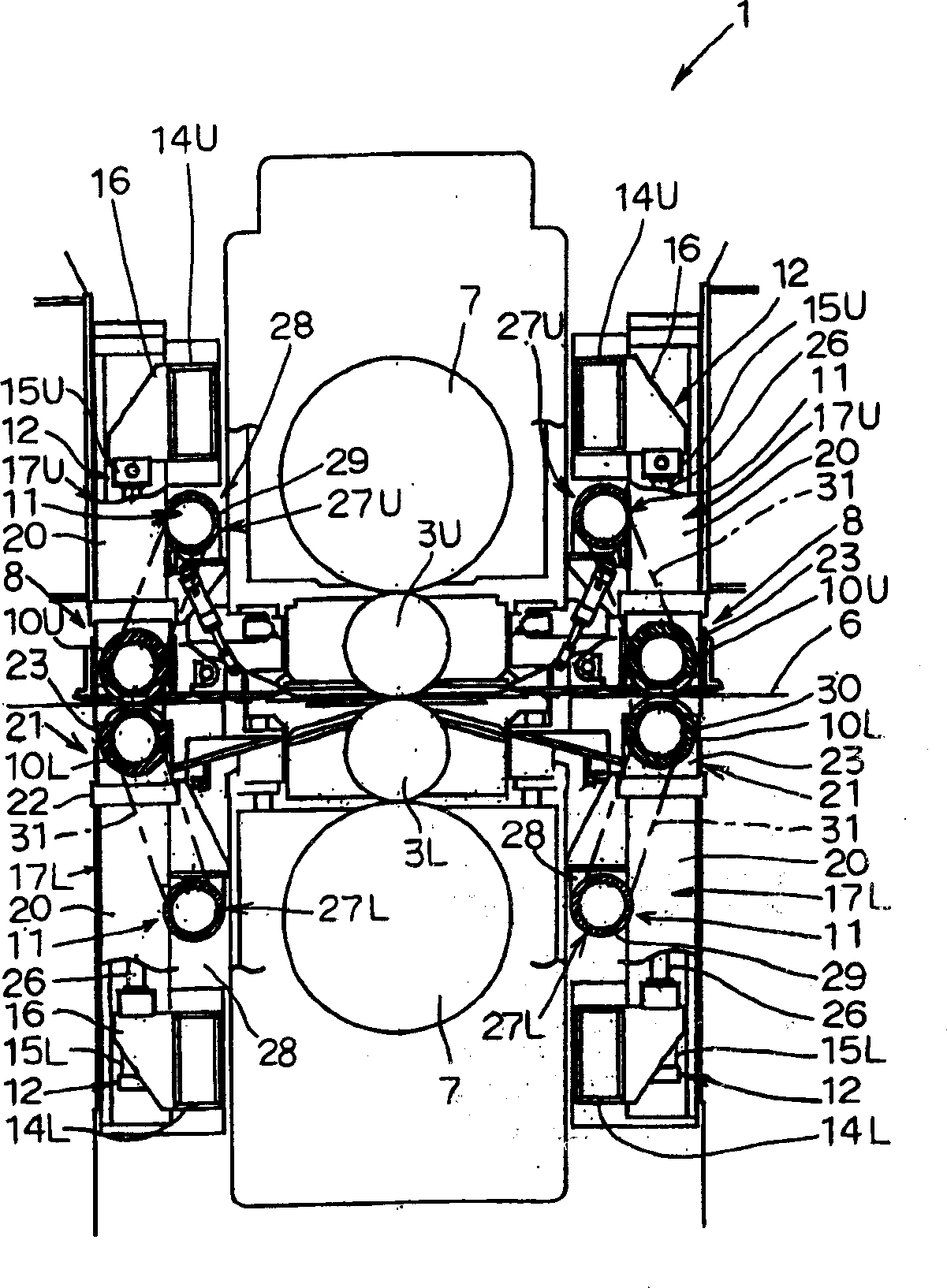

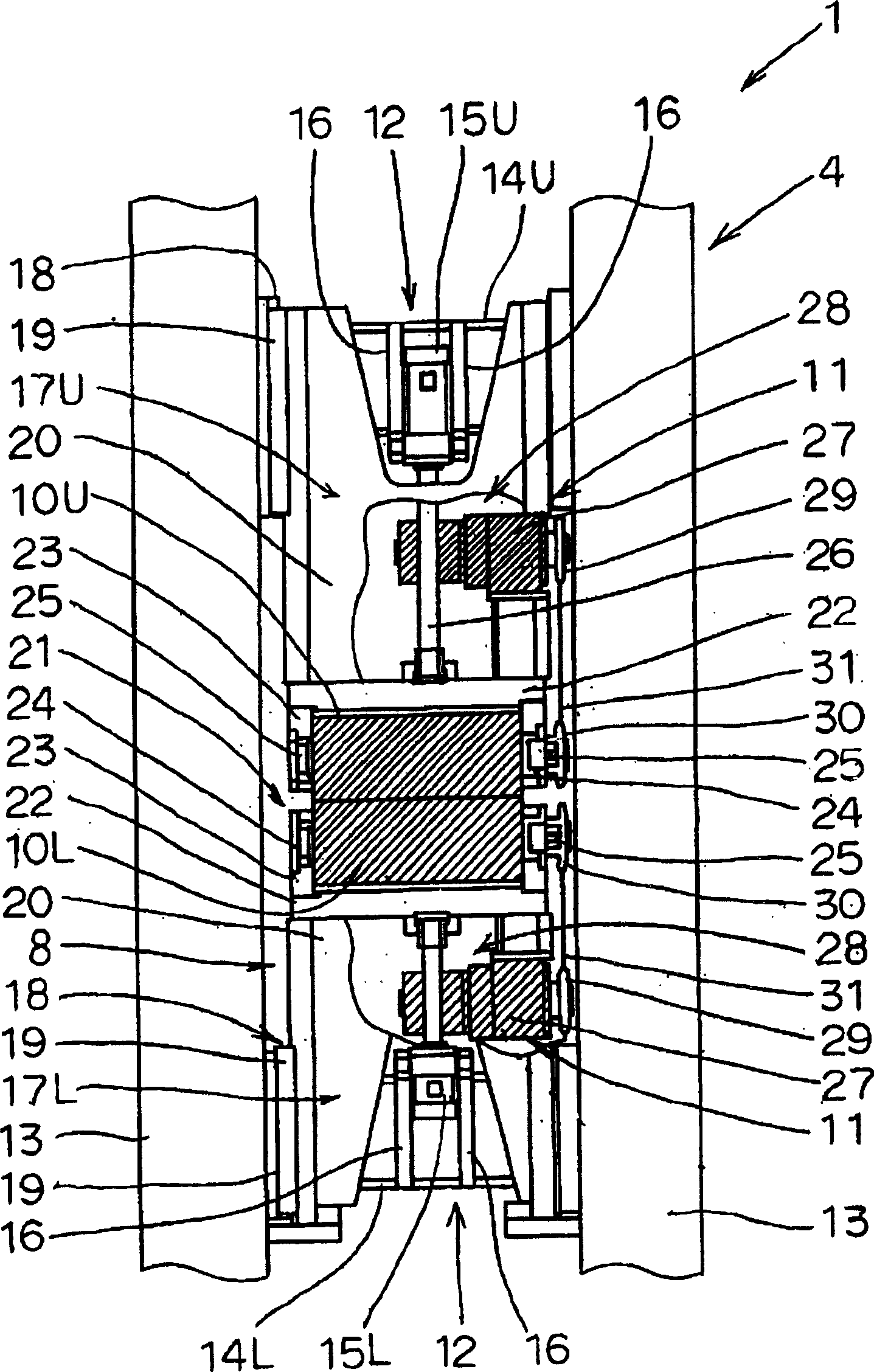

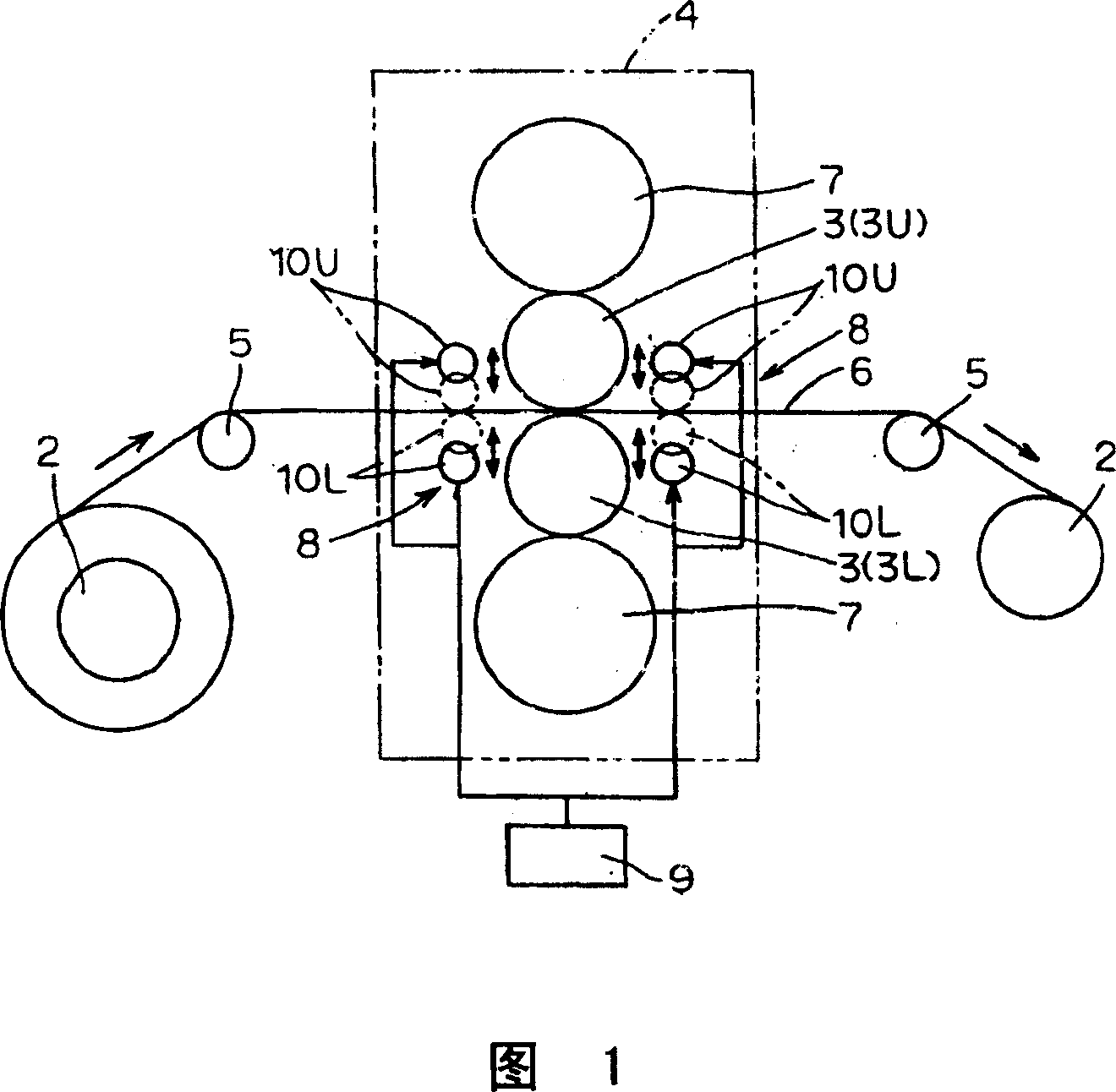

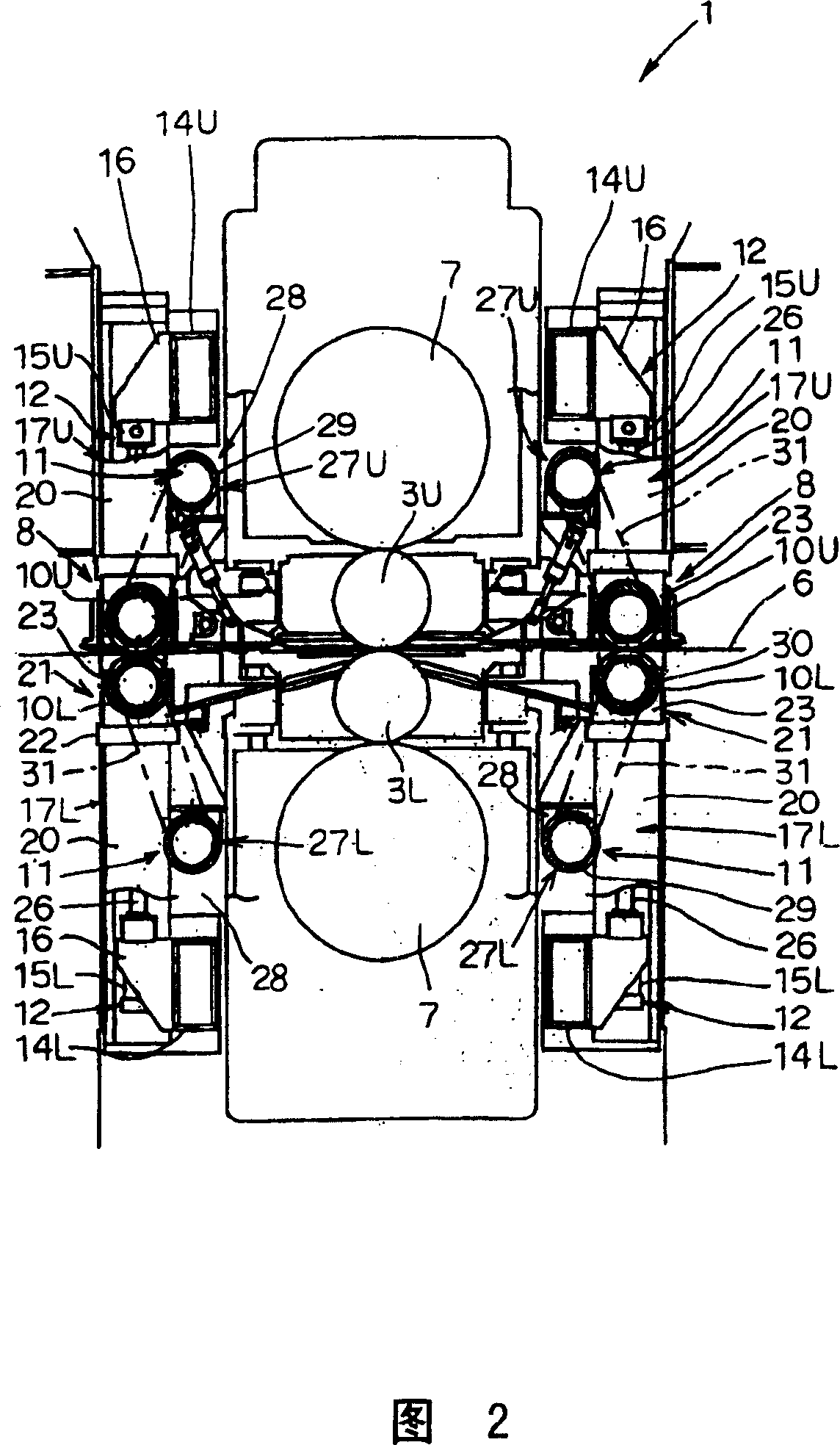

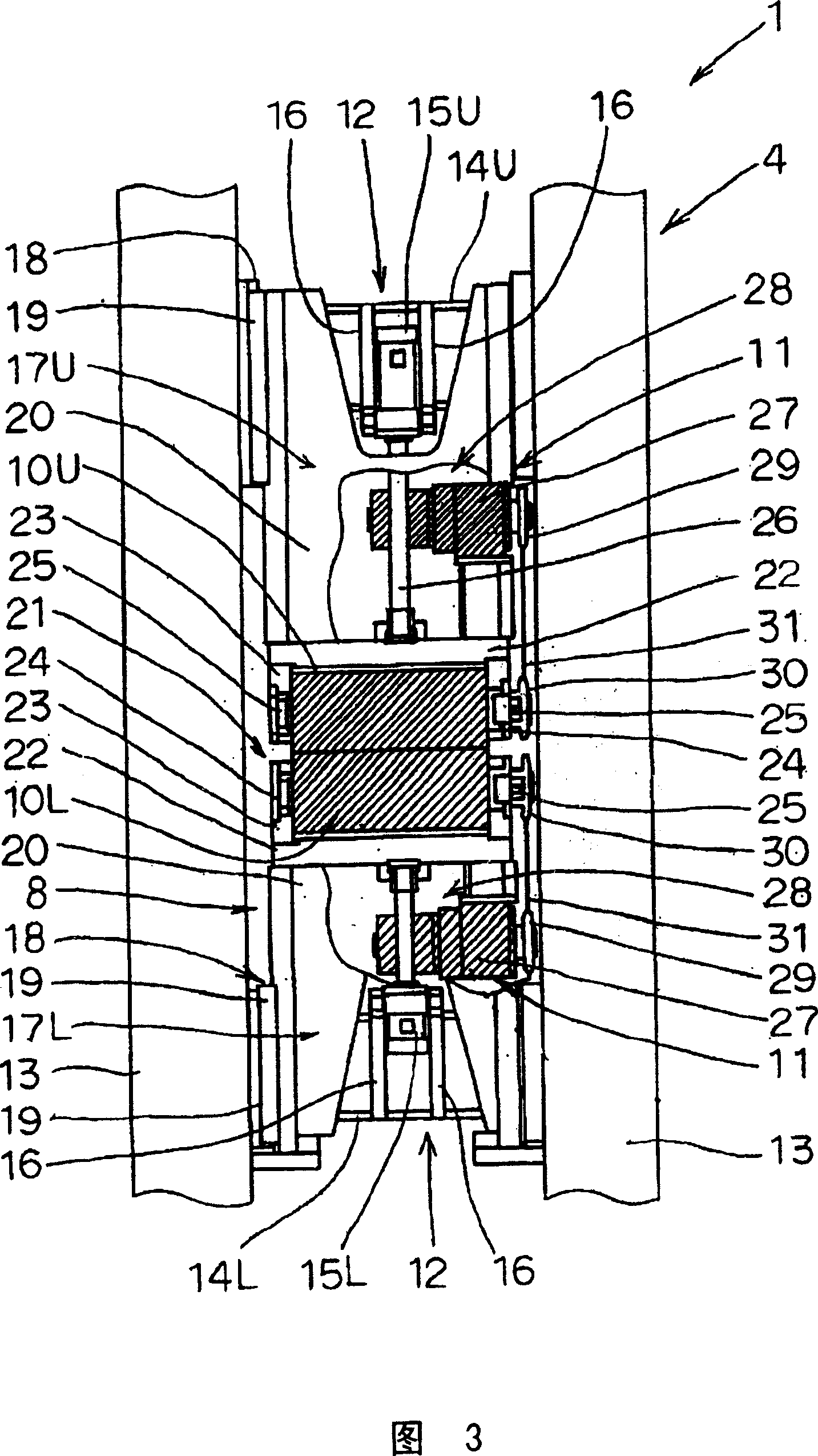

Rolling machine

InactiveCN1593800ANo defectsMetal rolling stand detailsTensioning/braking arrangementsEngineeringRolling mill

Owner:KOBE STEEL LTD

Coated glass sheet

Glass sheets according to the invention, have a coating provided on a surface thereof , wherein the coating comprises a first layer comprising an enamel precursor and a second layer comprising a resin. Such glass sheets may be heat treated and, before heat treatment, may be handled and ransported without damaging the coating, may be cut and ground without causing the coating to peel off or to be damaged at the borders of the cutting line, and offer a good resistance under running water avoiding the peeling off or destruction of the coating.

Owner:AGC FLAT GLASS EUROPE SA

Low chromium cast grinding ball, and manufacturing method thereof

The invention relates to the technical field of wear-resistant materials, and discloses a low chromium cast grinding ball, and a manufacturing method thereof. The low chromium cast grinding ball comprises the following chemical components by weight: 2.10-3.60% of C, less than or equal to 1.50% of Si, less than or equal to 1.50% of Mn, less than or equal to 1.00% of Mo, 1.00-3.00% of Cr, less than or equal to 0.80% of Cu, less than or equal to 0.08% of S, less than or equal to 0.10% of P, and the balance being Fe. A formula provided by the invention is reasonable; and the manufacturing method is simple. The raw materials are kept at a constant temperature for 2-2.5 hours after being melted, so as to guarantee few inclusions and uniform distribution. The raw materials are easily available and common steel scrap, pig iron and stainless steel scrap are used as the raw materials and can be used circularly, so that energy can be effectively saved; molten iron is subjected to modified treatment, so that the toughness and strength of the cast grinding ball are increased and the service life of the cast grinding ball is prolonged; and no defect phenomenon appears in the manufacturing process.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

Aluminum alloy constant-temperature fine die forging process

InactiveCN102430677AGuaranteed to warmTemperature controlMetal-working apparatusAngle grinderGraphite

The invention discloses an aluminum alloy constant-temperature fine die forging process, relating to an aluminum alloy die forging process. Aiming at problems of low temperature, waste generation due to overlarge forging blank materials, unstable process and easiness in soaking a mould of the traditional aluminum alloy constant-temperature fine die forming mould, the aluminum alloy constant-temperature fine die forging process comprises the following steps of: 1, determining a size of a forging piece blank material; 2, heating a forging mould and a forging piece blank material; 3, after the material temperature is reached, hoisting a forging piece blank material in a well furnace outside and then placing a first basket of a box furnace, continuously preserving the temperature; 4, smearing graphite lubricant on a mould, then placing the forging piece blank material on the mould; 5, forging and pressing; 6, starting an ejector rod for ejecting a button, ejecting a forming piece, clamping the forging piece by using a material clamp, placing on a counter top; and 7, grinding burrs on the bottom of the forging piece by using a angle grinder cleanly, and placing on the counter top for reducing the temperature. The invention is suitable for aluminum alloy constant-temperature fine die forging.

