Patents

Literature

76 results about "Joint sample" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

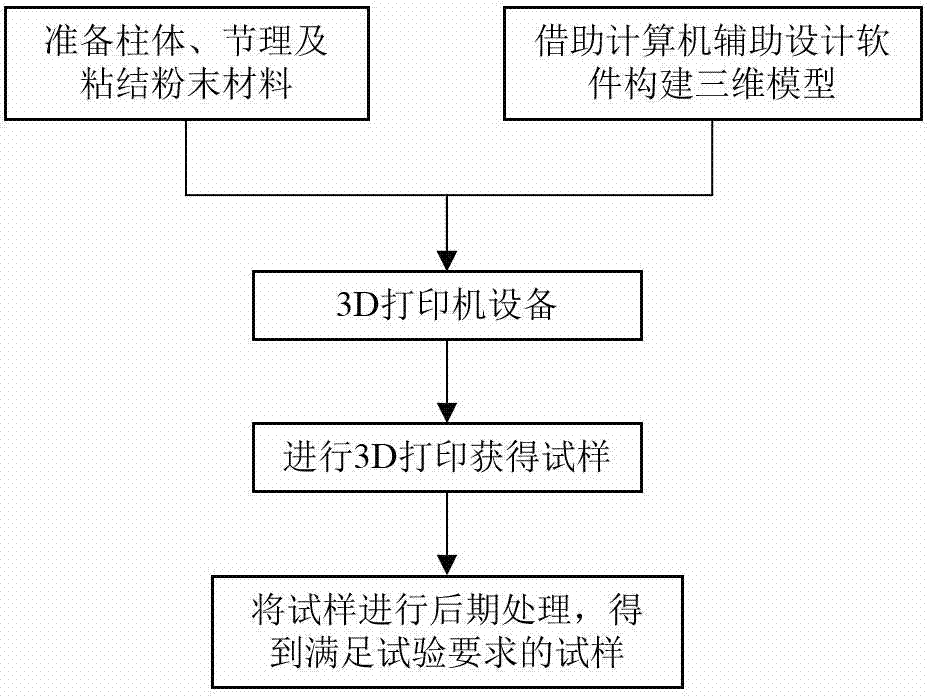

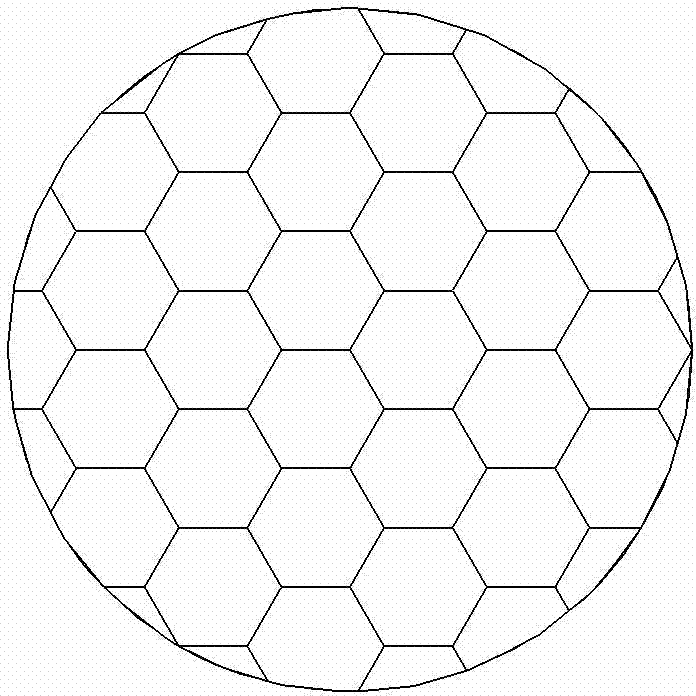

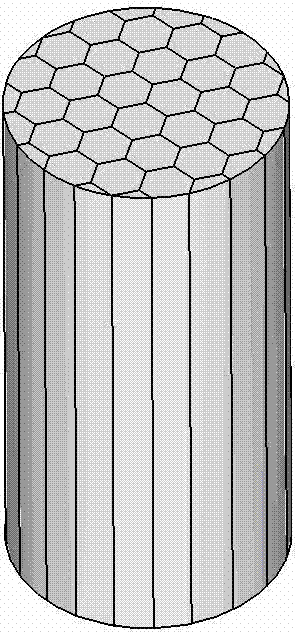

Method for preparation of columnar jointed rock mass similar material sample by 3D printing technology

InactiveCN104515696ASimple preparation processIncrease productivityPreparing sample for investigationAfter treatment3d printer

The invention discloses a method for preparation of a columnar jointed rock mass similar material sample by a 3D printing technology. The method includes: preparing powdered 3D printing raw materials: powder, columnar jointed column powder, joint needed powder and cementing bonding powder; loading the powdered materials into a 3D printer; establishing a columnar jointed sample three-dimensional model, and inputting the model into the 3D printer to conduct 3D printing; and carrying out after-treatment on the sample at the end of printing. The method provided by the invention applies the 3D printing technology into rock mechanical test for the first time, uses a similar material to simulate the basic characteristics of a columnar jointed rock mass in actual engineering, and has the advantages of simple preparation process, higher production efficiency than artificial sample preparation, and high yield, etc.

Owner:HOHAI UNIV

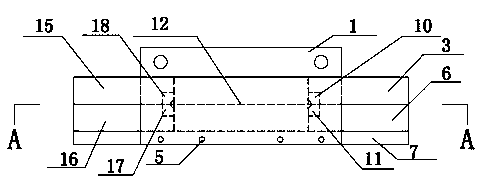

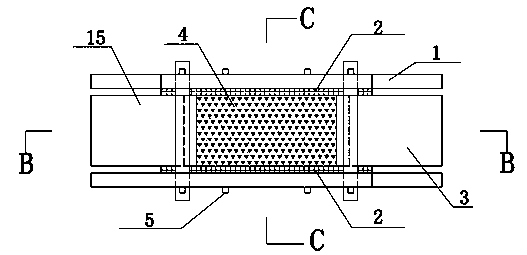

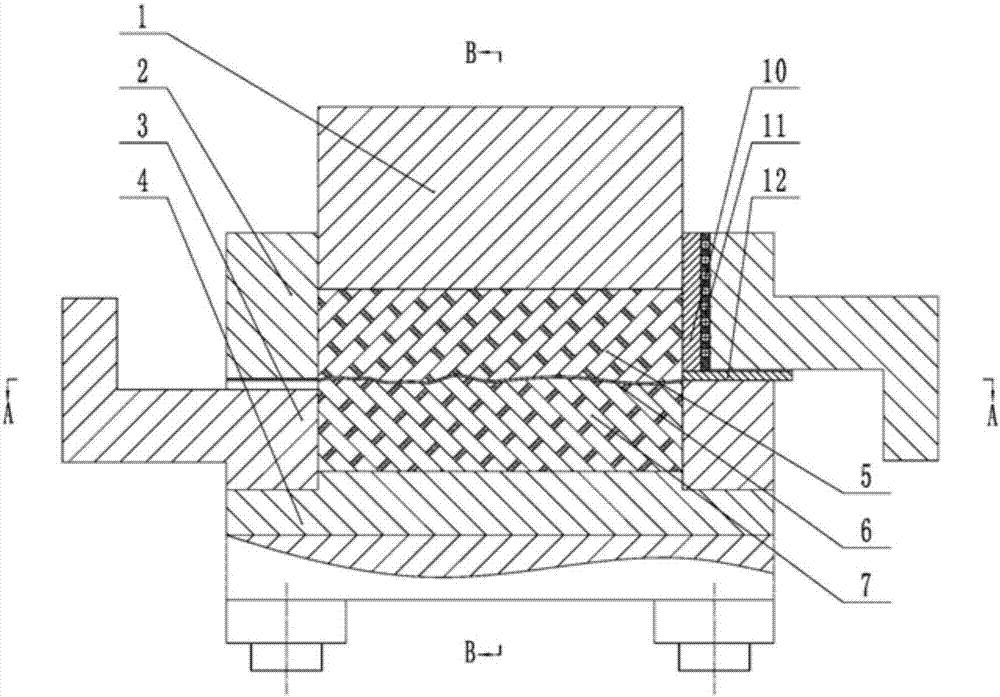

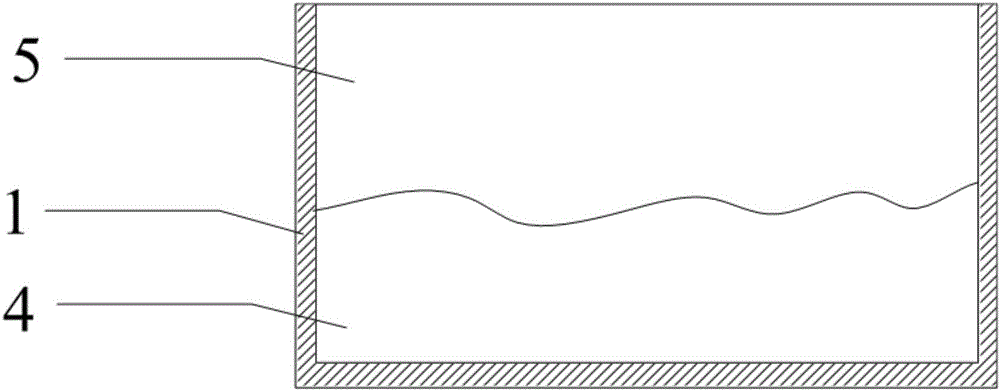

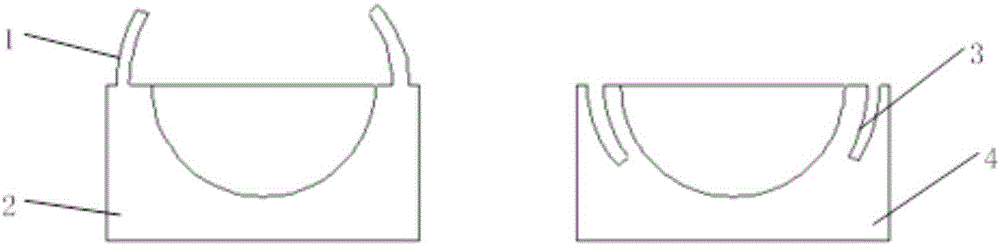

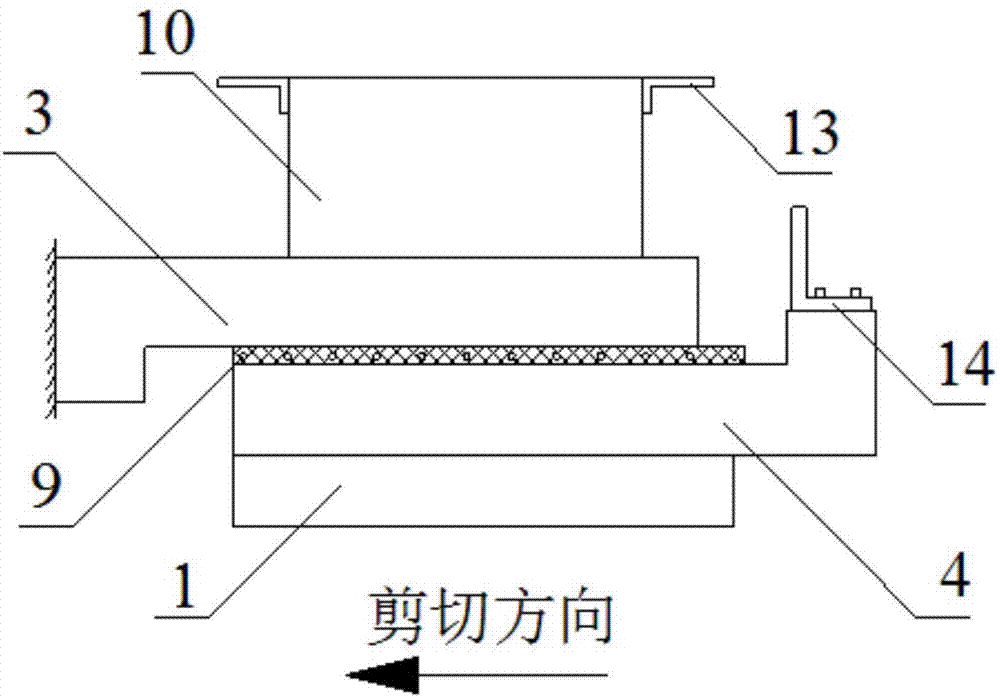

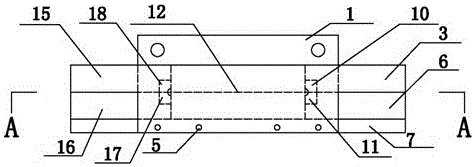

Shear box applicable to rock joint shearing, seepage and coupling tests and test method

InactiveCN102944665AFully study the variation law of permeability characteristicsGood sealing water boundaryEarth material testingJoint sampleEngineering

The invention relates to a shear box applicable to rock joint shearing, seepage and coupling tests and a test method. By the aid of the test box, water can be sealed strictly during shearing, and stable seepage water streams can be formed among joints. The shearing box is mainly composed of a bottom plate, a side plate, a lateral water sealing bag and a water inlet and outlet device. The shear box is characterized by the design of the lateral sealing bag and the method of water injection at the front end and water accumulation at the rear end. By the aid of the rock joint shearing, seepage and coupling test box, the shearing displacement within 20mm can be achieved, the seepage characteristic variation caused by dilation and contraction during rock joint shearing can be studied fully, a water head of 0.05-3.0MPa can be provided to provide conditions for studying the influence of water pressure on joint seepage fully, a minitype servo water pump is used for injecting water, stable water streams can be formed at one ends of joints, the seepage situation conforms to natural conditions, and shearing and seepage tests of joint samples under the effect of complex loads can be finished through the shearing box.

