Patents

Literature

86 results about "Mold tests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral polymeric material based active powder concrete and preparation method thereof

ActiveCN102001846AHigh strengthIncreased durabilitySolid waste managementCeramic shaping apparatusFiberUltimate tensile strength

The invention relates to a mineral polymeric material based active powder concrete and a preparation method thereof. The mineral polymeric material based active powder concrete is made of a gelled material, aggregate, an exciting agent, water, a water reducer and steel fiber in a mass ratio of 1: 0.8-1.3: 0.01-0.2: 0.1-0.3: 0.005-0.07: 0.01-0.25. The preparation method comprises the steps of: pouring the weighed gelled material, aggregate and steel fiber in an agitator and agitating evenly, adding the water in which the exciting agent and the water reducer are dissolved, mixing evenly and molding through vibration or compression, and carrying out autoclave curing or steamed curing on a molded test piece to obtain the mineral polymeric material based active powder concrete. By adopting thepreparation thought of introducing the mineral polymeric material, abundant solid wastes are mixed in the active powder concrete successfully; and the prepared active powder concrete not only has high strength and good durability, but also achieves the effects of reducing the cost and protecting the environment.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

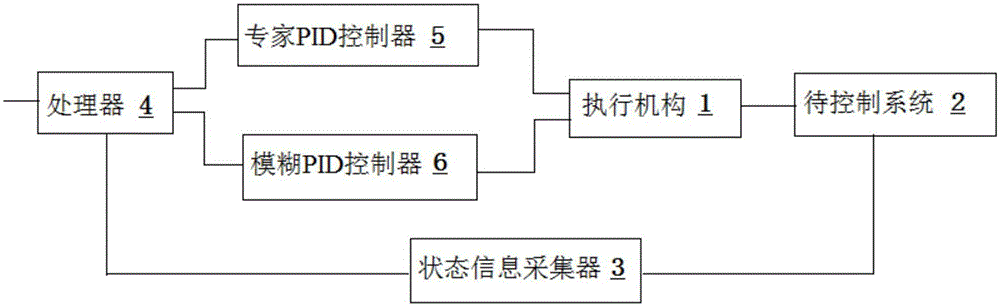

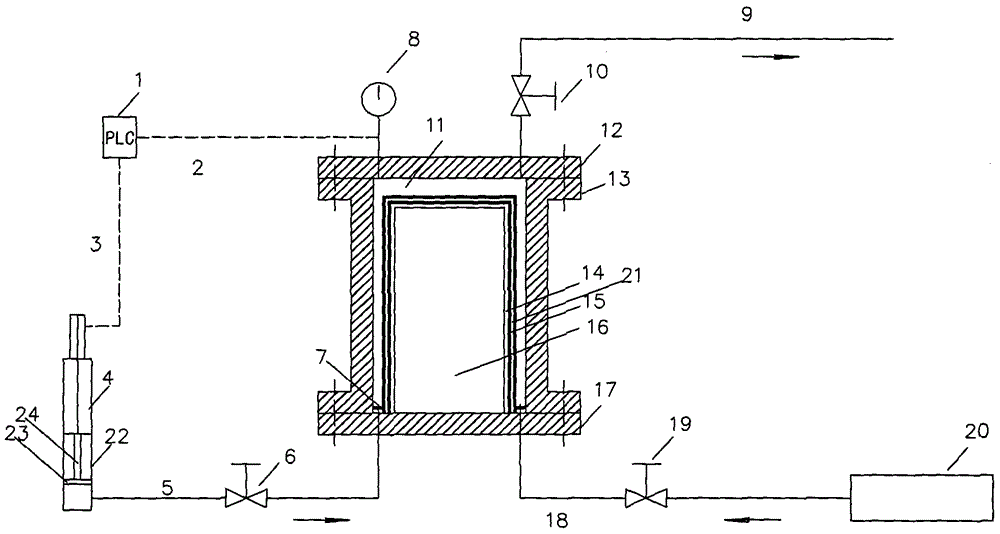

Adaptive PID control method and control system of executing mechanism

InactiveCN105045137AImprove control qualityQuick responseSimulator controlAircraft fuel systemControl system

The invention belongs to the aircraft fuel system full-mold test field and relates to an adaptive PID control method and control system of an executing mechanism. The objective of the invention is to solve the problems of poor effects and low precision of an existing PID control method. The adaptive PID control system includes an expert PID controller and a fuzzy PID controller which are respectively connected with the executing mechanism, a state information acquisition device used for monitoring the current status information of a system to be controlled in real time, and a processor used for selecting the expert PID controller or the fuzzy PID controller according to the current status information and expected status information to control the executing mechanism. According to the adaptive PID control system of the invention, the expert PID controller or the fuzzy PID controller is selected to perform control, and therefore, the adaptive PID control system has the advantages of high adjustment speed, short rise time, low overshoot and high control precision. With the control system adopted, requirements for high speed of a servo system can be satisfied, and the control quality of the servo system can be improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

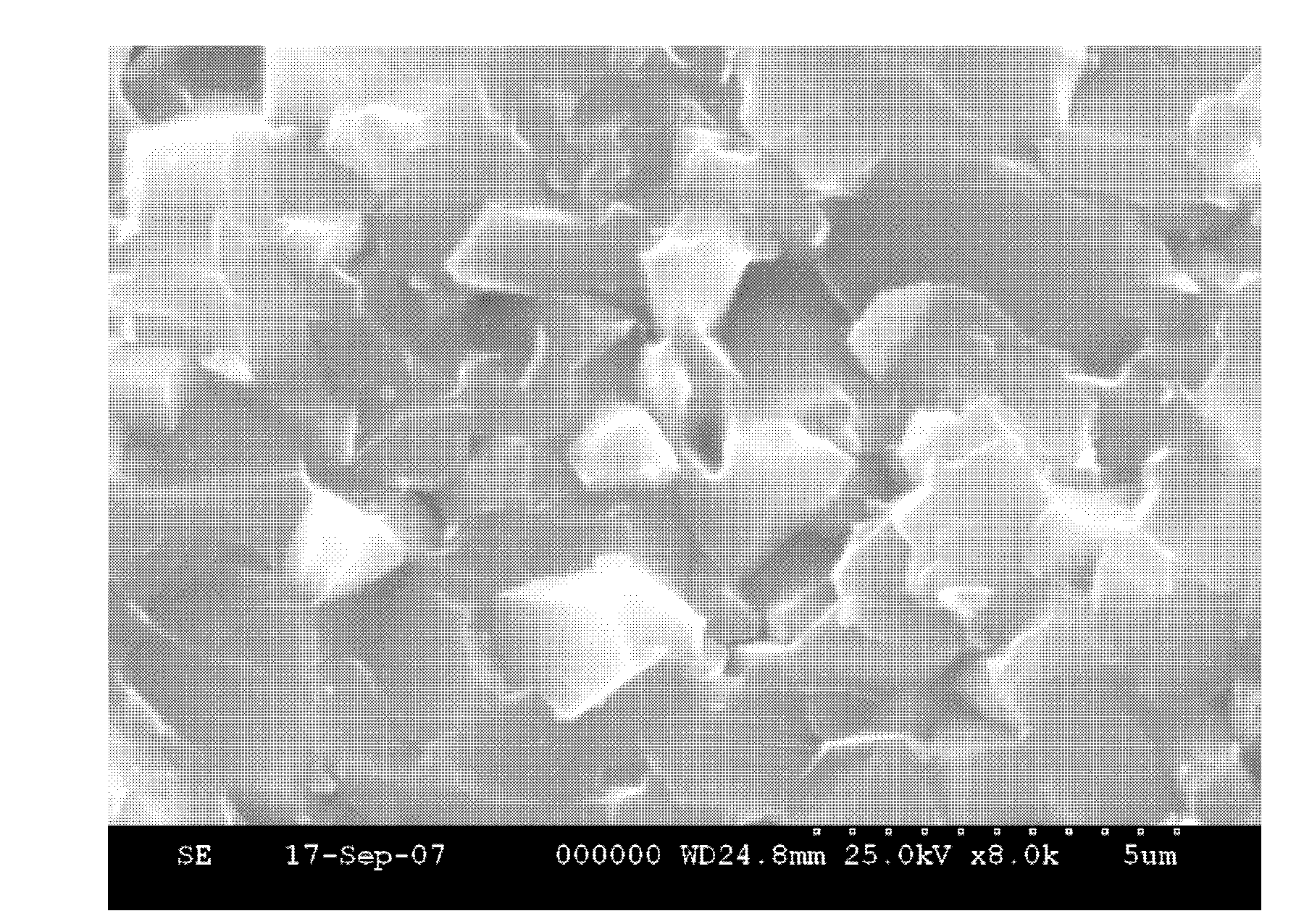

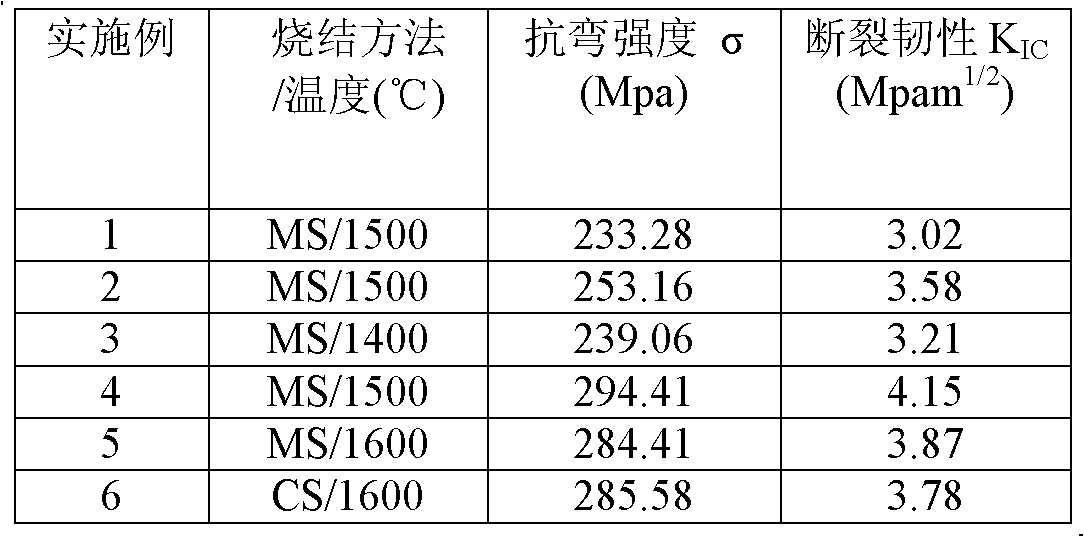

Low-temperature quick sintered high-strength aluminum oxide ceramic and preparation method thereof

The invention discloses low-temperature quick sintered high-strength aluminum oxide ceramic and a preparation method thereof. The low-temperature quick sintered high-strength aluminum oxide ceramic consists of coarse crystal Al2O3 powder, nano Al2O3 powder and a sintering auxiliary agent serving as raw materials, wherein the sintering auxiliary agent consists of SiO2 powder, talc powder and limestone powder. The preparation method comprises the following steps of: partially replacing coarse crystal aluminum oxide by using the nano aluminum oxide powder, mixing, dispersing, pre-pressing and molding, performing 200 to 300MPa cold isostatic pressing molding, performing dumping on a molded test sample in a muffle furnace at a temperature of between 400 and 600 DEG C for 30 to 60 minutes, and finally performing low-temperature quick sintering by adopting a microwave sintering method to obtain the high-strength aluminum oxide ceramic. Quick sintering of the aluminum oxide ceramic can be realized at a lower temperature in short time by partially replacing the coarse crystal aluminum oxide powder by using the nano aluminum oxide powder and combining a microwave sintering process, and therefore, the energy consumption is low, and the cost is saved.

Owner:ANHUI UNIV OF SCI & TECH

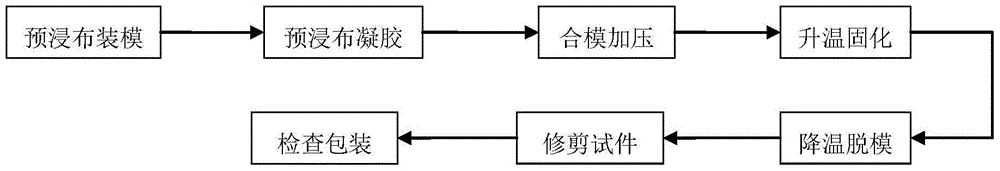

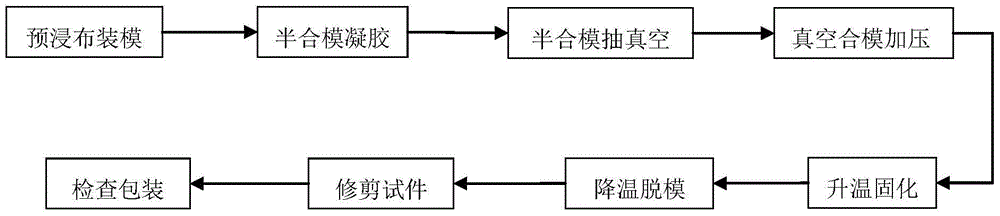

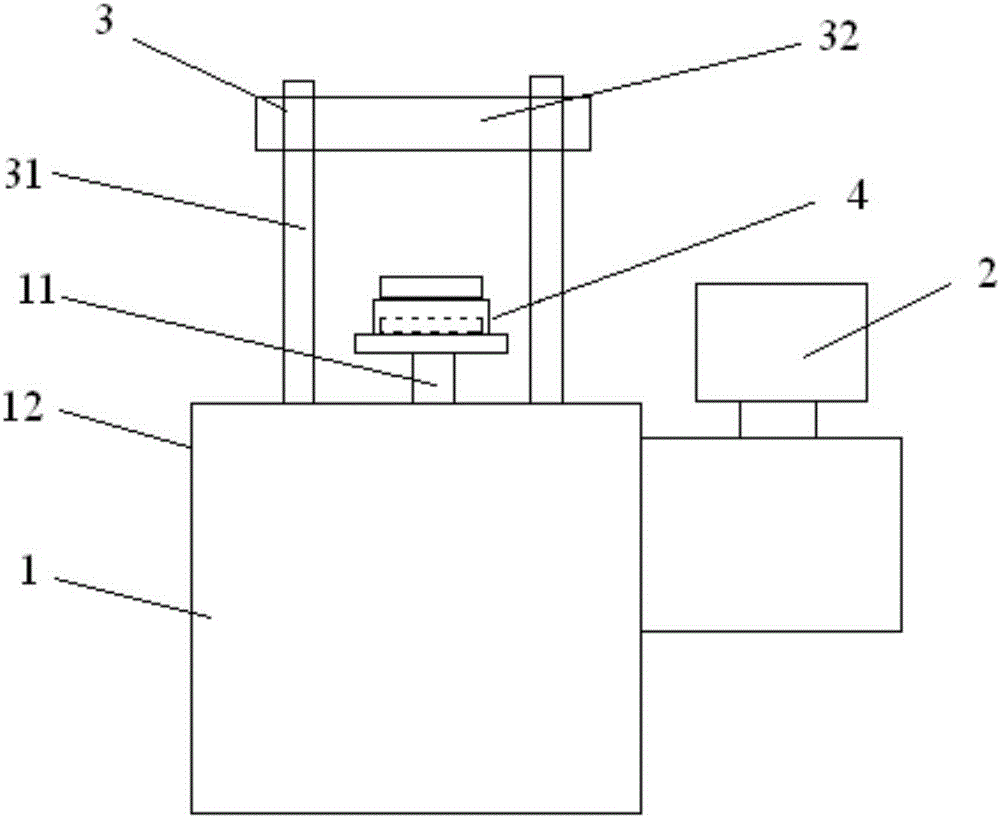

Vacuum compression molding device for carbon fiber composite

InactiveCN105034410AImprove mechanical propertiesImprove the finishCompression moldingNumerical control

The invention discloses a vacuum compression molding device for a carbon fiber composite. The vacuum compression molding device for the carbon fiber composite solves the problem that the performance of a carbon fiber composite molded test piece is poor and comprises an upper mechanism, a lower mechanism, a vacuumizing device, a temperature control device, a pressure control device and a numerical control operation platform. The upper mechanism is installed at the top end of guide posts installed in the lower mechanism through an upper heat conducting plate. Top-pasted type pressure sensors of the pressure control device adhere to the bottom face of the upper heat conducting plate and are connected with the numerical control operation platform through wires. Bottom-pasted type pressure sensors of the pressure control device adhere to a lower heat conducting plate and are connected with the numerical control operation platform through wires. Upper temperature sensors of the temperature control device adhere to the two sides of an upper male die of the upper mechanism and are connected with the numerical control operation platform through wires. Lower temperature sensors of the temperature control device adhere to the two sides of the upper surface of a lower female die and are connected with the numerical control operation platform through wires. The vacuumizing device is installed on a vacuum compression molding device base on the left side of the lower mechanism, and a one-way valve of the vacuumizing device is installed on the lower female die. The numerical control operation platform is installed on the right side of the lower mechanism.

