Test method and device for simulating high-ground-pressure environment through bentonite slurry pressurization

A technology of bentonite mud and test method, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of model freezing tube sensor damage, large consolidation deformation, test failure, etc., and achieve high flexibility and ability to deal with deformation Strong, water-reducing effect

Active Publication Date: 2014-05-28

BEIJING CHINA COAL MINE ENG CO LTD

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Using this method to load a large test piece with a large amount of compression deformation, the diaphragm material is easily embedded in the sample under the confining pressure and is punctured by the sample particles, and the hydraulic oil will enter the inside of the test piece through the rupture, resulting in test failure. And the specimen will be polluted, therefore, if this method is applied to large rock and soil specimens, it is only suitable for the condition of small confining pressure

The other is to make and tamp the test piece in the test cylinder, pour isolation material on the upper surface of the sample, and then

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

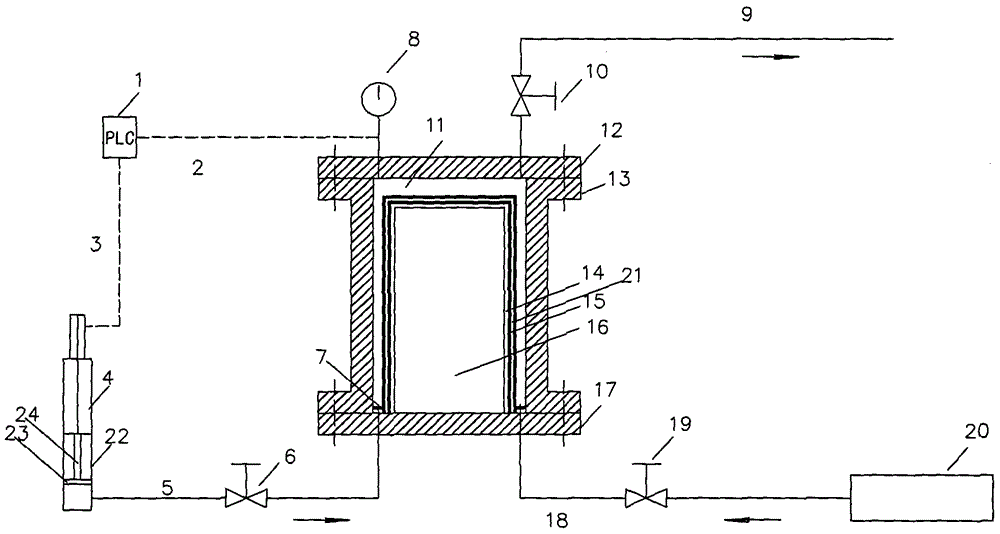

The invention discloses a test method and a test device for simulating a high-ground-pressure environment through bentonite slurry pressurization. The test method comprises the following steps of (a) manufacturing a test soil sample on a bottom cover of a test barrel, and molding the test soil sample on the bottom cover; (b) covering the molded test soil sample with a bentonite permeation prevention blanket; (c) smearing the outer surface of the bentonite permeation prevention blanket with bentonite plaster; (d) fixedly mounting the bottom end of the test barrel on the bottom cover, and closing an opening in the upper end of the test barrel through an upper end cover; (e) opening an emptying valve and a liquid inlet valve, switching on a slurry pump, injecting slurry into the test barrel, and closing the emptying valve until an emptying pipe can continuously leak slurry; (f) continuing to inject the slurry into the test barrel through the slurry pump to pressurize the test barrel until the test barrel gets the required pressure, closing the liquid inlet valve, and switching off the slurry pump. The test device can apply high surrounding pressure to a large test piece with a convex-concave surface so as to perform a high-ground-pressure environment simulation test; furthermore, devices such as a model freezing pipe and a sensor which are buried into the test sample cannot be damaged.

Description

technical field [0001] The invention relates to a confining pressure loading method for a rock and soil test piece, in particular to a test method for simulating a high ground pressure environment by pressurizing bentonite mud. Background technique [0002] At present, there are mainly two methods for confining pressure loading of rock and soil specimens. One is to isolate the specimen with a film or heat shrinkable material, and then use hydraulic oil to load the specimen under confining pressure. This test method is suitable for The whole is relatively dense and the surface is relatively smooth. Using this method to load a large test piece with a large amount of compression deformation, the diaphragm material is easily embedded in the sample under the confining pressure and is punctured by the sample particles, and the hydraulic oil will enter the inside of the test piece through the rupture, resulting in test failure. And the specimen is polluted, so if this method is lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08

Inventor 宁方波刘志强龚建宇张云利左永江徐兵壮崔建军高伟叶玉西许舒荣李宁陈红蕾张绪忠

Owner BEIJING CHINA COAL MINE ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com