Owner:WUHAN UNIV

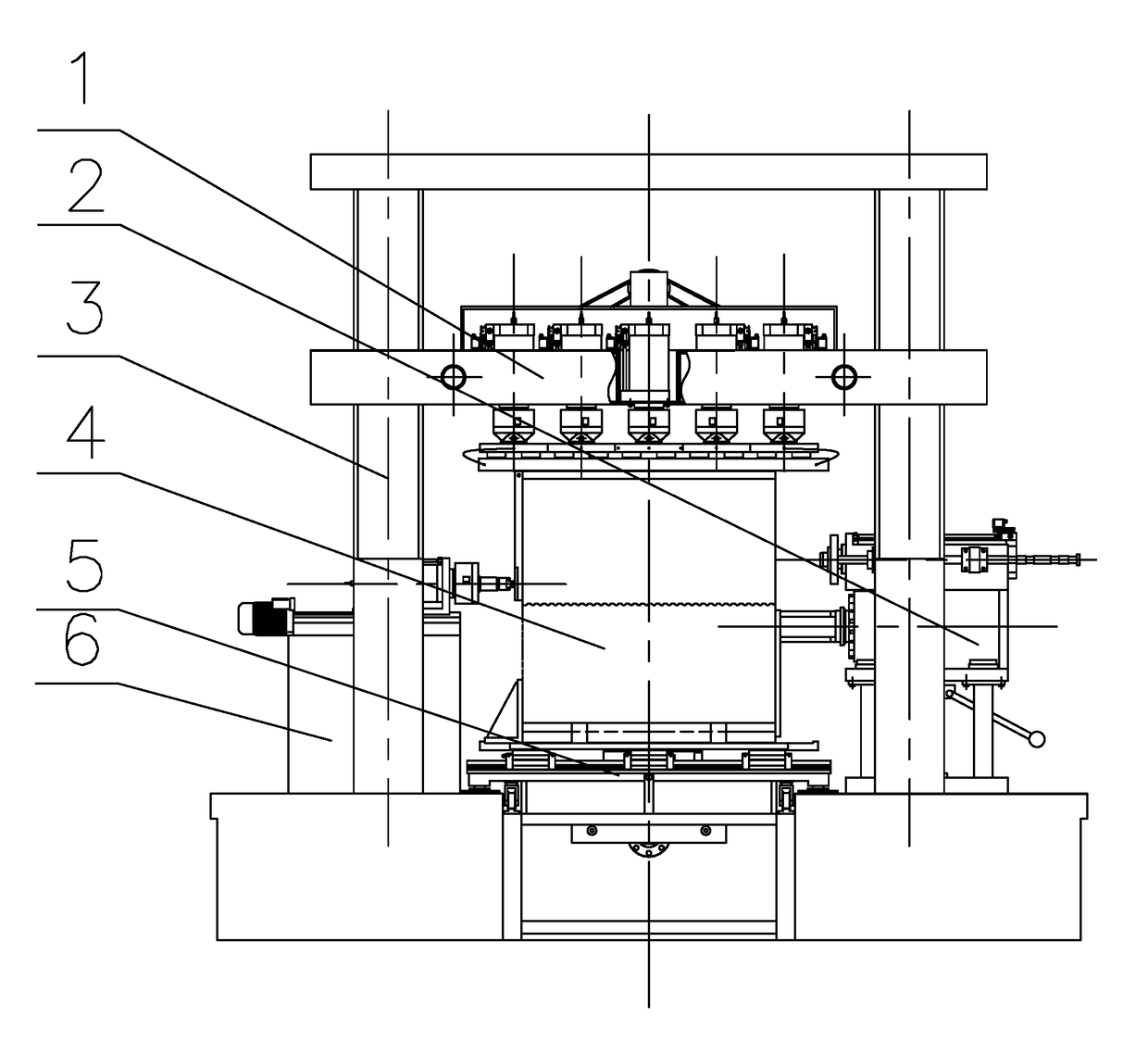

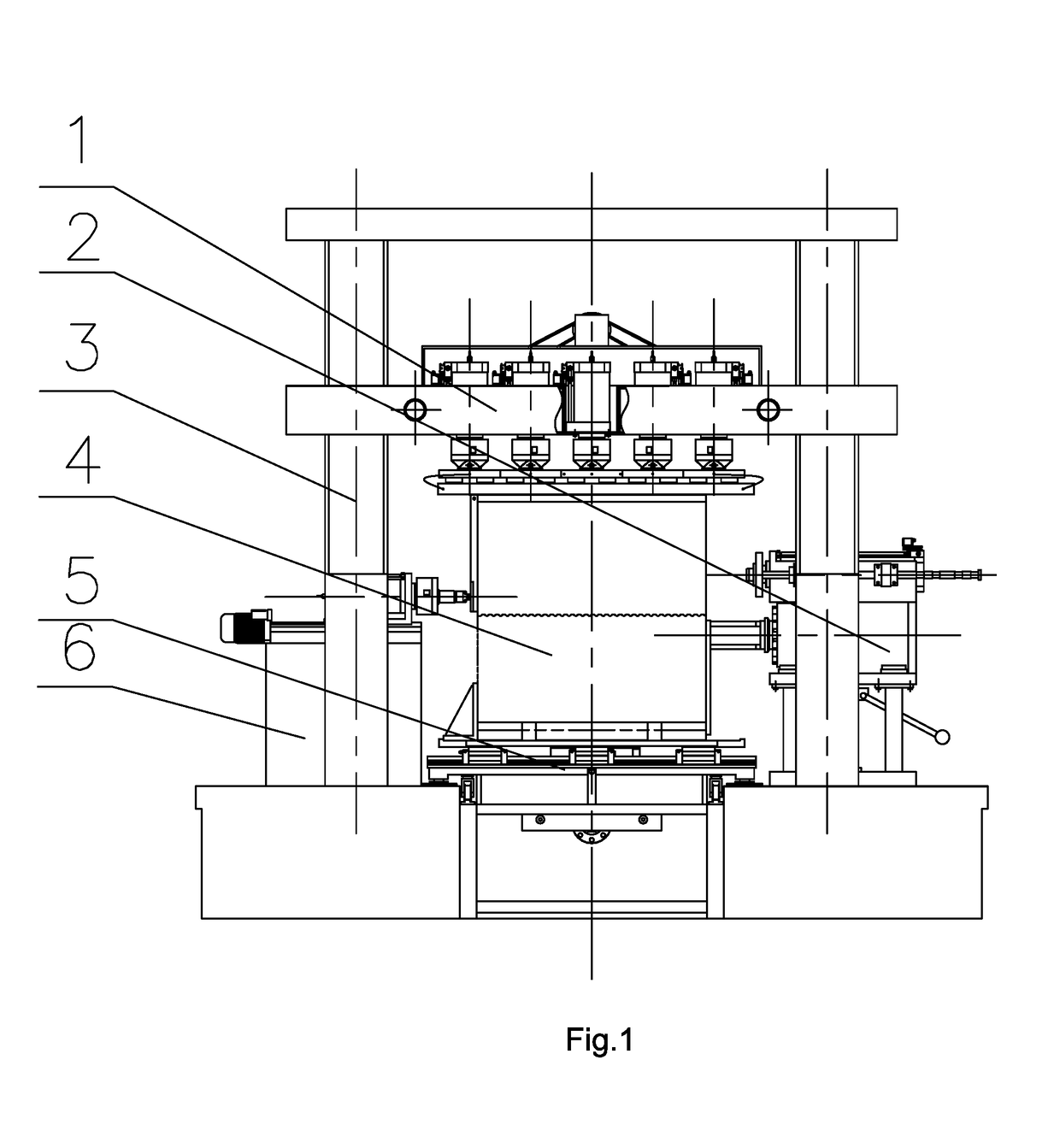

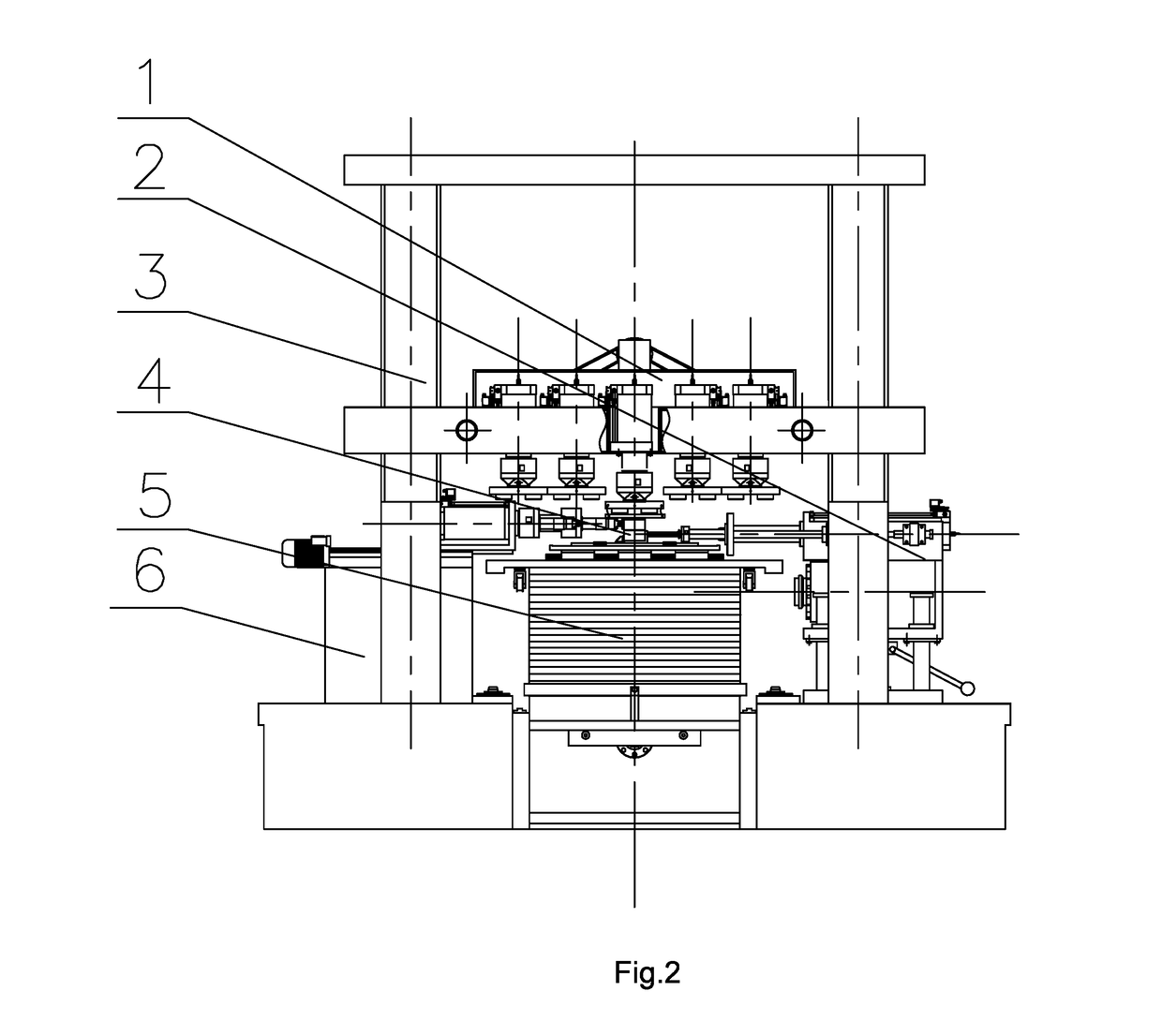

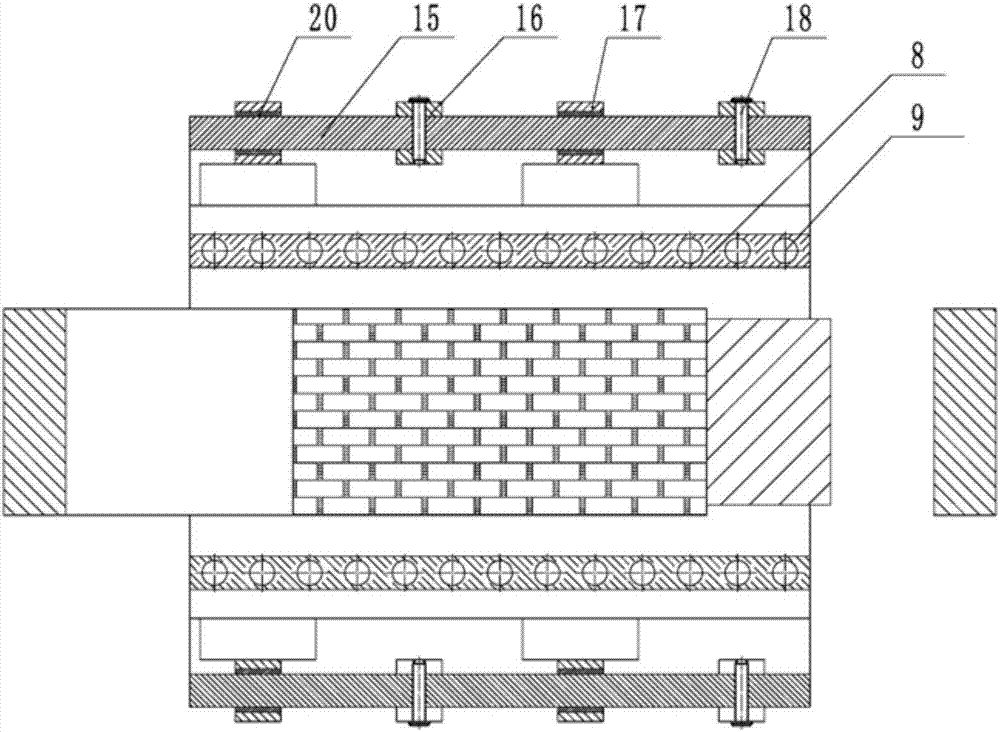

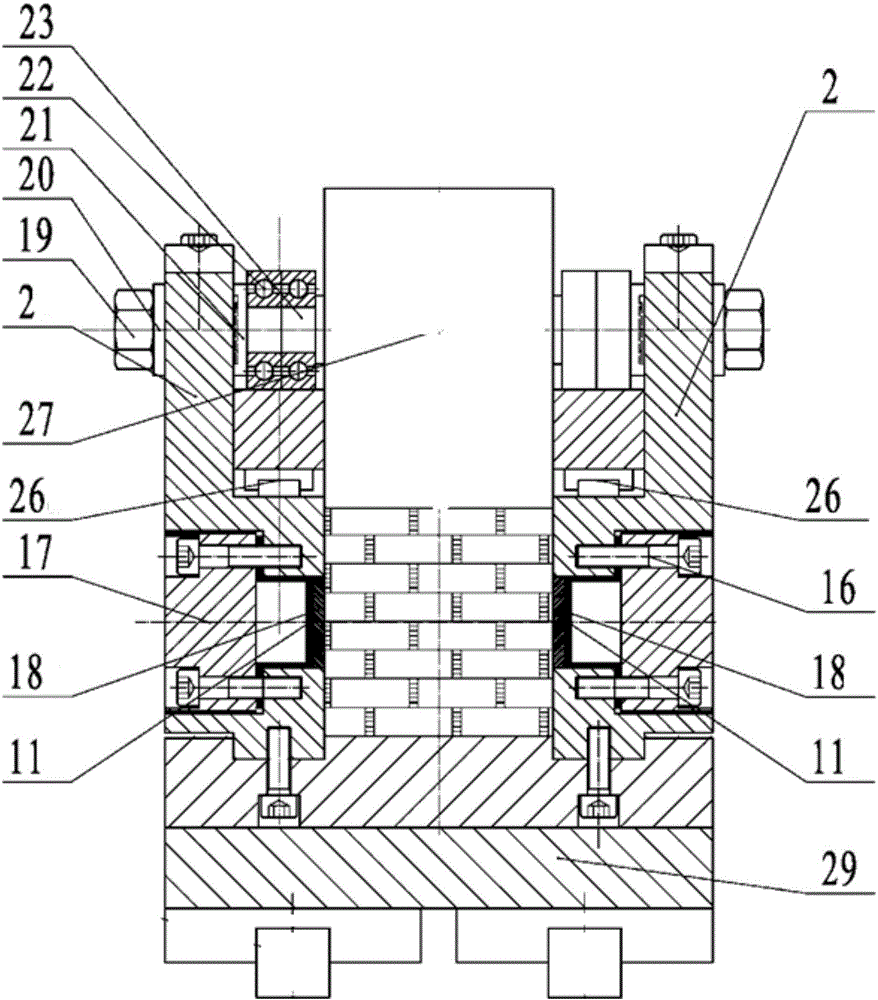

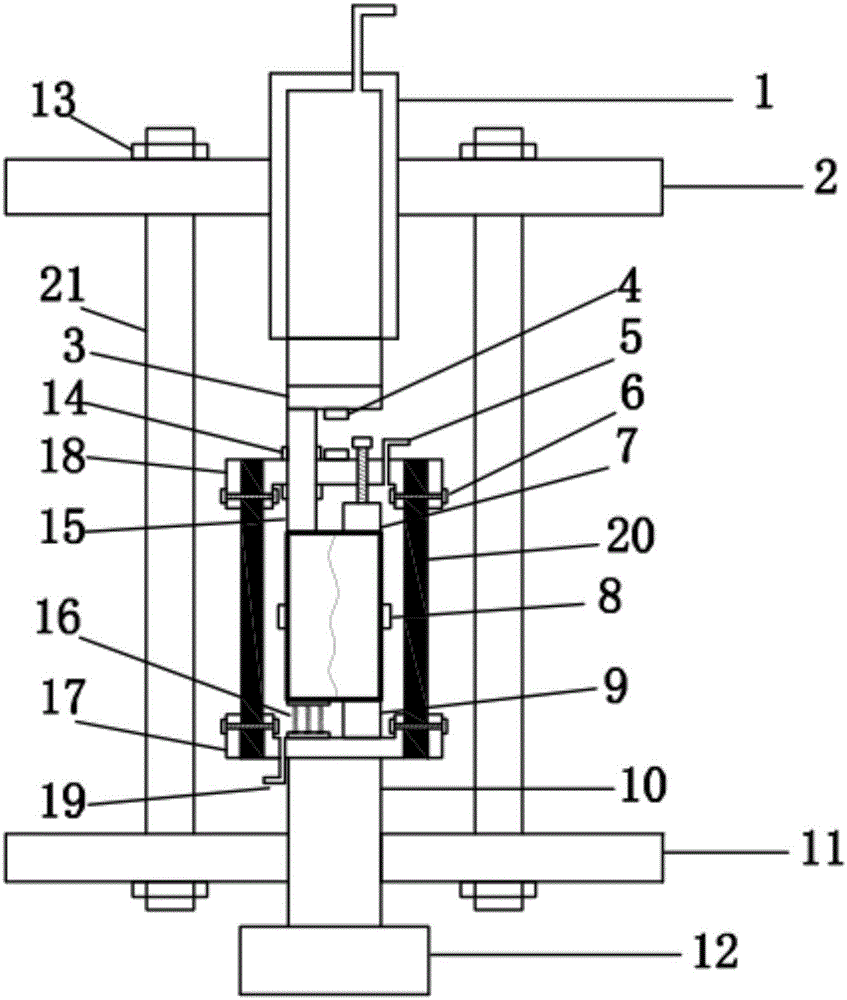

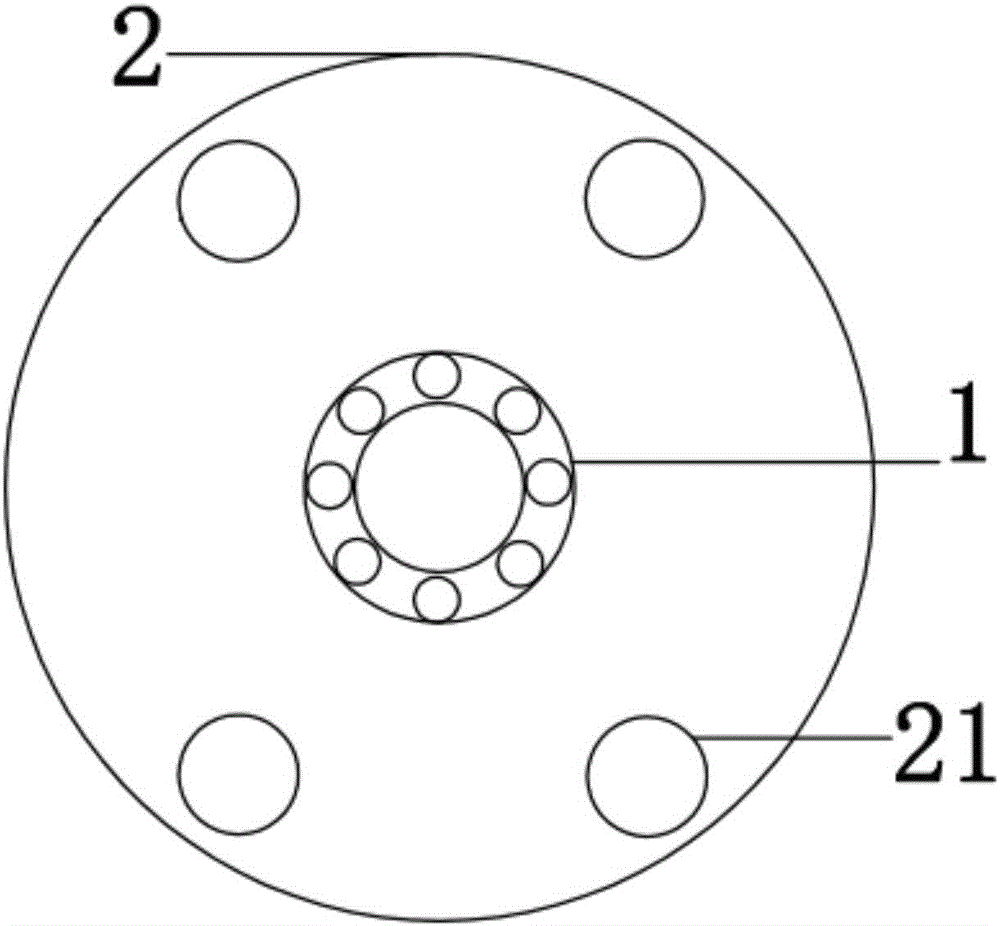

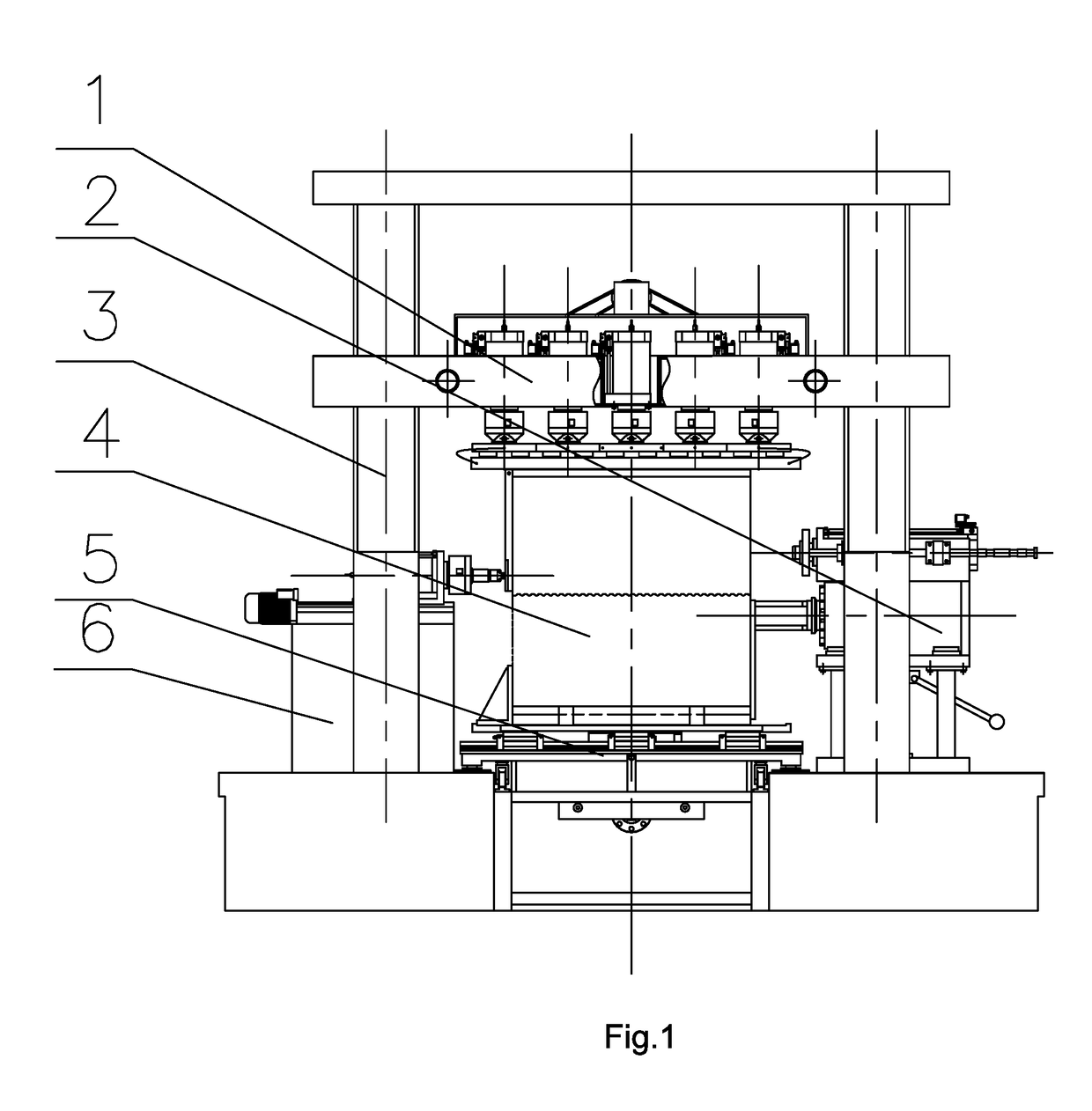

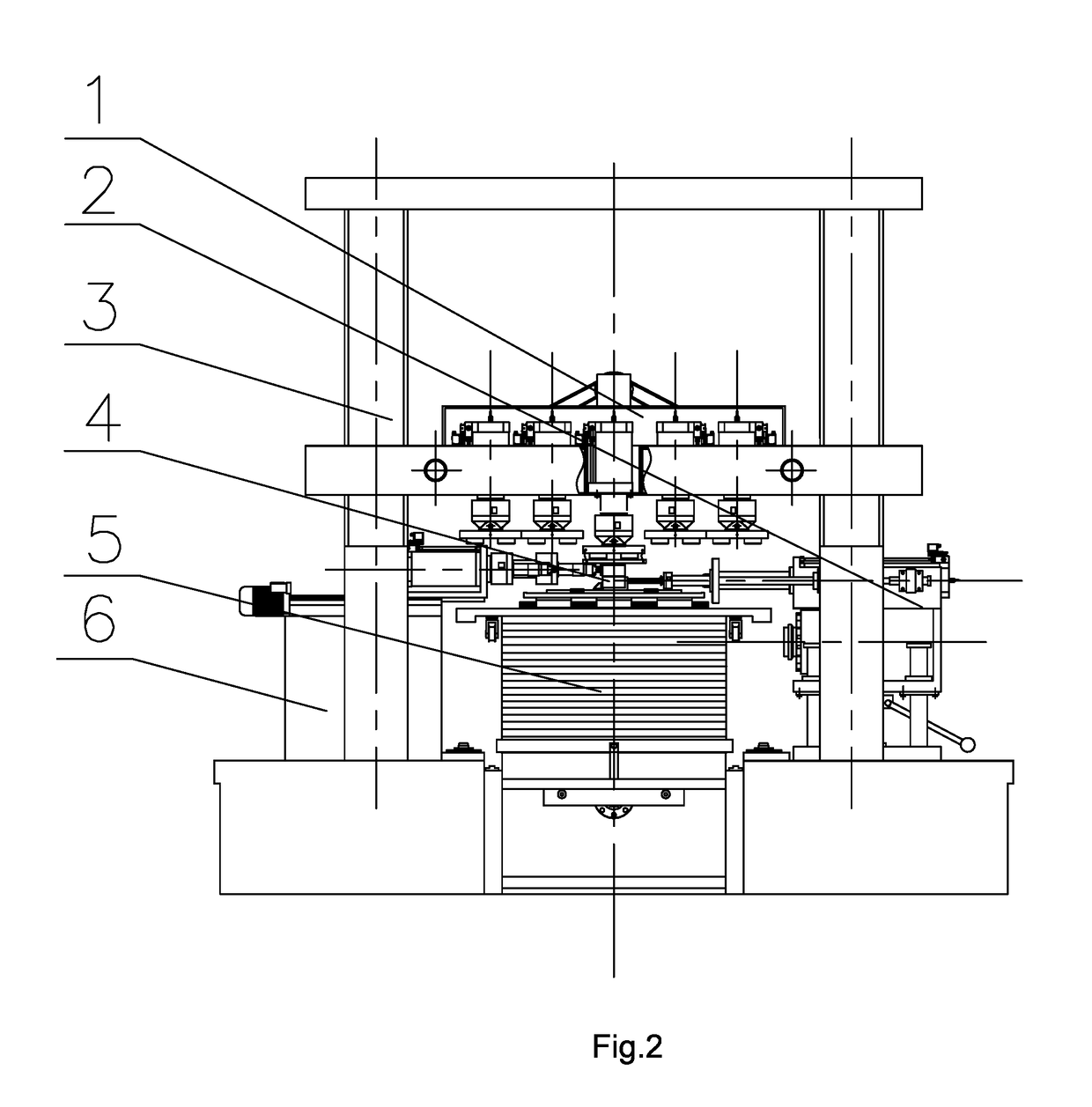

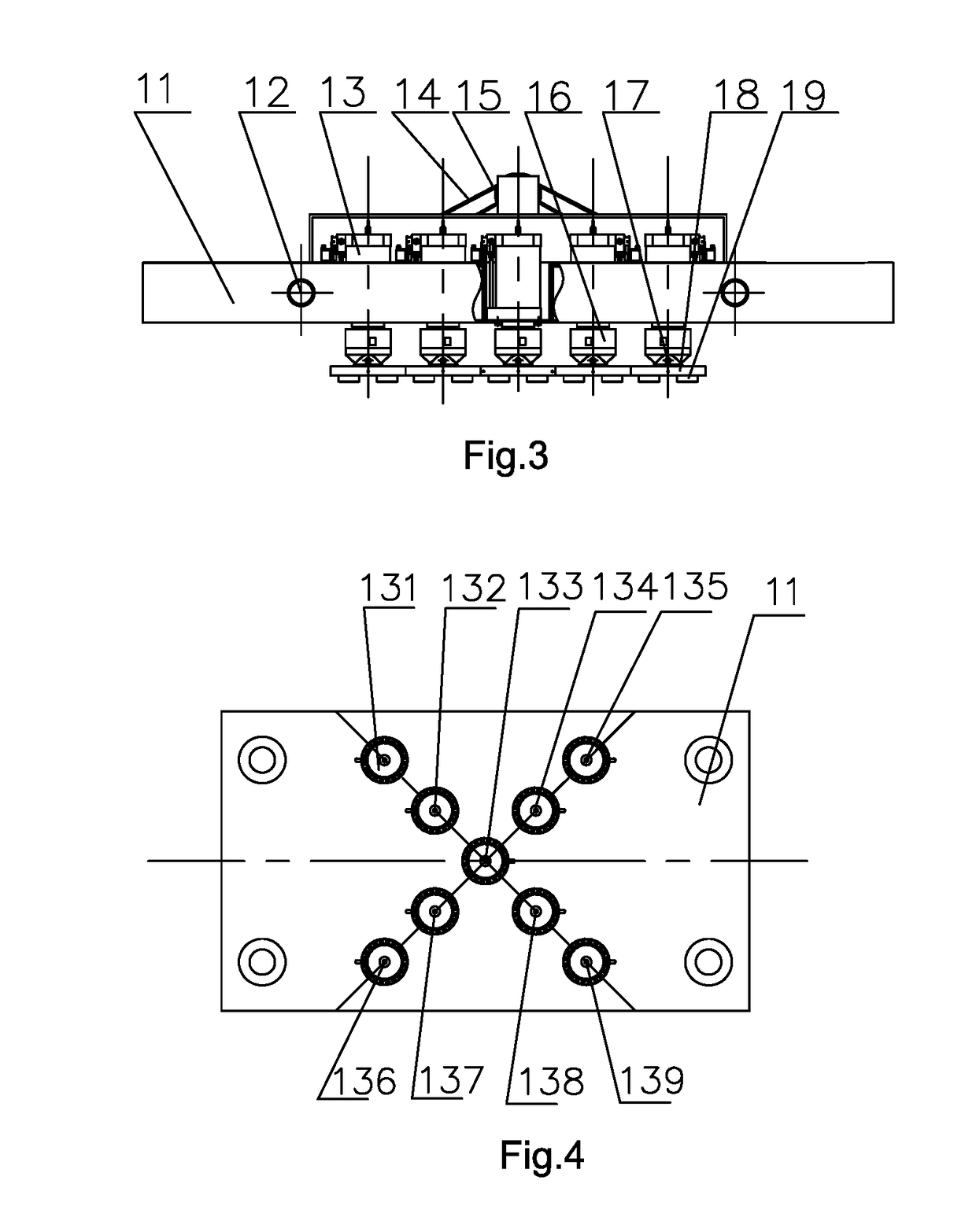

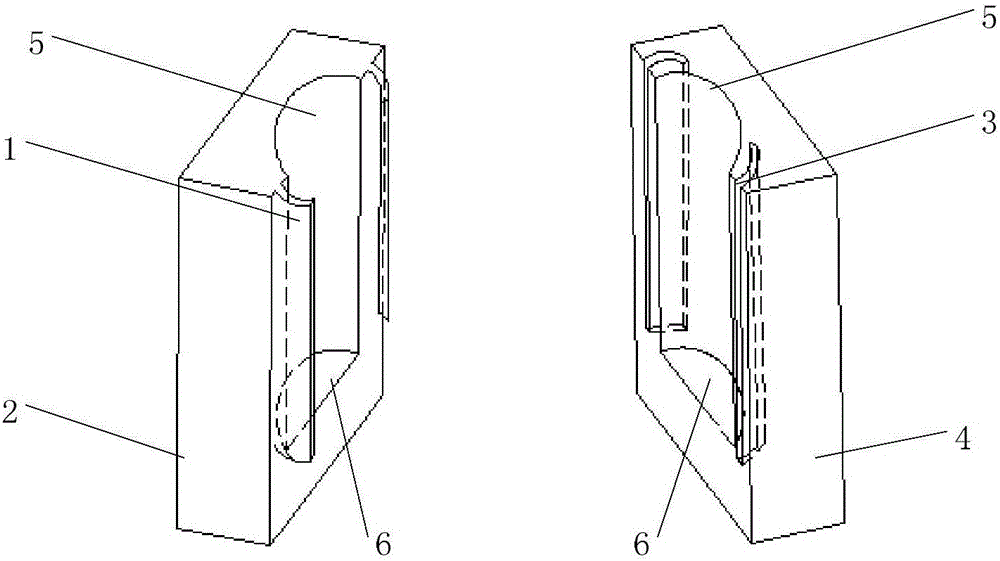

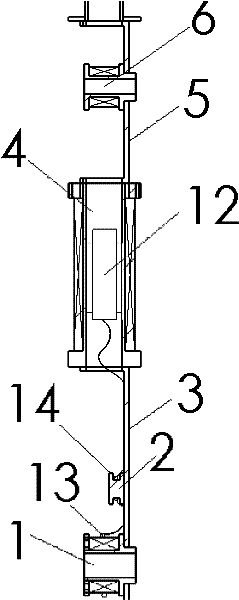

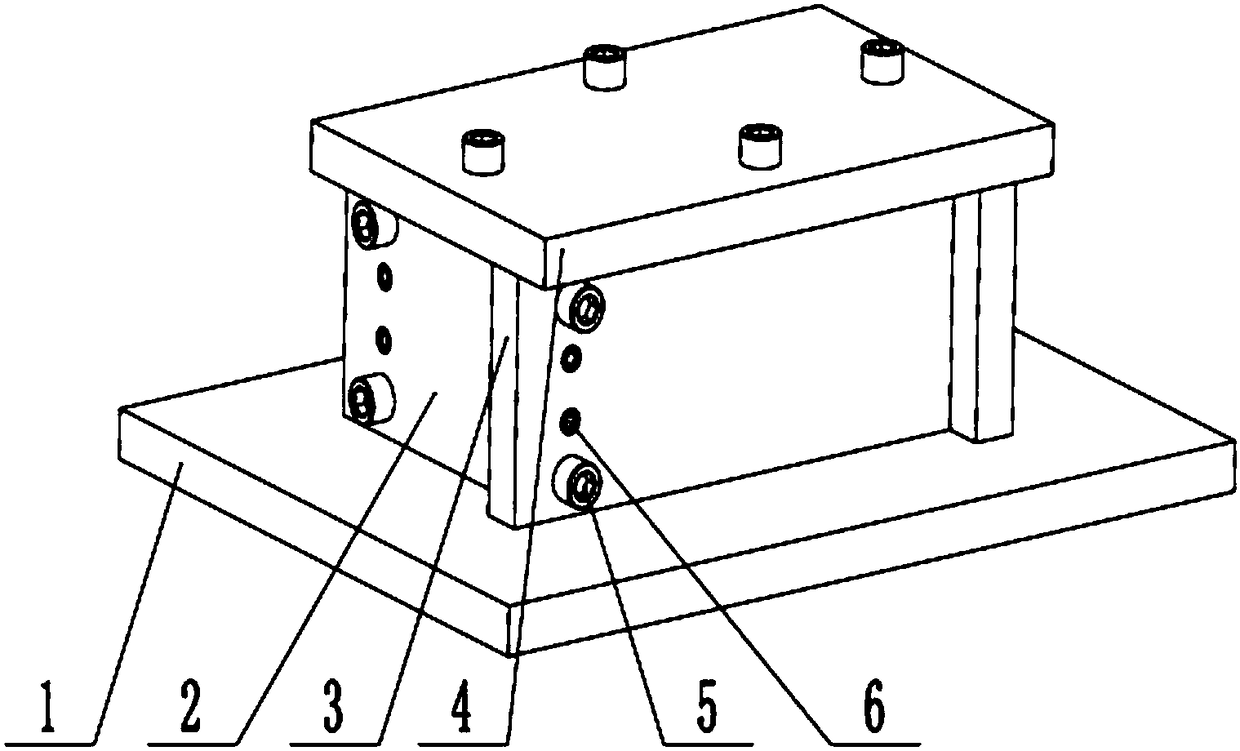

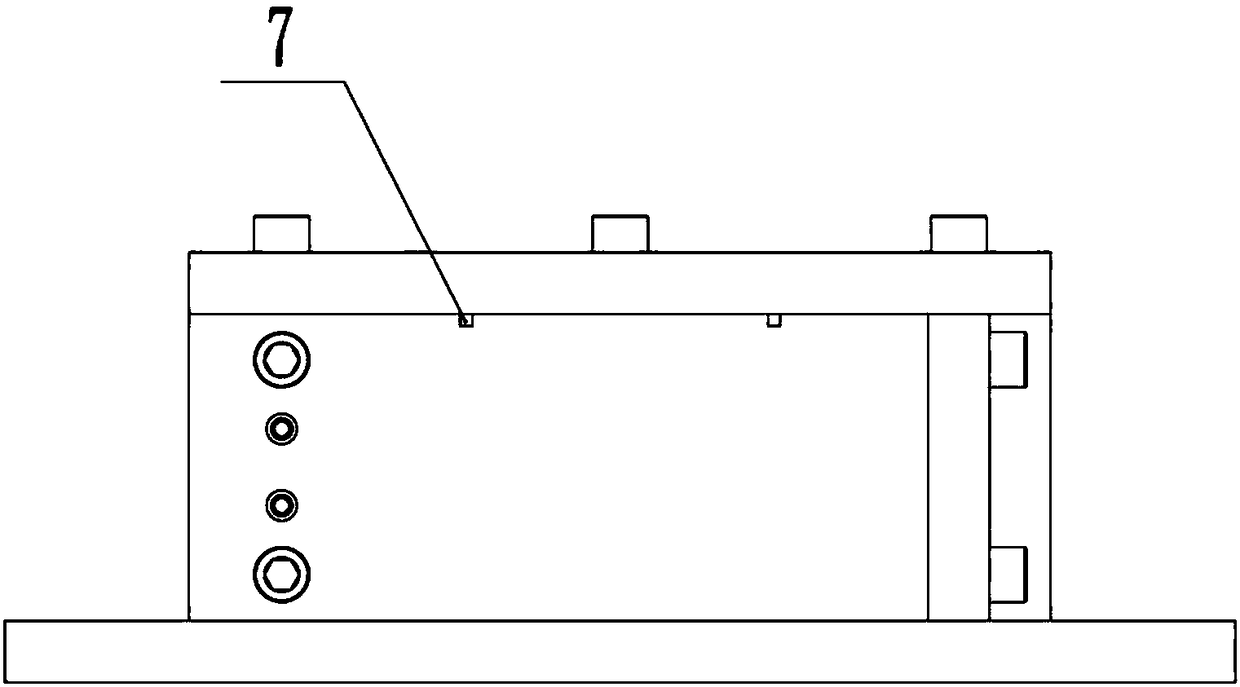

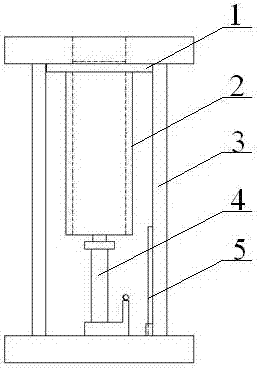

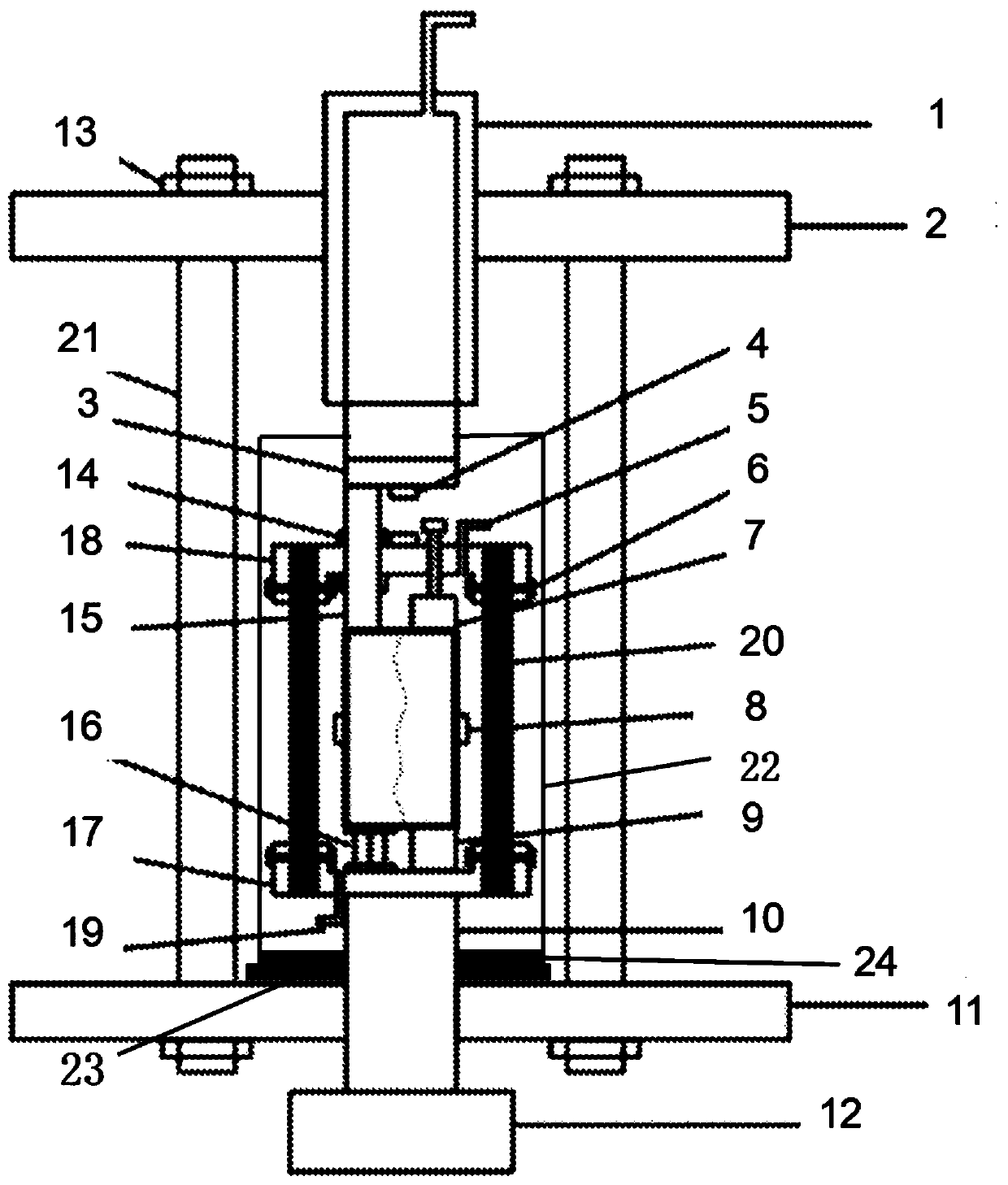

Tester assembled by multiple sets of mechanisms for shear strength-scale effect of rock joint

ActiveUS20180128725A1Improve reliabilityLow reliabilityMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesTester deviceEngineering

A tester assembled by multiple sets of mechanisms for shear strength-scale effect of a rock joint includes a horizontal loading mechanism, a horizontal supporting and force-measuring mechanism and a sample installation and lifting table are mounted on a platform on the bottom of a frame, the horizontal loading mechanism and the horizontal supporting and force-measuring mechanism are respectively located on two sides of the sample installation and lifting table; rock joint