Owner:JILIN UNIV

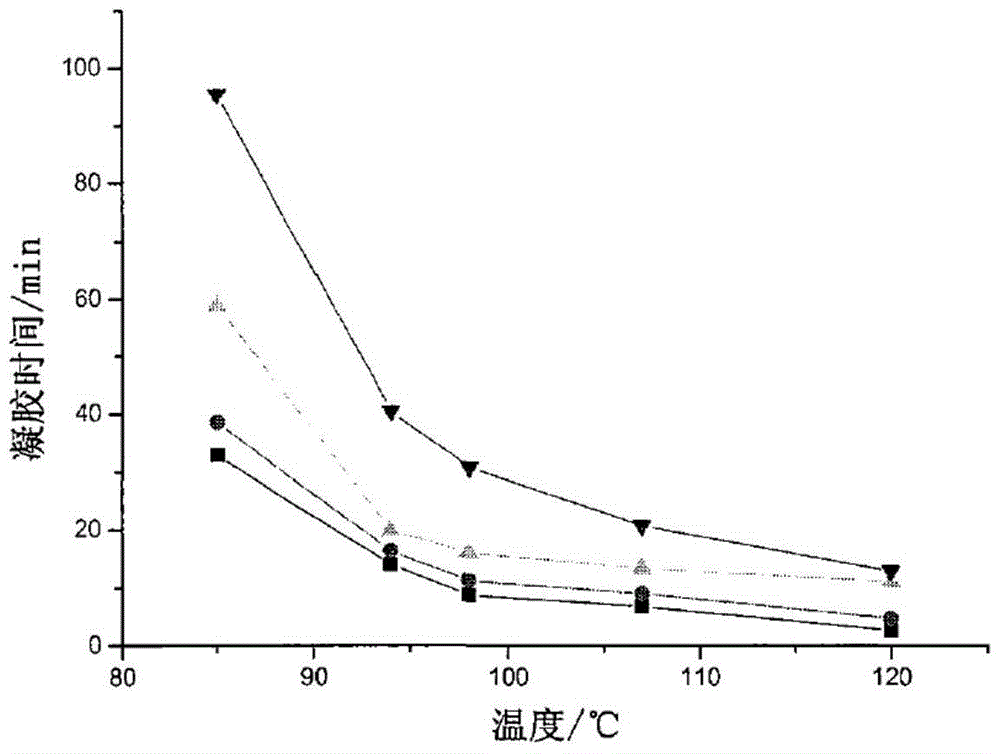

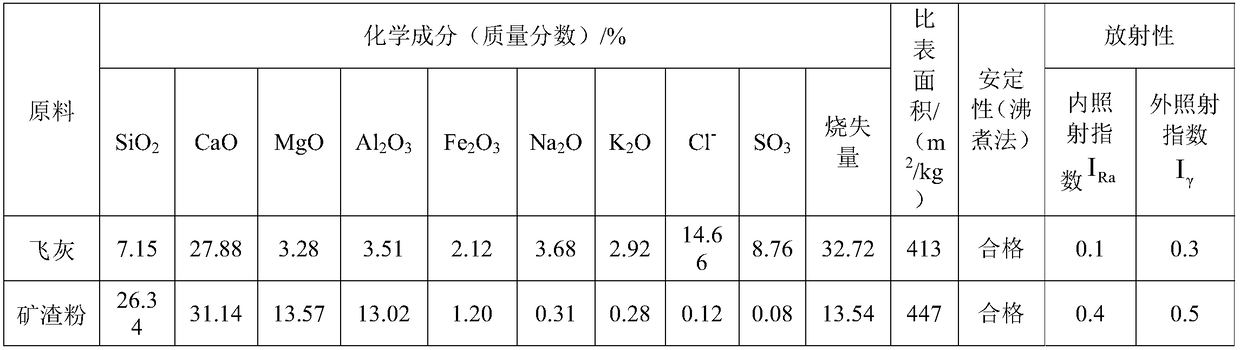

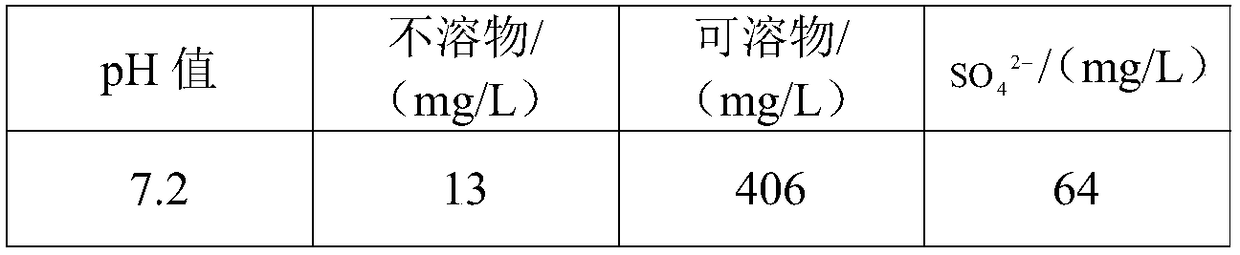

Method for preparing geopolymer gel material and geopolymer mortar

ActiveCN108623199AAchieving processing powerImplement resourcesCement productionResource utilizationSlag

The invention provides a method for preparing a geopolymer gel material and geopolymer mortar. The method comprises the following steps: carrying out drying, and fine grinding pre-treatment on fly ash; taking the pre-treated fly ash, mineral slag powder and a compound exciting agent according to the Si / Al mol ratio of 2.40 to 3.35, the Na / Si mol ratio of 0.30 to 0.50 and the Ca / Si mol ratio whichis less than or equal to 0.95, and uniformly mixing; adding blending water according to the mass ratio of the blending water to the sum of the fly ash and the mineral slag powder of 0.20 to 0.40, so as to obtain a neat paste mixture; filling the neat paste mixture into a mold; after curing the mold for 12 hours to 72 hours under the conditions that the temperature is 20 DEG C to 80 DEG C and the relative humidity is 50 percent to 95 percent, de-molding; after curing a de-molded test piece, obtaining the geopolymer gel material. According to the method provided by the invention, the combustionfly ash of domestic garbage and the mineral slag powder are used as gel components to produce and prepare the novel geopolymer gel material, and treatment and resource utilization of the fly ash are realized.