Owner:HARBIN ZHONGFEI NEW TECH CO LTD

Polishing composition for metal CMP

InactiveCN1436225ANo defectsOther chemical processesSemiconductor/solid-state device manufacturingSilane compoundsTantalum nitride

Owner:CABOT MICROELECTRONICS CORP

Aluminum alloy isothermal precision die forging technology

InactiveCN106807872AGuaranteed to warmTemperature controlMetal-working apparatusLubricationWaste material

The invention discloses an aluminum alloy warm precision die forging process, which relates to an aluminum alloy die forging process. Aiming at the problem that the current aluminum alloy isothermal precision die forging die temperature is not enough, the forging blank is too large to produce waste, the process is unstable, and it is easy to stick to the die. Step 1: Determine the size of the forging blank; Step 2: Heat the forging mold and the forging blank; Step 3: After the material temperature reaches, lift the forging blank from the pit furnace and put it into the No. 1 basket of the box furnace Inside, continue to keep warm; Step 4: Apply graphite lubrication on the mold, and then place the forging blank on the mold; Step 5: Forging. Step 6: Start the push-out button of the ejector rod, eject the formed part, use the material tongs to clamp the forging out, and place it on the table; Step 7: Use the angle grinder to clean the burr on the bottom of the forging, and place it on the table to cool down. The invention is used for isothermal precision die forging of aluminum alloy.

Owner:赵敏

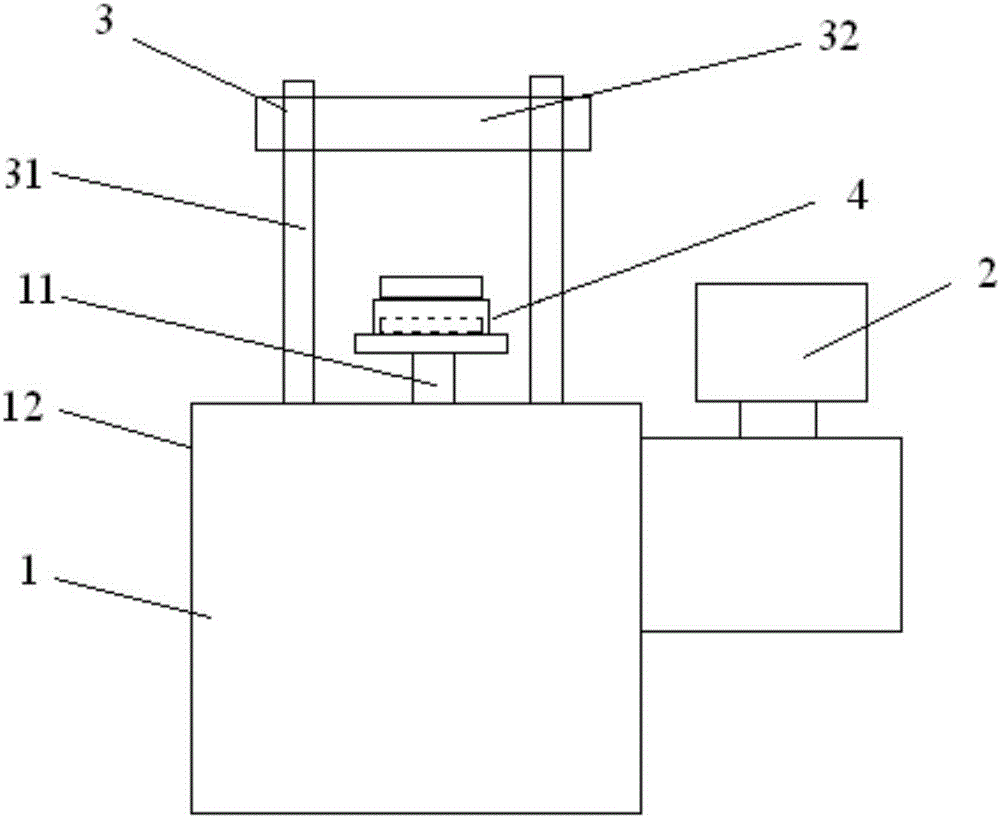

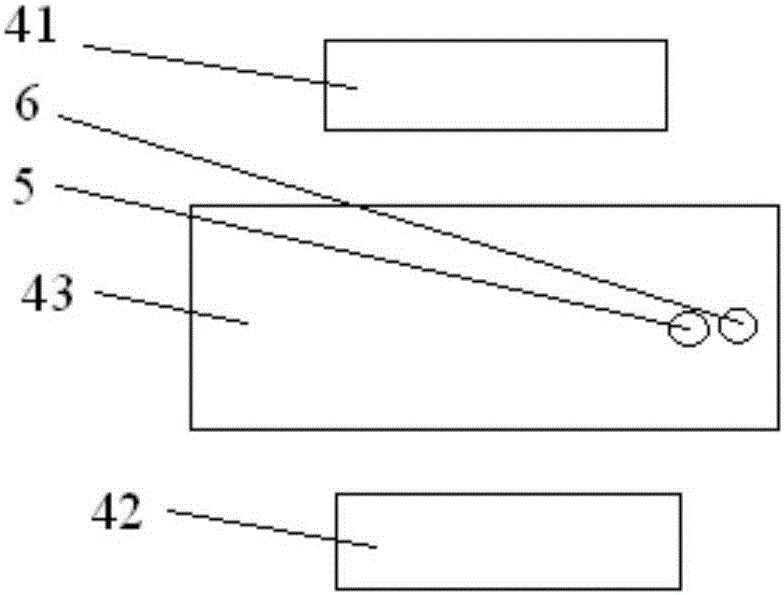

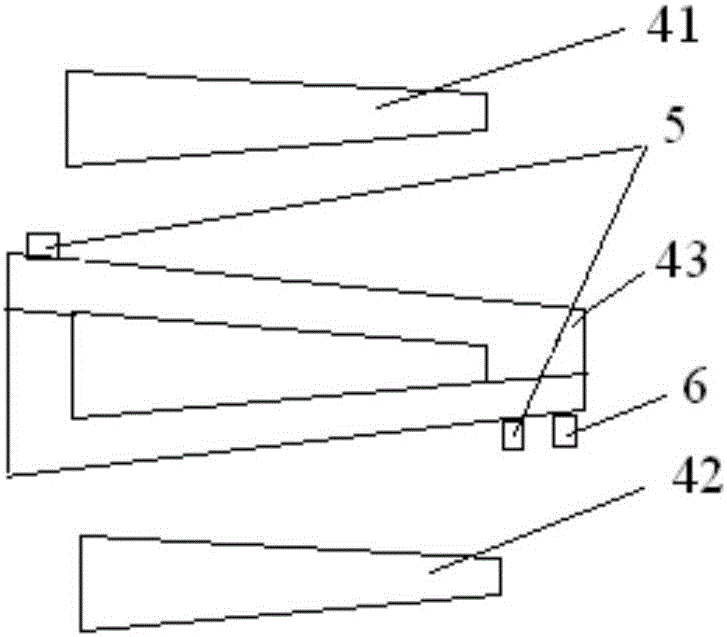

Preparation device and preparation method for asphalt mixture trapezoidal beam test specimen

ActiveCN105938063AShort preparation cycleHigh dimensional accuracyPreparing sample for investigationEngineeringMold tests

The invention relates to a preparation device and preparation method for an asphalt mixture trapezoidal beam test specimen; the device comprises a hydraulic system, a pressure control system, a counter force frame, and a test mold assembly; the counter force frame is erected at the upper part of a hydraulic jacking rod; the test mold assembly is arranged at the top of the hydraulic jacking rod and includes an upper press head, a lower press head and a test mold; the test mold has an inner cavity; the lower press head is located at the bottom of the inner cavity of the test mold; the upper press head presses the test mold from the upper part. The test mold assembly presses against the counter force frame in virtue of the jacking force of the hydraulic system so as to extrude and mold the test specimen. Rolling forming of the prior art is changed, only simply mixing static-pressure molding of trapezoidal beam test specimen-demolding cooling maintenance are required, the production cycle is short, and the molded test specimen has small error; and static pressure molding has no damage of high-frequency vibration during cutting of a specimen in the prior art on the test specimen.