sample is divided into an upper portion and a lower portion by a slit, the horizontal loading mechanism is configured to load the upper portion of the multi-scale rock joint sample, and the horizontal supporting and force-measuring mechanism is configured to support the lower portion of the multi-scale rock joint sample; a vertical loading mechanism is located above the multi-scale rock joint sample, and can be mounted on the frame in a manner of being movable up and down; and the horizontal loading mechanism comprises at least two tangential actuators, and the vertical loading mechanism comprises a vertical actuator group including at least two vertical actuators. The present invention effectively meets the test requirements on the scale of the multi-scale rock joint samples under large-range loads, and is good in reliability.

Owner:SHAOXING UNIVERSITY

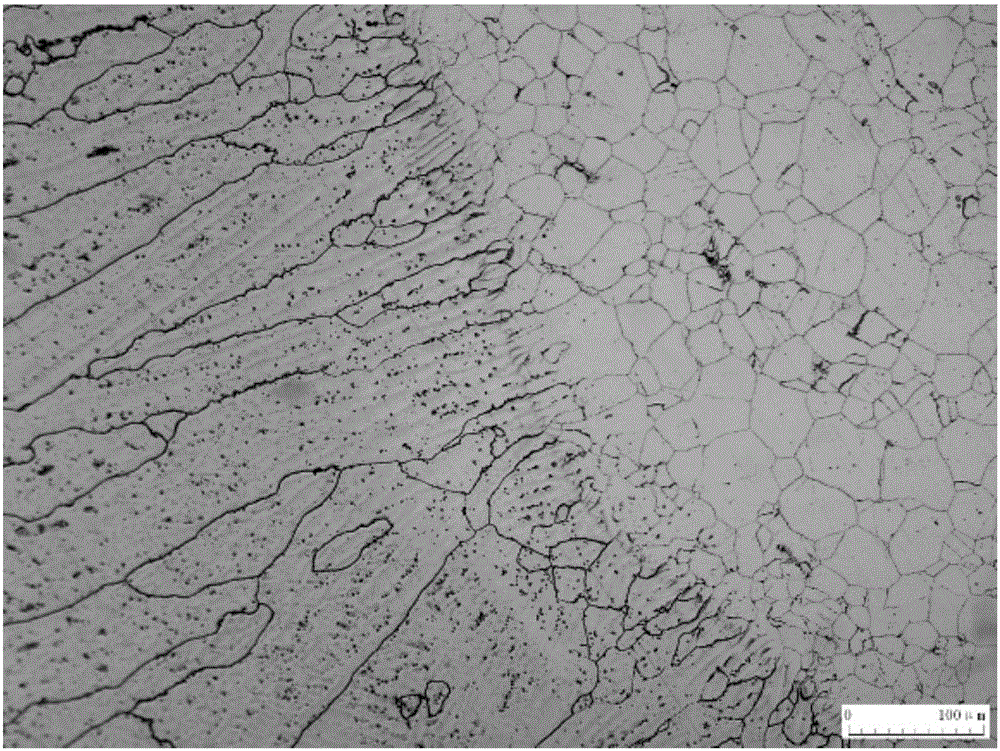

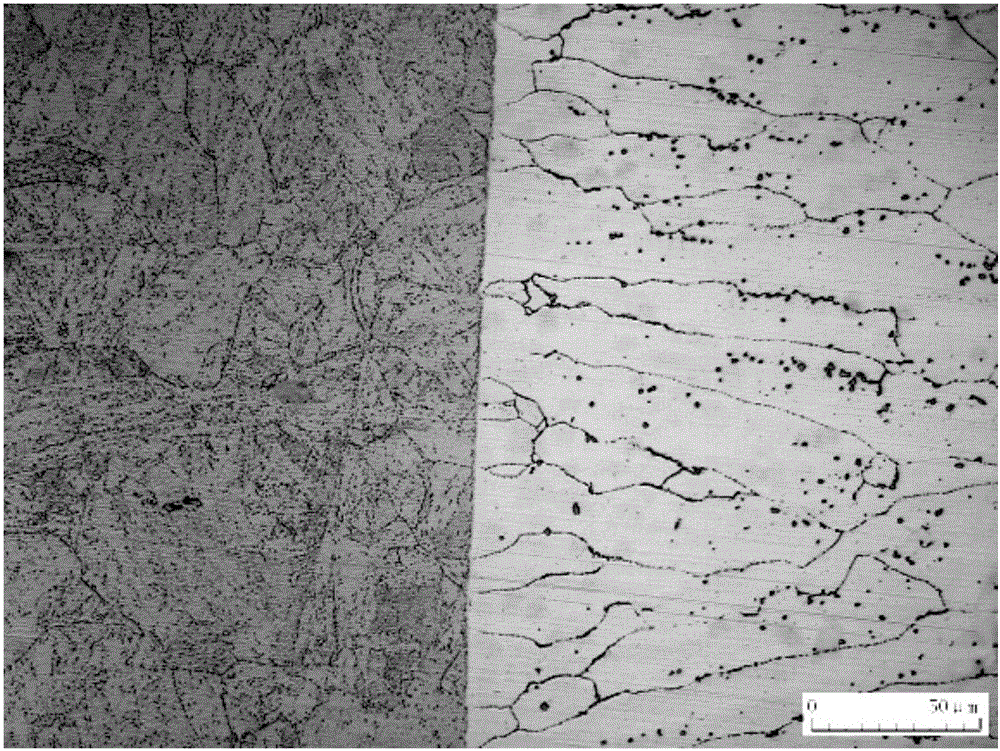

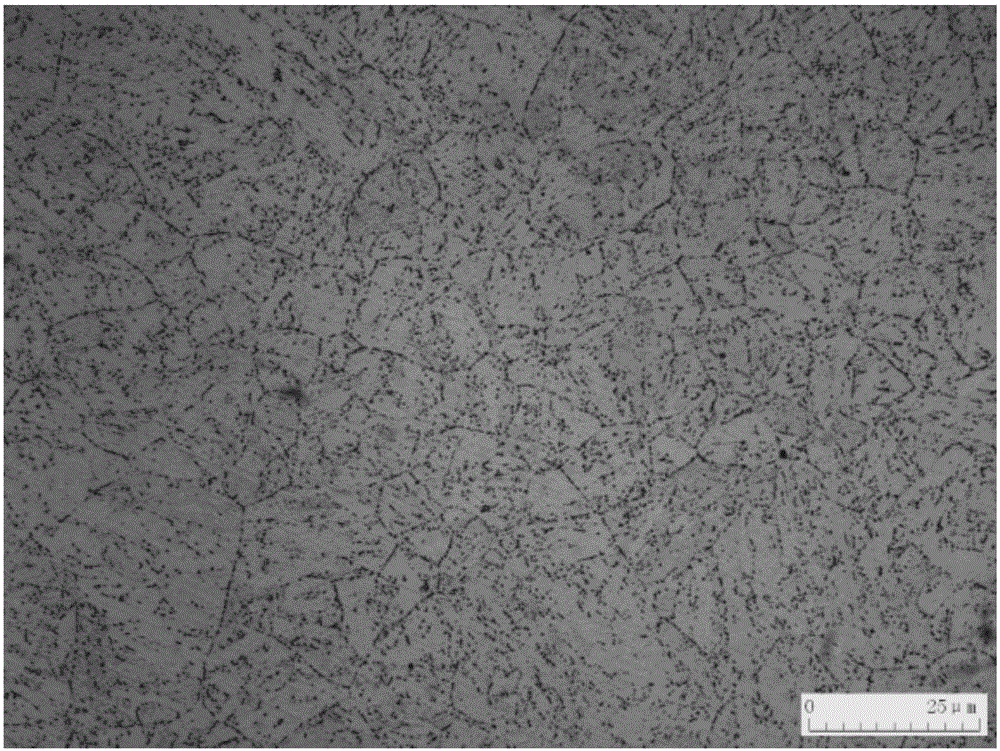

Display method for metallographic structure of austenite and ferrite dissimilar steel joint

ActiveCN106092710AEasy to prepareConvenient and accurate inspectionPreparing sample for investigationMaterial analysis by optical meansElectrolysisAlcohol

The invention discloses a display method for a metallographic structure of an austenite and ferrite dissimilar steel joint. According to the display method, the operation is simple, rapid and safe, and an etching process is easy to control. The display method comprises steps as follows: (1), sampling: sampling is performed at the austenite and ferrite dissimilar steel joint; (2), preparation of etching solutions: the etching solutions comprise an electrolysis etching solution, an intermediate treatment etching solution and a chemical etching solution; (3), etching treatment of a dissimilar steel joint sample: a to-be-detected sample is clipped by a pair of anodic stainless steel tweezers and soaked into the electrolysis etching solution, the distance between an analysis surface of the to-be-detected sample and a cathode is enabled to be 5-20 mm, and the to-be-detected sample is etched for 2-10 s; the sample is soaked into the intermediate treatment etching solution, and the surface is wiped for 2-10 s; then the sample is soaked into the chemical etching solution and wiped until the surface is silver gray; finally, the sample is washed with clean water, absolute ethyl alcohol is dropwise added to the sample, and the sample is blow-dried by a blower; (4), the sample is subjected to microexamination. The display method is simple to operate, convenient and rapid to use, good in repeatability and suitable for daily batch inspection and has great guiding significance for production.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