Owner:TIANJIN BUILDING MATERIALS SCI RES INST +2

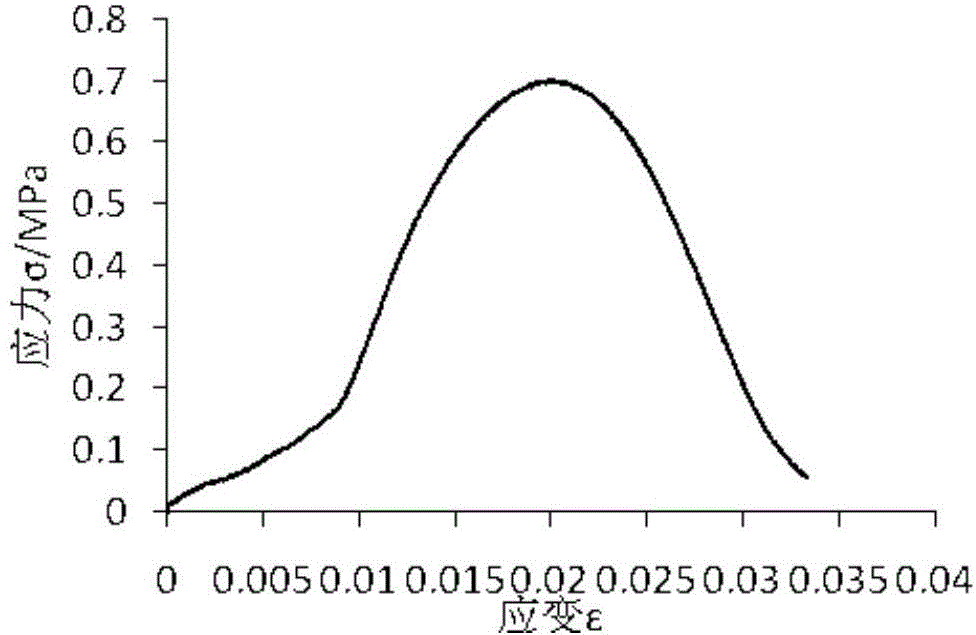

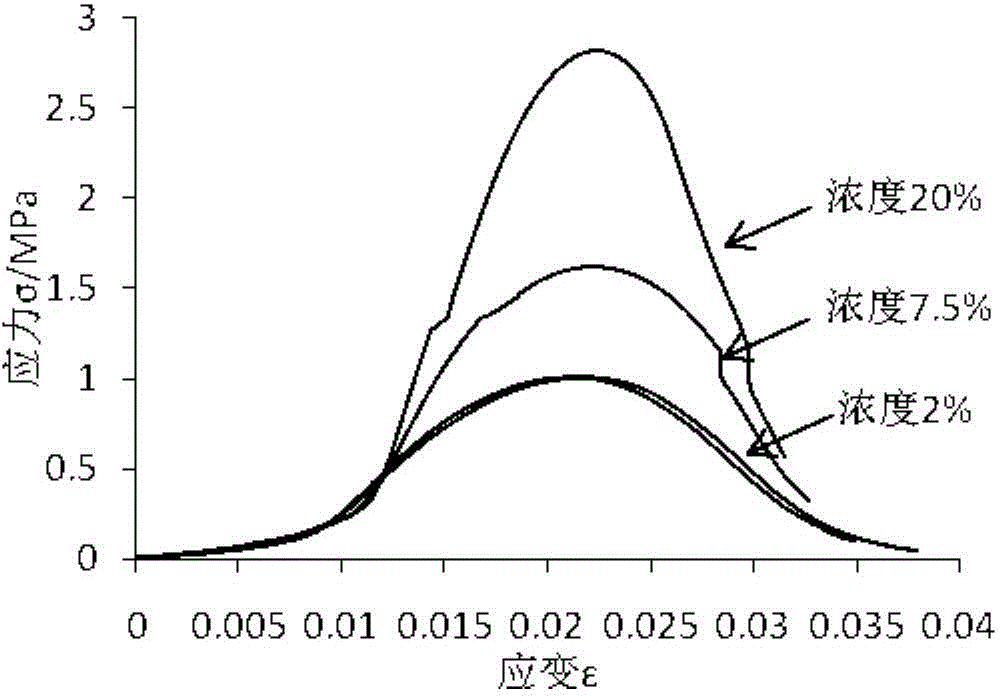

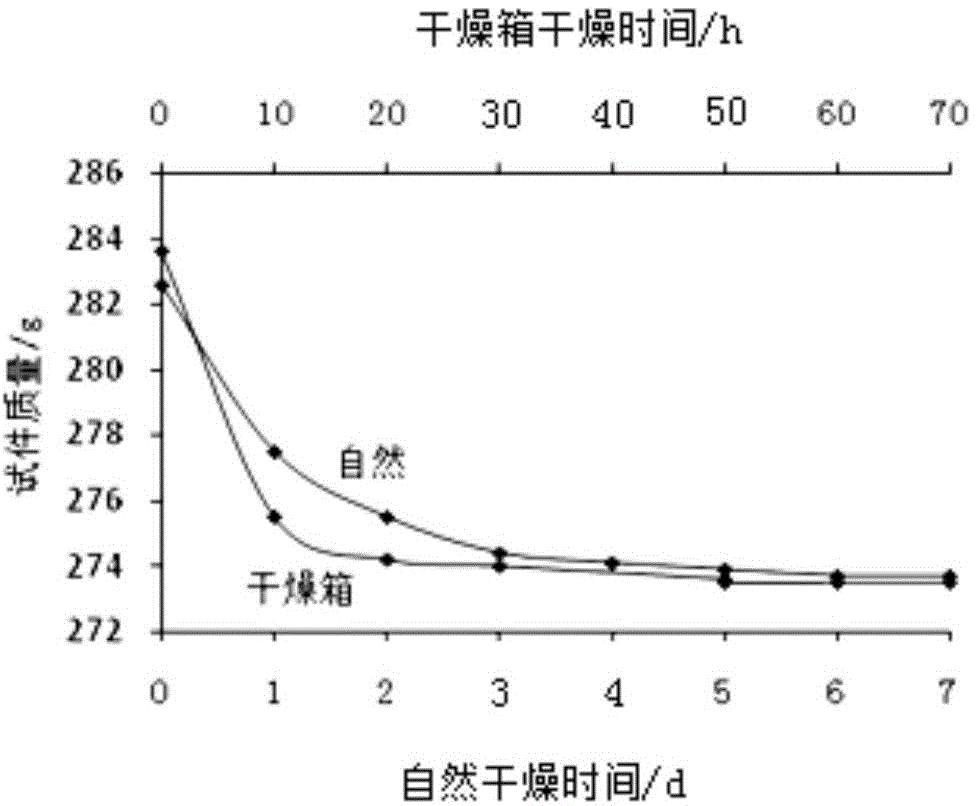

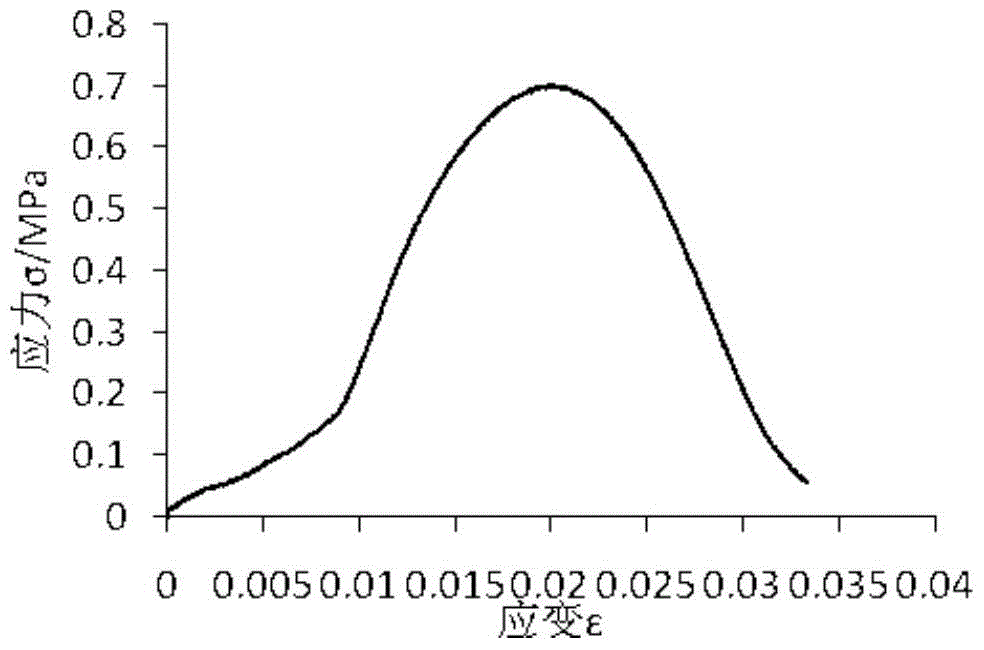

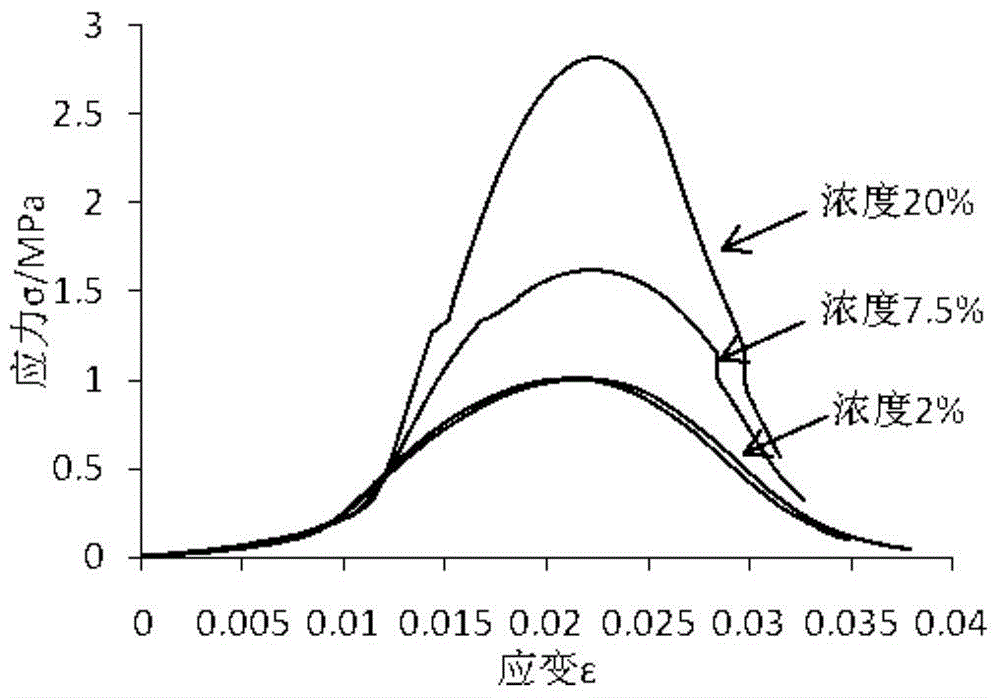

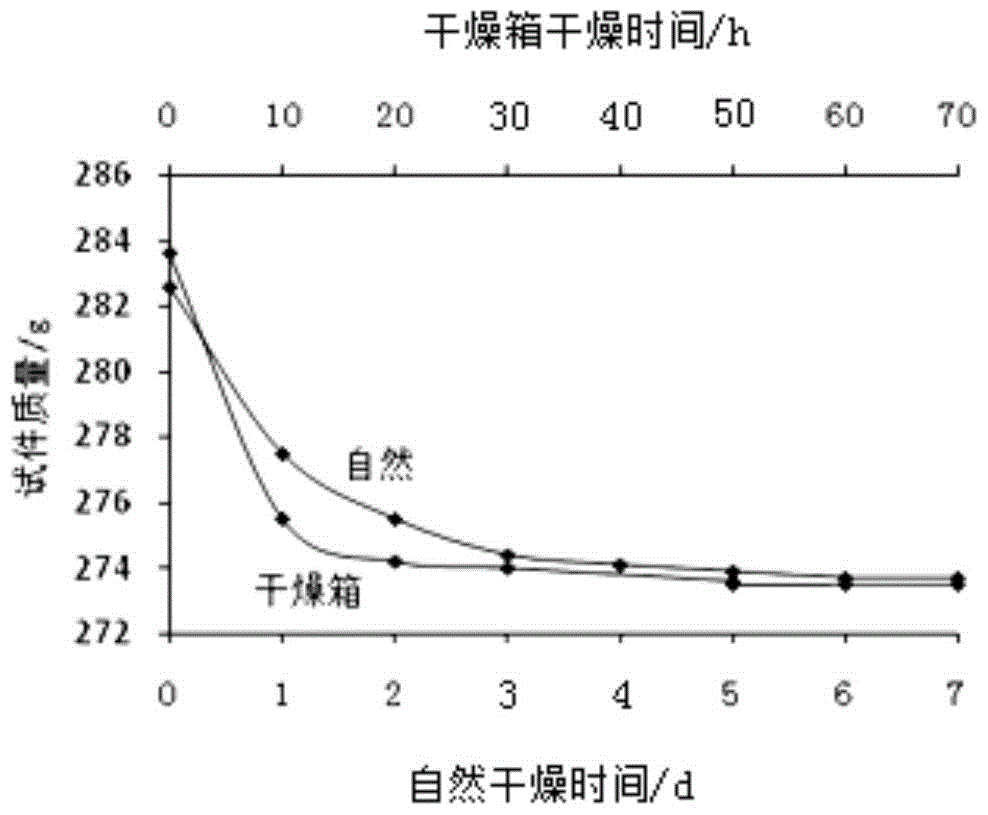

Gas-containing coal similar material and preparation method thereof

ActiveCN104694191AHigh compressive strengthImprove adsorption capacityOther chemical processesSolid fuelsPorositySide effect

The invention discloses a gas-containing coal similar material and a preparation method thereof. The similar material is prepared by the preparation method comprising the following steps: selecting coal powder with certain particle size distribution and a sodium humate aqueous solution as raw materials, wherein the coal powder is used as an aggregate and the sodium humate aqueous solution is used as a cementing agent; weighing the coal powder with the certain particle size distribution, water and sodium humate strictly according to proportions, fully stirring uniformly, pouring the well mixed and stirred mixture into a steel mold, and performing pressure molding on the mixture by using a certain pressure under a press machine; and separating the mold, taking out a molded test piece, and drying at normal temperature or in a drying box. A physical mechanical parameter test shows that the volume weight and porosity of the similar material are equivalent to those of raw coals, the adsorptivity of the similar material is very close to that of the raw coals, and the similar material has the advantages of high uniaxial compressive strength, wide mechanical parameter variation range and the like, and also has the advantages of simple material manufacturing process, stable performance, low price, no toxic or side effect and the like.

Owner:SHANDONG UNIV +1

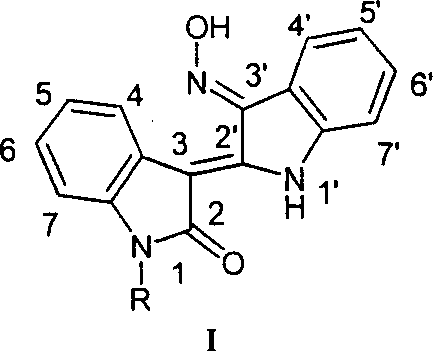

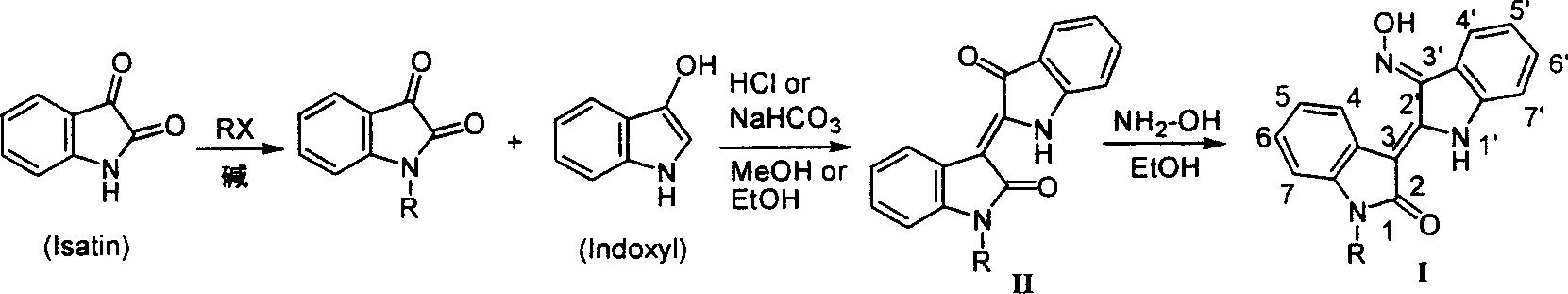

Preparation method and medical uses of Nú¿1ú®-hydrocarbyl-3íõ-nitrotylindirubin derivative 1

InactiveCN1763005ACheap methodThe method is simple and fastOrganic active ingredientsPowder deliveryHalohydrocarbonHydroxylamine

The present invention is preparation process and antitumor effect of N(1)-alkyl-3'-oximino indirubin derivative (I, JN-2528). The new synthesis process uses indirubin as initial material, and under the action of alkaline compound as promoter, indirubin is reacted directly with halohydrocarbon or other halide to obtain N(1)-alkyl indirubin derivative, which is then reacted with hydroxylamine to obtain N(1)-alkyl-3'-oximino indirubin derivative. The MTT and SRB process and transplanting C57 mouse Lewis lung cancer mold test proves the antitumor activity of N(1)-alkyl-3'-oximino indirubin. The compound shows extracorporeal and intracorporeal cancer inhibiting effect.

Owner:JC (WUXI) CO INC

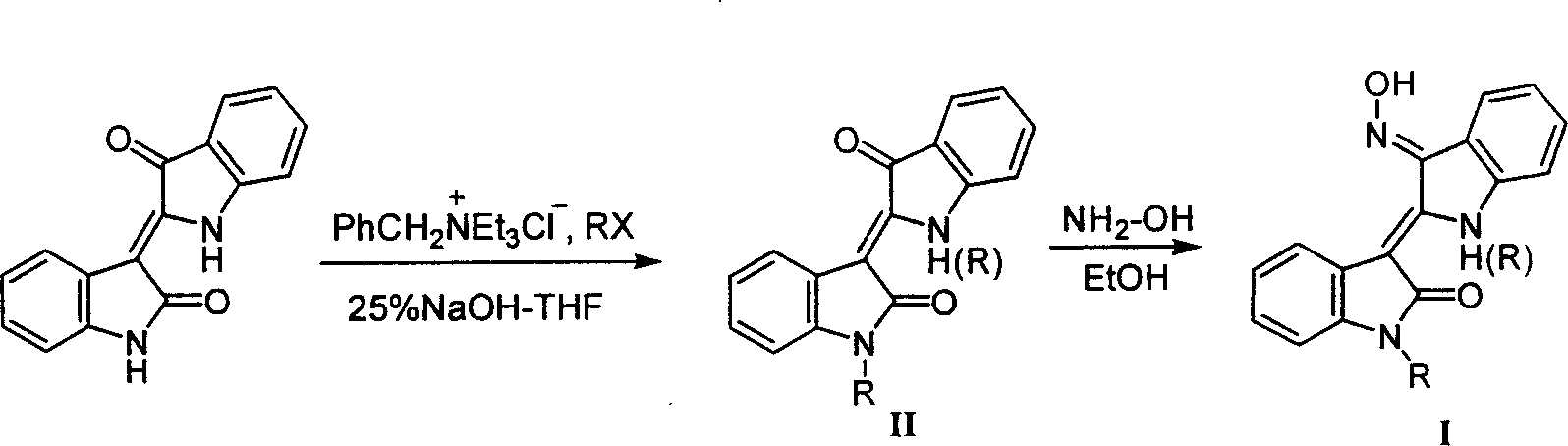

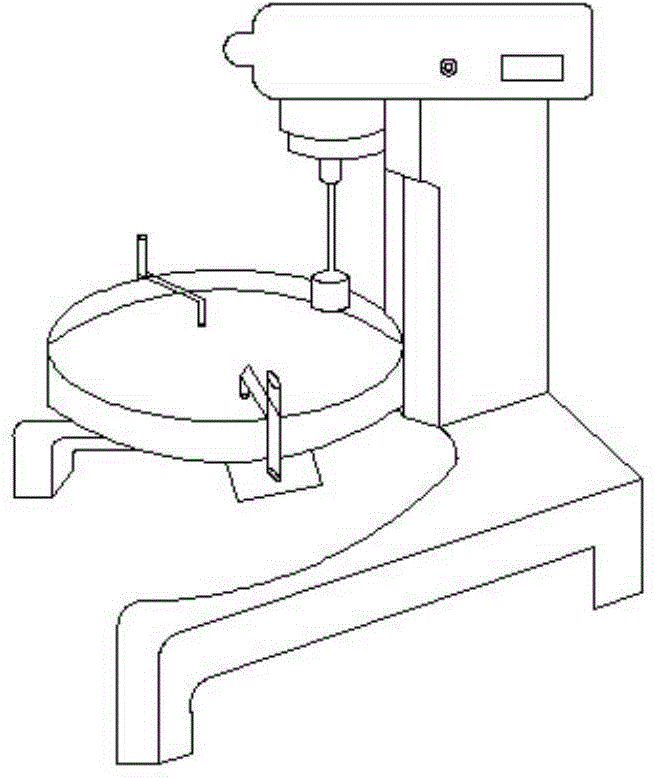

Machine-made sand and pitch adhesion evaluation method

InactiveCN104807751AEasy to operatePracticalUsing mechanical meansMaterial analysisRoad engineeringRoom temperature

The invention belongs to the technical field of road engineering construction and particularly relates to a machine-made sand and pitch adhesion evaluation method which comprises the following steps of blending machine-made sand and pitch in a blending boiler at a temperature of 150 DEG C, molding a test piece by use of a template, and placing the molded test piece at room temperature for 24 hours; uniformly painting edible oil on the abrasion region at the center of the test piece, placing for 15 minutes and then performing an abrasion test; taking a photo of the abraded test piece, calculating the pitch film stripping area of the abrasion region by use of image processing software, and dividing the pitch film stripping area by the abrasion area of the test piece, thereby obtaining the machine-made sand and pitch adhesion evaluation index, namely the pitch film stripping rate. The machine-made sand and pitch adhesion evaluation method is simple to operate, high in practicability, capable of accurately calculating the pitch film stripping rate, reliable in result and applicable to popularization and application in a construction site.