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST

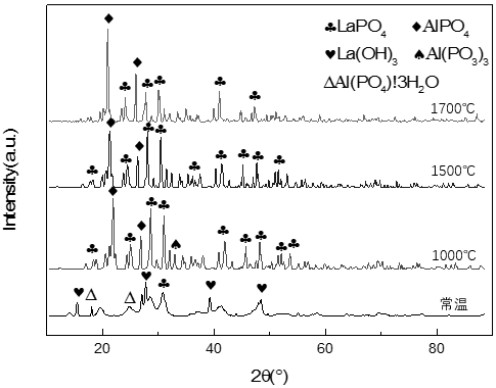

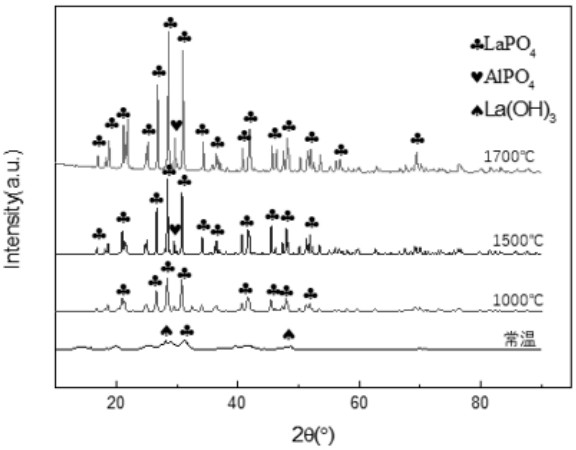

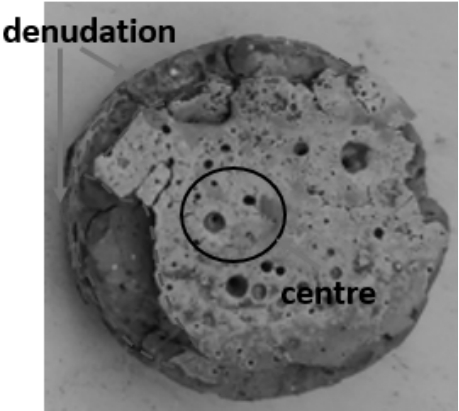

Lanthanum-aluminum phosphate composite material cured at normal pressure and low temperature as well as preparation method and application thereof

The invention provides a lanthanum-aluminum phosphate composite material. The lanthanum-aluminum phosphate composite material comprises lanthanum phosphate and aluminum phosphate compounded with lanthanum phosphate. The composite material has specific phase composition and micro-structure, and lanthanum phosphate and aluminum phosphate are mutually doped and compounded and bonded through ionic bonds, so that the lanthanum-aluminum phosphate composite material which can be quickly cured and molded at low temperature and has excellent performance at high temperature is obtained. The phosphate composite material provided by the invention can be cured and formed at normal pressure and low temperature, so that the product can be formed without special high-temperature sintering by special equipment, complex high-temperature sintering is omitted in the forming process, and energy is saved. The composite material is excellent in high temperature resistance and good in ablation resistance, the surface of an ablated sample is complete at the ablation temperature of 2000 DEG C, melting does not happen, the preparation process is simple, and the preparation period is short.