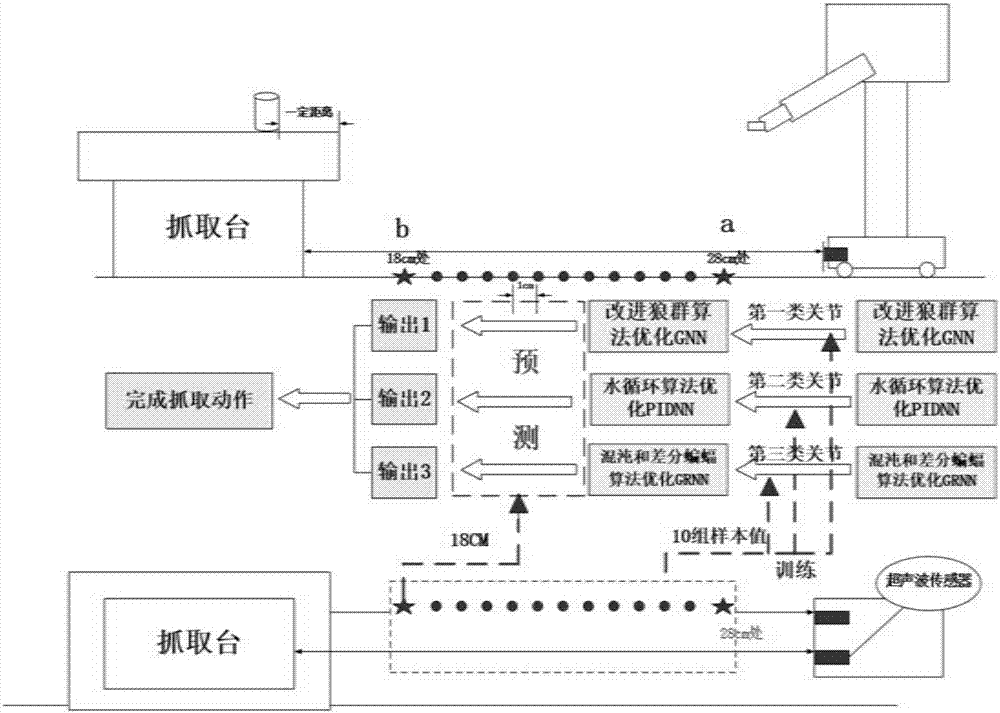

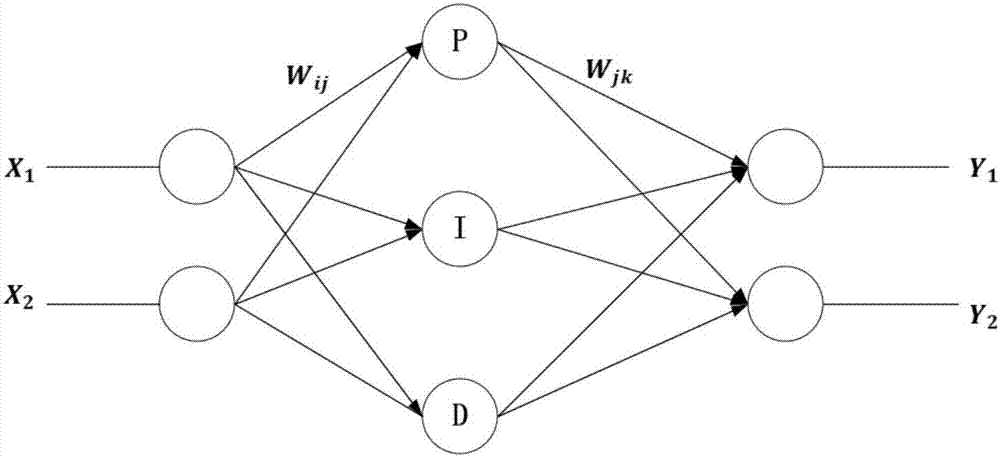

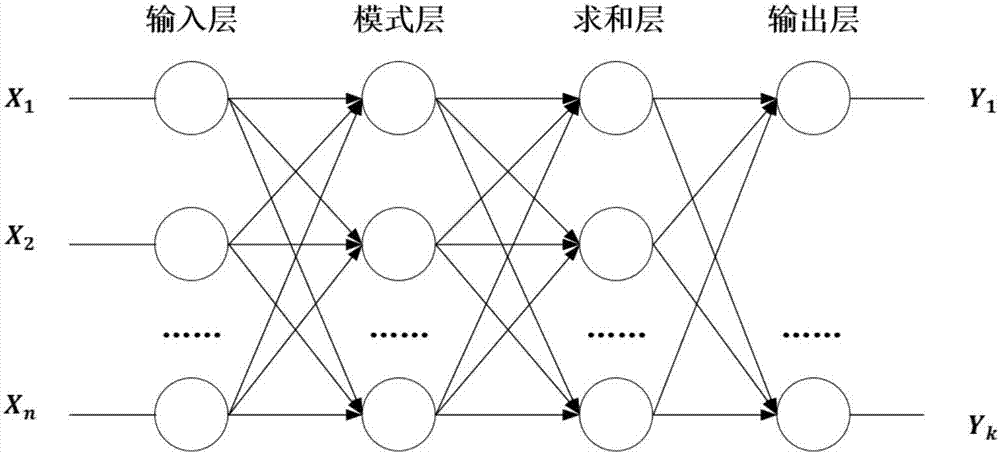

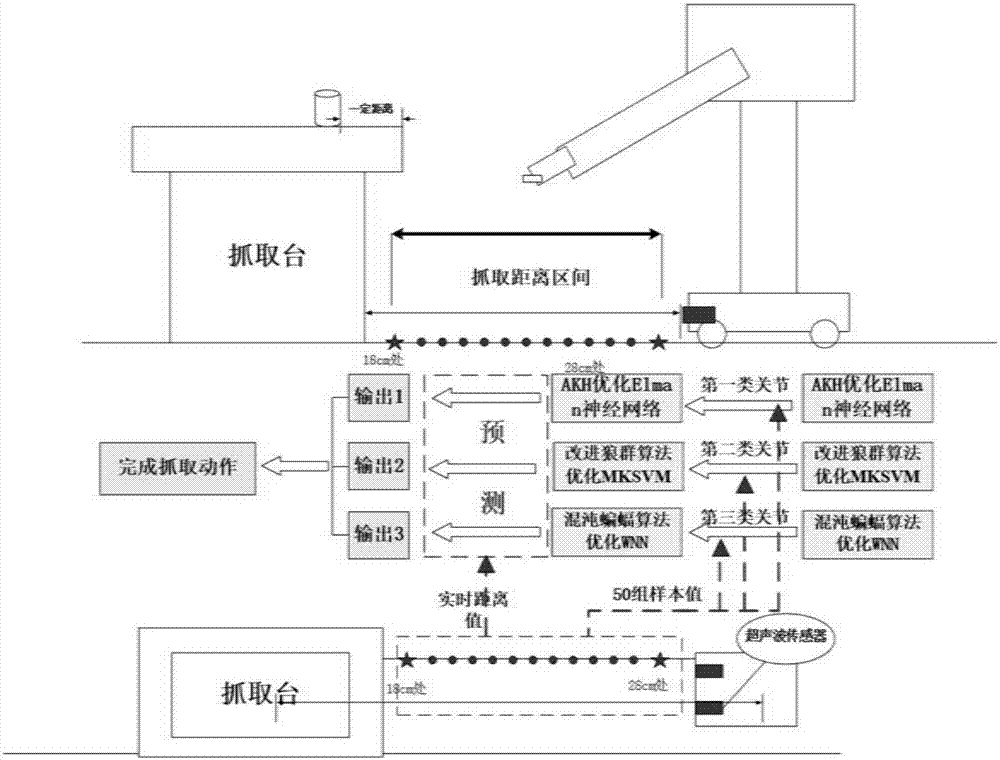

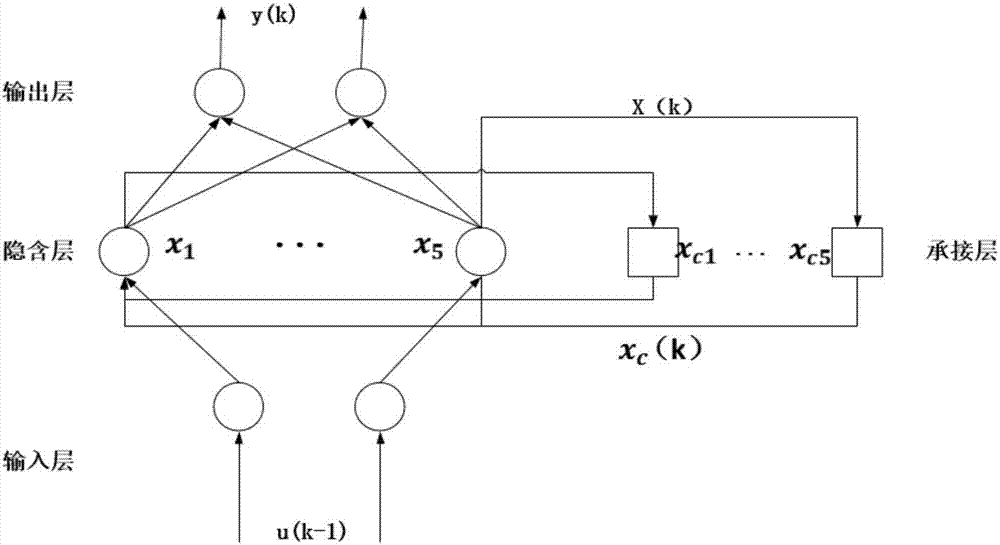

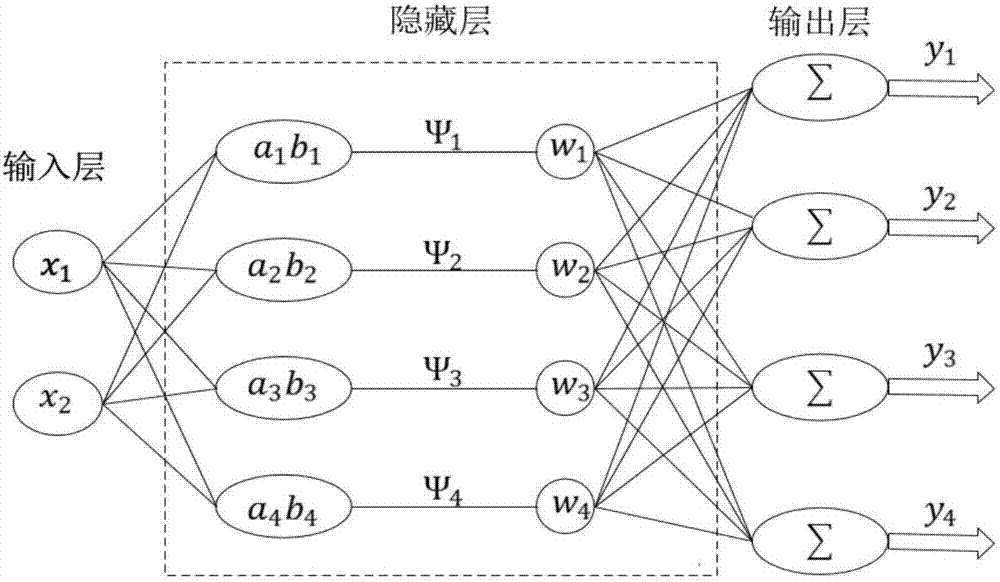

Loading robot arm control self-adaption blended learning mapping intelligent control method and system

ActiveCN107253195AEasy maintenanceWill not cause failureProgramme-controlled manipulatorKinematicsKinematics equations

The invention discloses a loading robot arm control self-adaption blended learning mapping intelligent control method and system. The method comprises the first step of using a remote server to control a loading robot arm to repeatedly conduct grabbing training multiple times to obtain a grabbing sample set; the second step of selecting an initial training sample according to an arm motion power consumption amount; the third step of conducting joint classification on the initial training sample according to the change amplitudes of all arm joint control values to obtain various joint sample sets; the fourth step of using the various joint sample sets as a final training set to construct a prediction model for the loading robot arm joint control values; the fifth step of inputting positions of all movable points to the prediction model in sequence to obtain the control values of all joints on each movable point, and then completing a grabbing task. According to the loading robot arm control self-adaption blended learning mapping intelligent control method and system, by constructing the map between the distance of a robot base and a grabbing platform and a robot arm posture, complicated construction of a kinematical equation is avoided; accurate joint control values are obtained, and the joints are flexibly controlled.

Owner:CENT SOUTH UNIV

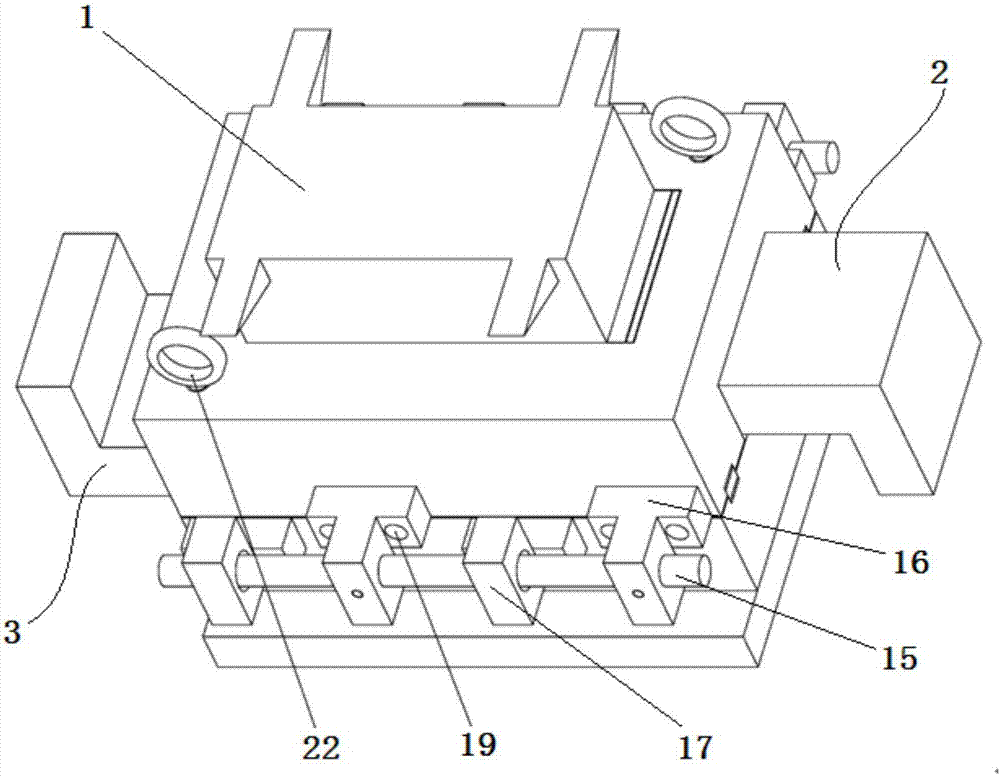

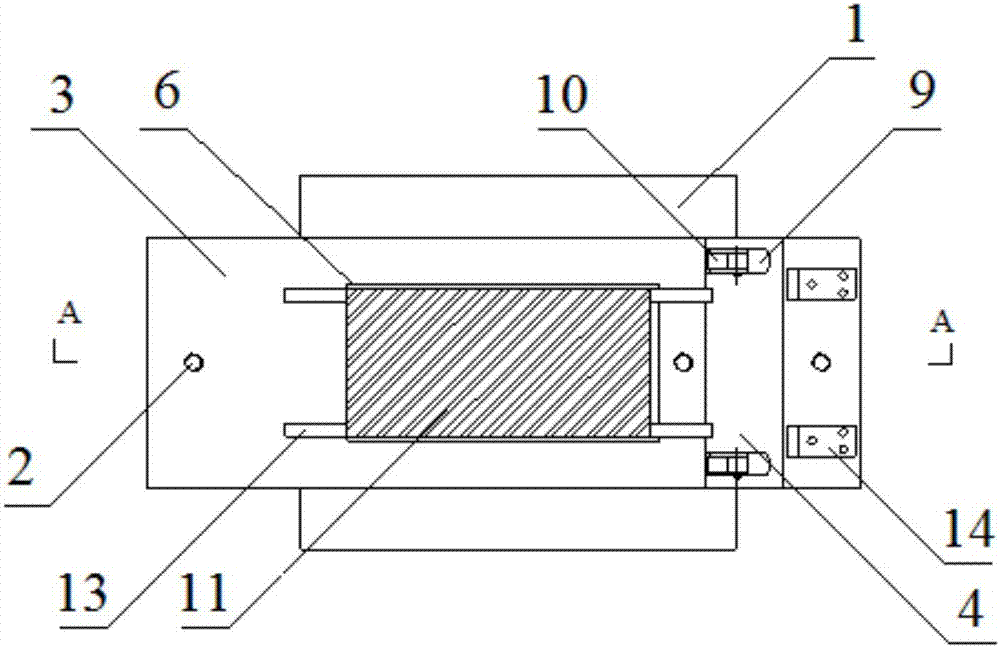

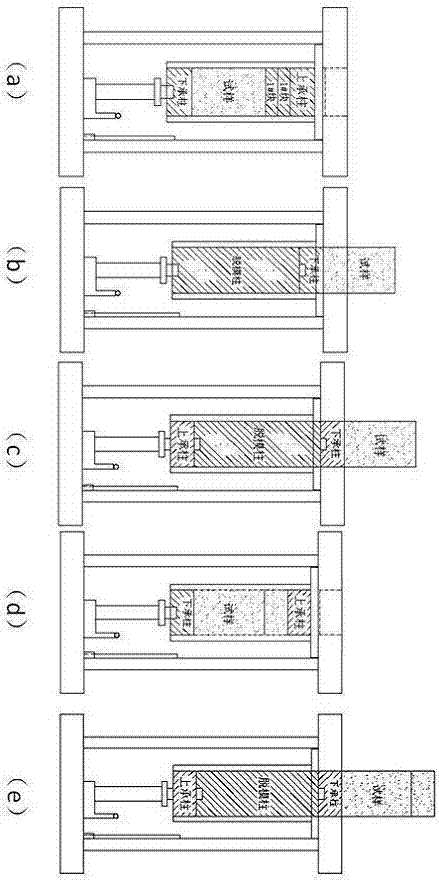

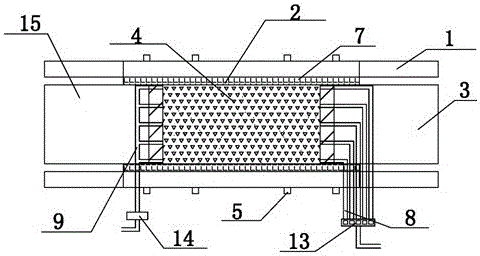

Rock joint sample direct shearing test box

InactiveCN107036906AStudy Dilatation PropertiesFreedom of movementMaterial strength using steady shearing forcesUpper jointEngineering

The invention relates to a rock joint sample direct shearing test box. The test box comprises a base, an upper shearing box and a lower shearing box which are used for placing a rock joint sample and a normal loading cushion block presses upon an upper joint block of a rock. A fixing support arranged downward is installed on the upper shearing box, a bearing support arranged upward is installed on the lower shearing box, a guiding rod is inserted into the fixing support and the bearing support in a penetrating mode, pin holes are formed in the fixing support, the guiding rod and the fixing support are fixed through a locating pin, and a linear motion bearing used for connecting the guiding rod with the bearing support is arranged in the slot of the bearing support. Compared with the prior art, by means of the test box, not only can free motion of the lower shearing box in the shearing direction in the rock joint sample shearing process be guaranteed, but also the problem that the upper shearing box is reversed upward is effectively solved; contact friction between the upper and lower shearing boxes in the rock joint sample shearing process and friction between the upper shearing box and the upper joint block of the rock are effectively reduced, so that the shearing process is more in line with the real condition.

Owner:TONGJI UNIV

Test method for studying rock joint surface morphology evolution in whole shear process

ActiveCN106556541AAvoid destructionFailure stress stateMaterial strength using steady shearing forcesShear stressEngineering

The invention relates to a test method for studying rock joint surface morphology evolution in a whole shear process. The method includes: using an artificial rock material to copy a rock joint surface to obtain multiple groups of joint samples with completely identical surface morphology, scanning all the joint samples before testing to obtain joint surface initial morphology data; conducting a group of joint shear test to obtain a complete joint shear displacement-shear stress test curve; in the follow-up study process, selecting shear displacements corresponding to different joint shear stress states, and performing multiple groups of joint shear test, stopping each group of test at different shear displacement positions, then scanning the joint surface morphology data obtained by the groups of test, and performing comparison with the morphology data of each sample before test so as to obtain morphology evolution data in the joint shear process. Compared with the prior art, the method provided by the invention has the advantages of simplicity and convenience, more accurate and reliable test result, good repeatability and wide application range, thus having very good application prospect.