Owner:XIAN HIGHWAY INST

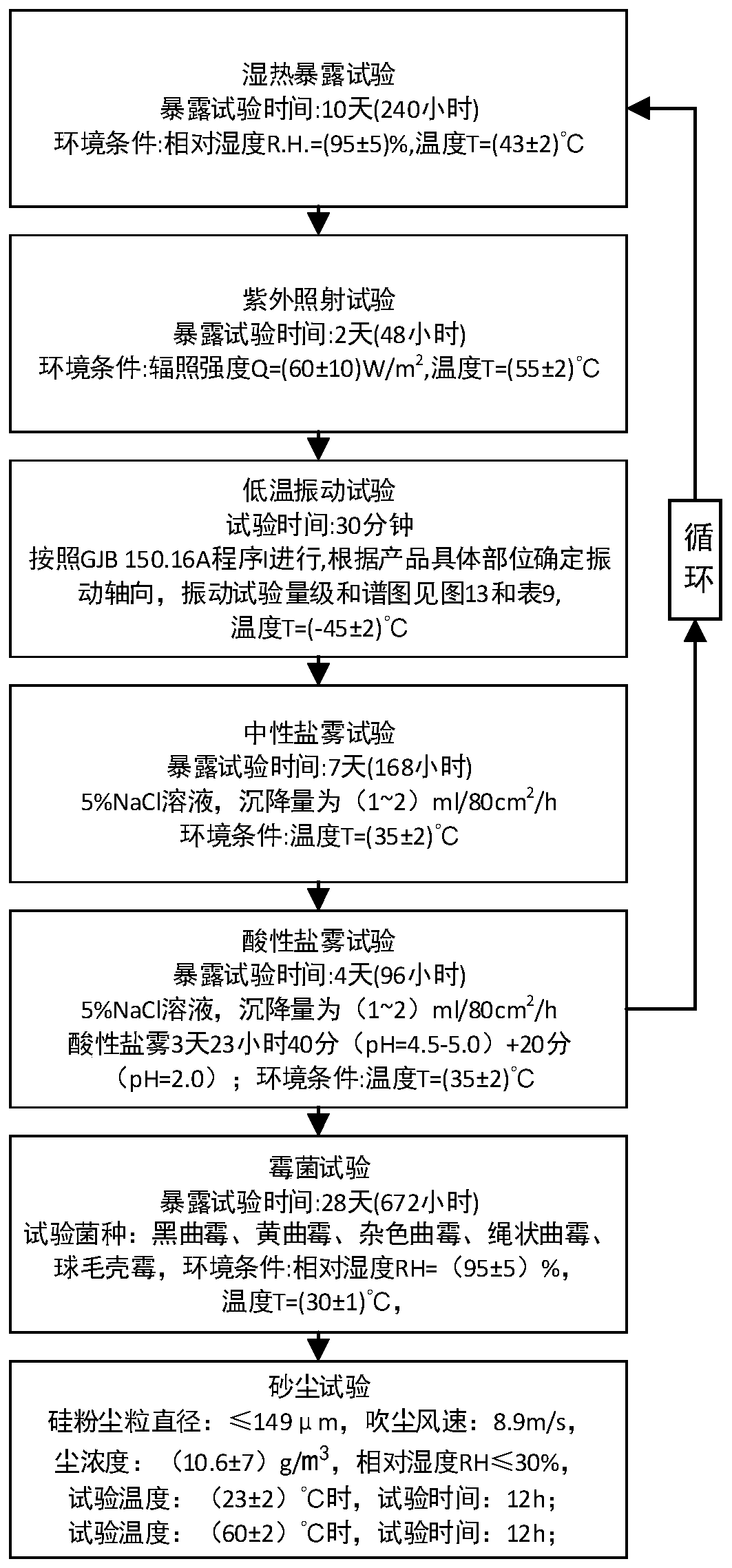

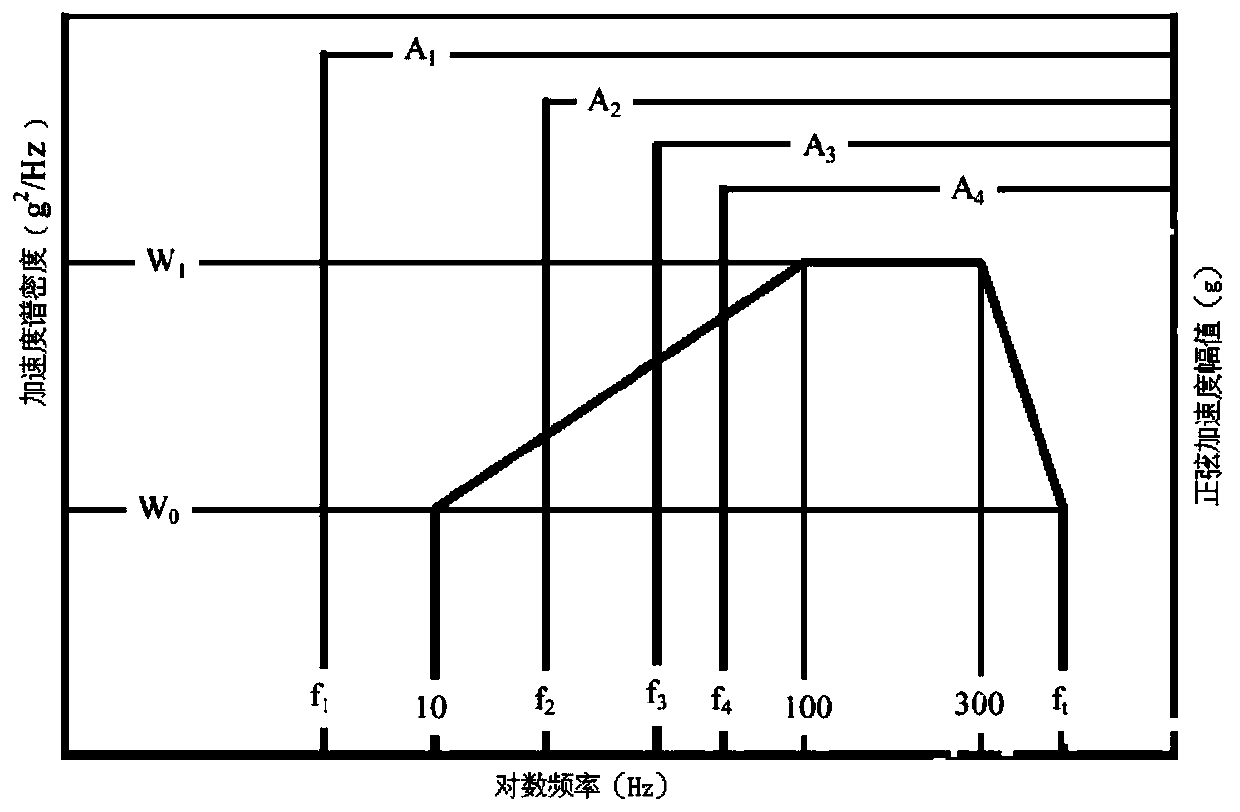

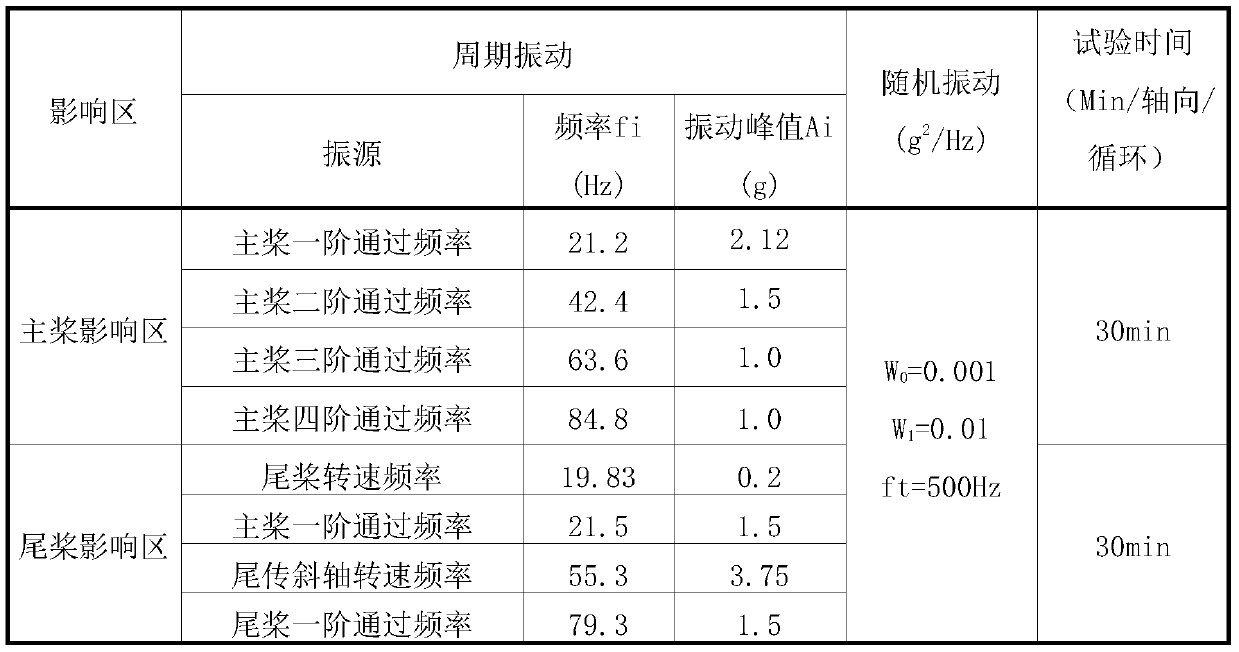

Laboratory acceleration test method for ship-based helicopter coating under marine atmospheric condition

The invention belongs to a helicopter coating laboratory acceleration test method, and discloses a laboratory acceleration test method for a ship-based helicopter coating under a marine atmospheric condition. The method comprises the following steps: S1, sequentially performing a damp and hot exposure test, an ultraviolet irradiation test, a low-temperature vibration test, a neutral salt spray test and an acidic salt spray test on the ship-based helicopter coating; S2, circularly executing the S1 according to a preset period; S3, after the S2 is completed, sequentially performing a mold test and a sand dust test on the ship-based helicopter coating; and S4, after the S3 is completed, performing environmental adaptability assessment on the ship-based helicopter coating according to the characteristics of the ship-based helicopter coating, and forming a laboratory acceleration test method by adding a helicopter vibration test and an acidic salt spray test, so that the coating of the ship-based helicopter is more accurately assessed.

Owner:CHINA HELICOPTER RES & DEV INST

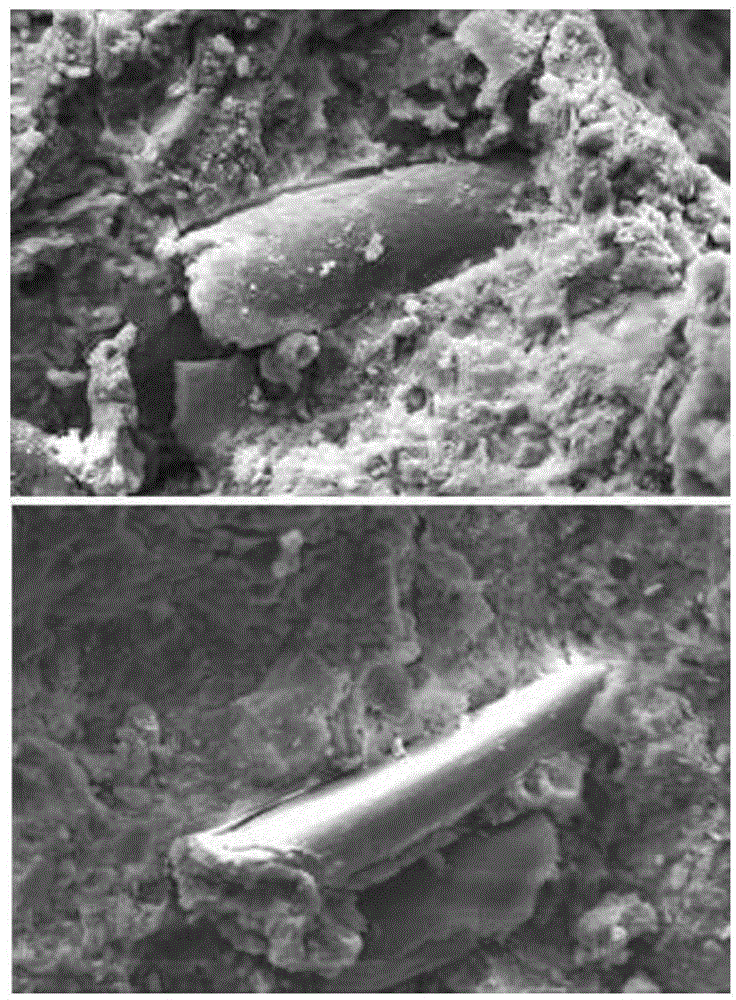

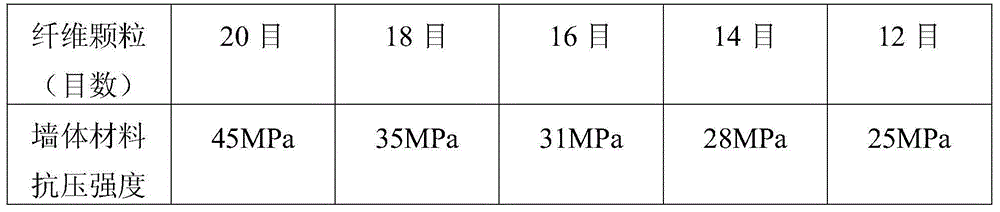

Preparation method of novel cement-based plant straw fiber particle wall material

The invention discloses a preparation method of a novel cement-based plant straw fiber particle wall material. The preparation method comprises cutting dried plant straw fibers into small pieces, immersing the small pieces in an alkali solution, carrying out air drying, sucking the air-dried plant straw fibers into a crusher from a feeing inlet for continuous 5-8min, carrying out crushing for 5-10min to obtain plant straw fiber particles, screening the plant straw fiber particles by a square hole sieve to obtain the plant straw fiber particles with appropriate particle sizes, mixing cement, fly ash, fine sand, the plant straw fiber particles and water to obtain a uniform mixture, pouring the mixture into a mold, carrying out demolding after coagulation, putting the molded test piece into a standard maintenance chamber, and carrying out maintenance to obtain the novel cement-based plant straw fiber particle wall material. The prepared wall has the bright and clean surface, is free of secondary treatment, effectively reduces wall treatment difficulty and processes, and has excellent heat insulation performances, good toughness, impact resistance and excellent sound insulation performances.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Wear-resistant copper alloy material and casting method thereof

The invention relates to a wear-resistant copper alloy material and a casting method thereof, wherein total seven raw materials, including an aluminum-copper alloy, a nickel plate, pure iron, electrolytic copper, metal manganese, hexachloroethane and cullet, are employed; the CuAl10Ni wear-resistant copper alloy material is obtained through the steps of stove charging, melting, sodium fluoroaluminate doping and sand mold test sample casting, casting molding and the like; and the mechanical properties of the obtained wear-resistant copper alloy material reach the following standards: yield strength B0.2: more than or equal to 270N / mm<2>; tensile strength Bb: more than or equal to 600N / mm<2>; elongation sigma5: more than or equal to 12%; and Brinell hardness HBW: more than or equal to 140; the wear-resistant copper alloy material is specially used for manufacture of the positioning guide sleeve of the air spring of a rail transit vehicle, and has excellent comprehensive mechanical properties, and extremely high abrasive resistance and corrosion resistance; and the service life of the wear-resistant copper alloy material is twice as long as that the service life of the traditional ZCuAl9Mn2(S) material.

Owner:株洲联诚集团铸业有限责任公司

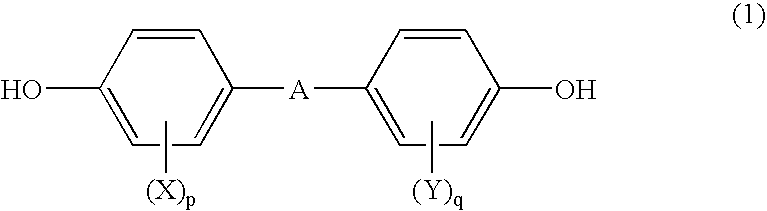

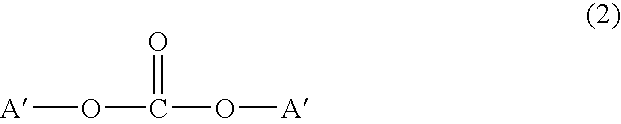

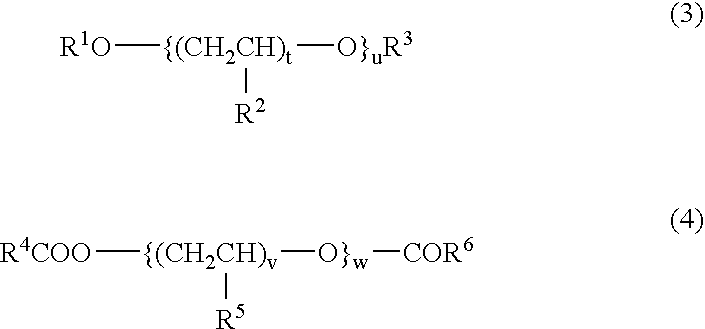

Polycarbonate resin composition and medical appliances comprising thereof

The present invention relates to a polycarbonate resin composition which comprises an aromatic polycarbonate resin (A) and a colorant (B) and which has such a property that a molded test specimen comprising said polycarbonate resin composition and having a thickness of 3 mm is exposed to 25 kGy of a cobalt-60 gamma radiation, and the b value of test specimen measured by the Hunter's Lab method after 7 days from the exposure is not more than 2. A molded product comprising the said polycarbonate resin composition is invisible in the yellow discoloration and excellent in the transparency even though it is exposed to 25 kGy of a cobalt-60 gamma radiation for sterilization, especially excellent in such a transparency that the fluid level and color of content such as a medicinal solution or blood in a medical appliance can be easily confirmed, and also is small in mechanical properties deterioration. Therefore, the molded product is suitably used for medical appliances.

Owner:MITSUBISHI ENG PLASTICS CORP

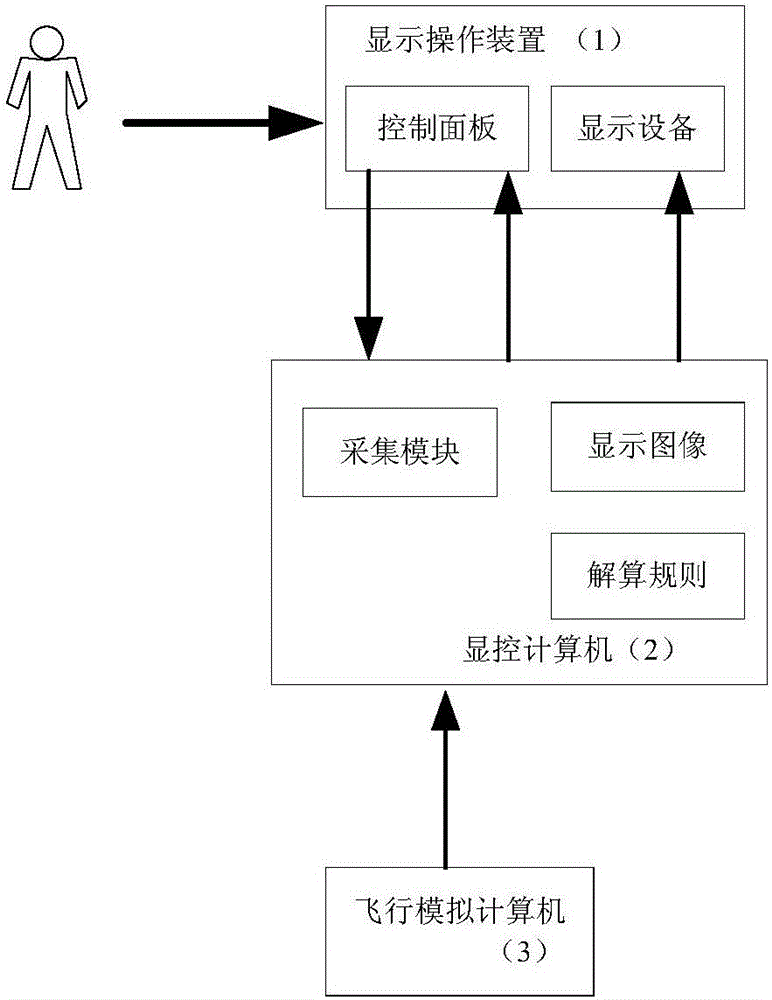

Operation and display system of engineering simulator

ActiveCN106773789ASimplify complexityIncreased attention to assessmentCosmonautic condition simulationsSimulator controlJet aeroplaneControl manner

The invention discloses an operation and display system of an engineering simulator. The operation and display system mainly comprises a display and operation device (1), a display and control computer (2) and a flight simulation computer (3), wherein the display and operation device (1) is engineering simulator cabin display and control equipment for displaying a flight quality estimation picture and receiving an operation instruction of a pilot; the display and control computer (2) is an engineering simulator PC for generating a display picture and controlling a display device; the flight simulation computer (3) is an engineering simulator PC for simulating an environment of an airplane body. The operation and display system of the engineering simulator aims to simplify the complexity of an airborne display system, reduce the requirement on test equipment and reduce the research expenses and can meet the requirement of a product mold test; content and a control mode can be quickly and timely updated and displayed, and estimation from a tester to a flight control system can be completed.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