Owner:CENT SOUTH UNIV

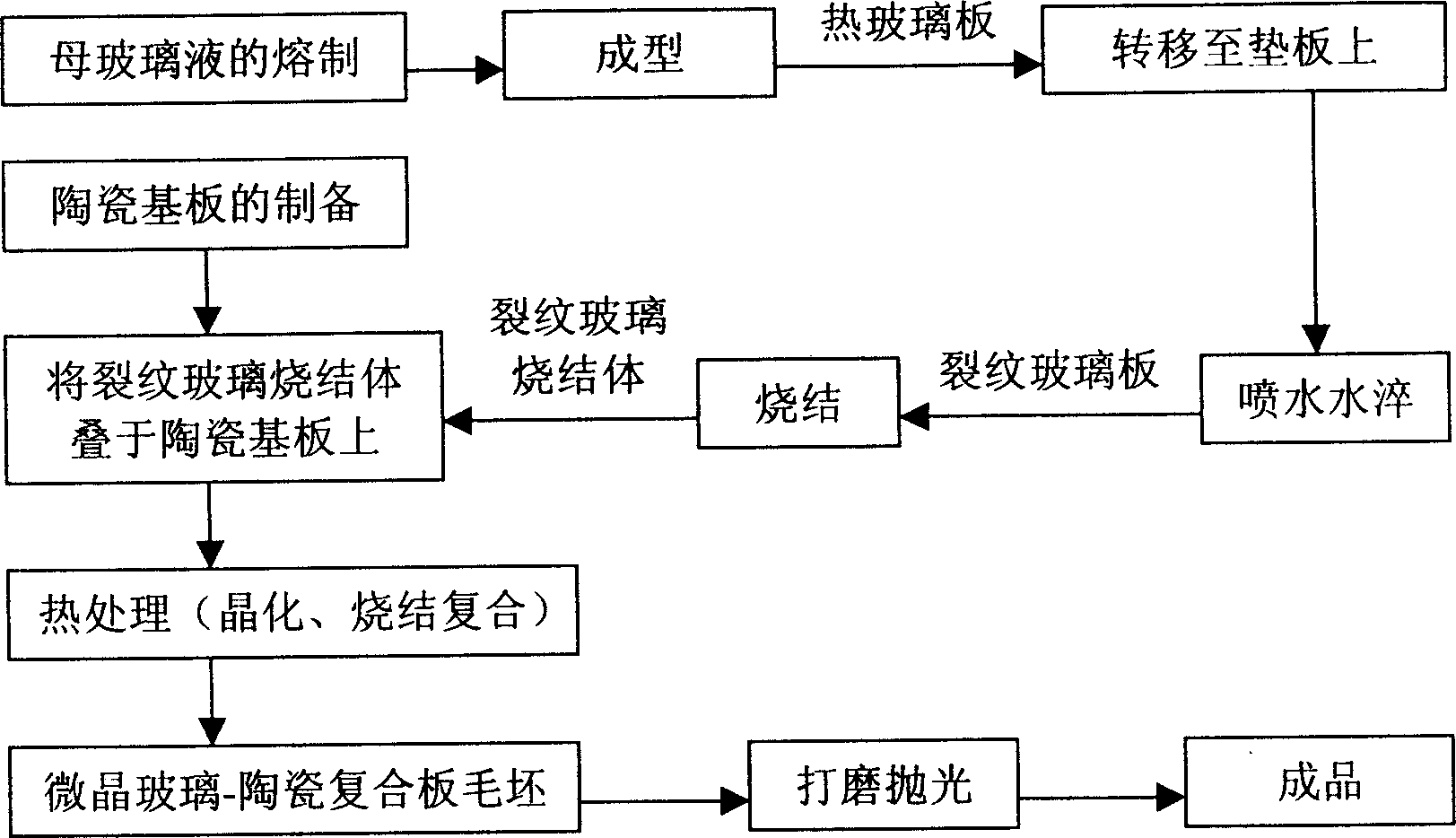

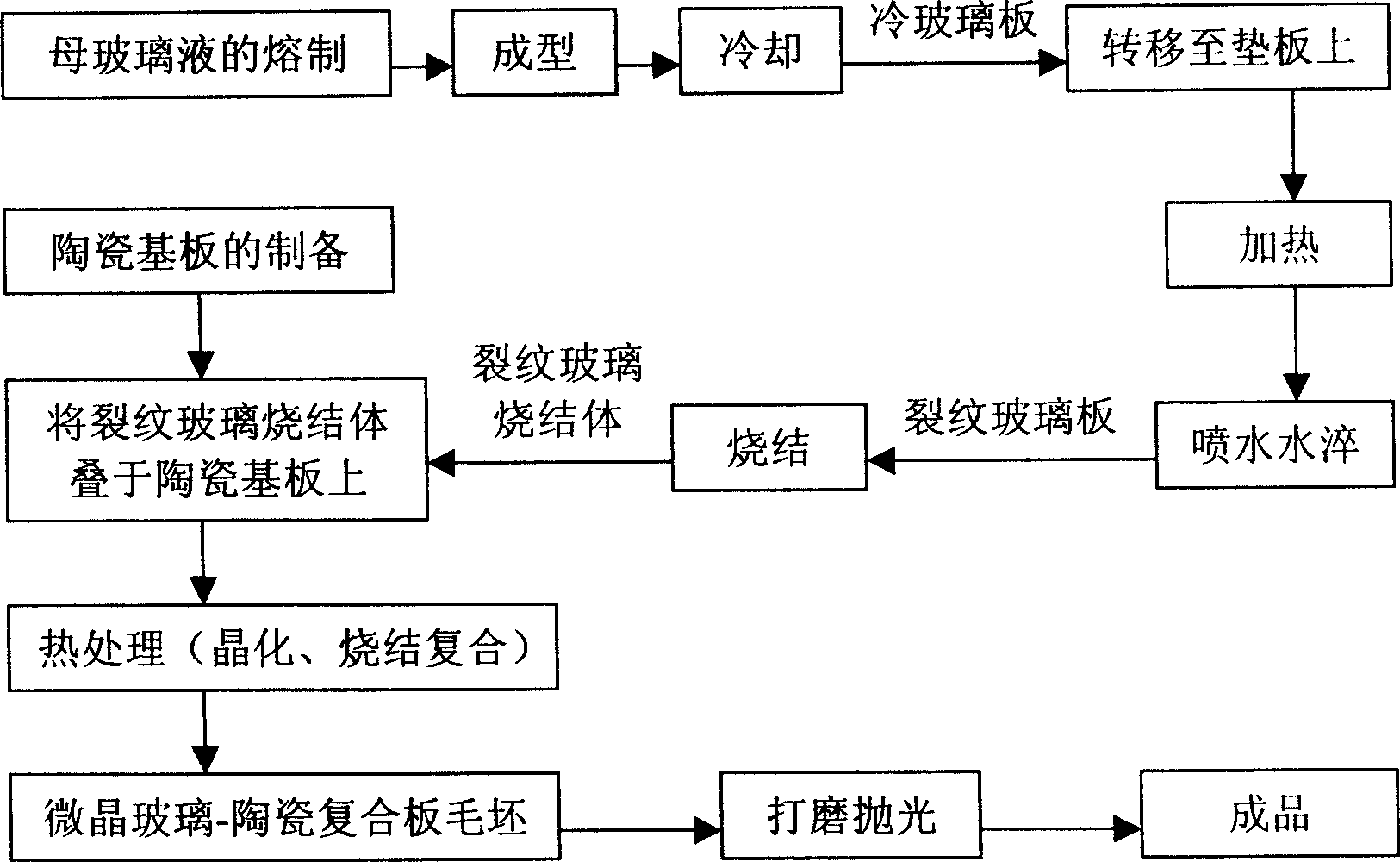

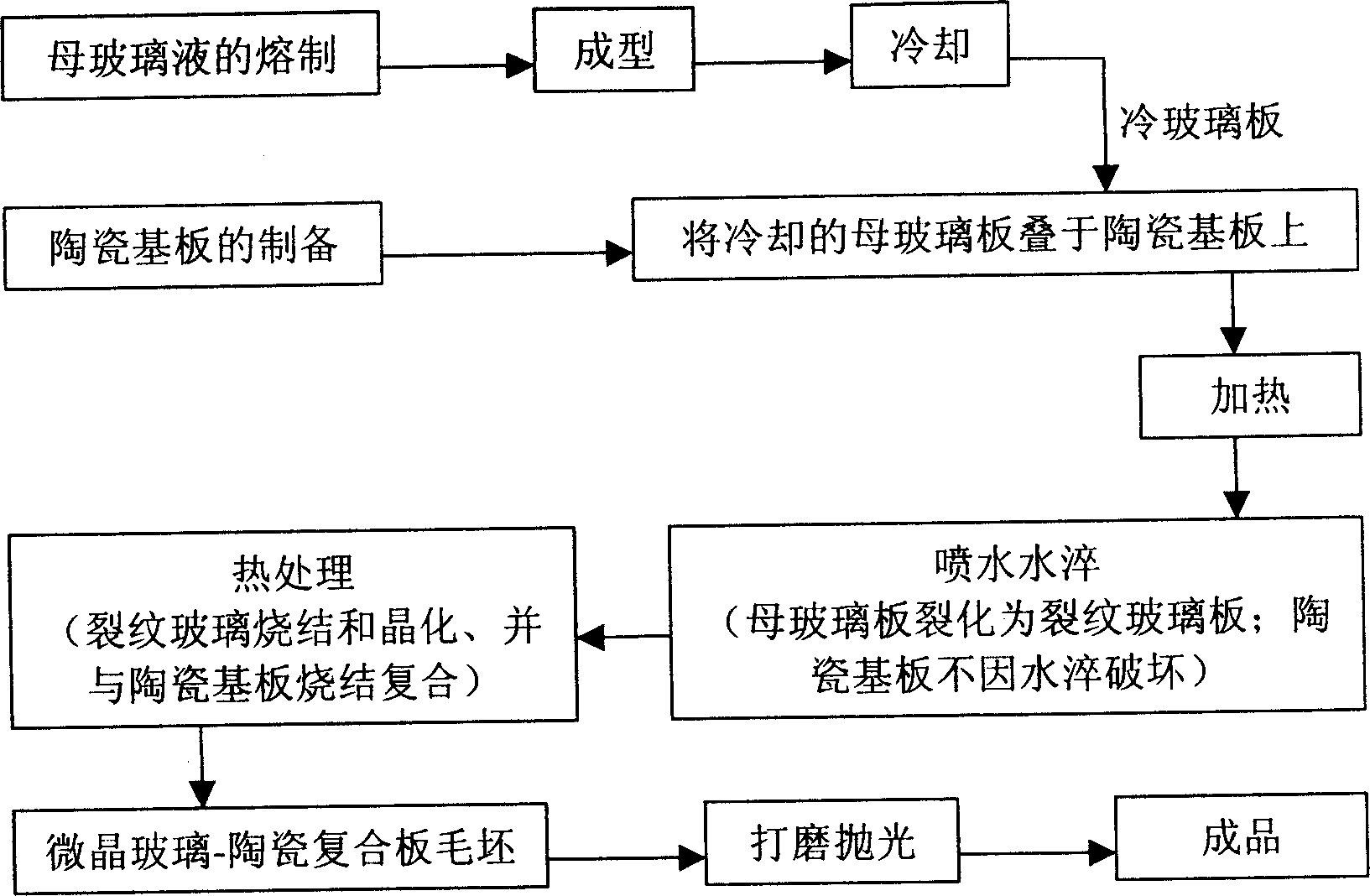

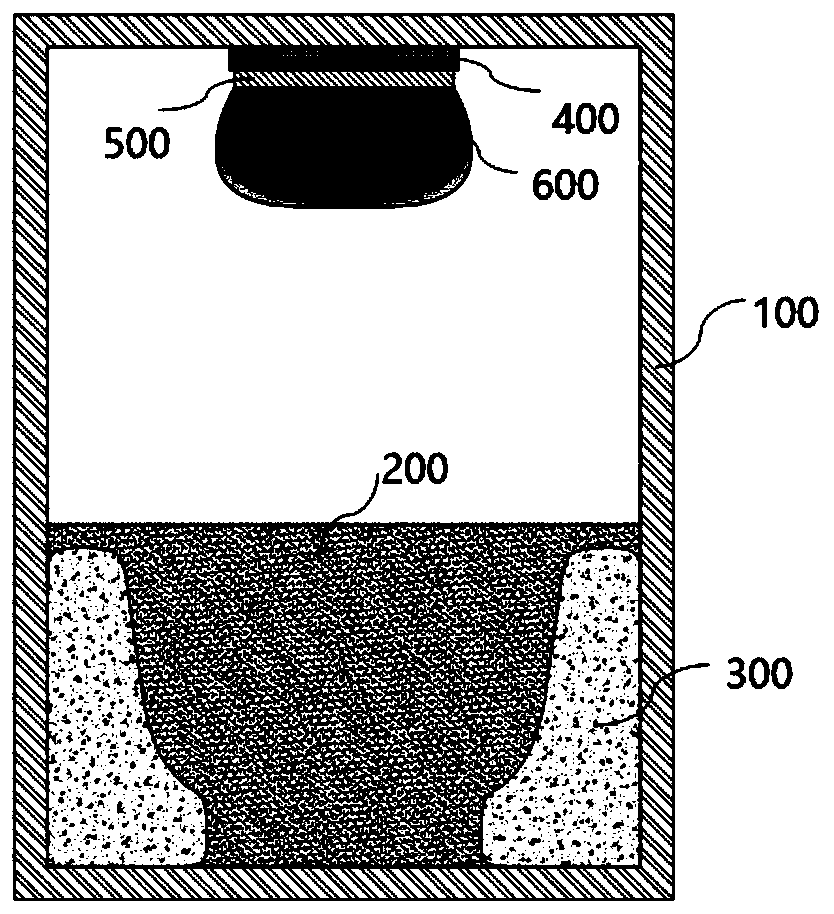

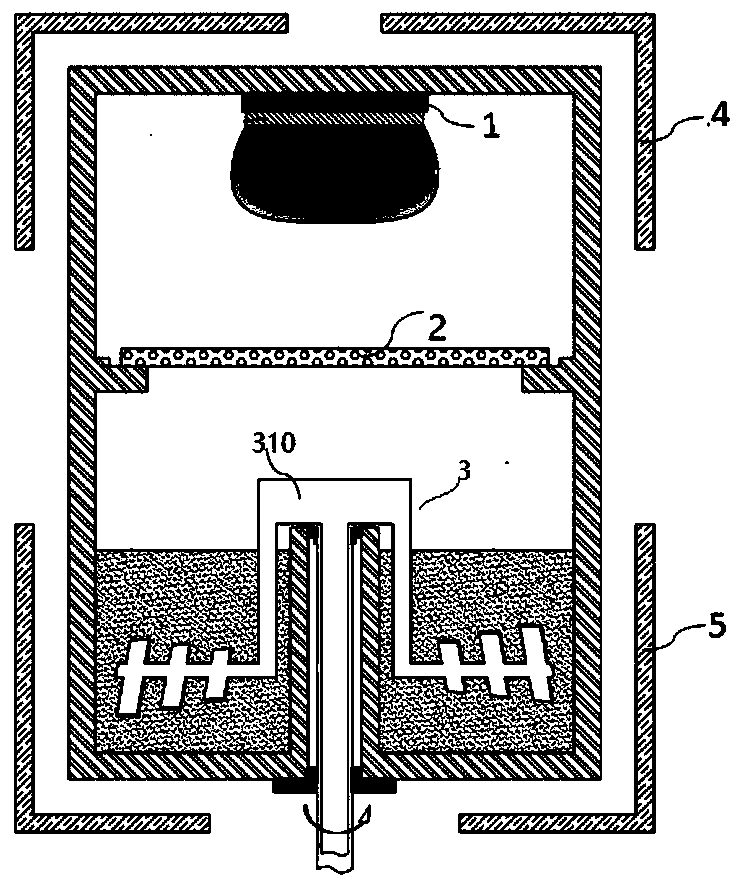

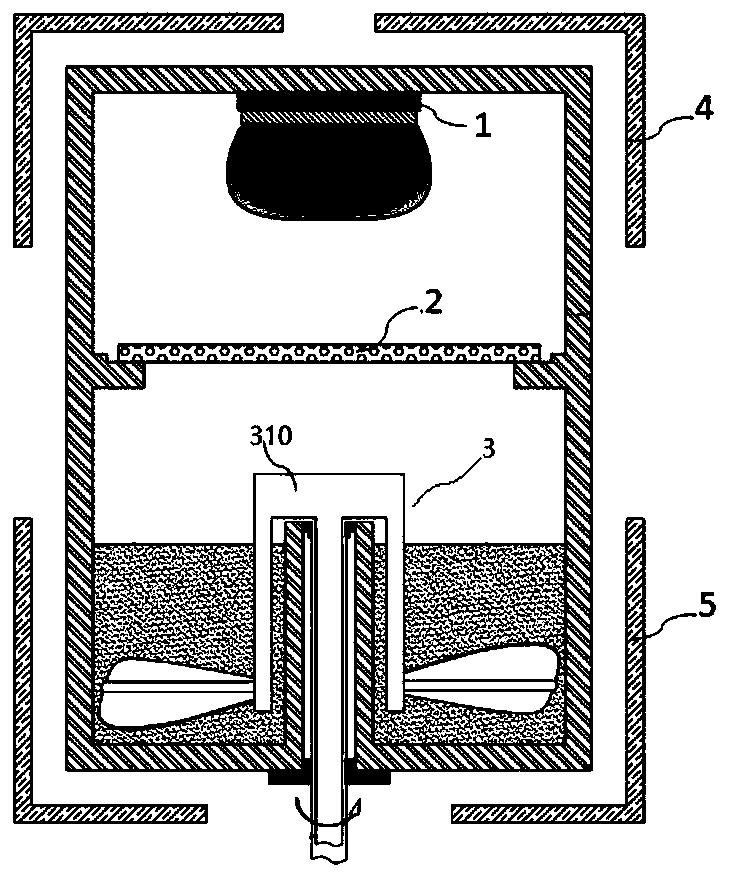

Process for preparing microcrystal glass-ceramic compounded plate

The invention discloses a preparing method of architectural decorative microcrystalline glass-ceramic composite board, which comprises the following steps: 1) preparing ceramic base; 2) preparing mother glass board; 3) preparing composite board from the following schemes: (1) transmitting the moulded mother glass board on the bearing plate; cooling to do crack disposal; heating again to sinter into integral to obtain the crack sintered bulk; overlapping the crack glass sintered bulk on the ceramic base to obtain the product; (2) transmitting the moulded and cooled mother glass board on the bearing plate; heating again to do crack disposal; (3) overlapping the moulded and cooled mother glass board on the ceramic base directly; 4) polishing to obtain the product.

Owner:浙江中地大科技有限公司

Silicon carbide crystal growth device and preparation method thereof

ActiveCN111455457AHigh purityNo defectsPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention relates to a silicon carbide crystal growth device and a preparation method thereof. The growth device comprises a crucible, a seed crystal seat provided with seed crystals, a graphite filter plate, a stirring device, a top heater and a bottom heater; the seed crystal seat, the graphite filter plate and the stirring device are all located in the crucible, wherein the seed crystal seat is fixed at the top of the crucible; the seed crystals are arranged downwards, the graphite filter plate is located in the middle of the crucible and divides the crucible into an upper half part anda lower half part, the stirring device is located at the lower half part, and the top heater and the bottom heater are both arranged outside the crucible. The preparation method comprises the step ofgrowing the silicon carbide crystal by using the growth device. The silicon carbide prepared by the growth device and the preparation method thereof has the advantages of few impurities, high purity,no inclusion defect, high raw material utilization rate and cost saving.

Owner:金华博蓝特新材料有限公司

Hollow shaft machining method

The invention discloses a hollow shaft machining method. A bar is machined into a hollow shaft, an annular step is arranged on the outer circle of the hollow shaft, a center through hole is formed in the hollow shaft, and a plurality of vertical through pin holes are formed in the outer circle of the hollow shaft. The hollow shaft machining method comprises following steps: the bar is machined, and the bar is machined into a semi-finished product with the step and the center through hole; the semi-finished product is stably treated so as to release machining stress; the stably-treated semi-finished product is subject to semifinishing; a drill mold for drilling the hollow shaft is adopted to fixedly clamp and drill the semi-finished product subject to semifinishing, and a semifinishing product with the step, the center through hole and multiple small holes is formed; the semifinishing product is subject to nitrogen treatment, and the semifinishing finished product subject to nitrogen treatment is subject to finishing, and the hollow shaft is formed. The hollow shaft machining method is low in machining cost, high in yield and short in machining period.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

Method of increasing oxygen content in vertical pulling silicon single crystal rod and automatic aerator

InactiveCN1414148AIncrease oxygen contentRich varietyBy pulling from meltOxygen contentCrystallographic defect

A process for increasing the oxygen content of vertical pulling monosilicon rod includes such steps as arranging the oxygen increaser made of quartz to the bottom of quartz crucible, adding monosilicon to said oxygen increaser, smelting monosilicon, and pulling. Its advantages are simple structure and high effect.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