Owner:TONGJI UNIV

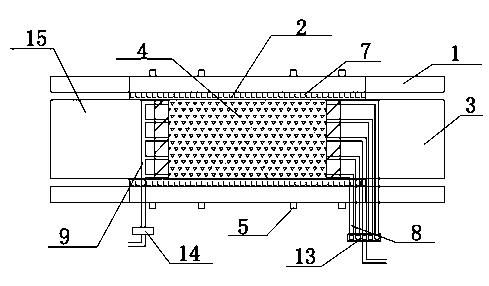

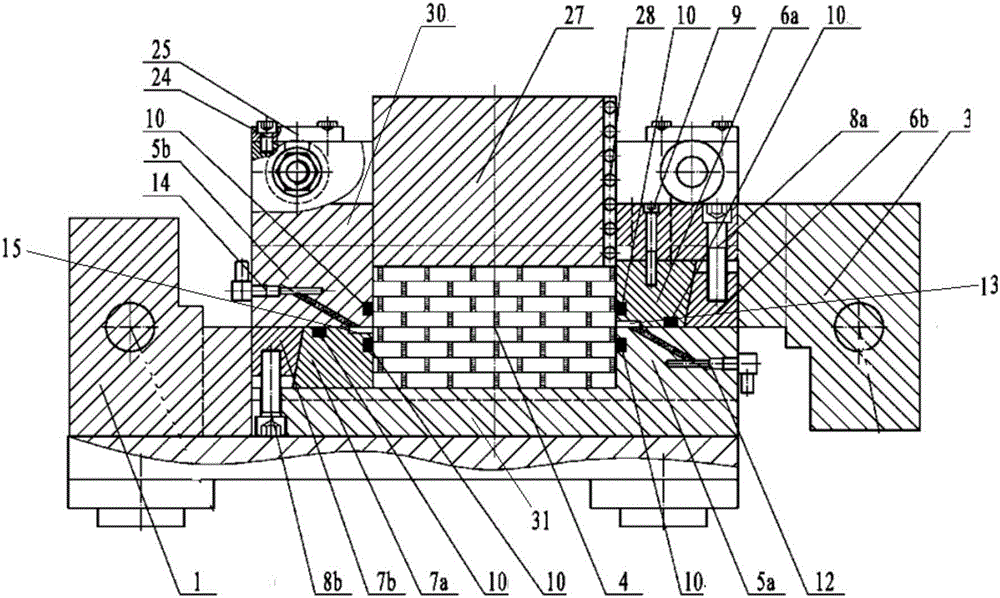

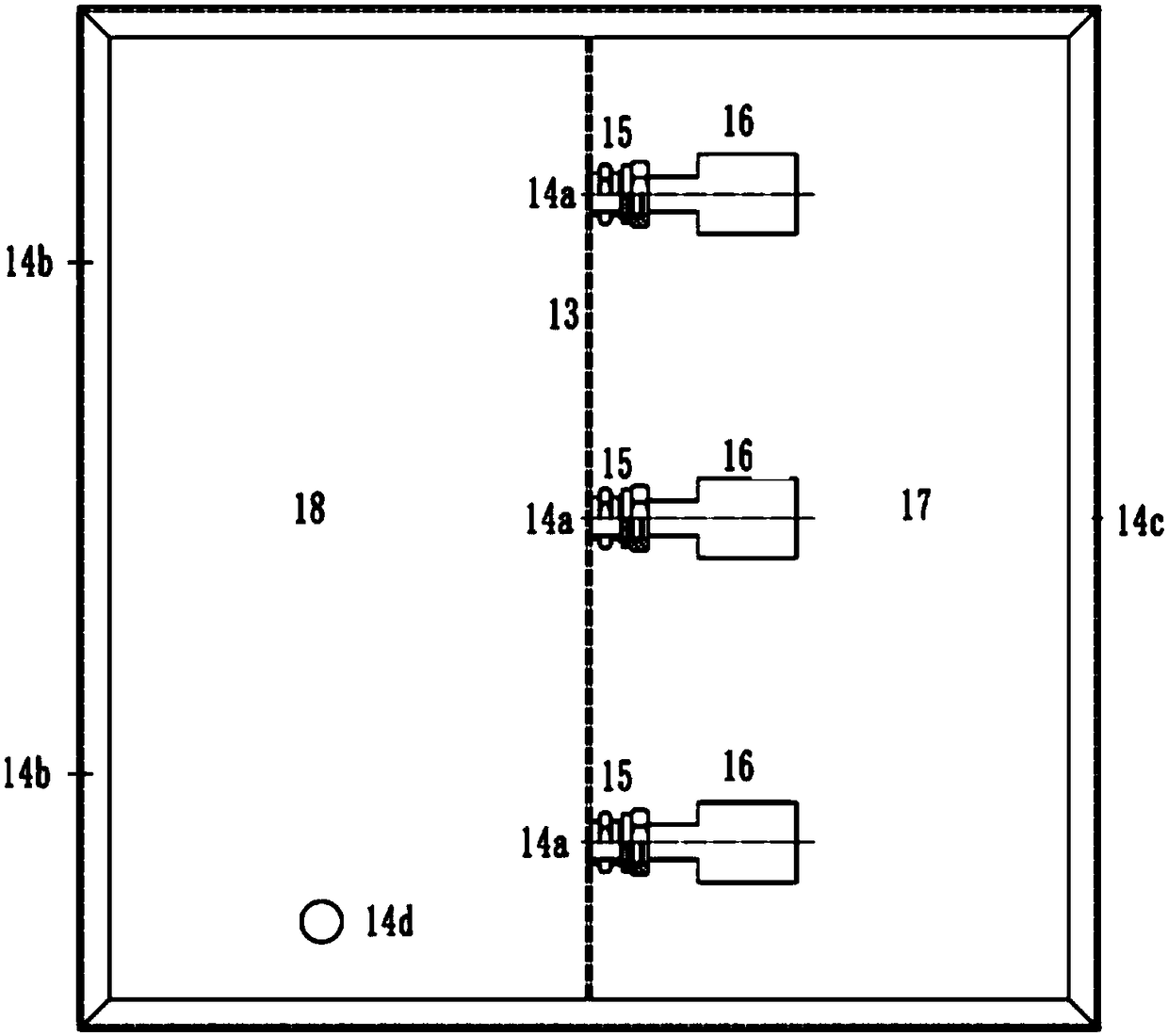

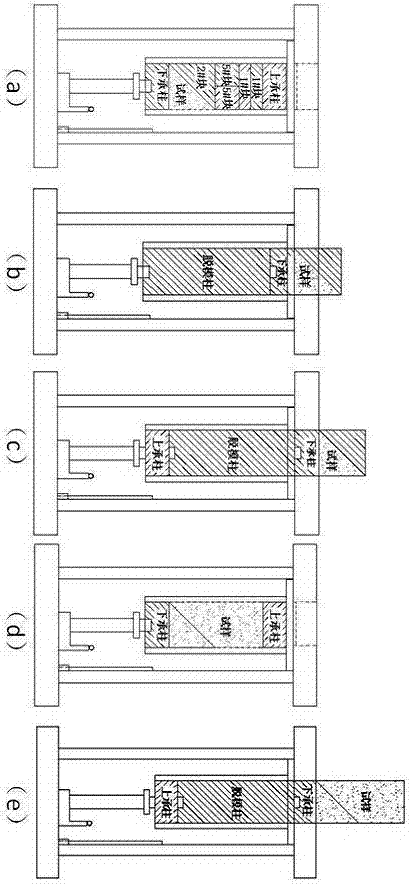

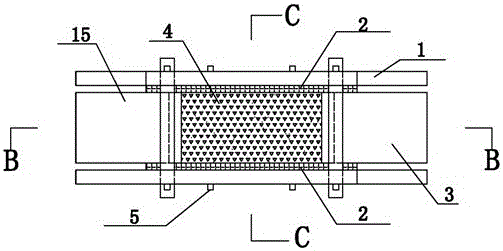

Shearing seepage box for full shearing-seepage coupling test for rock joint under high permeability pressure

ActiveCN106769780AStabilize water pressureSolve the problem of pressure control accuracyPermeability/surface area analysisCouplingNatural state

The invention relates to a shearing seepage box for a full shearing-seepage coupling test for a rock joint under high permeability pressure. The shearing seepage box comprises an upper box body, a lower box body, lateral plates, a bearing platform and a normal loading cushion block, wherein the upper box body and the lower box body are used for accommodating a rock sample; the lateral plates are arranged on the two sides along the width direction of the rock sample; the bearing platform is arranged at the bottom of the lower box body; the normal loading cushion block is pressed on the rock sample; the upper box body, the lower box body and the lateral plates are jointly formed into a chamber for accommodating the rock sample; the lower box body is fixed with the lateral plates through bolts; a straight rail is arranged on the middle parts of the lateral plates; the upper box body is placed on the straight rail; a water entering channel which is communicated with the chamber is arranged in the upper box body; a water draining channel which is communicated with the chamber is arranged in the lower box body. Compared with the prior art, the invention has the advantages that the test condition is more approximate to a true seepage condition of the rock in the engineering, the sealing in the shearing process of the rock joint sample can be effectively realized, high permeability water pressure can be endured, the test precision is high and the full shearing-seepage coupling test for the rock joint under natural state can be more effectively simulated.

Owner:TONGJI UNIV +1

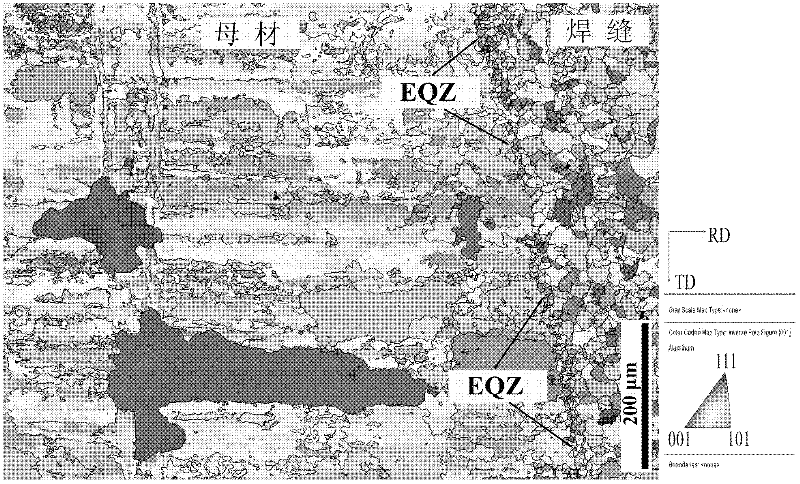

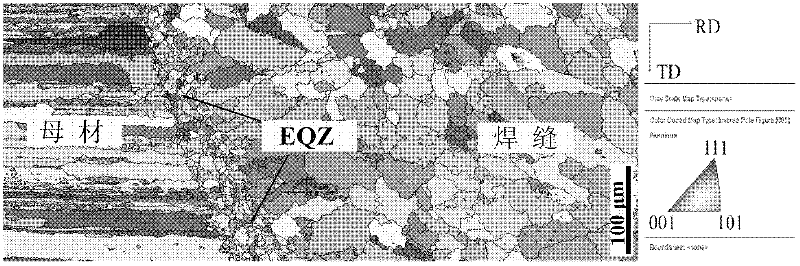

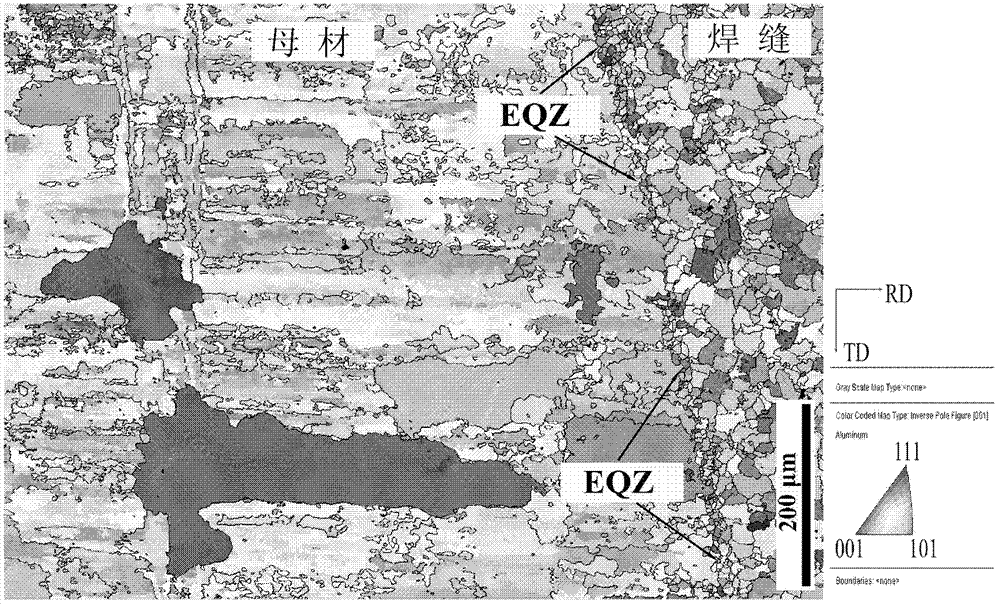

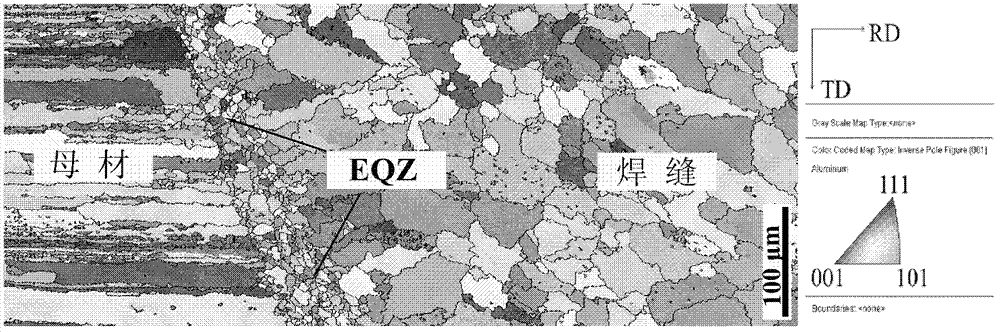

Method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding

InactiveCN102507619AQuality improvementConfidenceMaterial analysis using wave/particle radiationPreparing sample for investigationLithiumElectron

The invention discloses a method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding, belonging to the technical field of material analysis. The method comprises the following steps of mechanical polishing of a joint sample, preparation of electrolytes, electrolytic polishing, EBSD (Electron Back Scattering Diffraction) test and the like. The method disclosed by the invention has the advantages of successfully solving the difficult problem of displaying the EQZ textures of the welded joints and the fusion zones of the 5A90 aluminum-lithium alloy laser welding, and clearly displaying the characteristics, such as form, size and grain orientation, of the EQZ textures of the welded joints and the fusion zones of the 5A90 aluminum-lithium alloy laser welding. The method disclosed by the invention has the advantages of simpleness in equipment, convenience for operation, and capability of being applied to observation of the EQZ textures of fusion zones of various types of aluminum alloy welded joints.

Owner:BEIJING UNIV OF TECH

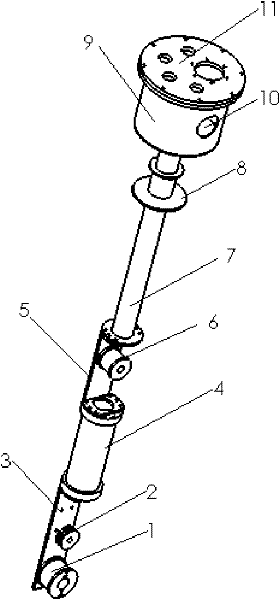

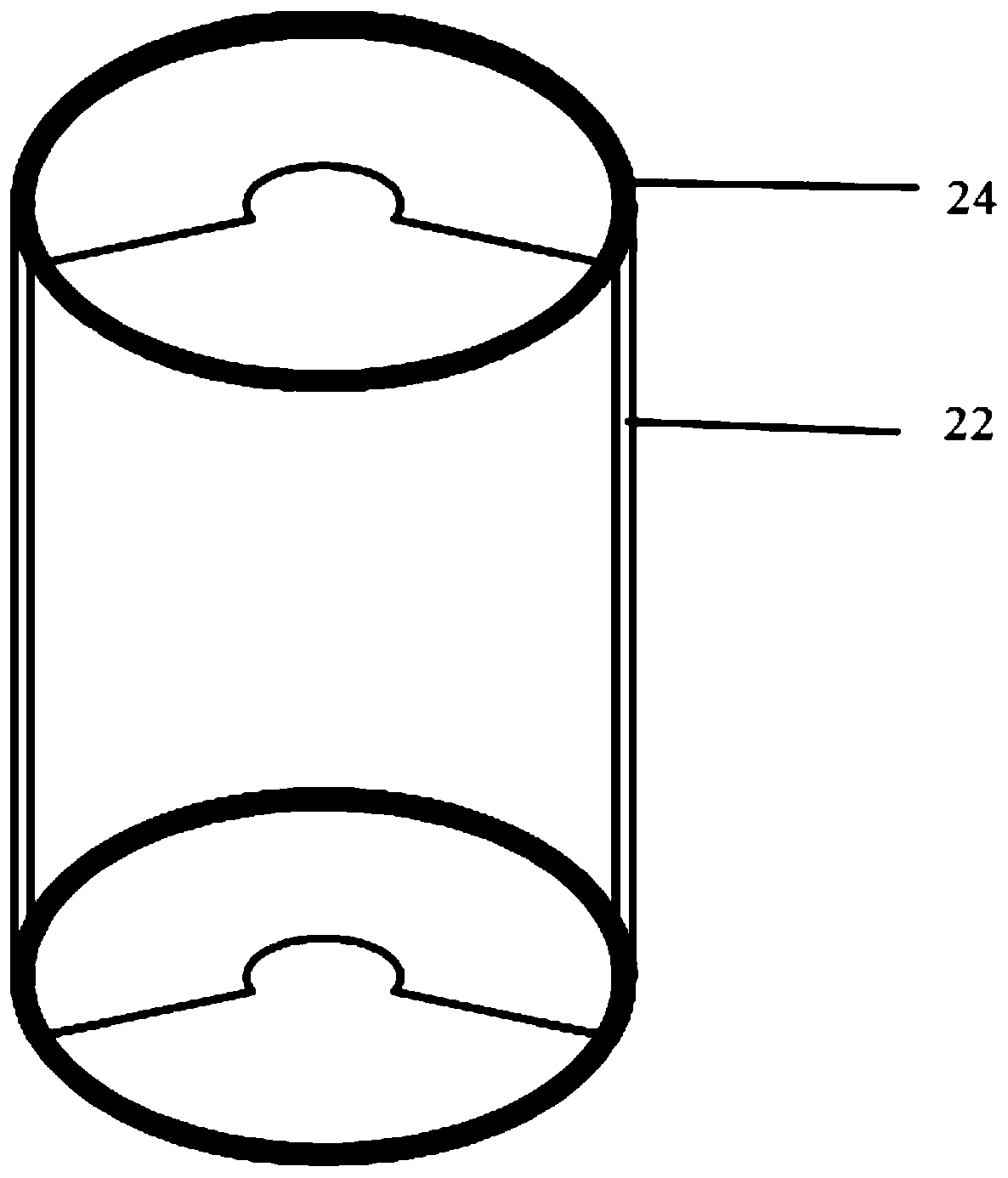

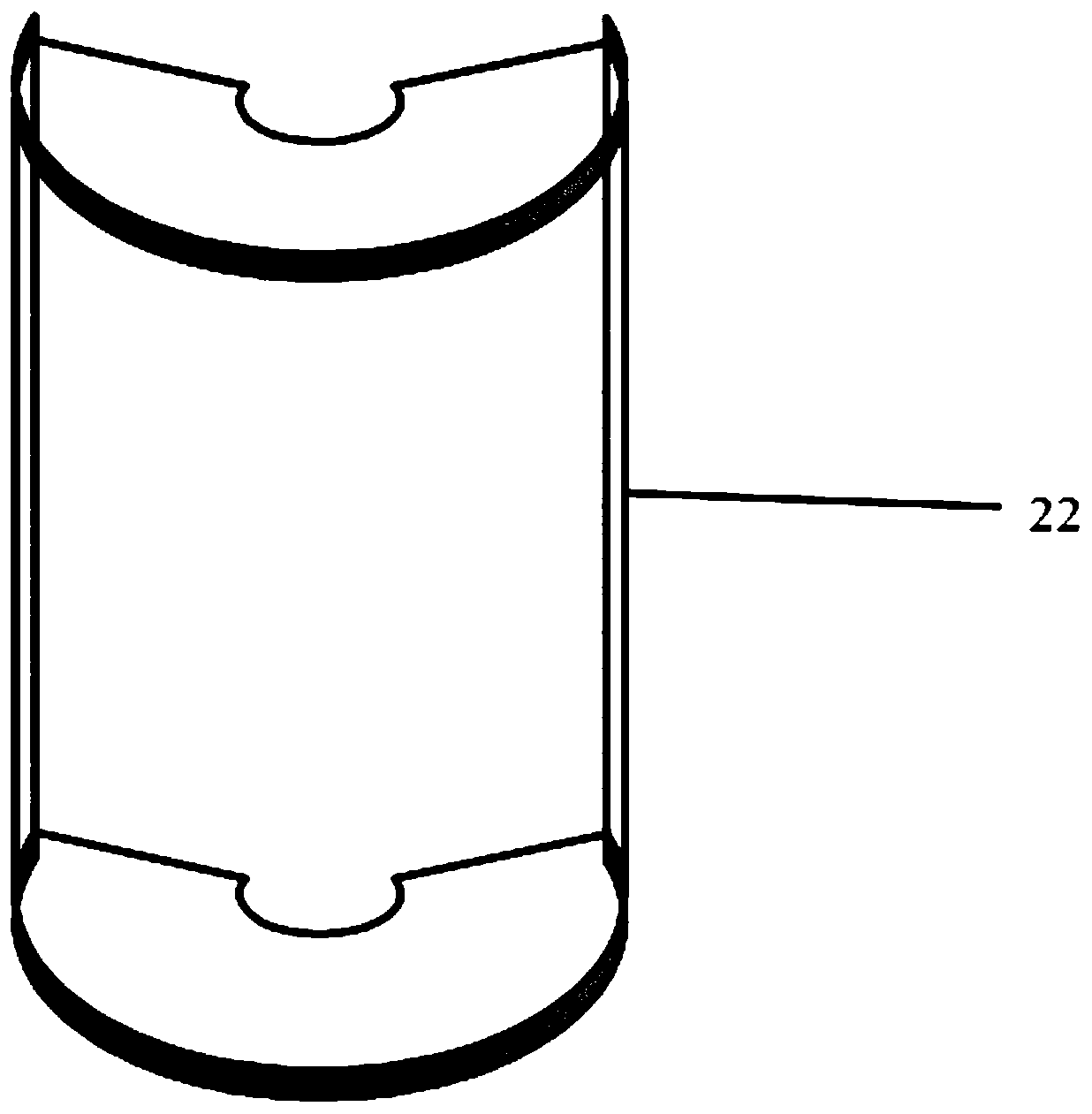

Real-time three-dimensional CT (computed tomography) scanning type rock joint shear test system

PendingCN106353201ADoes not affect the scanning effectGuaranteed StrengthMaterial strength using steady shearing forcesMaterial analysis by transmitting radiationThree dimensional ctComputed tomography

A real-time three-dimensional CT (computed tomography) scanning type rock joint shear test system comprises a shear chamber, a mainframe framework, a loading device, a rotating device and a CT scanning device. The shear chamber is a hollow cylindrical shear chamber, and a rock joint sample is positioned in the shear chamber. An action end of the loading device is connected with a rotating gasket which is connected with a pressure block, the pressure block penetrates the outer wall of the shear chamber to abut against one side of a half portion of the rock joint sample, the other side of the half portion of the rock joint sample is positioned on a spring retaining plate which is fixed in the shear chamber, and the other half portion of the rock joint sample is fixed in the shear chamber. The rotating device comprises a rotating mechanical support frame and a driving component used for driving the rotating mechanical support frame to rotate, the rotating mechanical support frame is in linkage with the shear chamber, and the rotating mechanical support frame, the shear chamber and the rotating gasket are in coaxial arrangement. The CT scanning device comprises a radioactive source and a detector, and the radioactive source and the detector are arranged on two opposite sides of the shear chamber. The real-time three-dimensional CT scanning type rock joint shear test system has advantages that 360-degree scanning is effectively realized, and great real-time performance is achieved.