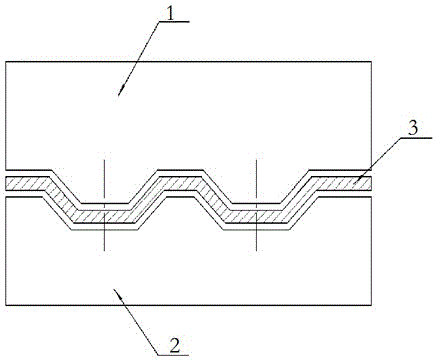

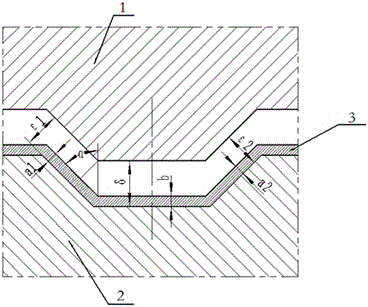

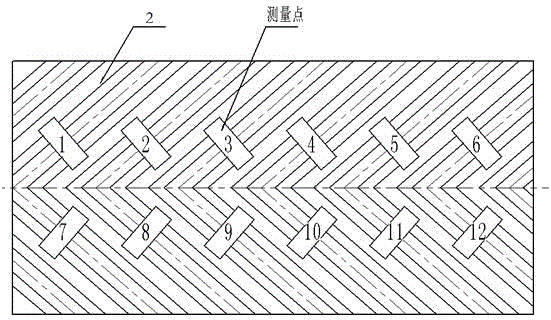

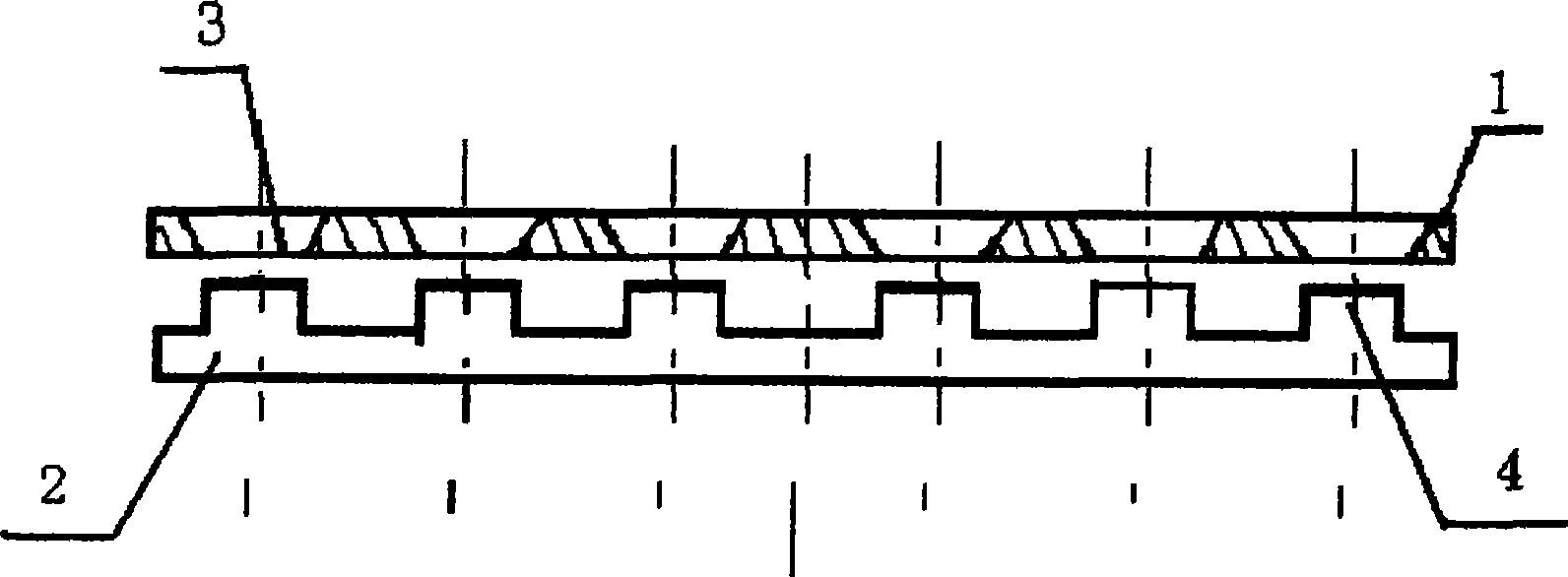

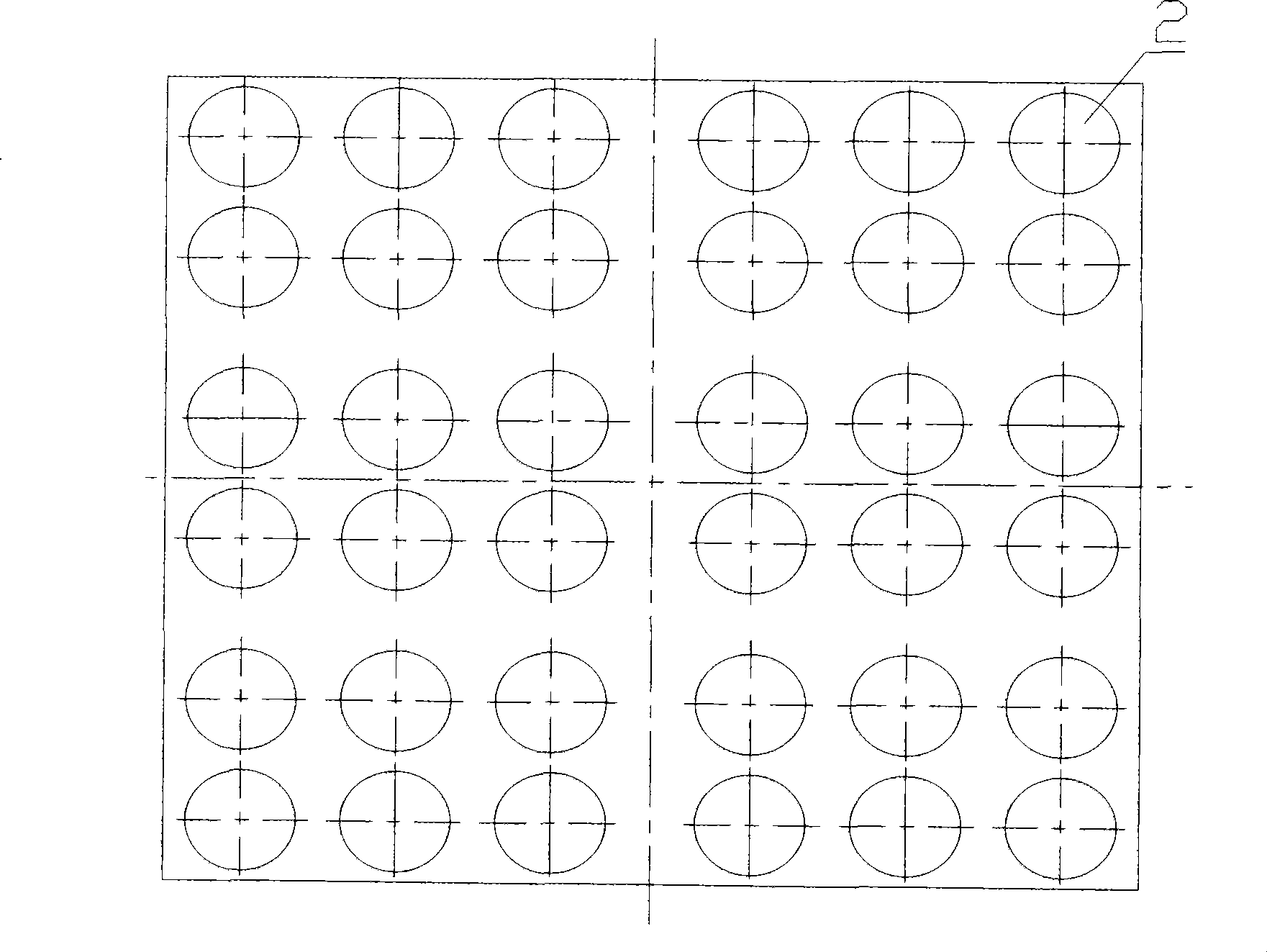

Measuring method for mold clearance of plate molding of plate type heat exchanger

ActiveCN105115464AReduce hardnessImprove liquidityMeasurement devicesHardnessPlate fin heat exchanger

The invention relates to the technical field of production auxiliary equipment detection of plate type heat exchangers, and discloses a measuring method for the mold clearance of plate molding of a plate type heat exchanger. According to the method, characteristics of low hardness of soft metal materials, good liquidity during extrusion, and extremely small resilience after molding are employed, lead wires or tin wires of the soft metal materials are cut into a plurality of sections and prepared to soft metal samples arranged on the internal surface of a lower mold of mold test points, the test points are uniformly, comprehensively, and symmetrically distributed on the internal surface of the lower mold, a proper pressure is applied to the samples on a hydraulic press for pressing, the mold clearance is filled by the soft metal materials, the mold clearance is calculated by employing the thickness of the molded soft metal, and the actual mold clearance of a calendaring mold can be accurately detected. The test method is simple, the precision of the measuring result is high, the consumption of the soft metal materials is low, and the detection cost is lowered; besides, the hardness of the soft metal materials is low so that the molding pressure is low, the damage to the internal surface of the mold is prevented, and the service lifetime of the mold is extended.

Owner:LANZHOU LS GRP

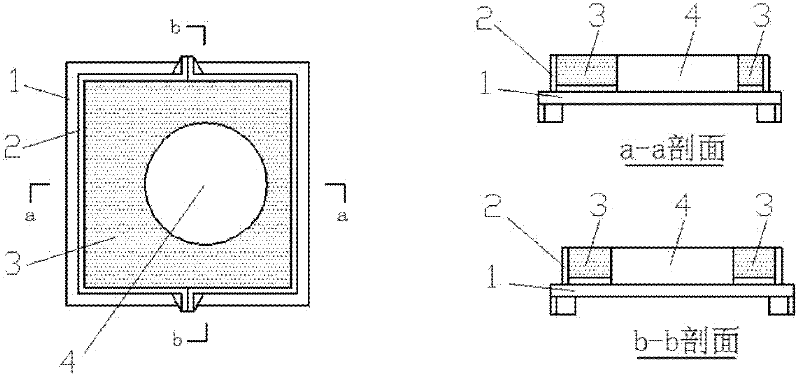

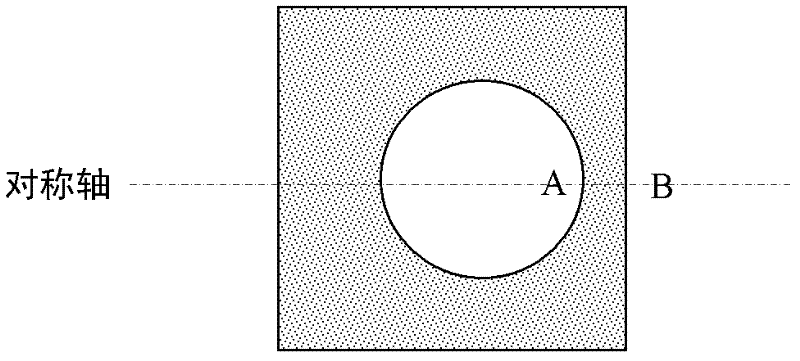

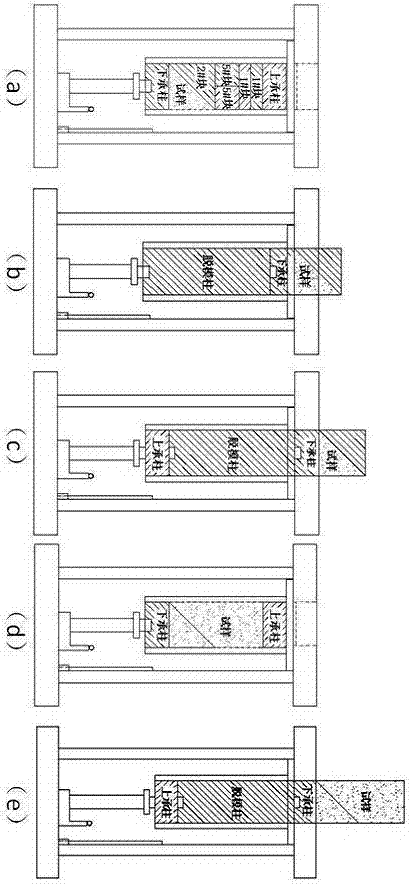

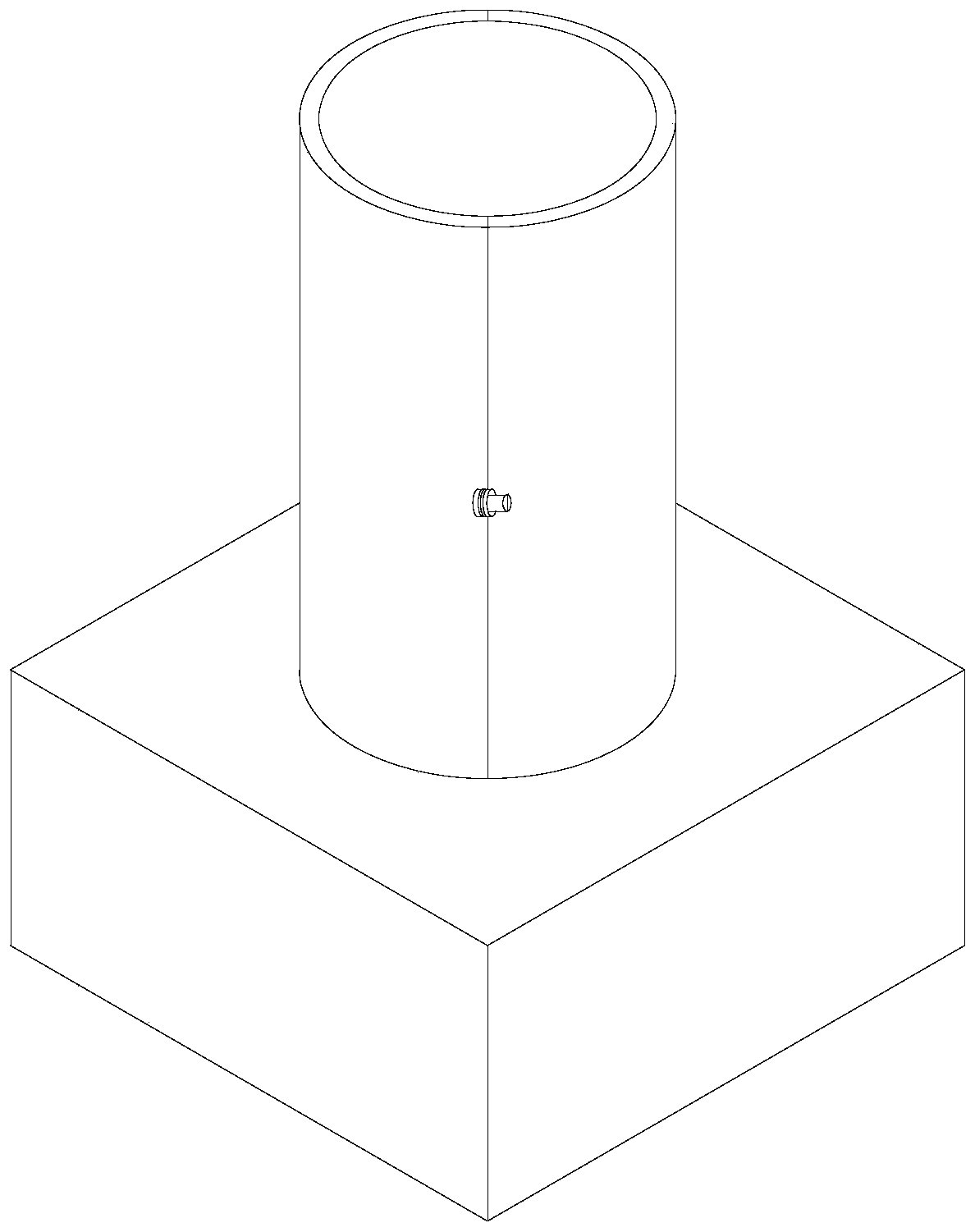

Method for testing shrinkage cracking performance of cement paste or mortar

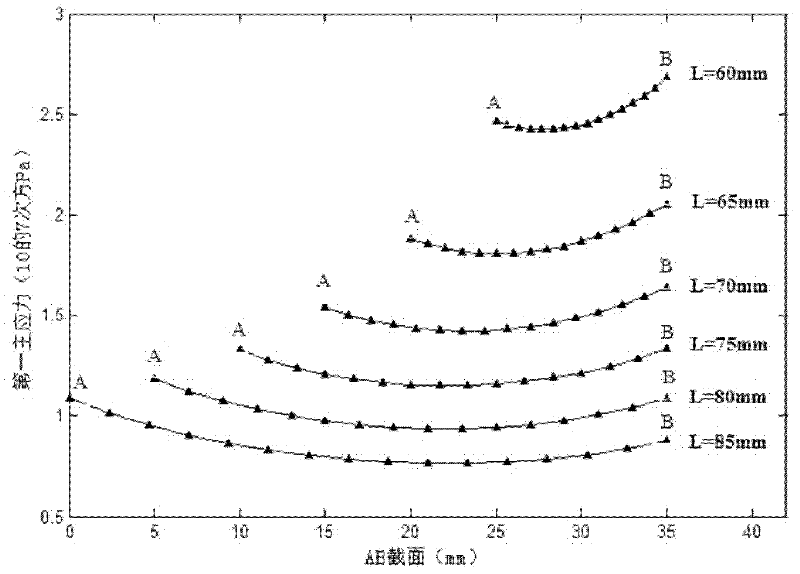

InactiveCN102520143AEasy to crackShorten the test cyclePreparing sample for investigationMaterial testing goodsShrinkage crackingElement analysis

The invention relates to a method for testing the shrinkage cracking performance of a cement paste or a mortar. A molded test piece of a novel mold is adopted to carry out the cracking test to test the shrinkage cracking performance of the cement paste or the mortar. The mold comprises a pedestal, an outer mold and a steel cylinder; the steel cylinder is fixed on the pedestal; the outer mold is movably connected with the pedestal; and the outer mold is square, the steel cylinder is in the outer mold, and the steel cylinder which is not in the center of the square is in a unidirectional eccentric position. The ratio of the diameter of the steel cylinder to the inner side length of the outer mold, i, satisfies a case that i is greater than 0.5 and less than 1; and heights of the steel cylinder and the outer mold satisfy a case that the thickness of the molded test piece is equal to or greater than 5 times the largest particle size used in the test. The selection of the eccentric position of the steel cylinder is determined through carrying out finite element analysis on the molded test piece by ANSYS software. According to the invention, the cracking position can be foreseen, the test piece cracking can be accelerated, and the cracking can start from the outer interface.

