Device and method for discharging drainage sand by utilizing electromagnetism

A technology of drainage sand and electromagnetism, which is used in casting melt containers, mechanical cleaning, manufacturing tools, etc., can solve the problems of difficult installation and incomplete removal process, and achieve the effect of high return, low investment and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

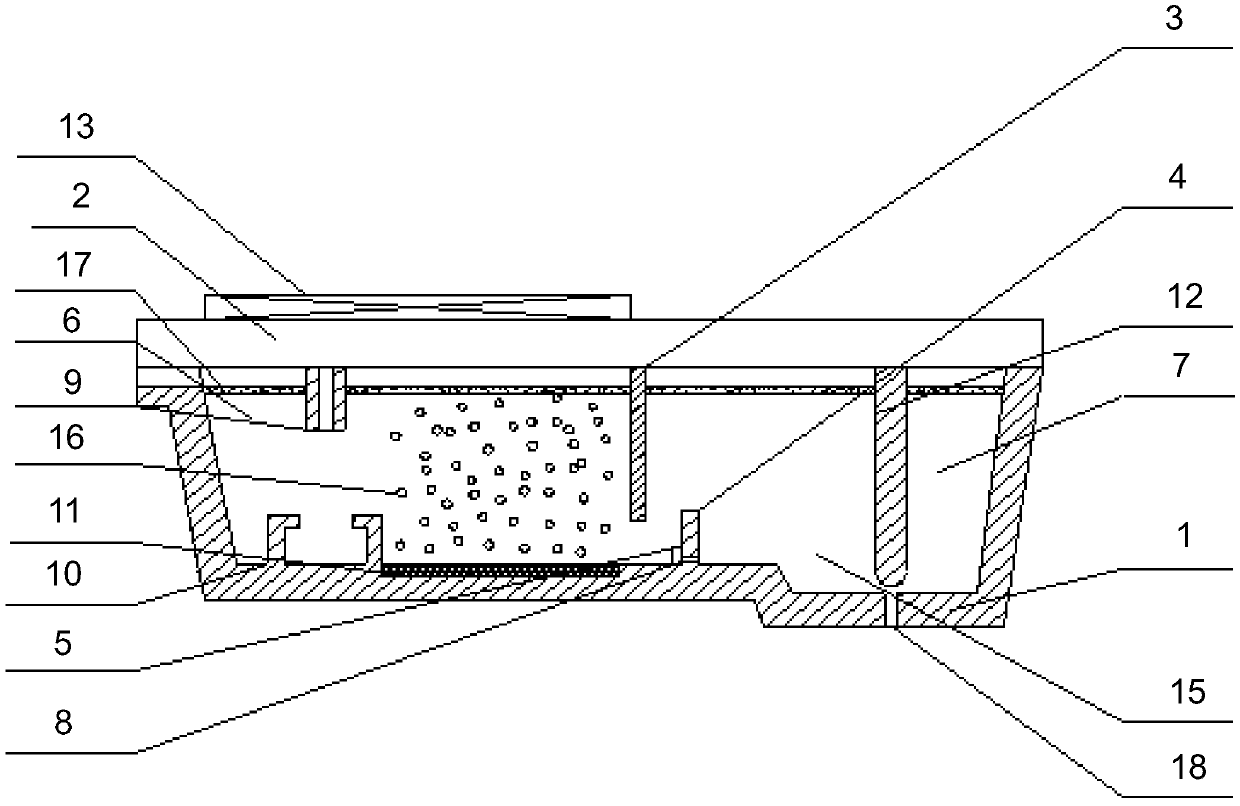

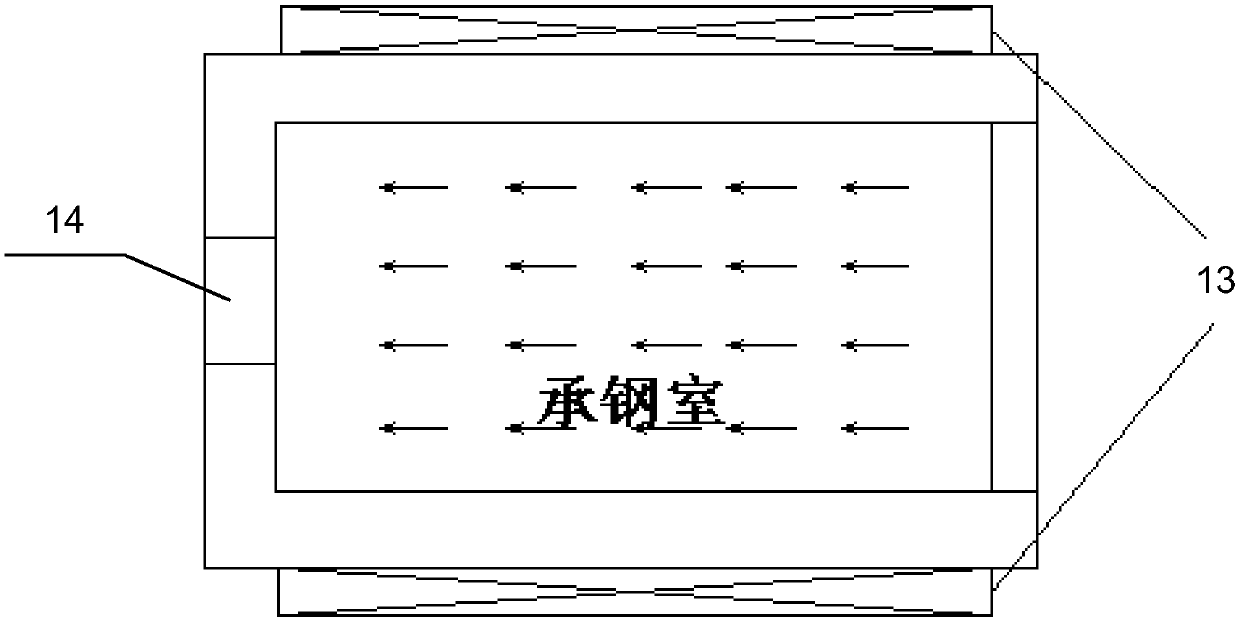

[0053] The tundish is a 25t channel-type single-flow tundish, which is divided into a steel chamber and a pouring chamber. The two chambers are connected through two channels. The thickness of the metal baffle is 2mm. When pouring, the metal baffle is placed in the channel. At the entrance, after pouring is started, the drainage sand falls into the tundish steel chamber before the molten steel, and then is driven by the molten steel to move in the tundish steel chamber. When the liquid level reaches the channel, the molten steel is blocked by the metal baffle. Can not quickly enter the channel, at this time, the liquid level of molten steel rises rapidly, submerging the position of the channel. As the molten steel increases, the metal baffle melts, and the molten steel enters the channel and flows into the pouring chamber. When the liquid level in the steel chamber rises above 200mm, open the air blowing device at the bottom of the tundish, and set the air volume to 0.2L / min. ...

Embodiment 2

[0056] The tundish is a 32t channel-type single-flow tundish, which is divided into a steel chamber and a pouring chamber. The two chambers are connected through two channels. The thickness of the metal baffle is 3mm. When pouring, the metal baffle is placed in the channel. At the entrance, after pouring is started, the drainage sand falls into the tundish steel chamber before the molten steel, and then is driven by the molten steel to move in the tundish steel chamber. When the liquid level reaches the channel, the molten steel is blocked by the metal baffle. Can not quickly enter the channel, at this time, the liquid level of molten steel rises rapidly, submerging the position of the channel. As the molten steel increases, the metal baffle melts, and the molten steel enters the channel and flows into the pouring chamber. When the liquid level in the steel chamber rises above 200mm, open the air blowing device at the bottom of the tundish, and set the air volume to 0.5L / min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com