Owner:SHAOXING UNIVERSITY

Loading robot arm control multipoint mapping intelligent control method and system

ActiveCN107253194AImprove stabilityEasy maintenanceProgramme controlProgramme-controlled manipulatorKinematicsKinematics equations

The invention discloses a loading robot arm control multipoint mapping intelligent control method and system. The method comprises the first step of conducting grabbing training multiple times for a loading robot arm to obtain a grabbing sample set when a loading robot completes a grabbing task in different fixed grabbing points; the second step of conducting joint classification on the grabbing sample set according to the change amplitude a% of all arm joint control values to obtain various joint sample sets; the third step of using the joint sample sets obtained in the second step to construct a prediction model of loading robot arm joint control values; the fourth step of regarding the distance between a loading robot base and the edge of the bottom end of a grabbing table as an input value, and through a prediction model, obtaining control values of all joints respectively, and outputting the control values to complete the control over the grabbing task. According to the loading robot arm control multipoint mapping intelligent control method and system, by constructing the map between the distance of the robot base and the grabbing platform and a robot arm posture, complicated construction of a kinematical equation is avoided; accurate joint control values are obtained, and the joints are flexibly controlled.

Owner:CENT SOUTH UNIV

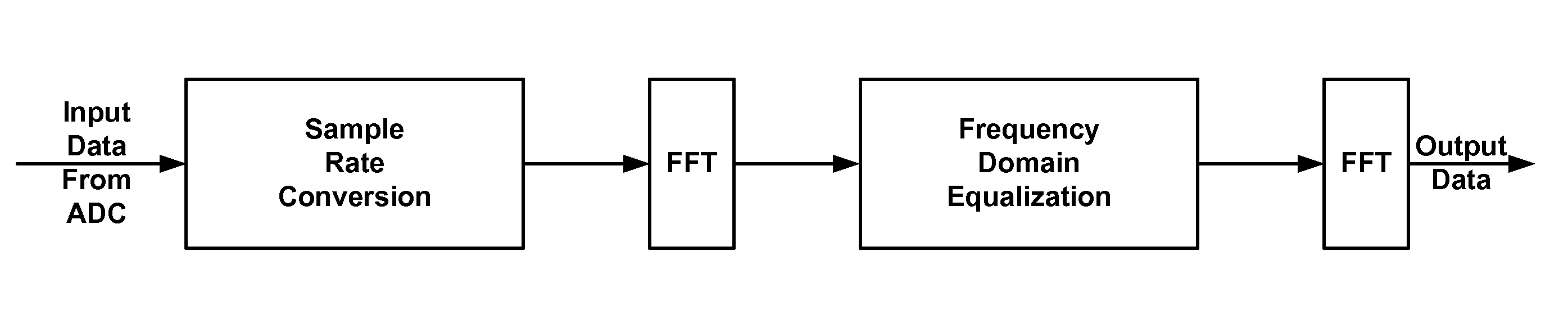

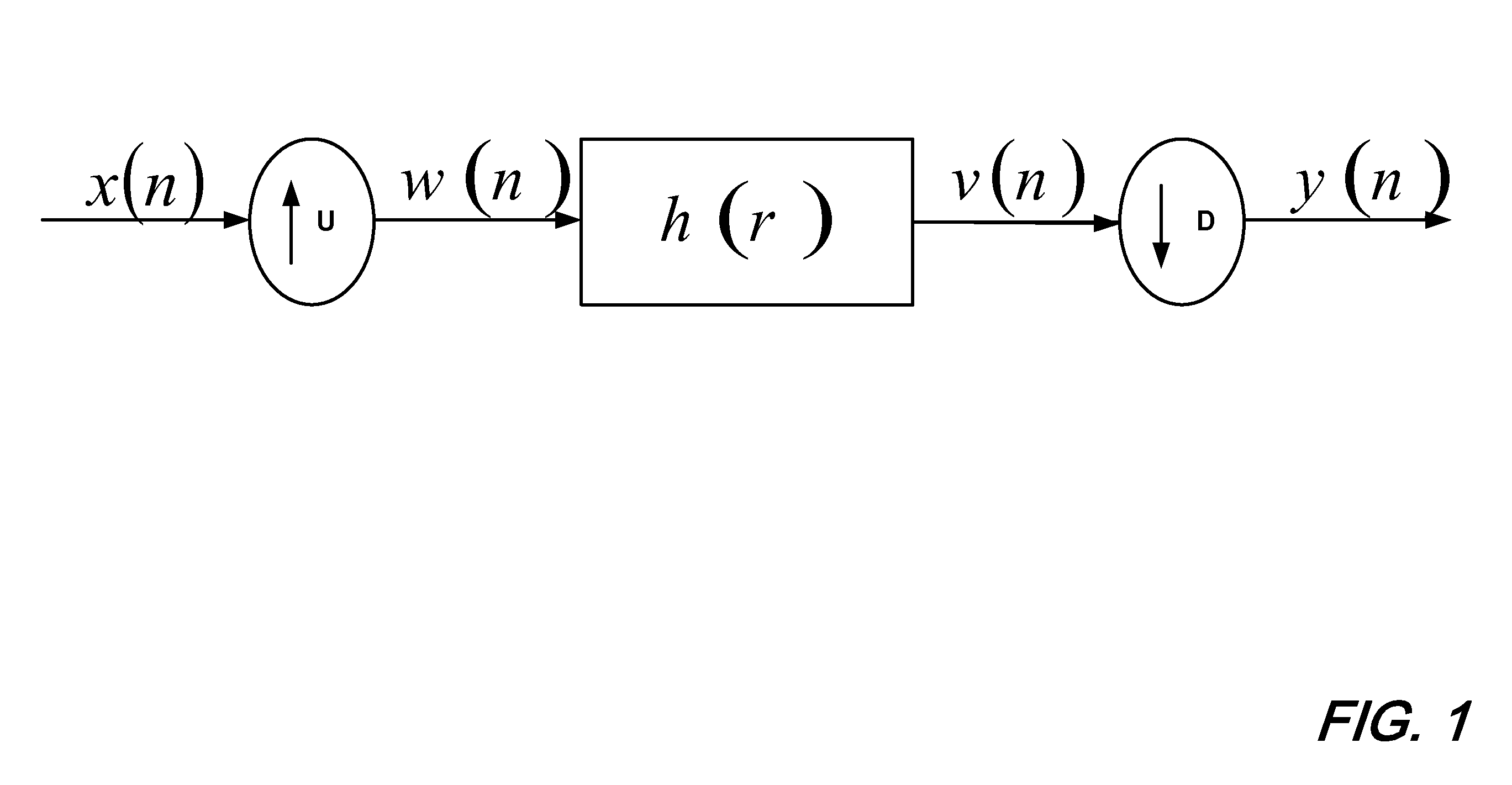

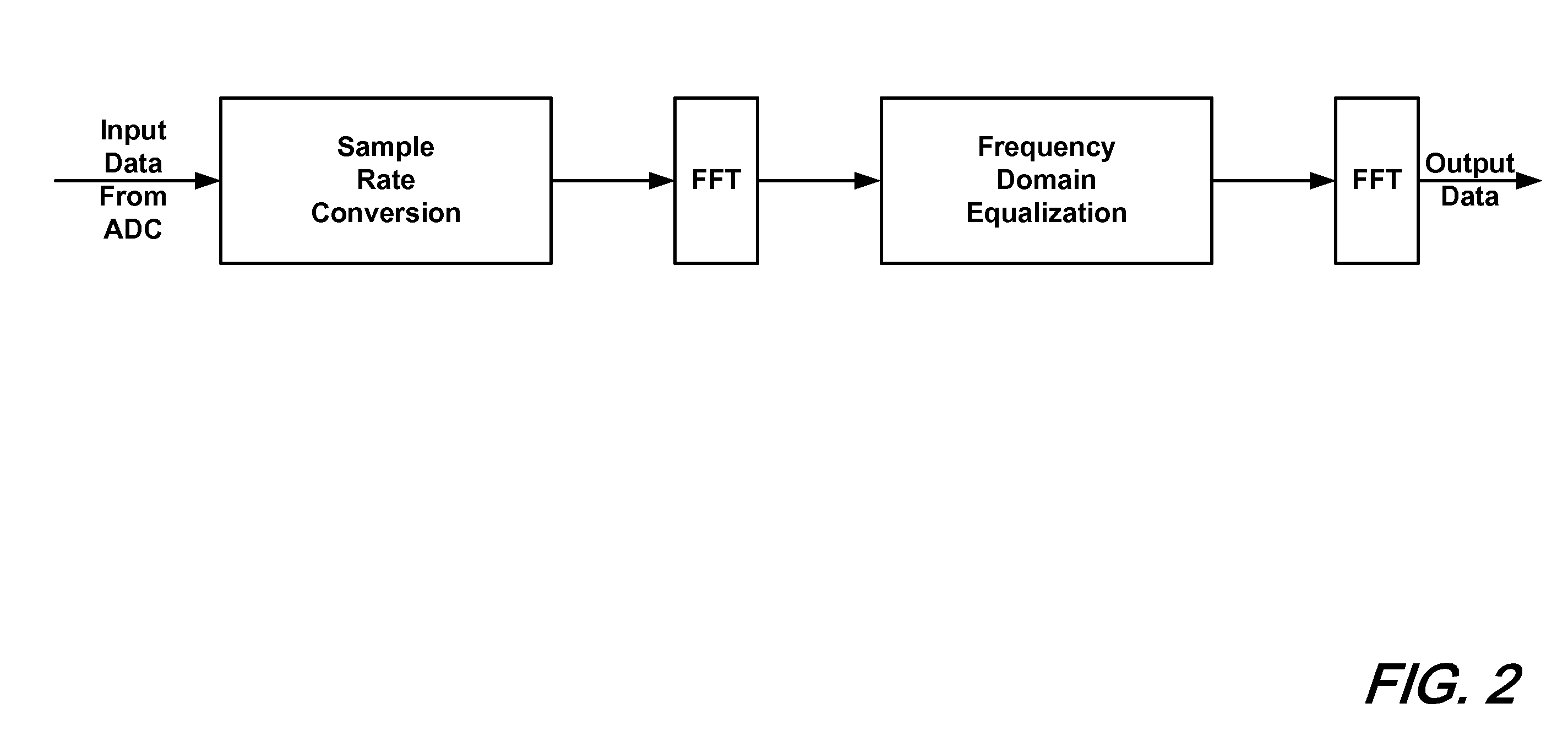

Joint sample rate conversion and CD compensation in frequency domain for coherent polmux

InactiveUS20110182582A1Less complexEasy to implementPolarisation multiplex systemsDistortion/dispersion eliminationSample rate conversionEngineering

Owner:NEC LAB AMERICA

Tester assembled by multiple sets of mechanisms for shear strength-scale effect of rock joint

ActiveUS10197483B2Improve reliabilityLow reliabilityMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringTest requirements

A tester assembled by multiple sets of mechanisms for shear strength-scale effect of a rock joint includes a horizontal loading mechanism, a horizontal supporting and force-measuring mechanism and a sample installation and lifting table are mounted on a platform on the bottom of a frame, the horizontal loading mechanism and the horizontal supporting and force-measuring mechanism are respectively located on two sides of the sample installation and lifting table; rock joint sample is divided into an upper portion and a lower portion by a slit, the horizontal loading mechanism is configured to load the upper portion of the multi-scale rock joint sample, and the horizontal supporting and force-measuring mechanism is configured to support the lower portion of the multi-scale rock joint sample; a vertical loading mechanism is located above the multi-scale rock joint sample, and can be mounted on the frame in a manner of being movable up and down; and the horizontal loading mechanism comprises at least two tangential actuators, and the vertical loading mechanism comprises a vertical actuator group including at least two vertical actuators. The present invention effectively meets the test requirements on the scale of the multi-scale rock joint samples under large-range loads, and is good in reliability.

Owner:SHAOXING UNIVERSITY

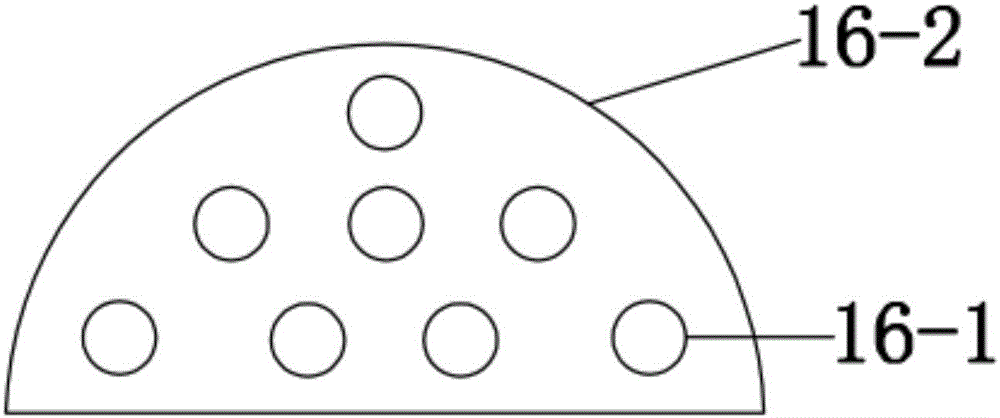

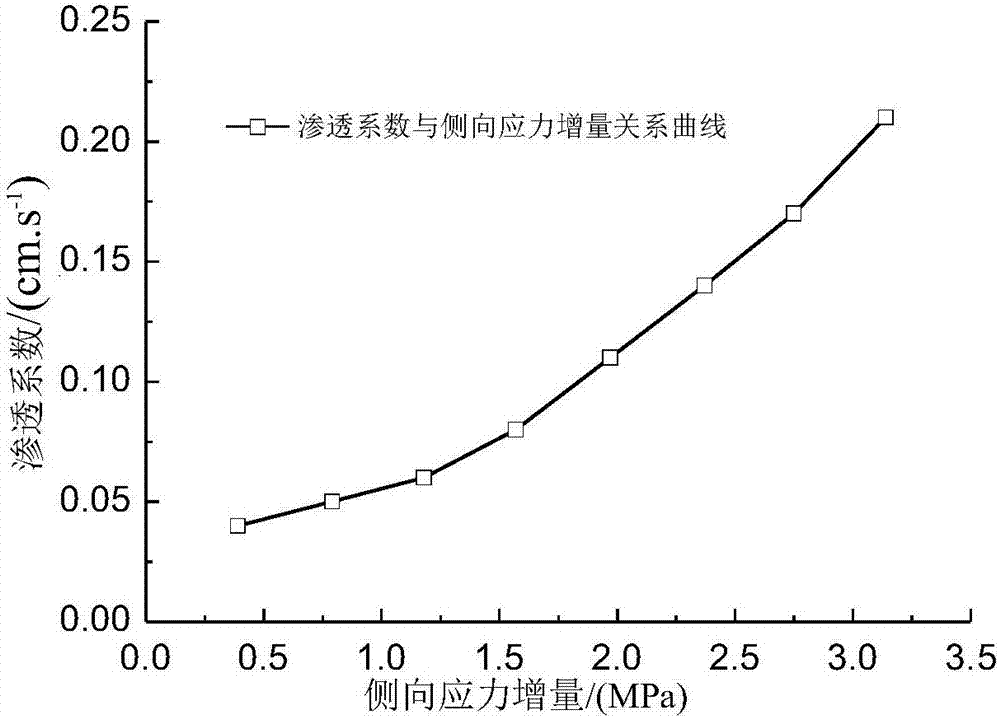

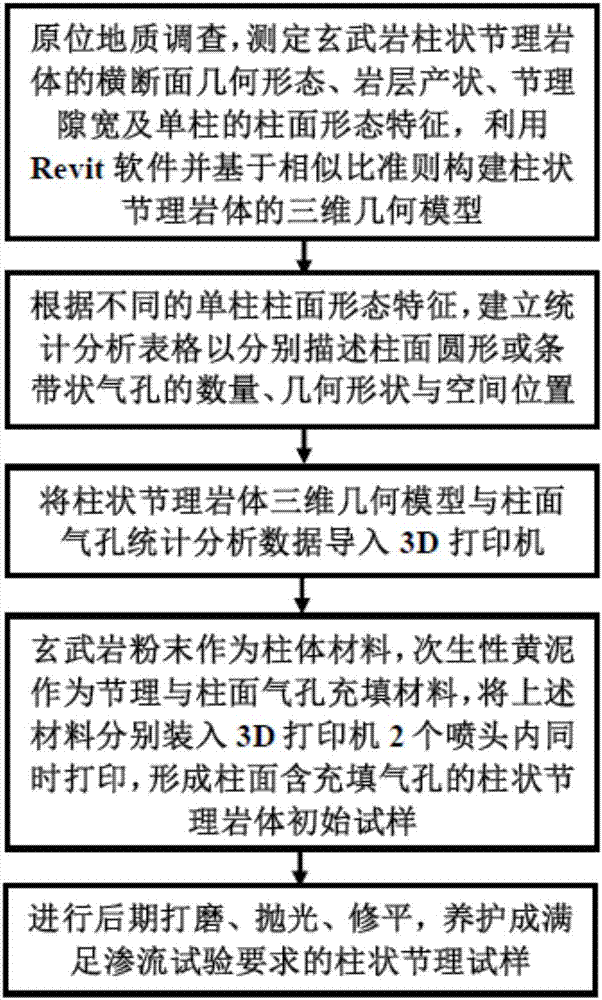

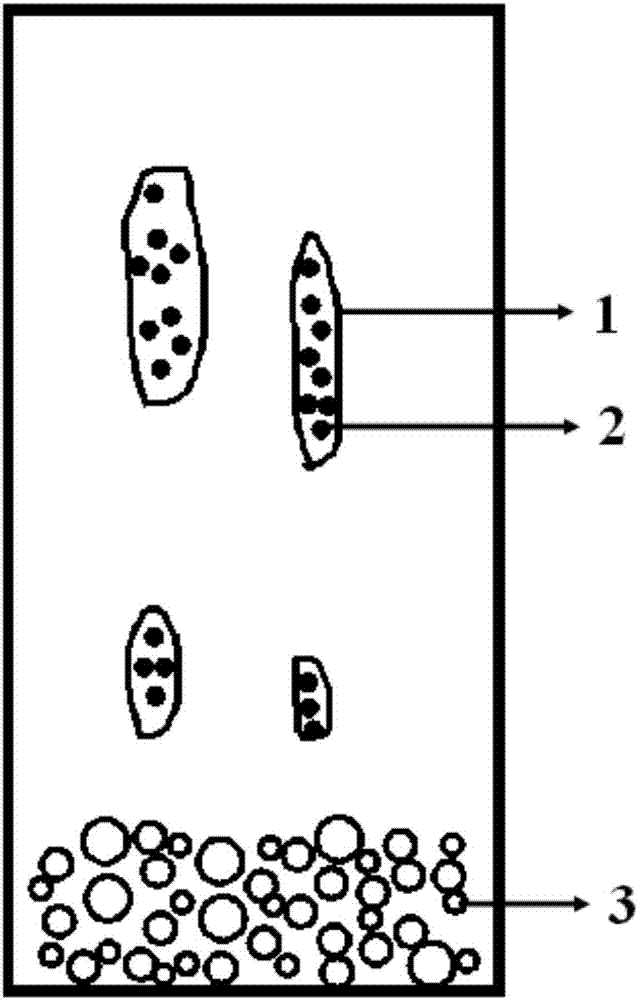

Preparation method of columnar joint rock sample with filled pores in columnar surface