Owner:TIANJIN UNIV

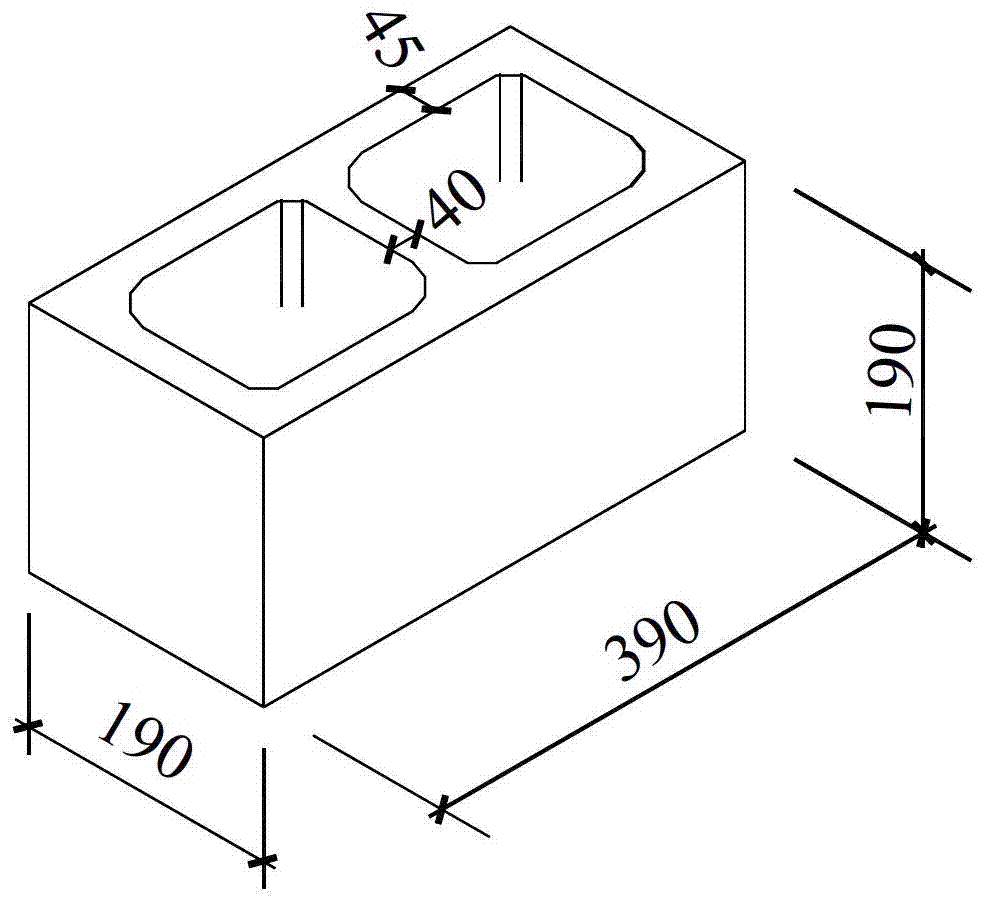

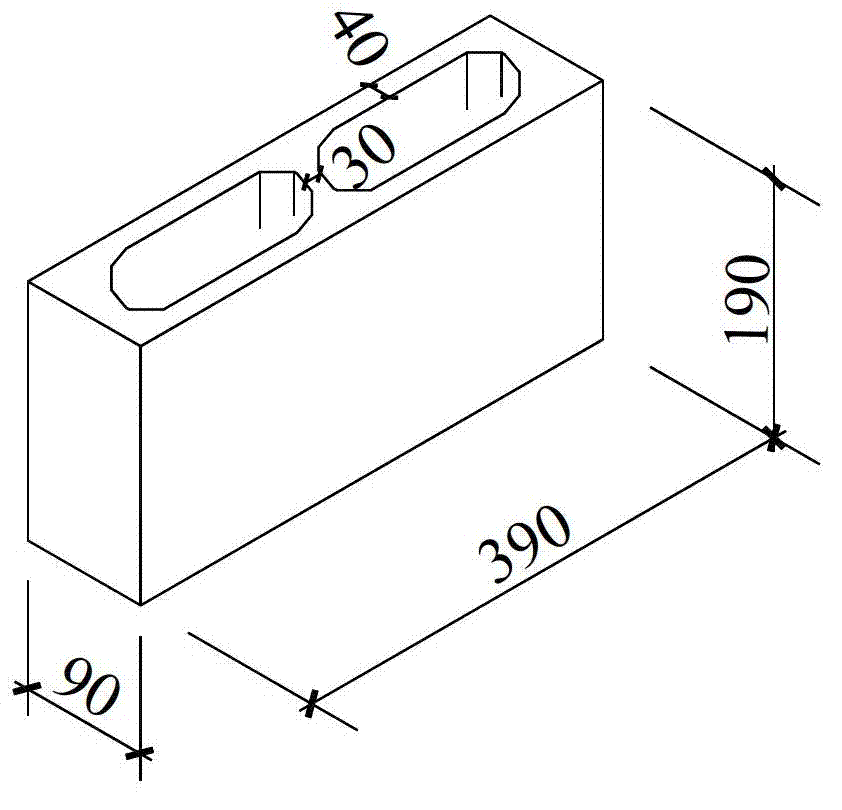

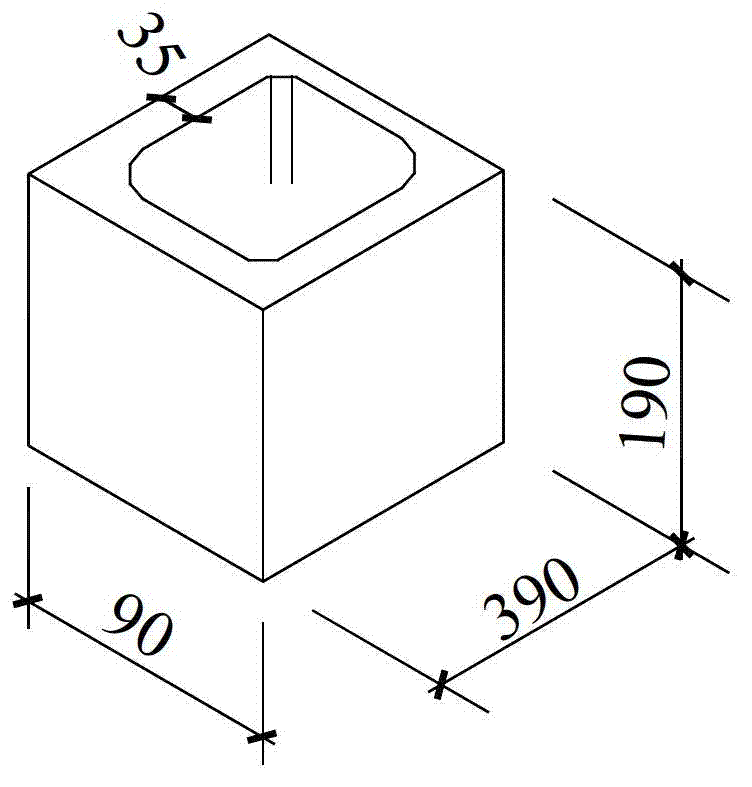

High-ductility hollow building block and fabrication method thereof

The invention discloses a high-ductility hollow building block and a fabrication method thereof which are used for solving the problems of low bearing capacity and poor ductility and seismic resistance of the existing hollow building block. According to the high-ductility hollow building block disclosed by the invention, high-ductility fiber concrete is taken as a main raw material, and a molded test piece is formed by using a building block molding machine and cured for a certain age under standard curing conditions, thereby obtaining the hollow building block. The high-ductility hollow building block disclosed by the invention has better compressive capacity, shearing resistance and seismic resistance in comparison with the traditional building block, and is difficultly subjected to brittle fracture; and meanwhile, the production process of the building block is simple.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

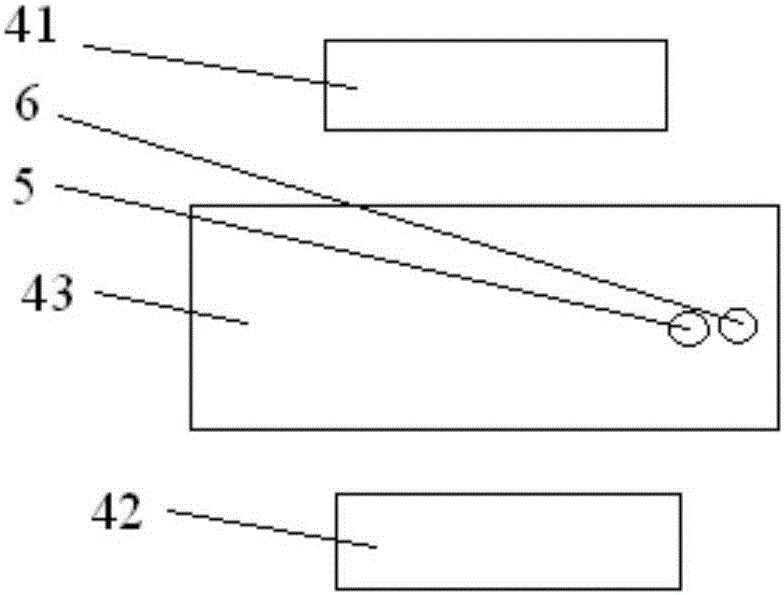

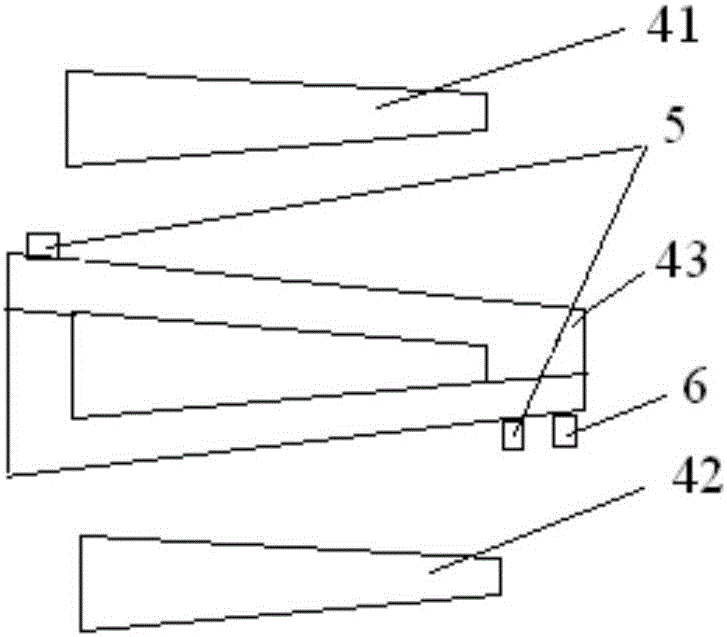

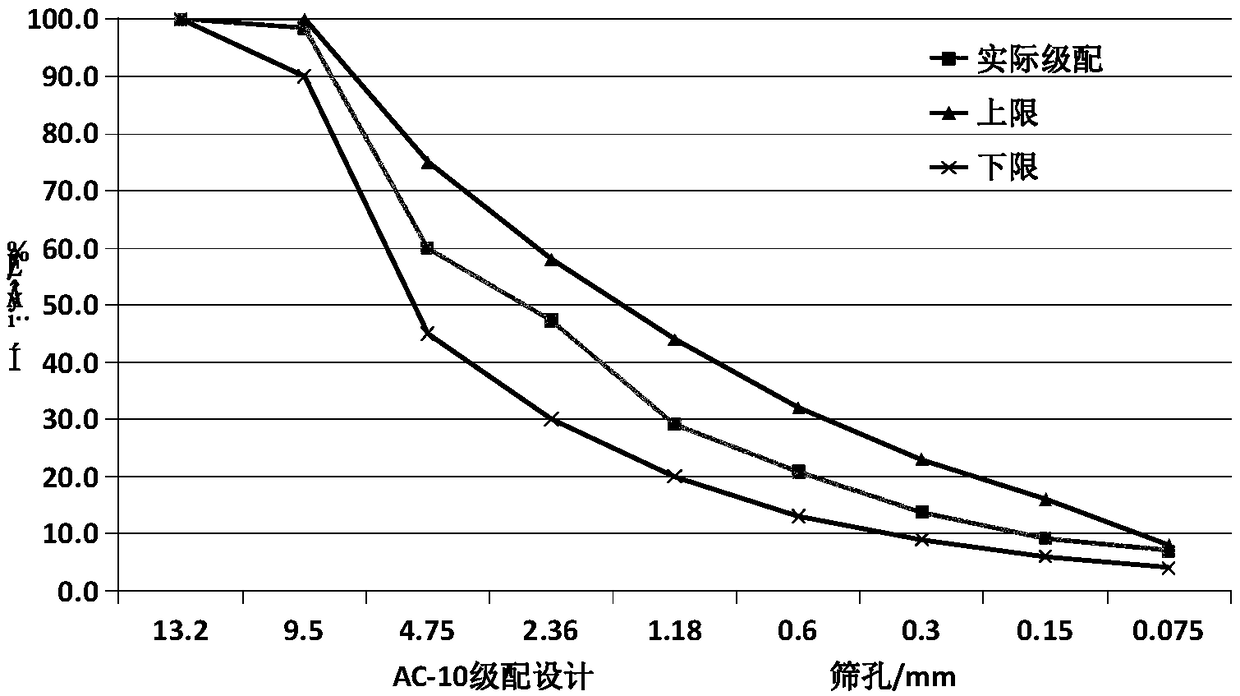

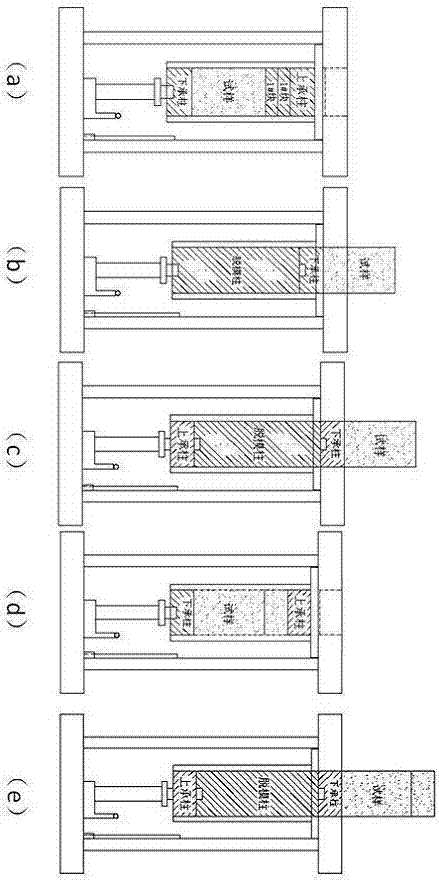

Preparation device and preparation method for asphalt mixture trapezoidal beam test specimen

ActiveCN105938063AShort preparation cycleHigh dimensional accuracyPreparing sample for investigationEngineeringMold tests

The invention relates to a preparation device and preparation method for an asphalt mixture trapezoidal beam test specimen; the device comprises a hydraulic system, a pressure control system, a counter force frame, and a test mold assembly; the counter force frame is erected at the upper part of a hydraulic jacking rod; the test mold assembly is arranged at the top of the hydraulic jacking rod and includes an upper press head, a lower press head and a test mold; the test mold has an inner cavity; the lower press head is located at the bottom of the inner cavity of the test mold; the upper press head presses the test mold from the upper part. The test mold assembly presses against the counter force frame in virtue of the jacking force of the hydraulic system so as to extrude and mold the test specimen. Rolling forming of the prior art is changed, only simply mixing static-pressure molding of trapezoidal beam test specimen-demolding cooling maintenance are required, the production cycle is short, and the molded test specimen has small error; and static pressure molding has no damage of high-frequency vibration during cutting of a specimen in the prior art on the test specimen.

