Joint geotechnical triaxial test sample preparation method

A triaxial test and rational technology, applied in the preparation of test samples, using stable tension/pressure to test the strength of materials, etc., can solve the problem that it is impossible to make triaxial samples with joints, and it is impossible to make jointed samples, etc. problem, to achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

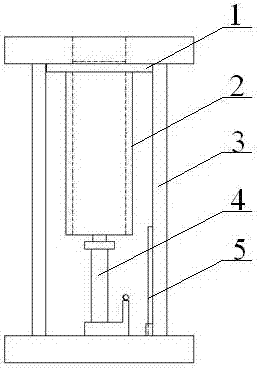

[0031] The concrete steps of joint rational geotechnical triaxial test sample preparation method of the present invention are as follows:

[0032] Step S1. Determine the joint-related data of the target sample, and calculate the mass of soil material required for each sub-sample according to the volume of each sub-sample in the target sample and the preset sample density.

[0033] In practical applications, it is usually the design drawing or idea of the existing target sample (the final desired sample), through which the number of joints in the target sample and the position information of each joint can be determined Joint-related data such as inclination information, such as a through-type horizontal joint located in the middle, two uniformly distributed and parallel 45° inclination joints, it can be understood that the target sample is composed of sub-samples divided by each joint, If the target sample has a penetrating joint, then it has two sub-samples; when the joint ...

Embodiment 2

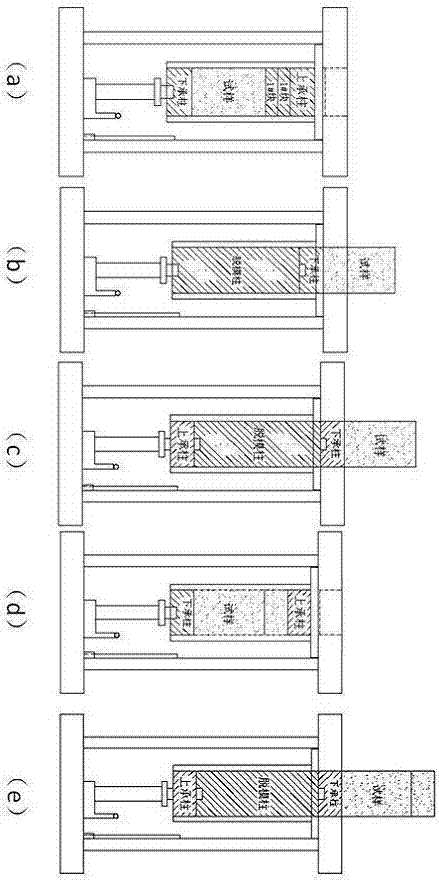

[0049] Example 2 Horizontal joints

[0050] refer to figure 2 , the target sample contains a through-type horizontal joint, and the joint position is at a height of 20mm or 60mm. Therefore, two 1# blocks are selected as molded test blocks. The manufacturing process is as follows:

[0051] (1) Before sample preparation, first calculate the volume V1 of the sample soil below the joint according to the preset joint position, and calculate the mass m1 according to the volume V1 and the preset sample density ρ1, and weigh m1 mass with an electronic scale soil.

[0052] (2) if figure 2 As shown in middle (a), place the lower support column at the bottom of sleeve 2, then pour m1 mass of soil into the sample in the middle, that is, the sample in the figure, and then place two 1# blocks and the upper support column on the soil sample respectively directly above, and then put the sleeve 2 on the oil pump 4 as a whole, put the top cover 1 under the round hole on the top of the reac...

Embodiment 345

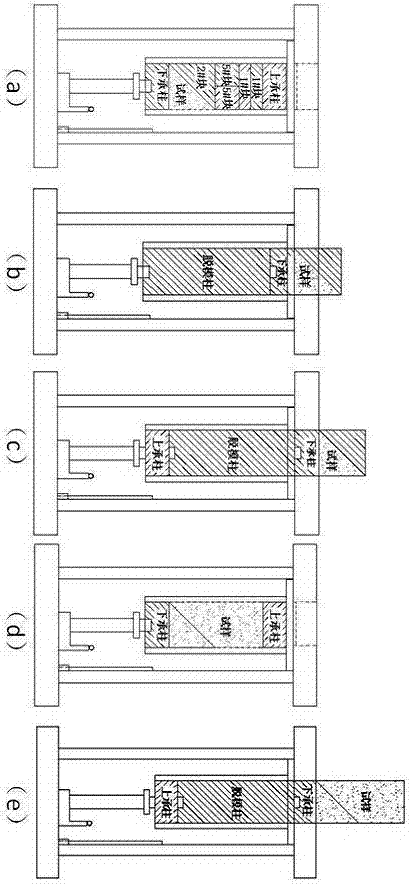

[0056] Example 3 45° inclination joint

[0057] refer to image 3 , the target sample contains a through-type joint with an inclination angle of 45°, and the joint extends upward from the bottom of the target sample at an angle of 45°, so one 2# block, two 5# blocks and two 1# blocks are selected for combination Form the molded test block to make the first sub-sample, and refer to Example 1 for the details of the rest of the manufacturing process. Moreover, under the combination of 1# block, 2# block, and 5# block, up to 4 parallel joints with an inclination angle of 45° can be made, and the joint spacing is 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com