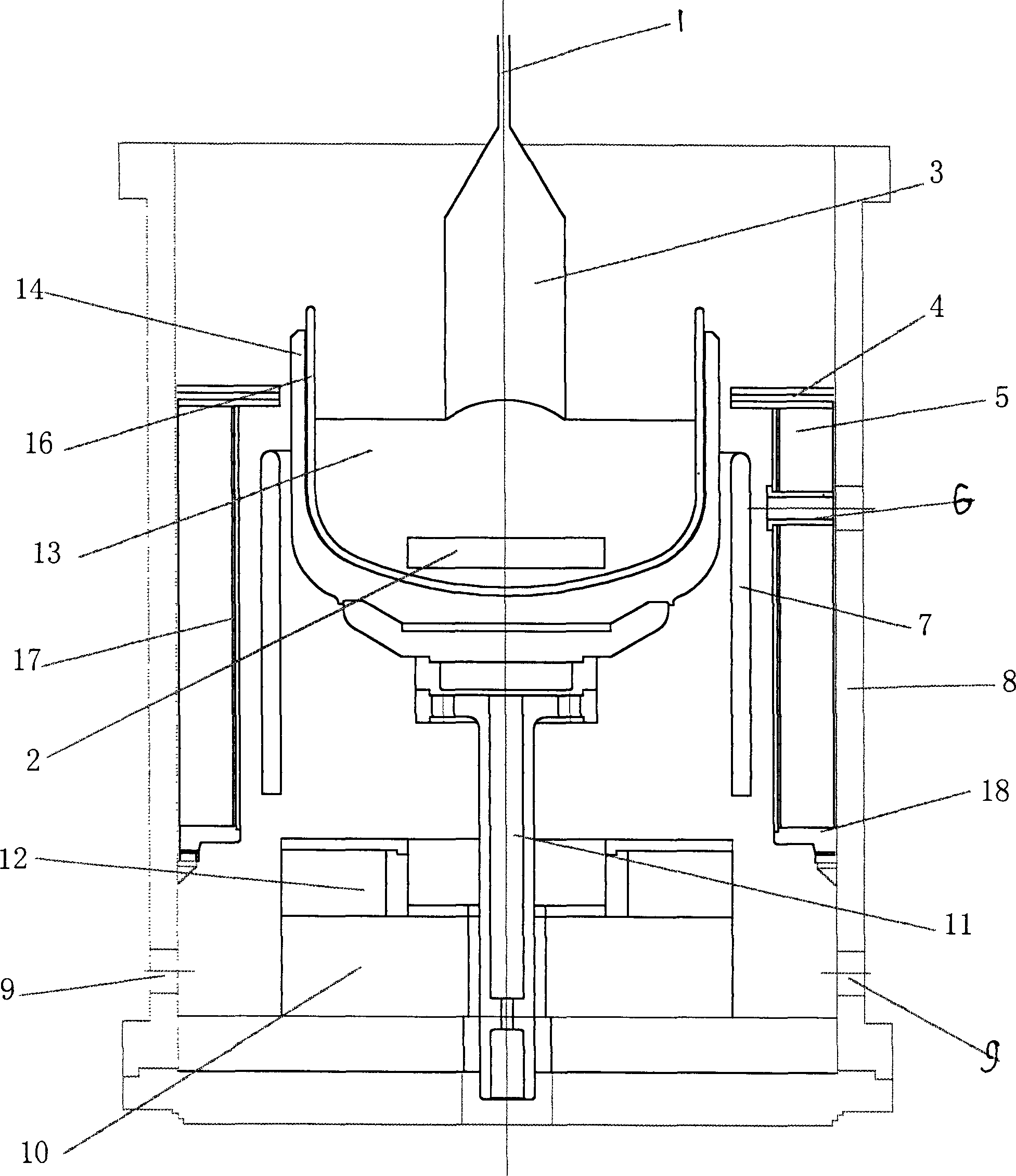

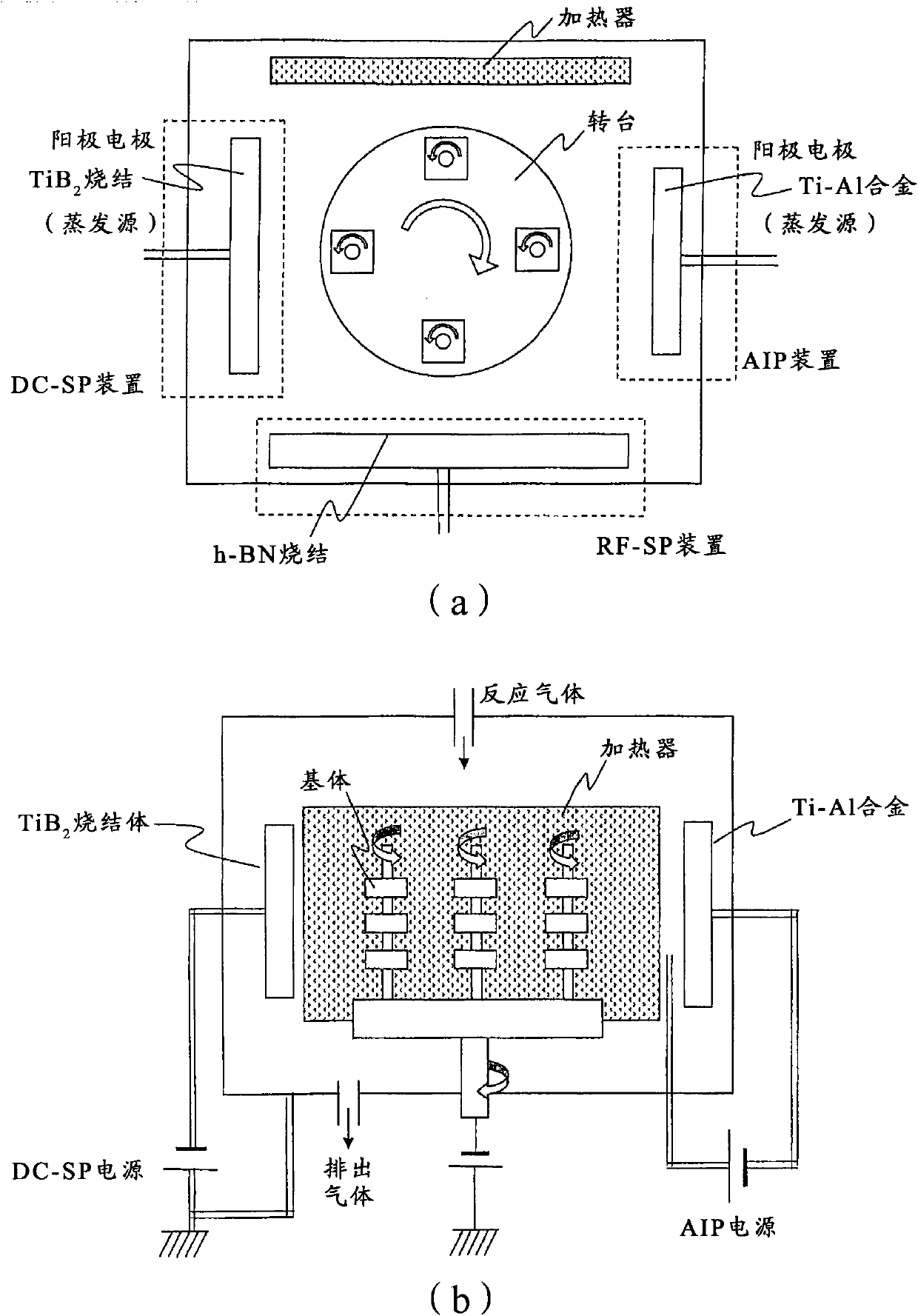

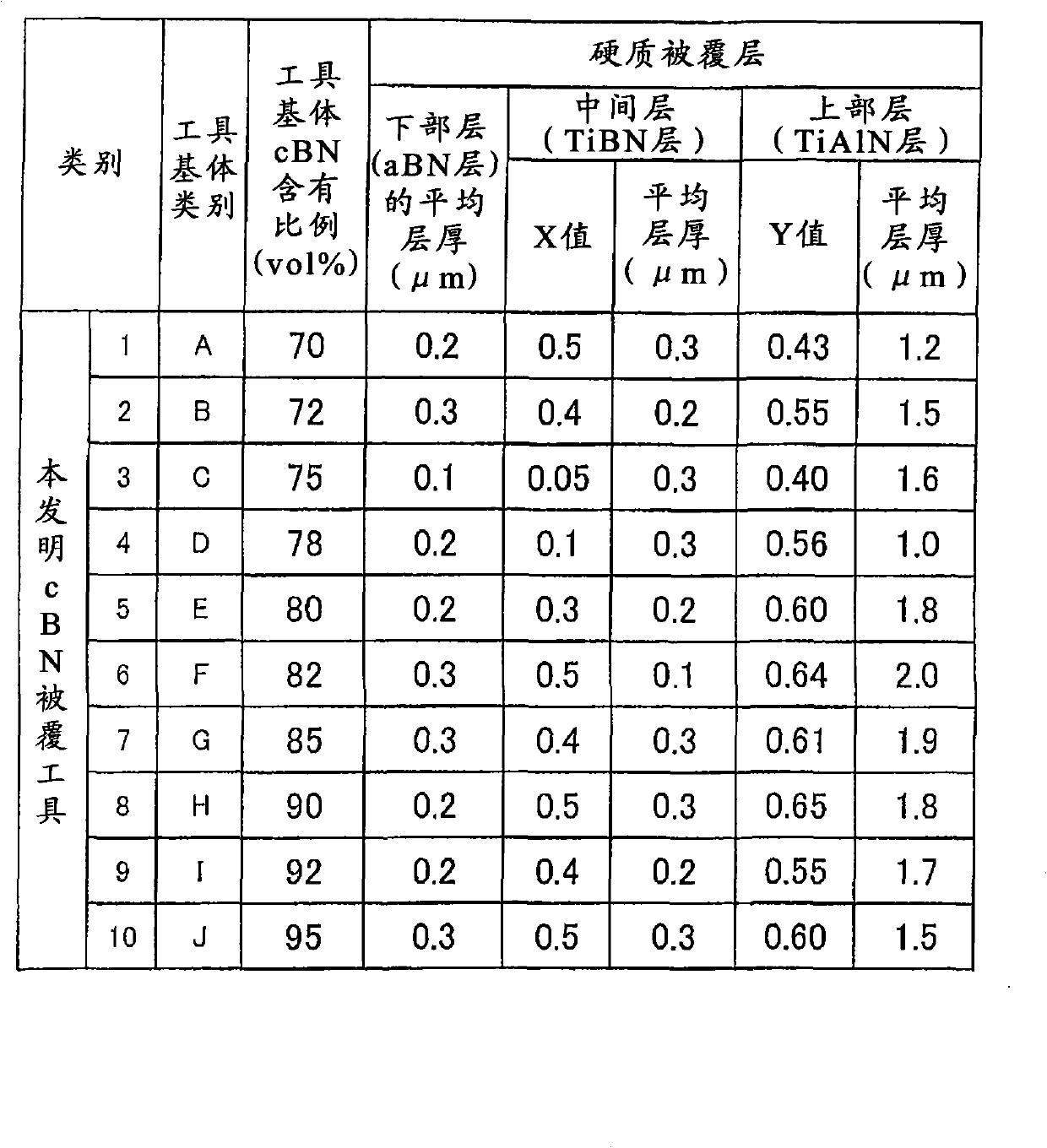

Surface-coated cutting tool

InactiveCN102021516AExtend your lifeImprove adhesion strengthVacuum evaporation coatingSputtering coatingHardnessUltimate tensile strength

The invention provides a surface-coated cutting tool which has excellent anti-defecting property and durability after long-time use, has excellent adhesive strength of a hard coated layer and is applied to high-speed interrupted cutting process of high-hardness steels such as quenched steels. The hard coated layer having excellent adhesive strength is formed by successively evaporating the surface of a cBN-base ultrahigh-pressure firing materials with high content of cBN so as to form a lower part layer made of amorphous BN layer with an average thickness of 0.1 to 0.3 microns, a middle layer made of TiBN with an average thickness of 0.1 to 0.3 microns and an upper part layer made of TiAlN with an average thickness of 1.0 to 2.0 microns.

Owner:MITSUBISHI MATERIALS CORP

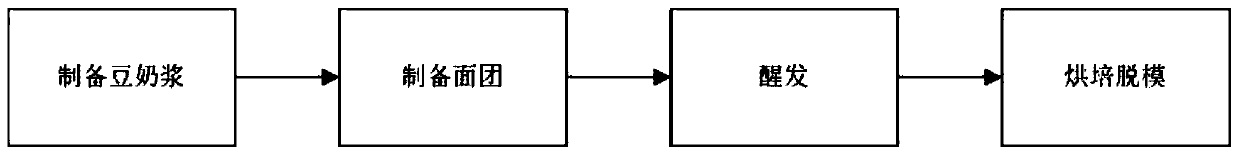

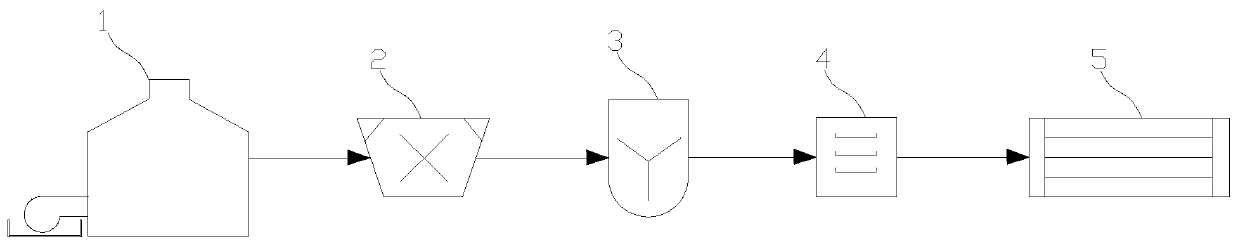

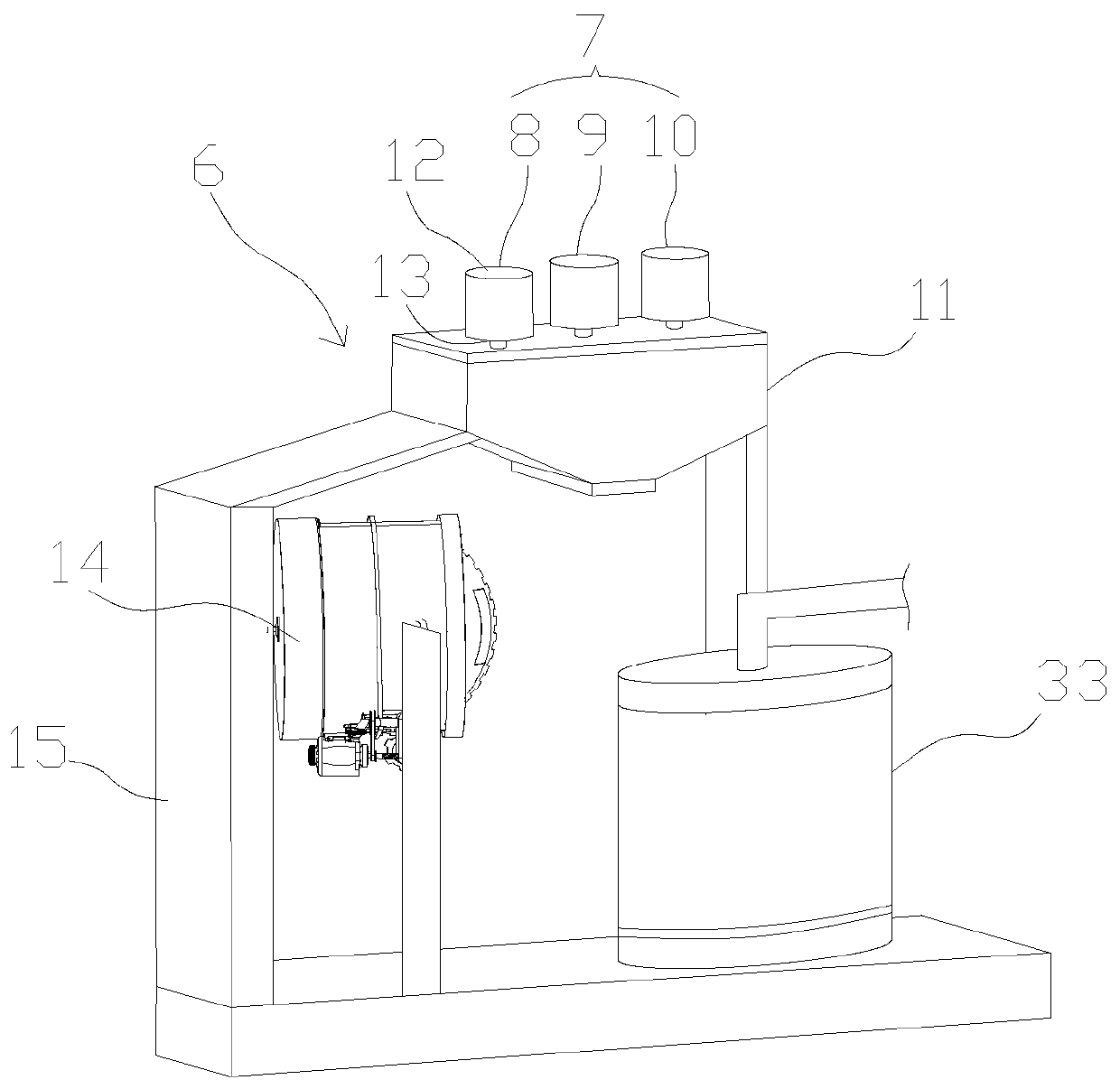

Double-protein nutritious bread, preparation method and device

ActiveCN110432299AUniform tasteUniform colorDough treatmentMixing/kneading structural elementsCooking & bakingRoom temperature

The invention relates to double-protein nutritious bread, a preparation method and a device. The method comprises the steps that soaked soybean is boiled in boiling water; the boiled soybean and milkare mixed in a certain proportion, and then fed into a colloid mill to be ground into soymilk paste; a certain proportion of bread powder, the soymilk, eggs, sugar and yeast are evenly mixed and prepared into dough, a certain proportion of shortening and salt are added when the dough is ready to form, and the dough is continuously stirred or kneaded evenly; the dough is statically placed for a predetermined time, after the dough goes slack, stirring and kneading are continuously conducted, the stirred or kneaded dough is placed in a mold for shaping, and then is placed in a wake-up oven for waking up for a predetermined time; and after the oven is preheated, the wake-up dough is placed in a baking tray and baked for a predetermined time at a set temperature, and is demolded and cooled to the room temperature. According to the preparation method, the double-protein bread with color, taste and nutrition balance can be obtained.