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST

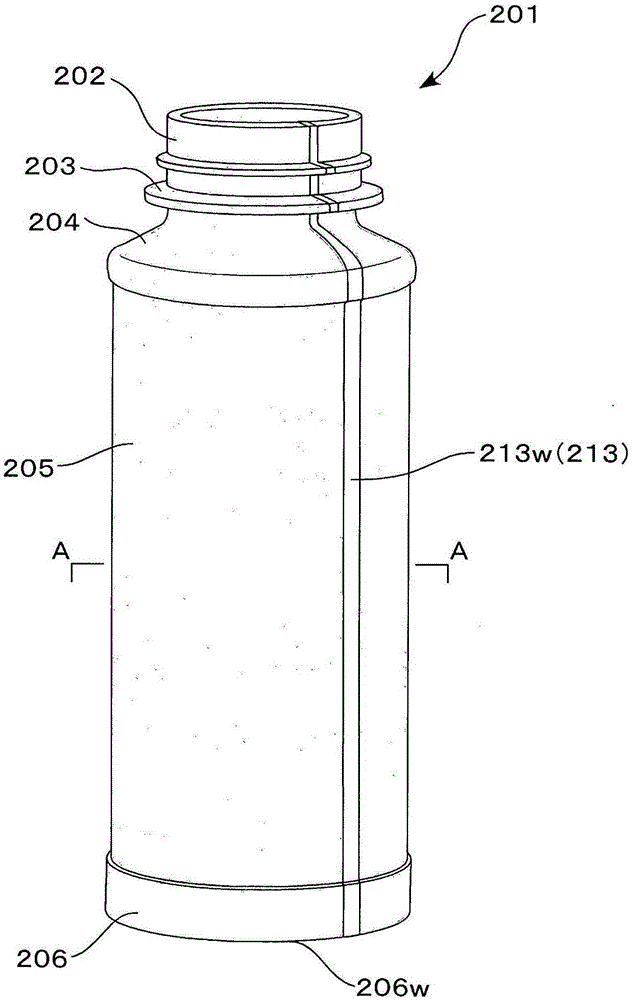

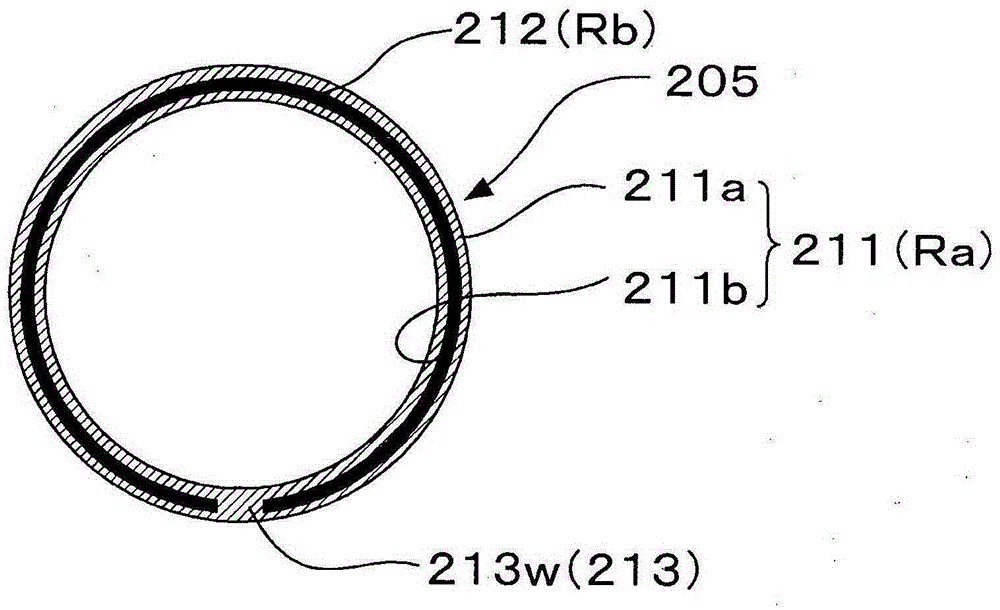

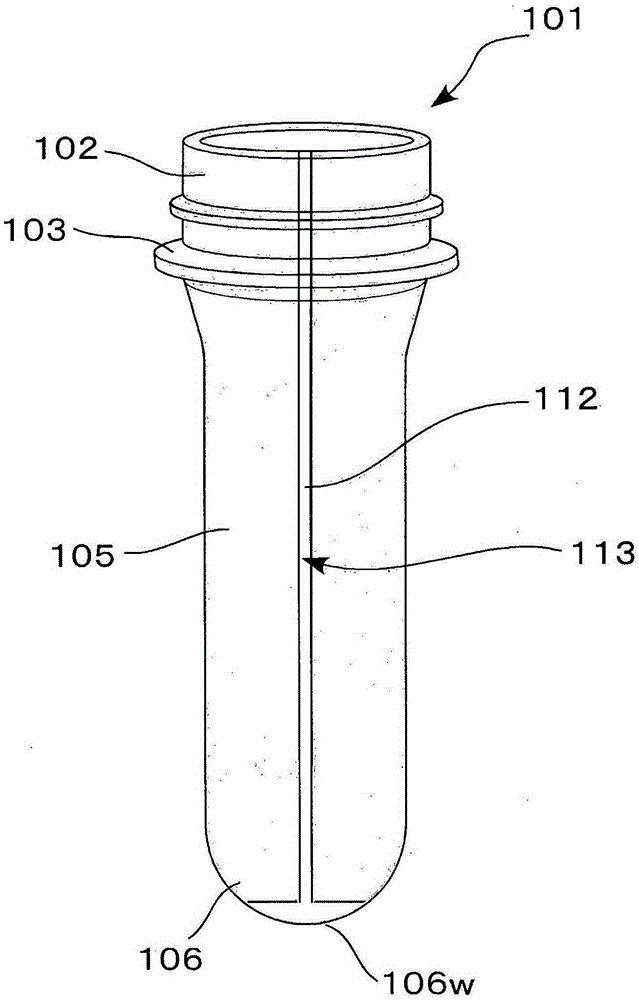

Container with synthetic resin window, preform and preform injection molding method

InactiveCN105324228AEliminate appearance damageEliminate damageContainer decorationsLevel indicationsBand shapeLongitudinal bands

In a container with a synthetic resin window, which is an injection-molded test tube-shaped preform that has been biaxial stretch blow molded to a bottle-shaped container with a synthetic resin window, a circumferential wall is formed from a transparent base layer (211). A light-blocking or non-transparent intermediate layer (212) is laminated in the base layer (211) over a region of said circumferential wall at a specified height. The intermediate layer (212) is configured so as to be laminated on the region covering the entire circumference of the circumferential wall except for a non-laminated section (213), which extends on the circumferential wall of the container as a longitudinal band along the direction of the central axis of the container and where the intermediate layer (212) is not laminated. Said non-laminated section (213) configures the window (213w).

Owner:YOSHINO KOGYOSHO CO LTD

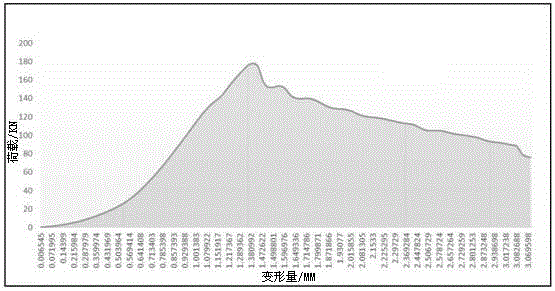

Large strain based macromoleclar polymer concrete fatigue life evaluation method

The invention relates to a large strain based macromoleclar polymer concrete fatigue life evaluation method. The method includes the steps of: 1. conducting mix proportion design on a macromoleclar polymer mixture; 2. determining the adhesive-stone ratio of aggregate gravel and a polymer binder; 3. blending the aggregate gravel and the polymer binder according to the mixing proportion to form a test piece, and performing splitting test to determine the curing period; 4. according to the well determined grading and adhesive-stone ratio, molding a rut test plate by wheel rolling; 5. when reaching the curing time, performing cutting into a beam test piece; and 6. conducting four-point loaded trabecular fatigue test on the molded test piece. By controlling large strain, the invention puts forward the evaluation method suitable for macromoleclar polymer concrete. Different from the fatigue life of ordinary asphalt mixtures, the fatigue life of macromoleclar polymer concrete can reach the million level, therefore ordinary methods directed at the fatigue life of asphalt mixtures are not applicable.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Mold of plastic density sheet for molding test

InactiveCN101470053ASuitable for monitoringSimple structurePreparing sample for investigationStrength propertiesEngineeringFrustum

Owner:SHANGHAI KINGFA SCI & TECH +1

Method for preparing low-density oil well cement test block by using zirconium diboride ceramic micro-beads

The invention provides a method for preparing a low-density oil well cement test block by using zirconium diboride ceramic micro-beads. The method comprises the following steps: preparing zirconium diboride ceramic pore-closed hollow micro-beads, batching, mixing, stirring, starching and performing a mold test and a strength test, uniformly mixing 40wt%-50wt% of G-grade oil well cement, 10wt%-15wt% of superfine cement of which the particle size is 13 micrometers, 25wt%-35wt% of zirconium diboride ceramic pore-closed hollow micro-beads of which the particle size is 5-50 micrometers, 5wt%-7wt% of fly ash of which the loss on ignition is 1.1%, 1.5wt%-2wt% of calcium oxide of which the purity is 99.9%, 0.5wt%-1.0wt% of sodium sulfate and 1wt%-3wt% of micro-silicon and stirring; stirring and starching for 40 seconds in a stirrer by a water-cement ratio of 0.5-0.6 (W / C), pouring into a test mold, maintaining for 24 hours and 48 hours in a water-bath maintenance box at a constant temperature of 52 DEG C, demolding, soaking for 1 hour in cold water and then performing a performance test.

Owner:YUEYANG PENGCHENG TECH DEV

Test method and device for simulating high-ground-pressure environment through bentonite slurry pressurization

ActiveCN103822827AReduce water lossRealize high pressure loadingMaterial strength using tensile/compressive forcesSodium BentoniteTest sample

Owner:BEIJING CHINA COAL MINE ENG CO LTD

A kind of gas-containing coal similar material and preparation method thereof

ActiveCN104694191BHigh compressive strengthImprove adsorption capacityOther chemical processesSolid fuelsPorosityCompressive strength

The invention discloses a gas-containing coal similar material and a preparation method thereof. The similar material is prepared by the preparation method comprising the following steps: selecting coal powder with certain particle size distribution and a sodium humate aqueous solution as raw materials, wherein the coal powder is used as an aggregate and the sodium humate aqueous solution is used as a cementing agent; weighing the coal powder with the certain particle size distribution, water and sodium humate strictly according to proportions, fully stirring uniformly, pouring the well mixed and stirred mixture into a steel mold, and performing pressure molding on the mixture by using a certain pressure under a press machine; and separating the mold, taking out a molded test piece, and drying at normal temperature or in a drying box. A physical mechanical parameter test shows that the volume weight and porosity of the similar material are equivalent to those of raw coals, the adsorptivity of the similar material is very close to that of the raw coals, and the similar material has the advantages of high uniaxial compressive strength, wide mechanical parameter variation range and the like, and also has the advantages of simple material manufacturing process, stable performance, low price, no toxic or side effect and the like.

Owner:SHANDONG UNIV +1

Method for detecting activity index of waste ceramic polishing sludge slurry

InactiveCN110763540AIncrease profitHigh activityPreparing sample for investigationMaterial strength using tensile/compressive forcesSludgeSlurry

The invention belongs to the technical field of solid waste resource utilization and particularly relates to a method for detecting the activity index of waste ceramic polishing sludge slurry. The method comprises a step of preparing a detected mortar test piece and a comparison mortar test piece, wherein the preparation raw materials of the detected mortar test piece comprise the waste ceramic polishing sludge slurry and first cement, the preparation raw materials of the comparison mortar test piece comprise second cement, the sum of the solid weight of the waste ceramic polishing sludge slurry and the weight of the first cement is equal to the weight of the second cement, and a water-binder ratio and a sand-binder ratio are respectively equal, a step of carrying out maintenance treatmenton the detected mortar test piece and the comparison mortar test piece, wherein the maintenance treatment comprises the following steps of removing molds of the prepared and molded test pieces and then sequentially carrying out maintenance in a heating stage, a constant-temperature stage and a cooling stage, a step of detecting the compressive strength of the maintained detected mortar test pieceand the comparison mortar test piece which are subjected to the maintenance treatment to respectively obtain a first compressive strength value and a second compressive strength value, and a step ofcalculating a ratio of the first compressive strength value to the second compressive strength value to obtain the activity index.

Owner:GUANGDONG GAITEQI NEW MATERIAL TECH CO LTD

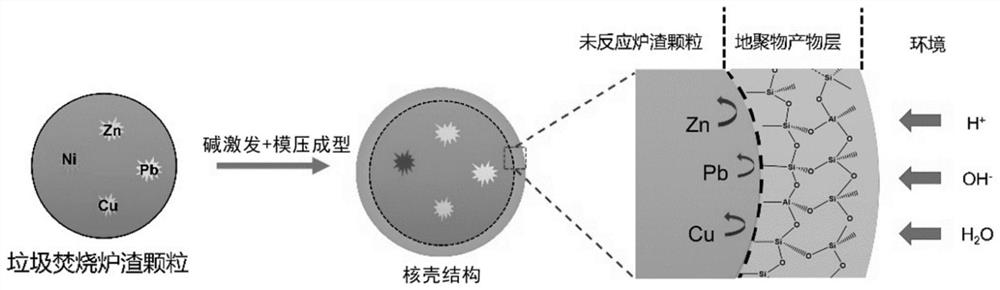

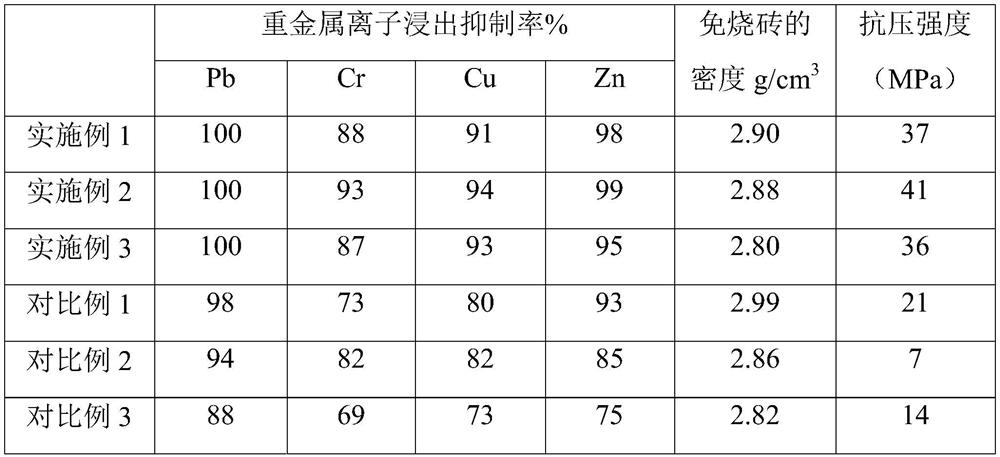

Cement-free waste incineration slag-based baking-free brick and preparation method thereof

ActiveCN113233821AStable hardening processIncrease usage intensitySolid waste managementCompression moldingBrick

The invention relates to the technical field of resource utilization of waste incineration slag, and particularly discloses a cement-free waste incineration slag-based baking-free brick and a preparation method thereof. The cement-free waste incineration slag-based baking-free brick comprises the following components in parts by mass: 6-8 parts of waste incineration slag, 2-4 parts of an admixture and 3-5 parts of an alkali activator. The preparation method of the cement-free waste incineration slag-based baking-free brick comprises the steps of a, grinding the waste incineration slag, and uniformly mixing the ground waste incineration slag with the admixture and the alkali activator to obtain a semi-dry material; b, adding the semi-dry material into a mold for compression molding to obtain a molded test block; and c, curing the molded test block to obtain the baking-free brick. The cement-free waste incineration slag-based baking-free brick provided by the invention has the advantages of simple materials, low cost, high use strength, good curing effect of heavy metal elements, difficulty in leaching and large-scale popularization and application.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

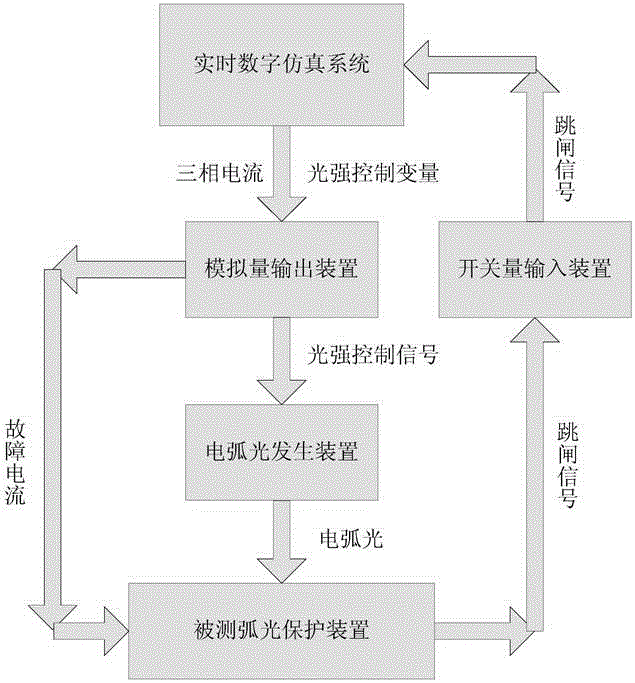

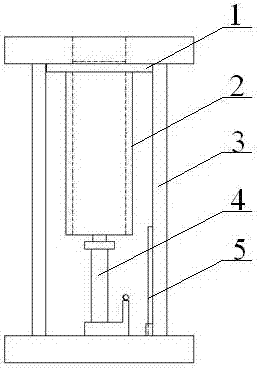

Test method for arc protection device based on real-time digital simulation system

InactiveCN106569058AStrong targetingStrong customizationElectrical testingTransient stateMathematical model

The invention discloses an arc protection device based on a real-time digital simulation system and a test method thereof. A closed-loop environment which tests the arc protection device and is based on the real-time digital simulation system is constructed. In the simulation environment, a mathematical model which is exactly the same as a power primary system network is created according to the power primary system network at a protection installation site. The test method is highly targeted and customized, and has a real test environment. The real-time digital simulation system is used as a digital movable mold test tool, and the output electrical quantity contains transient component. The waveform is closer to the waveform of a real fault in a power grid. Various types of short circuit faults can be simulated. The arc protection device is tested. The test method can be used to truly simulate the on-site operating environment of the arc protection device. The operation reliability of the arc protection device after on-site operating can be greatly improved.