Owner:CANGZHOU MEDICAL COLLEGE

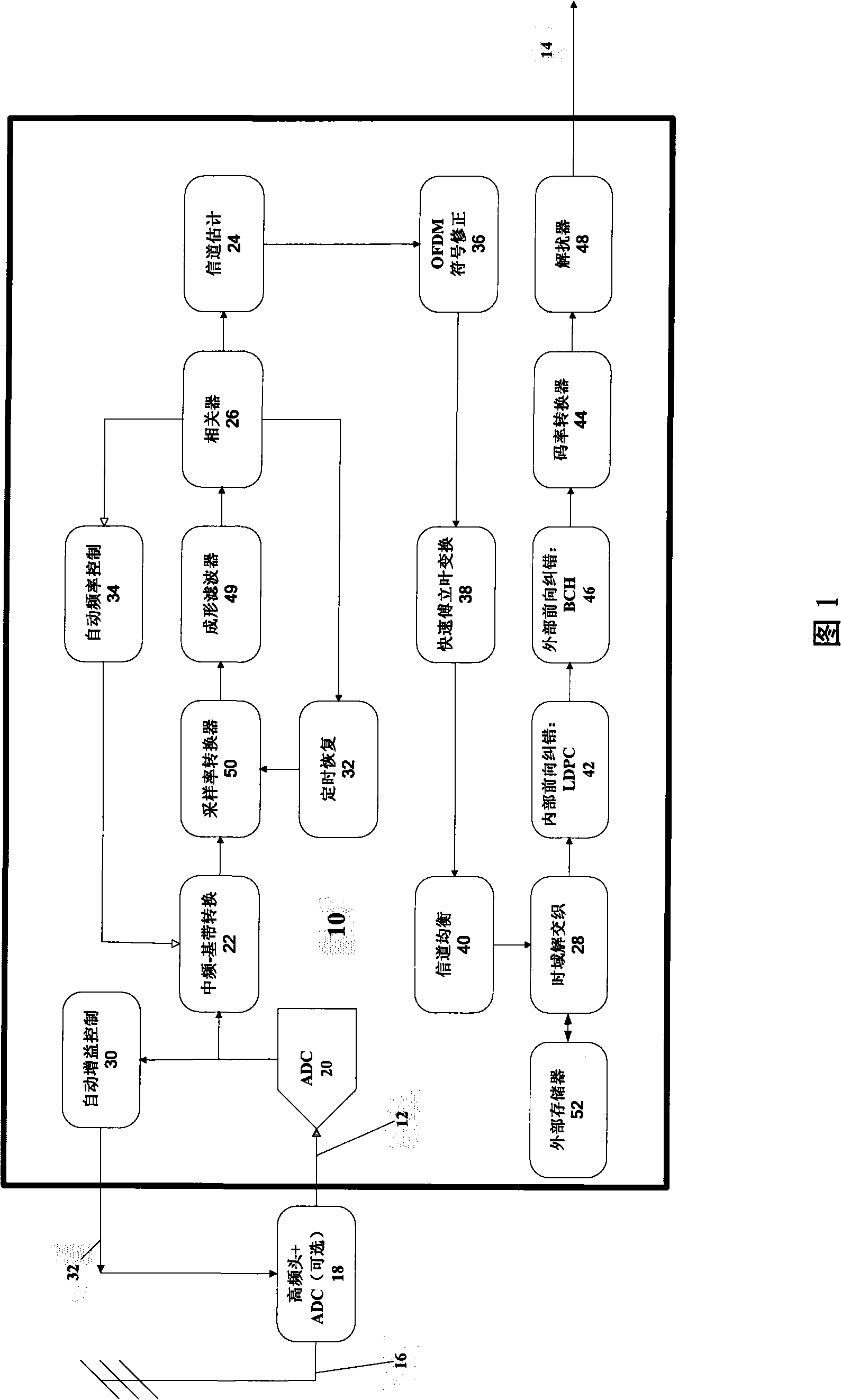

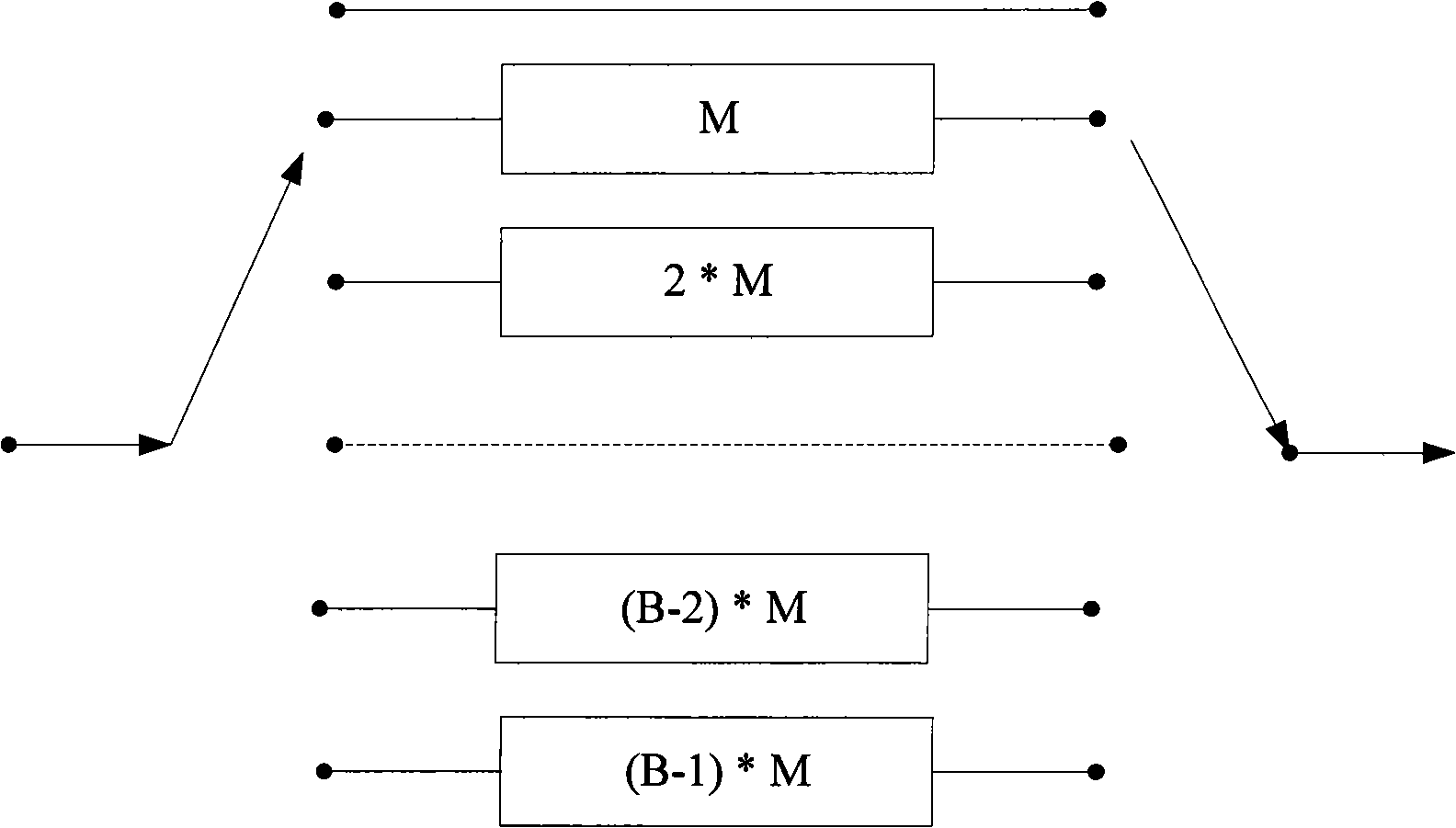

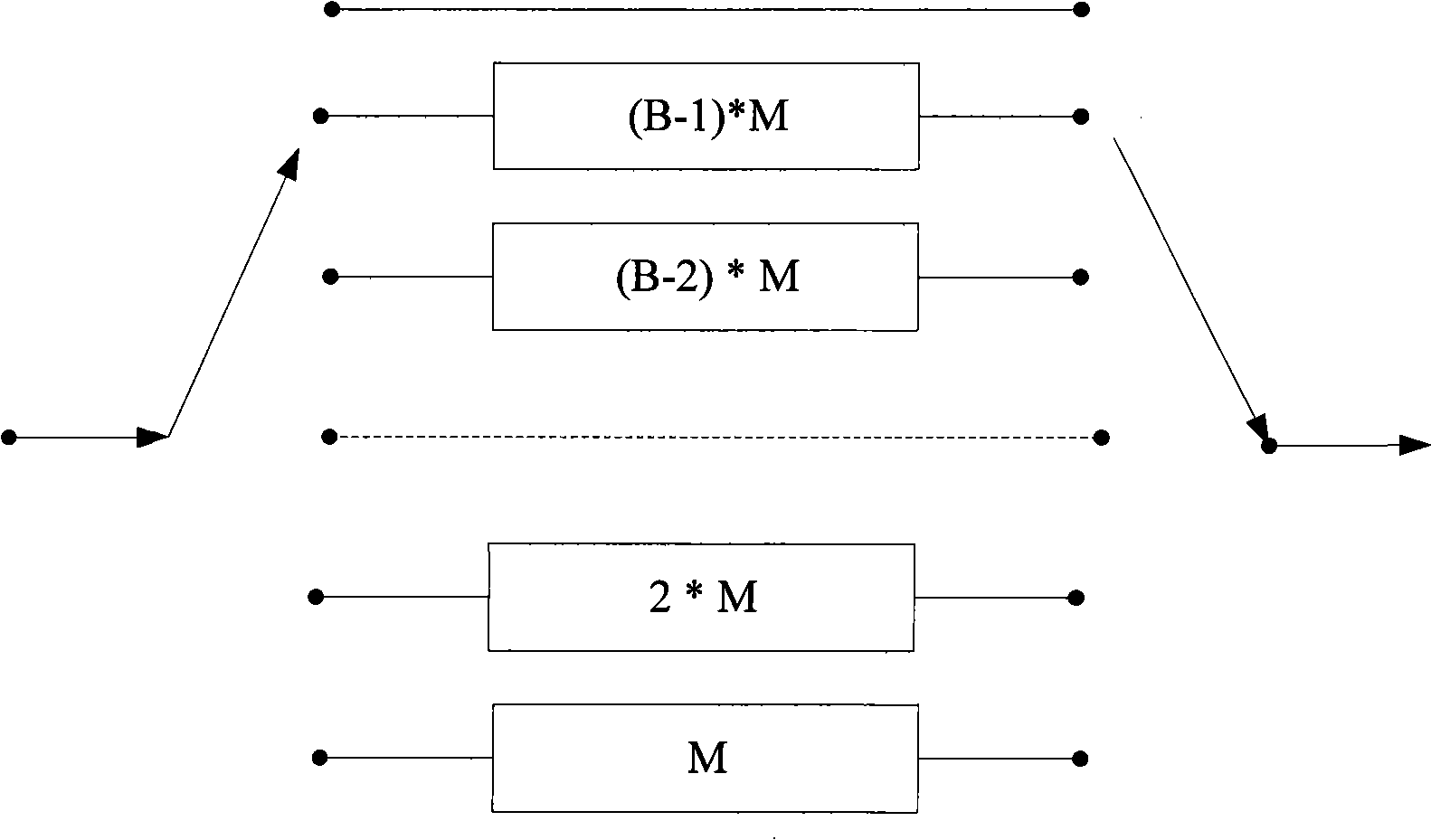

De-interweaving device and receiver

InactiveCN101345603AFewer pinsReduce power consumptionMulti-frequency code systemsTransmitter/receiver shaping networksTime domainComputer science

The present invention realizes the time domain de-interleaving using embedded eDRAM in a time domain synchronous orthogonal frequency division multiplexing receiver, belonging to de-interleaving domain of digital communication. A receiver having a de-interleave with a processor for processing interleaved data; and a built-in eDRAM coupled to the processor for processing the interleaved data is provided.

Owner:TSINGHUA UNIV

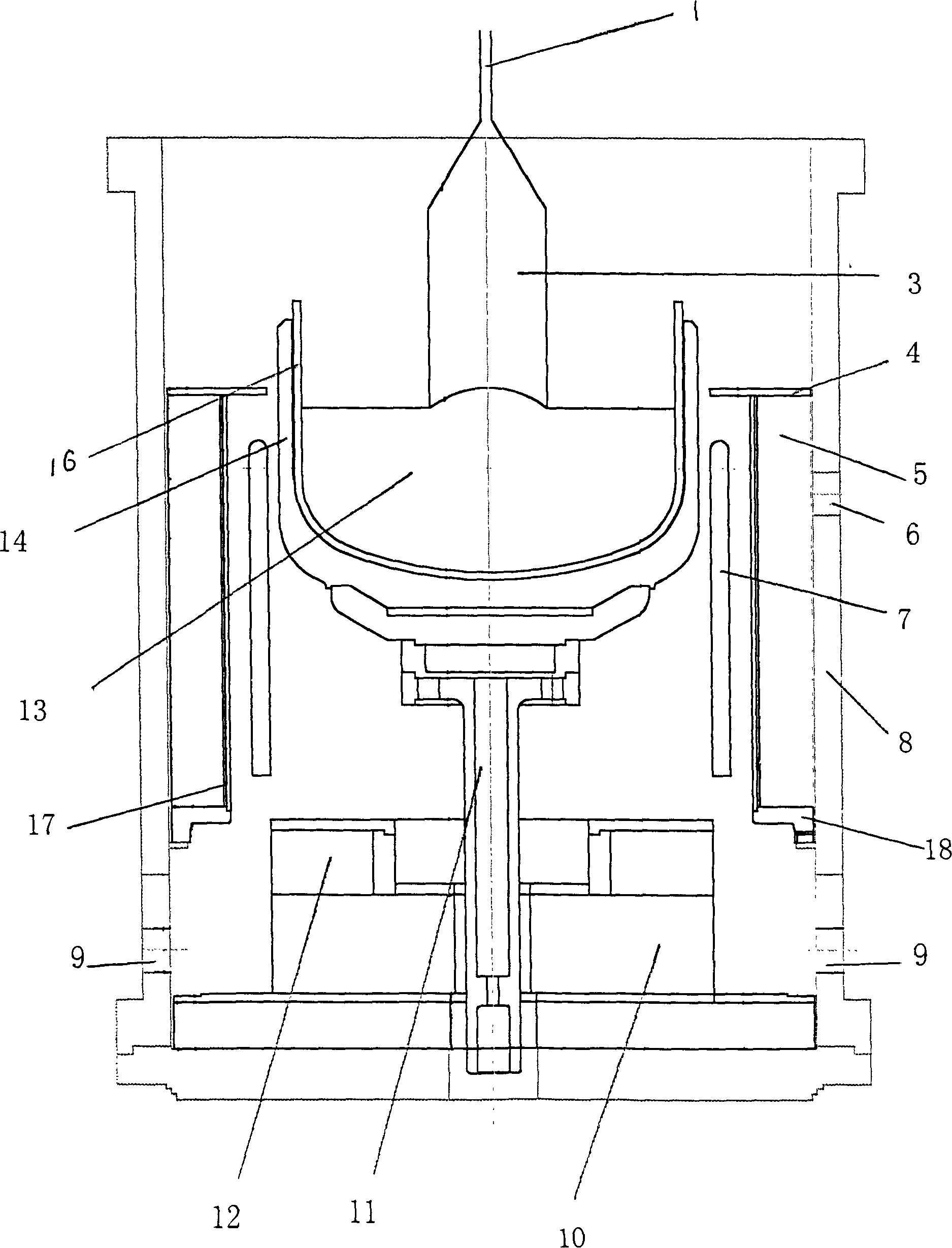

Mold for preparing EPP steering wheel

The invention discloses a mold for preparing an EPP steering wheel. The mold comprises an upper mold and a lower mold, the upper mold is internally provided with an upper cavity, and the lower mold is internally provided with a lower cavity. The mold for preparing the EPP steering wheel is characterized in that a movable insert is arranged in the lower mold, the movable insert is driven by a driving mechanism to move up and down in the lower mold, the top of the movable insert is provided with a movable cavity, and the upper cavity in the upper mold, the lower cavity in the lower mold and the movable cavity in the movable insert are matched to form a forming cavity used for forming an EPP layer on the steering wheel. The EPP layer of the EPP steering wheel prepared through the mold is large in density and compact in structure, the surface is smooth and elastic, the whole EPP layer is complete and free of shrinkage cavities, no defect exists, and the quality is very high. Meanwhile, due to the fact that the upper mold and the lower mold are subjected to mold closing before material injection is conducted, and parting surfaces of the upper mold and the lower mold are gapless, no burr exists on the final EPP steering wheel basically, burrs do not need to be removed manually, and the cost of manually removing the burrs is reduced.

Owner:SHANGHAI JIXIANG AUTOMOBILE ROOF TRIMMING

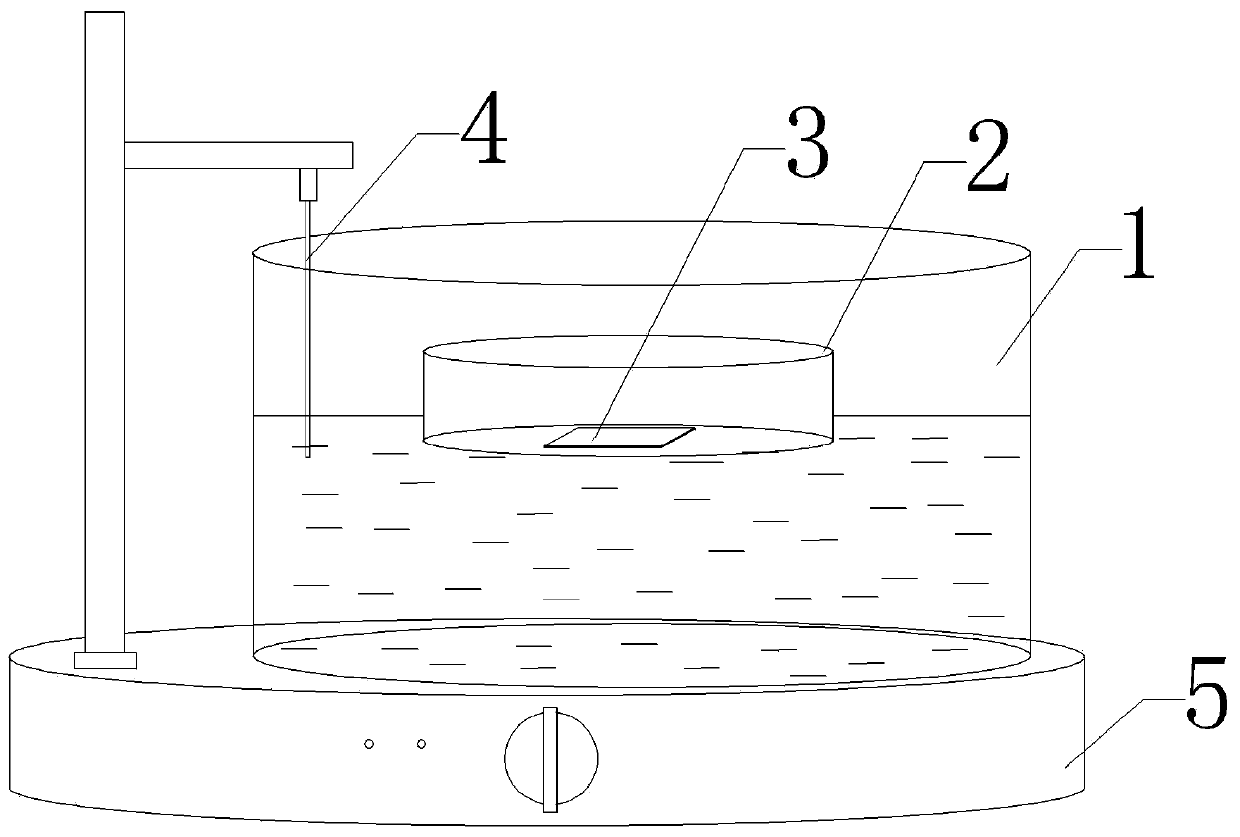

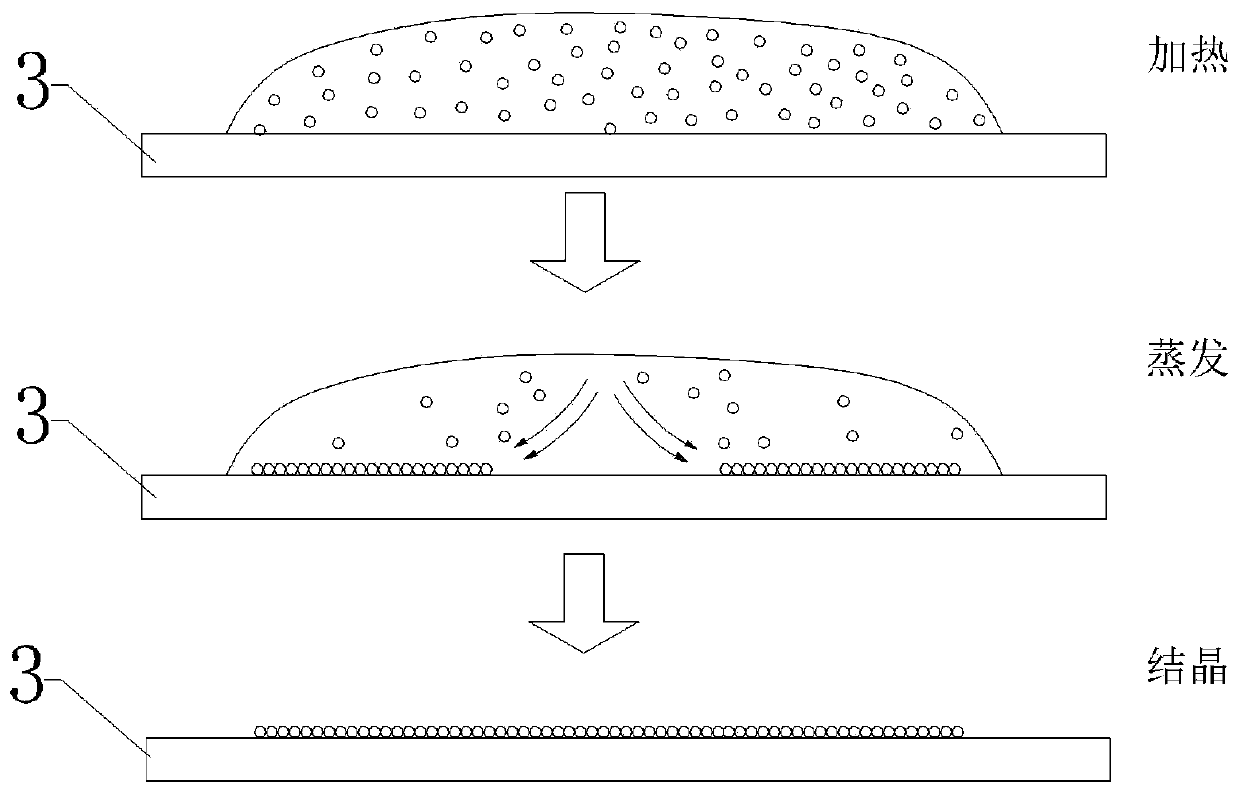

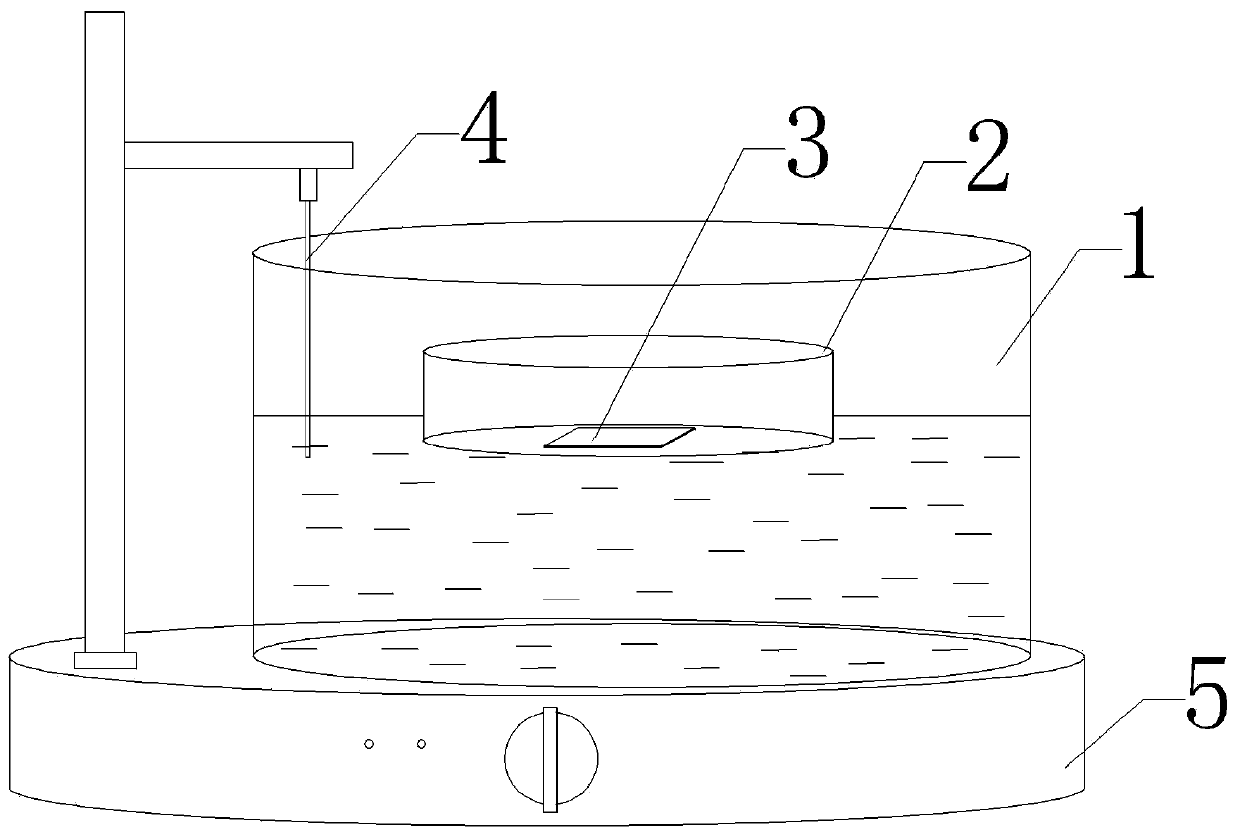

Method for preparing large-size three-dimensional photonic crystal through constant-temperature liquid baking method

InactiveCN109972206AEvenly distributedNovel ideaPolycrystalline material growthFrom normal temperature solutionsPolymer scienceMicrosphere

The invention discloses a method for preparing a large-size three-dimensional photonic crystal through a constant-temperature liquid baking method. The method is characterized by comprising the following steps that 1, polymer material colloidal microspheres, a substrate, a dispersion medium, constant-temperature liquid, a first container and a second container are prepared, wherein the particle size of the polymer material colloidal microspheres is in a micron size and is uniform, the substrate is obtained through hydrophilization, the temperature of the constant-temperature liquid is a DEG C,the size of the second container is smaller than that of the first container, and the thermal conductivity of the second container is good; 2, the polymer material colloidal microspheres are put intothe dispersing medium, the polymer material colloidal microspheres are dispersed in the dispersion medium through ultrasonic vibration, and a mixed solution with the concentration of b% is obtained;3, the constant-temperature liquid is poured into the first container, the second container is put into the constant-temperature liquid to float, the substrate is put into the second container, and the substrate is heated for c minute by using the constant-temperature liquid; 4, the mixed solution is dropwise added onto the substrate, after a solvent is volatilized, the constant-temperature liquidis used for continuous heating, and the colloidal three-dimensional photonic crystal made of the polymer material colloidal microspheres is obtained. The method is novel in concept, reasonable in design and easy and convenient to operate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

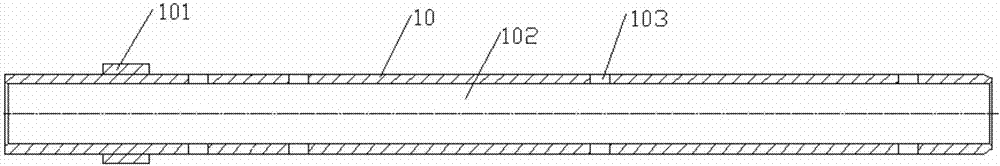

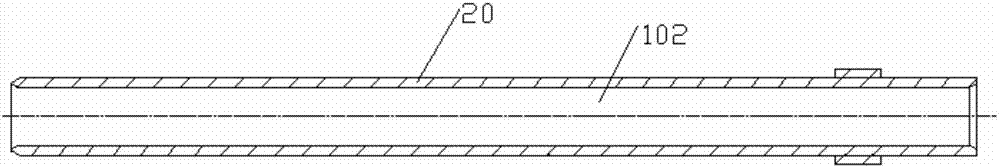

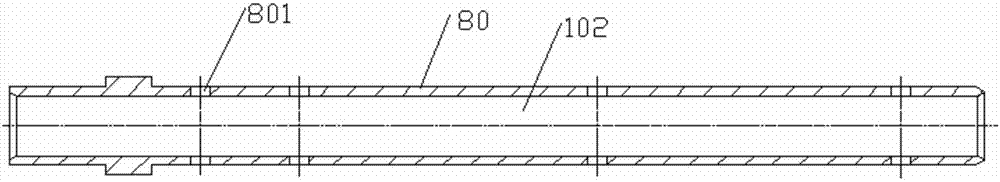

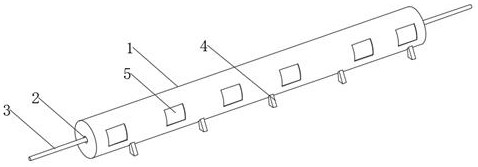

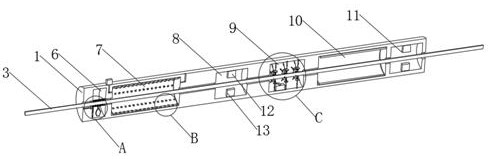

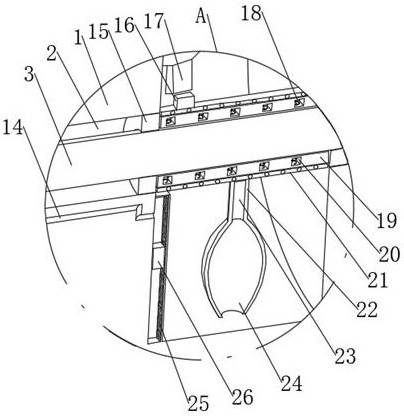

Defect monitoring device for flat enameled wire production and processing

ActiveCN113314270AHigh integrationImprove efficiencyOptically investigating flaws/contaminationInsulating conductors/cablesManufacturing engineeringElectrical and Electronics engineering

The invention discloses a defect monitoring device for flat enameled wire production and processing, and relates to the field of defect monitoring devices, and the defect monitoring device comprises a flat enameled wire defect monitoring machine body which is of a cylindrical structure. The middle part of the flat enameled wire defect monitoring machine body is provided with processing drain holes which are distributed along the length direction of the flat enameled wire defect monitoring machine body, and the processing drain holes penetrate through the two ends of the flat enameled wire defect monitoring machine body; when a flat enameled wire is drawn to move in the processing drain holes in the flat enameled wire defect monitoring machine body by a traction mechanism, a series of operations such as painting, drying, defect detection and paint make-up are completed, the integration is high, and the efficiency is high.

Owner:CHANGZHOU WELLYUN ELECTRICAL

Rolling machine

InactiveCN1309492CNo defectsMetal rolling stand detailsTensioning/braking arrangementsEngineeringRolling mill

Owner:KOBE STEEL LTD

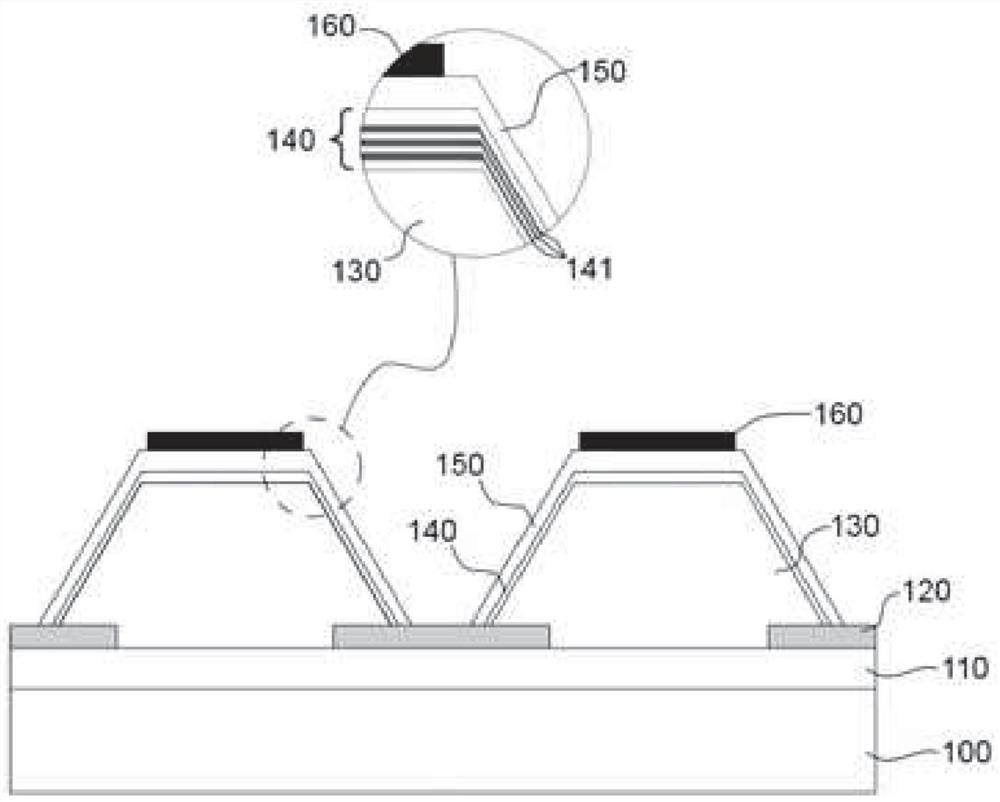

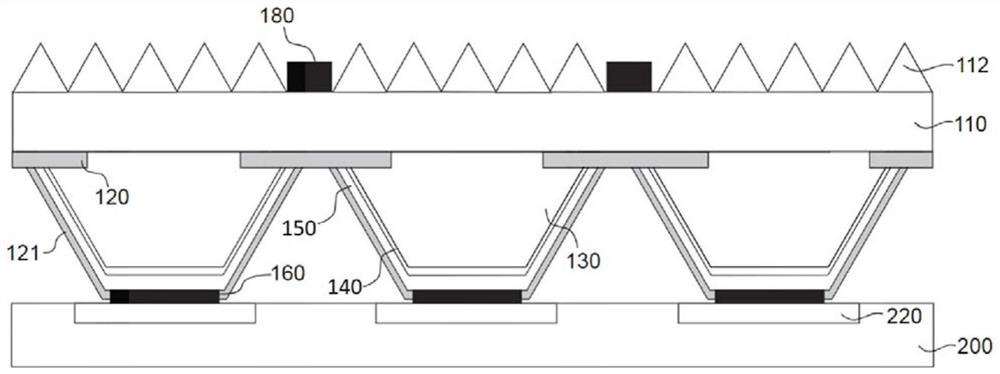

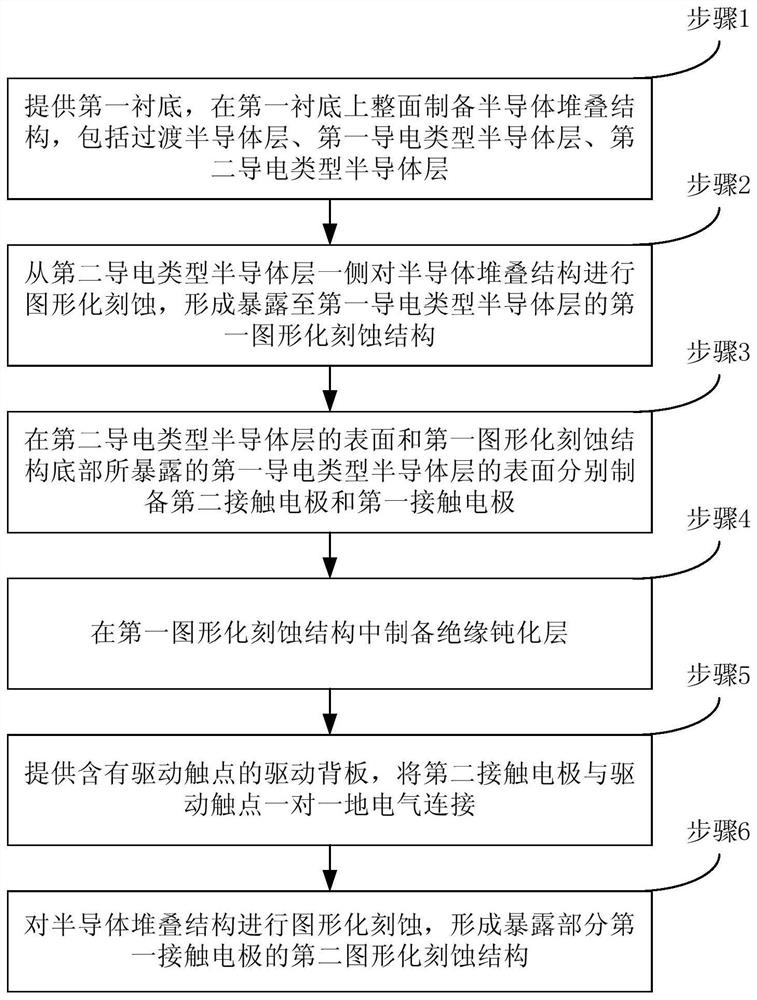

Preparation method of compound semiconductor device and compound semiconductor device

InactiveCN113451146ANo defectsAvoid Signal CrosstalkSemiconductor/solid-state device detailsSolid-state devicesEtchingContact electrode

The invention discloses a preparation method of a compound semiconductor device and the compound semiconductor device. The preparation method mainly comprises the following steps of preparing a first conductive type semiconductor layer and a second conductive type semiconductor layer on the whole surface of a substrate, performing graphical etching from one side of the second conductive type semiconductor layer to form a first graphical etching structure exposed to the first conductive type semiconductor layer, respectively preparing a second contact electrode and a first contact electrode on the surface of the second conductive type semiconductor layer and the surface of the first conductive type semiconductor layer at the bottom of the first graphical etching structure, preparing an insulating passivation layer in the first graphical etching structure, electrically connecting the second contact electrode with the driving contact, and forming a second graphical etching structure which exposes a part of the first contact electrode from one side of the first conductive type semiconductor layer. The defects of the material layer caused by selected area growth do not exist, signal crosstalk between devices can be avoided, and the performance of the compound semiconductor device can be improved on the whole.