Owner:NANJING NARI GROUP CORP +1

Joint geotechnical triaxial test sample preparation method

ActiveCN107144454AImprove efficiencyImprove accuracyPreparing sample for investigationMaterial strength using tensile/compressive forcesTriaxial shear testTest sample

The invention relates to a joint geotechnical triaxial test sample preparation method. Due to the fact that a target sample is composed of child samples divided through joints, the joint geotechnical triaxial test sample preparation method comprises selecting a first child sample in an edge position, and selecting mold test blocks identical in shape and size to other child samples, wherein the mold test blocks are single blocks or combined blocks; placing the mold test blocks and soil materials in position into a mold sleeve and performing compression; extracting shaped samples and taking the samples as mold test blocks, repeating the steps above to manufacture a next child sample neighboring to the first child sample until manufacturing the target sample. During the manufacturing processes, deburring treatment on the natural contact surfaces where the joints among the child samples are positioned is saved, namely, every pair of natural contact surface can serve as joint surfaces. By means of a static-pressure layered manufacturing mode and through different combination of the mold test blocks, the joint geotechnical triaxial test sample preparation method can be applied to manufacturing through type or non-through type joint samples with different inclinations ranging between 0 and 90 degrees and different numbers of joints.

Owner:SEISMOLOGICAL BUREAU OF GANSU PROVINCE CHINA EARTHQUAKE ADMINISTRATION

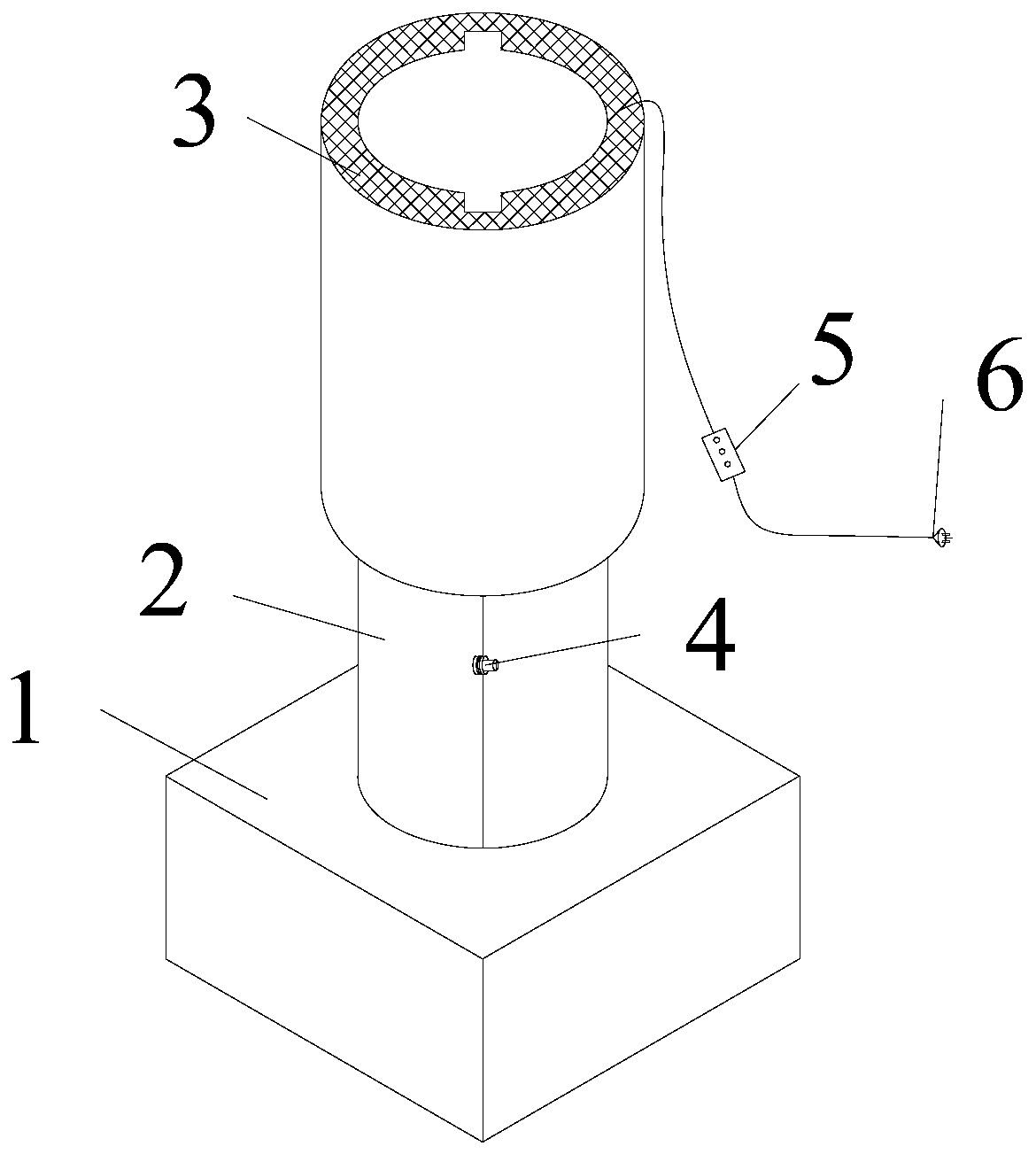

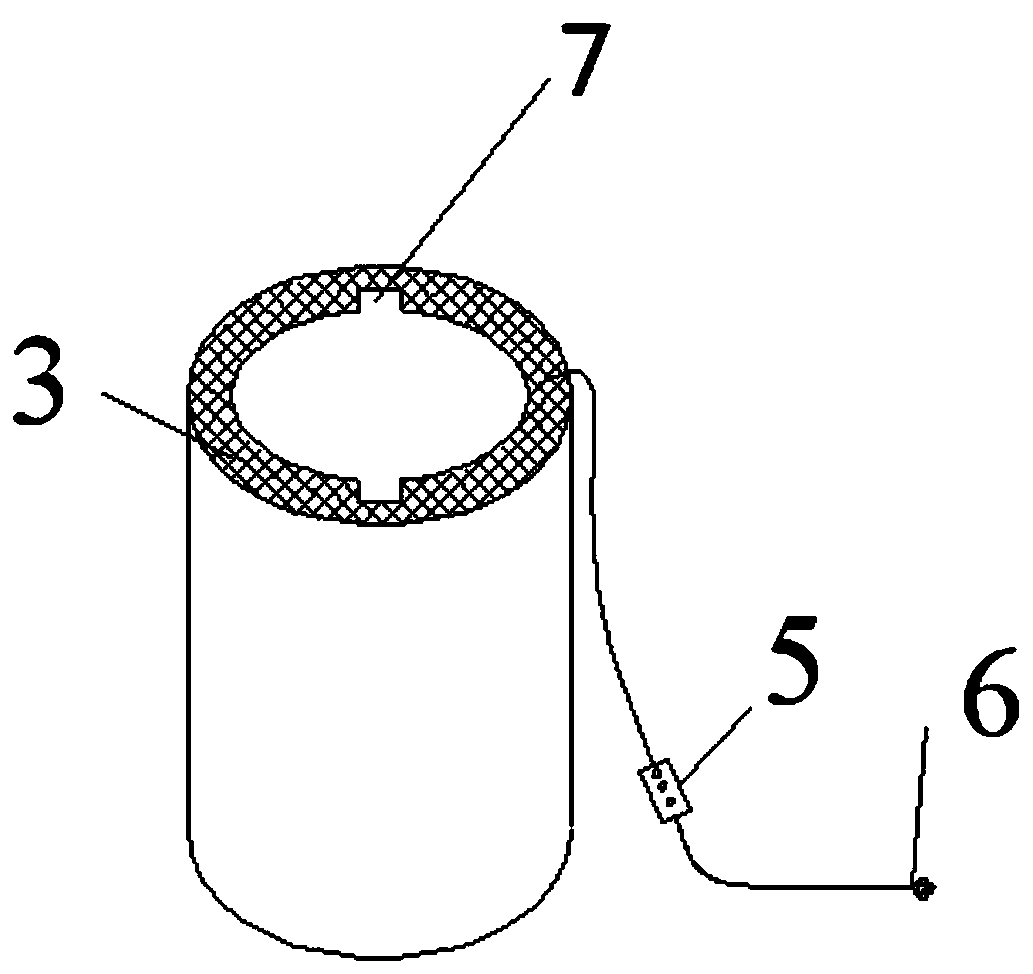

Rapid molding device and method for standard similar material test piece

InactiveCN110567770AExtended production timeSimple structurePreparing sample for investigationTemperature controlRapid prototyping

The invention relates to a rapid molding device and method for a standard similar material test piece. The molding device comprises a molding base and a molding die arranged on the base. The molding die is sleeved with a heating and drying coat for heating the test piece filled in the molding die, the inner wall of the heating and drying coat device makes contact with the inner wall of the moldingdie, the bottom of the heating and drying coat device is located on the upper surface of the base, and the heating and drying coat device is connected with a temperature and an electric heating plug.The molding die and the heating and drying coat device can be produced and used in a matched way, so that preparation time of similar material test piece can be prolonged; multiple heating and dryingcoat layer devices can be used for heating and drying a group of mold test pieces at the same time, and the heating and drying coat layer devices are recycled after heating and drying are completed;and the rapid molding device and method are characterized by being simpler in structure, shorter in consumed time, capable of realizing batch production and the like.

Owner:SHANDONG UNIV OF SCI & TECH

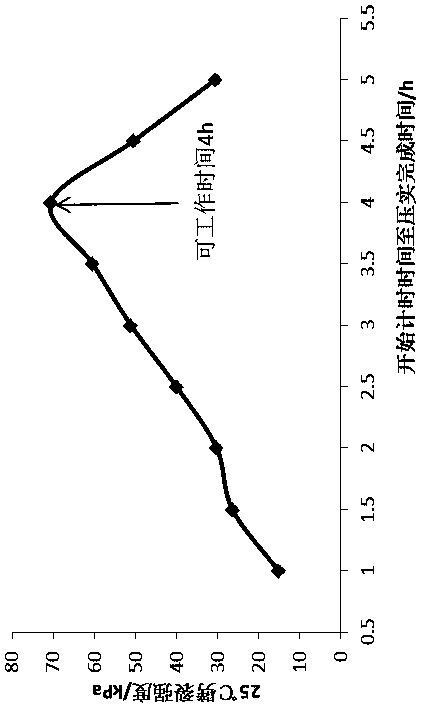

Method for measuring working time of plant mixed emulsified asphalt cold recycled mixtures

InactiveCN109541190AQuantitative determinationEasy to operateMaterial testing goodsCompletion timeUltimate tensile strength

The invention relates to a method for measuring working time of plant mixed emulsified asphalt cold recycled mixtures. The method comprises the following steps of: (1) mixing a plant mixed emulsifiedasphalt cold recycled mixture according to a designed mix proportion, and starting timing; (2) placing a circular stainless steel gasket in in a circular test mold, loosening the mixed cold recycled mixture into the test mold for levelling, placing another circular stainless steel gasket on the mixture and balancing the weight, and simulating the transplantation process of the mixture in a material vehicle; (3) simulating a paving process after placing the mixture together with the test mold at a specified health temperature for prescribed health time; (4) loading the poured mixture into a rotary compaction test mold in three layers and carrying out tamping for 25 times; (5) simulating the compaction process; (6) carrying out demolding, measuring the height of a molded test piece and preserving the heat; and (7) testing the splitting strength of the molded test piece at 25 DEG C to determine a time from the beginning of the molded piece corresponding to the maximum splitting strength AT 25 DEG C to the compaction completion time as the working time of the mixture. The method is simple to operate and accurate.

Owner:GANSU CHANGLONG HIGHWAY MAINTENANCE TECH RES INST CO LTD +1

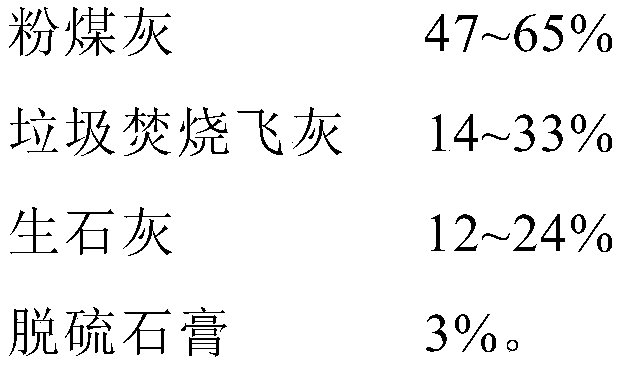

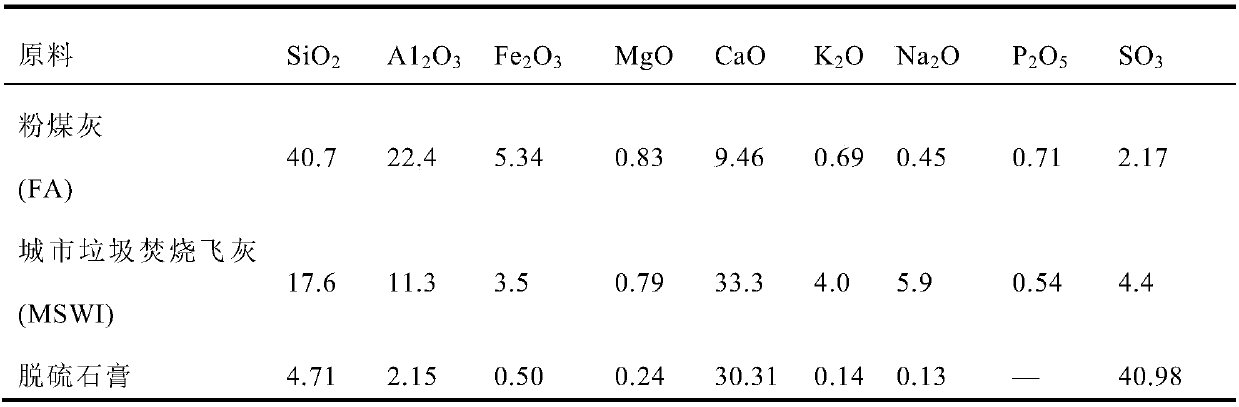

Autoclaved flyash-lime brick prepared from waste incineration flyash and preparation method for autoclaved flyash-lime brick

InactiveCN108675745ALow thermal conductivityHigh temperature resistantCompression moldingFly ash brick

The invention relates to an autoclaved flyash-lime brick prepared from waste incineration flyash and a preparation method for the autoclaved flyash-lime brick. The autoclaved flyash-lime brick is prepared from flyash, quicklime, the waste incineration flyash and desulfurization gypsum by compression molding and hydrothermal reaction, wherein the calcium-silicon ratio is 1.0 swung dash 1.3. The preparation method specifically comprises the following steps: uniformly mixing the flyash, the quicklime, the waste incineration flyash and the desulfurization gypsum; adding de-ionized water in an amount which is 15 to 25 percent of the total mass of the raw materials into the uniformly mixed raw materials, performing grinding and enabling the water to fully contact with the raw materials; loadingthe ground raw materials into a mold, performing compression molding on a pressing machine and performing demolding to obtain a molded test block; performing hydrothermal reaction on the molded test block in a hydrothermal reaction kettle to obtain a product. The autoclaved flyash-lime brick has the advantages of strong strength, low cracking rate, high freezing resistance and the like, the usingamount of cement is reduced, the solid waste flyash and the waste incineration flyash are also reduced, the burden of the environment and the cost are reduced, and energy saving and emission reductionare facilitated.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com