Owner:格芯致显杭州科技有限公司

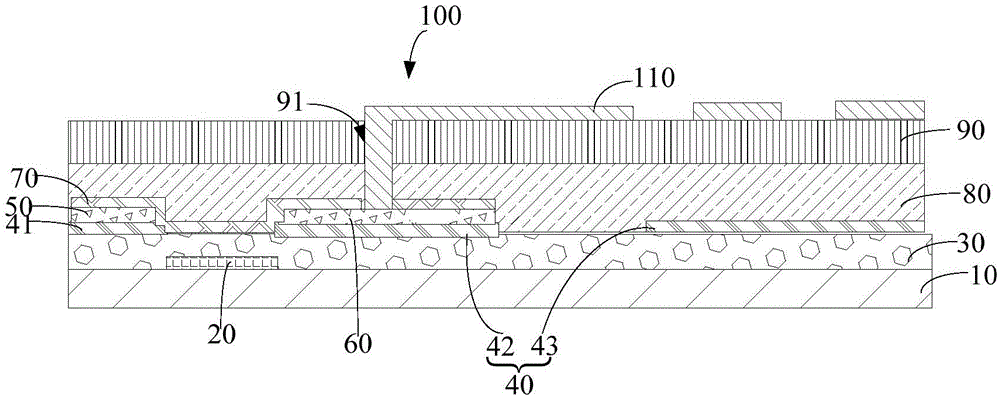

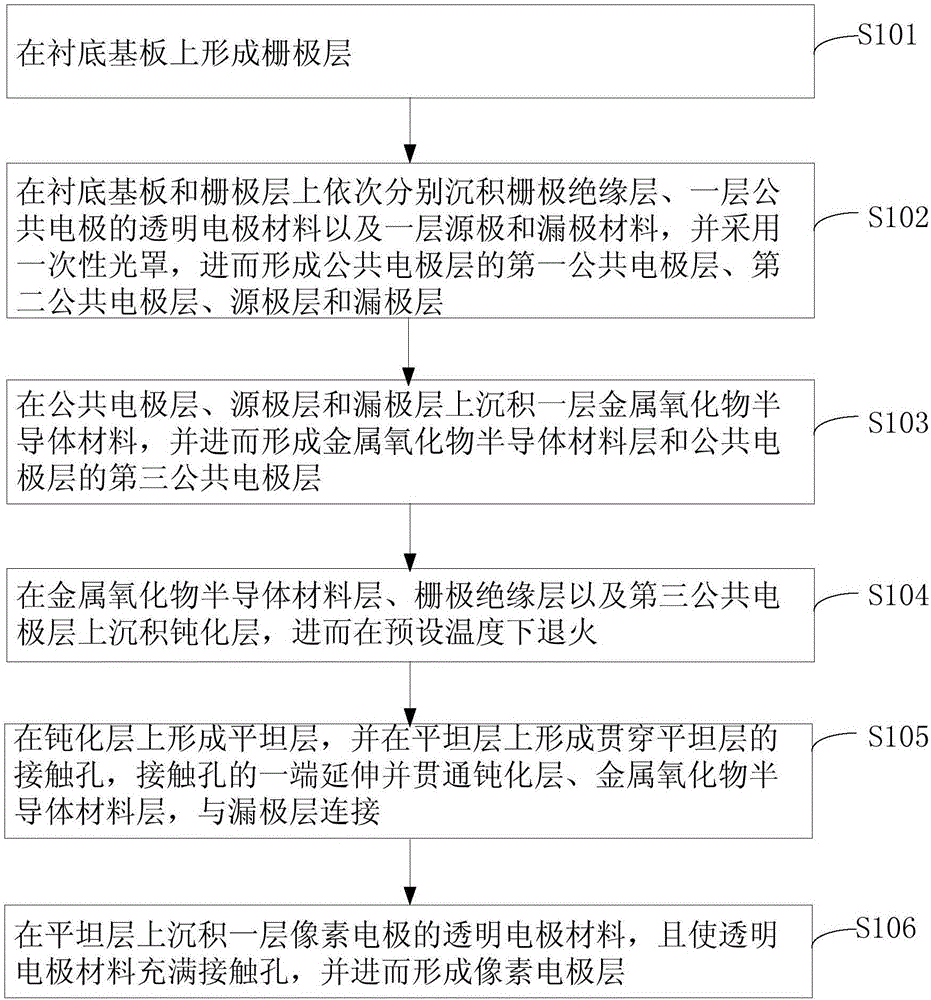

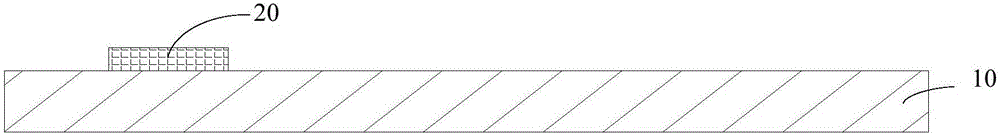

Array substrate, manufacturing method thereof and liquid crystal display panel

ActiveCN107527924ANo defectsImprove stabilityTransistorSolid-state devicesLiquid-crystal displaySemiconductor materials

The invention provides an array substrate, a manufacturing method thereof and a liquid crystal display panel. The array substrate comprises the components of a substrate; a gate electrode layer; a gate electrode insulating layer; a common electrode layer which comprises a first common electrode layer, a second common electrode layer and a third common electrode layer, wherein the first common electrode layer and the second common electrode layer are arranged at two ends of the gate electrode layer; a source electrode layer and a drain electrode layer; a metal oxide semiconductor material layer which covers the source electrode layer, the gate electrode insulating layer and the drain electrode layer, wherein the transparent electrode material of the first common electrode layer and the second common electrode layer and metal oxide semiconductor material of the metal oxide semiconductor material layer form a lightly doped drain structure LDD in a mutual contact area; a passivation layer; a flat layer; and a pixel electrode layer. Through the array substrate, the manufacturing method thereof and the liquid crystal display panel, the lightly doped drain structure LDD can be formed in a non-ion-injection manner, thereby eliminating interface defects.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Large-diameter thin-wall silver-copper alloy collector ring and manufacturing method thereof

InactiveCN102684028BFlat surfaceNo defectsRotary current collectorSlip-rings manufactureMetallurgyIngot

The invention provides a method for manufacturing a large-diameter thin-walled silver-copper alloy collector ring and the large-diameter thin-walled silver-copper alloy collector ring manufactured by the method. The silver-copper alloy material is smelted into a square ingot, and then made into a plate, annealed, and then Apply pressure to the surface of the sheet and extend it into a long tube. The method of the invention has high yield, high production efficiency, low energy consumption, less loss, is not limited by weather conditions, can be used for large-scale production, and can also be used for the production of a small amount of products.

Owner:SHANGHAI YOUYAN PRECIOUS METAL MATERIAL

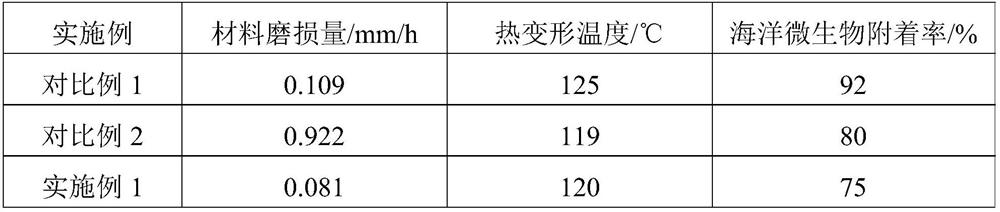

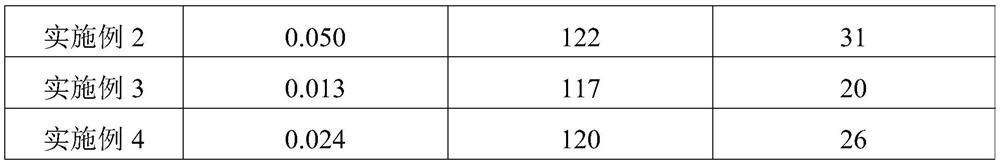

Marine microorganism adhesion-resistant olefin composite material and preparation method thereof

The invention relates to a marine microorganism adhesion-resistant olefin composite material and a preparation method thereof. The preparation method comprises the following steps: (1) weighing a copolymerized olefin material, an inorganic nano component and an olefin monomer with a cyclopentadiene structure, performing blending, and carrying out ultrasonic dispersion treatment to obtain a blend;and (2) adding the blend obtained in the step (1) and a catalyst into a reactor, mixing the substances uniformly, injecting the mxiture into a mold, and conducting polymerizing, curing and molding toobtain a target product. Compared with the prior art, the prepared olefin composite material has excellent mechanical properties like good wear resistance, high strength, high toughness and the like,and more importantly, adhesion of marine microorganisms can be effectively inhibited, and the olefin composite material has excellent marine corrosion resistance and is beneficial to application of the composite material in the field of ocean engineering.

Owner:SHANGHAI RES INST OF CHEM IND

Large-diameter thin-wall silver-copper alloy collector ring and manufacturing method thereof

InactiveCN102684028AFlat surfaceNo defectsRotary current collectorSlip-rings manufactureMetallurgyIngot

The invention provides a method for manufacturing a large-diameter thin-wall silver-copper alloy collector ring and the large-diameter thin-wall silver-copper alloy collector ring manufactured by adopting the method. The method comprises the following steps of: smelting a silver-copper alloy material into a square ingot; processing the square ingot into a panel; annealing; and applying pressure to the surface of the panel and extending, thereby obtaining a long tube. The method provided by the invention has the advantages of high yield, high production efficiency, low energy consumption and low loss; the method is not limited by climate conditions; and the method is suitable for large-scale production as well as production for few products.

Owner:SHANGHAI YOUYAN PRECIOUS METAL MATERIAL

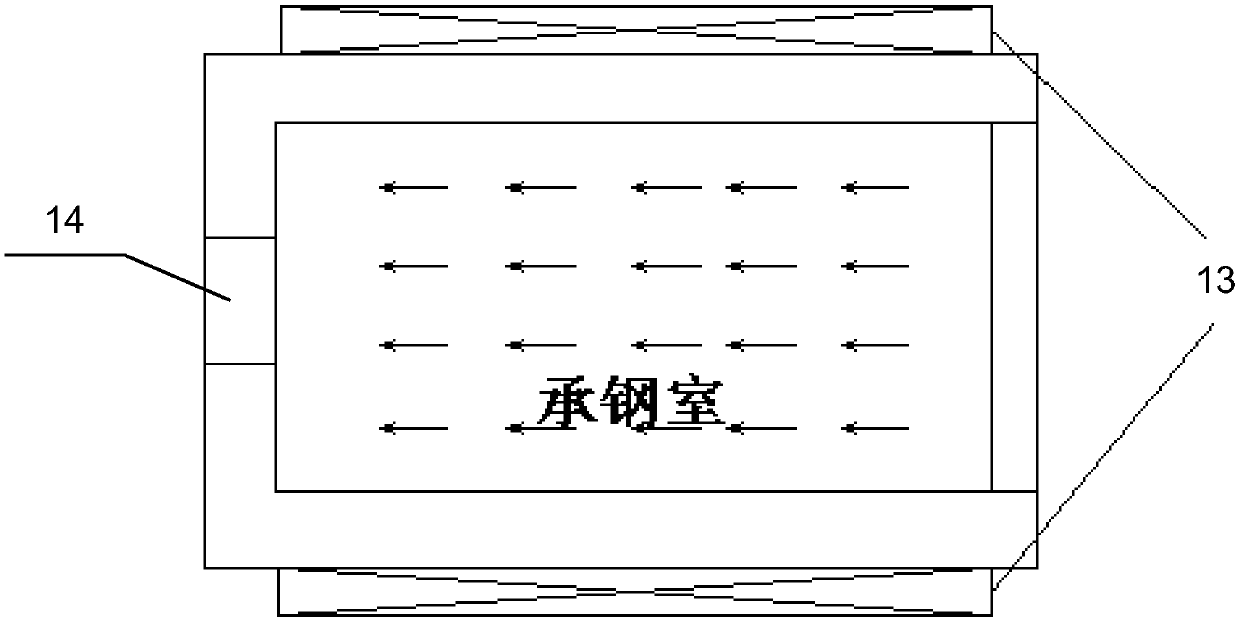

Device and method for discharging drainage sand by utilizing electromagnetism

InactiveCN111195722AImprove purityHigh yieldMelt-holding vesselsCasting cleaning apparatusSlagStructural engineering

The invention discloses a device and a method for discharging drainage sand by utilizing electromagnetism. The device comprises a tundish, wherein a ladle cover is arranged at the top end of the tundish, a slag blocking dam, a slag blocking weir and a metal baffle are arranged in the tundish, the interior of the tundish is divided into a steel bearing chamber and a steel pouring chamber, a steel through hole is formed in the slag blocking weir, and the metal baffle is connected with the steel through steel hole; the steel bearing chamber is provided with a long water port, a turbulence suppressor and a bottom blowing device, the long water port is arranged above the steel bearing chamber, the turbulence suppressor and the bottom blowing device are both arranged at the bottom of the steel bearing chamber, and the turbulence suppressor is arranged below the long water port; the steel pouring chamber is provided with a water outlet and a stopper rod, the stopper rod is arranged above thesteel pouring chamber, and the water outlet is arranged at the bottom of the steel pouring chamber and correspondingly arranged below the stopper rod; and the tundish is further provided with a traveling wave electromagnetic induction device, and the traveling wave electromagnetic induction device is connected on the tundish cover or on two sides of the tundish wall. The device and method disclosed by the invention can effectively discharge the drainage sand entered into the tundish, thereby reducing the pollution of the drainage sand to the molten steel, and improving the cleanliness of the molten steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com