ActiveCN106908289AGood repeatabilityEasy to operatePreparing sample for investigationStatistical analysisRock sample

The invention discloses a preparation method of a columnar joint rock sample with filled pores in a columnar surface. The preparation method comprises the following steps: measuring the cross section geometrical morphology, the rock stratum attitude, the joint gap width and the single columnar surface morphological characteristics of a columnar joint basalt rock, and establishing a three-dimensional model of the columnar joint rock by virtue of Revit software and based on a similarity ratio criteria; according to different single columnar surface morphological characteristics, establishing a statistical analysis form; introducing the three-dimensional geometrical model of the columnar joint rock and statistical analysis data of the columnar surface pores into a 3D printer; taking basalt powder as a column material and secondary yellow mud as a joint and columnar surface pore filling material, charging into double nozzles of the 3D printer respectively, and printing at the same time to form an initial columnar joint rock sample; in the later stage, performing grinding, polishing, leveling and curing to obtain the columnar joint sample meeting requirements of a seepage test. The sample prepared with the preparation method provided by the invention can really reflect the distribution state of the filled columnar surface pores, and can be used for studying the influence of the filled columnar surface pores on seepage characteristics of a columnar joint surface.

Owner:HOHAI UNIV

Manufacturing and measuring method for low temperature resistance measurement system of CICC superconductive joint

InactiveCN103336179AMeasurable resistance performanceAccurate measurementResistance/reactance/impedenceYarnPotential measurement

The invention discloses a manufacturing and measuring method for a low temperature resistance measurement system of a CICC superconductive joint. Two to-be-detected superconductive joints, a U-shaped CICC conductor, a U-shaped CICC conductor with two coils, a superconductive coil formed by dense winding of Nb Ti folded yarns, a Hall sensor, and an electric potential measuring lead wire are included. The method comprises the following steps: firstly, calibrating the relation of current and a magnetic field of an entire measurement system by using the Hall sensor at a room temperature; then soaking the entire measurement system into liquid helium so as to realize low temperature work environment; inducting heavy current in the loop of the CICC conductor by changing the working current of a primary coil composed of the superconductive coil formed by dense winding of the Nb Ti folded yarns; calculating the induced current of the entire loop through voltage signals of the Hall sensor; measuring out the resistance performance of the CICC superconductive joint through voltages at the two ends of the electric potential signal measuring joints at the two ends of the joint. According to the invention, measurement to the low temperature resistance performance of a superconductive joint sample can be achieved at a lower cost, accurately and reliably.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

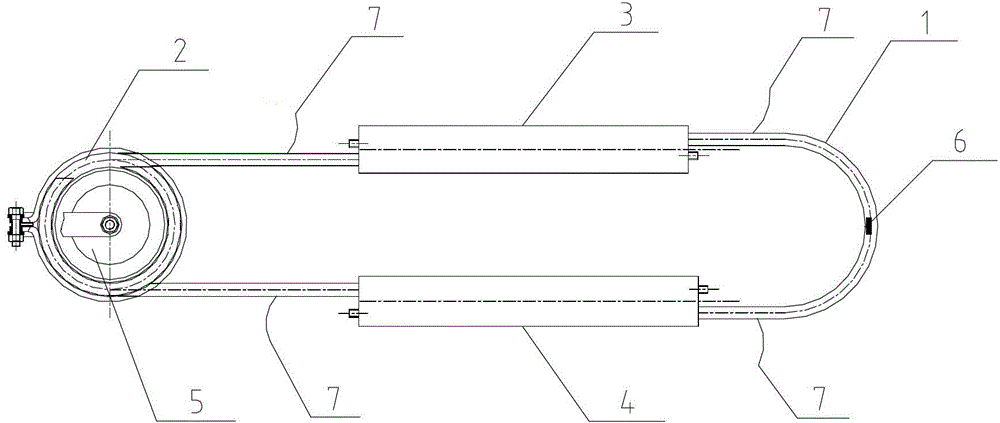

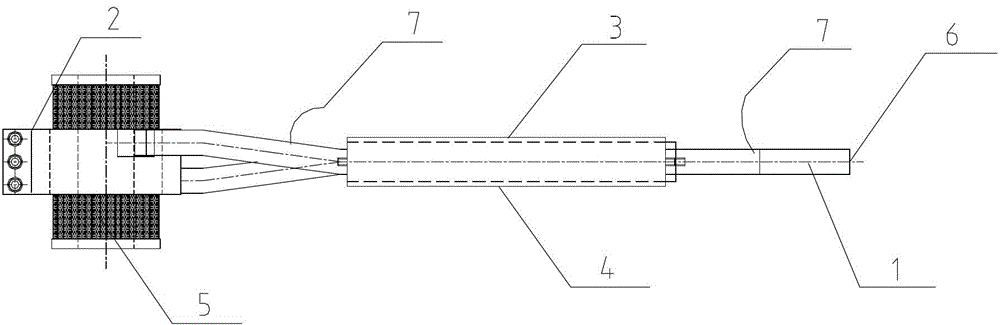

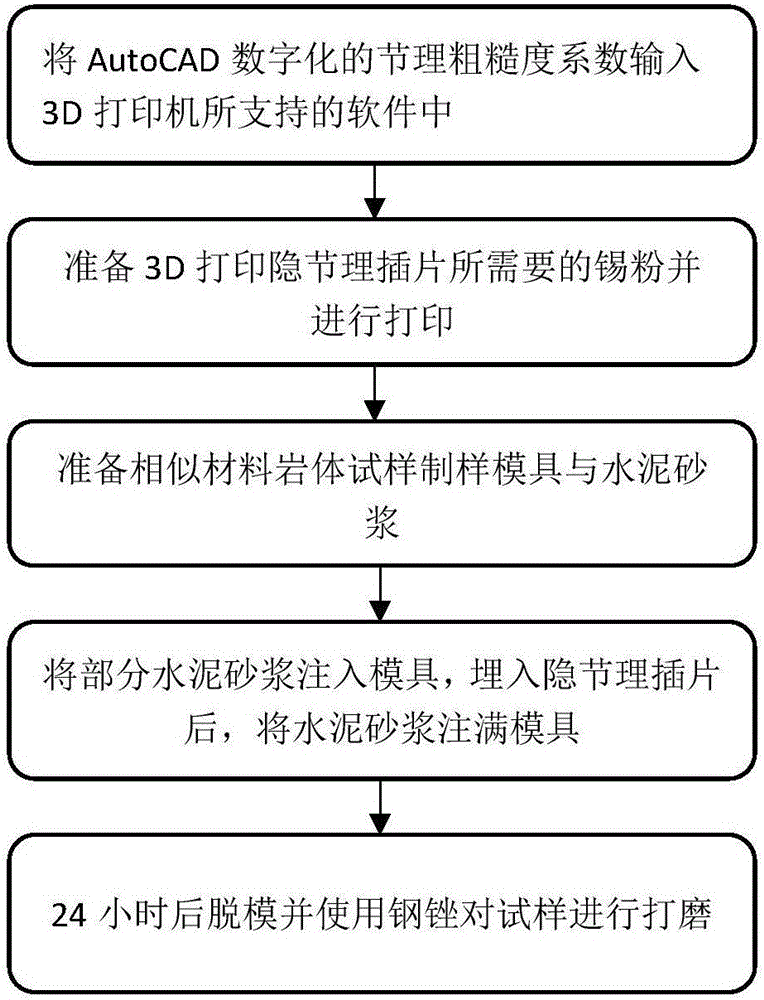

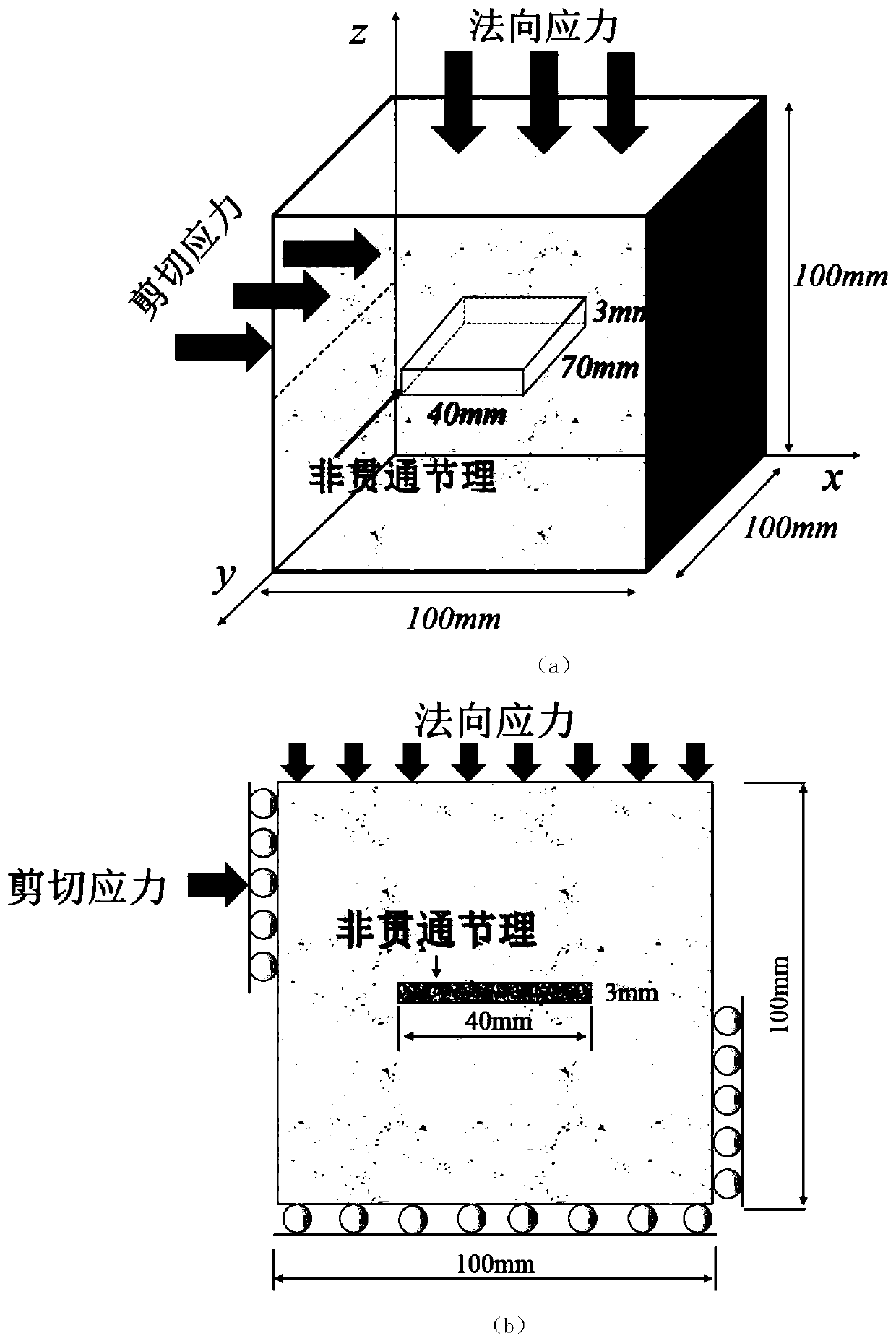

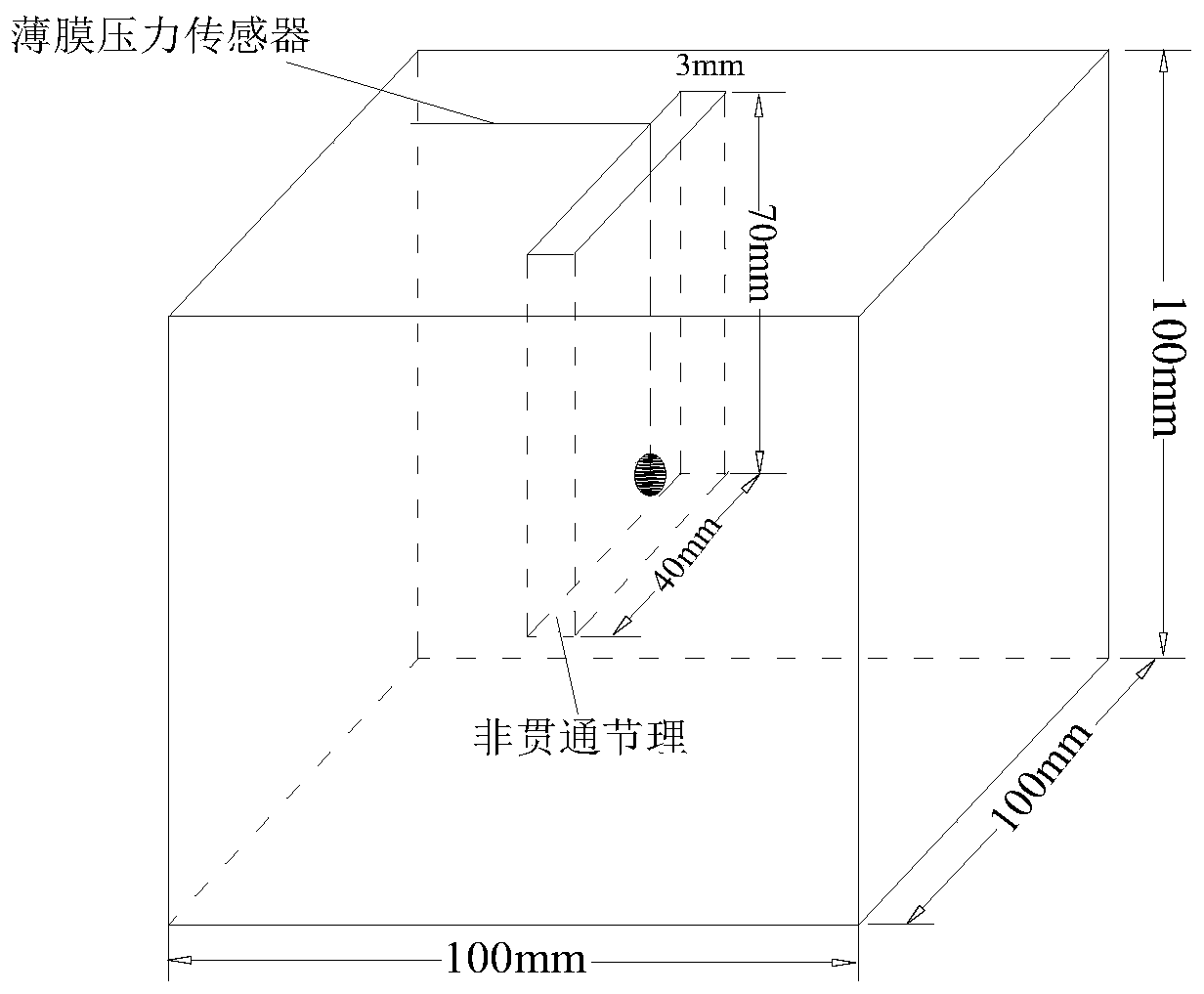

Preparation method and preparation mold of blind-joint rock mass model sample containing different joint roughness

InactiveCN106769321AHigh precisionRealistic effect of simulated joint roughnessPreparing sample for investigationModel sampleAdhesive glue

The invention discloses a preparation method of a blind-joint rock mass model sample containing different joint roughness. The preparation method comprises the following steps: modeling blind-joint samples containing different joint roughness, digitalizing a standard contour curve of joint roughness coefficients, inputting the digitized joint roughness curve to a computer, and connecting with a 3D printer; preparing a powdery raw material and adhesive glue required for the 3D printer, loading into the 3D printer, and printing blind-joint inserts according to a set joint roughness curve; cutting the printed blind-joint inserts to obtain blind-joint pieces required for tests; pouring part of cement mortar into a mold, placing the blind-joint pieces, filling the mold with the cement mortar; curing until the cement mortar is solidified and formed to form a sample part beginning to take a shape, and then demolding; polishing the sample to obtain the blind-joint rock mass model sample containing different joint roughness and satisfying test requirements. The method can be used for accurately preparing the blind-joint rock mass model sample containing different joint roughness.

Owner:HOHAI UNIV

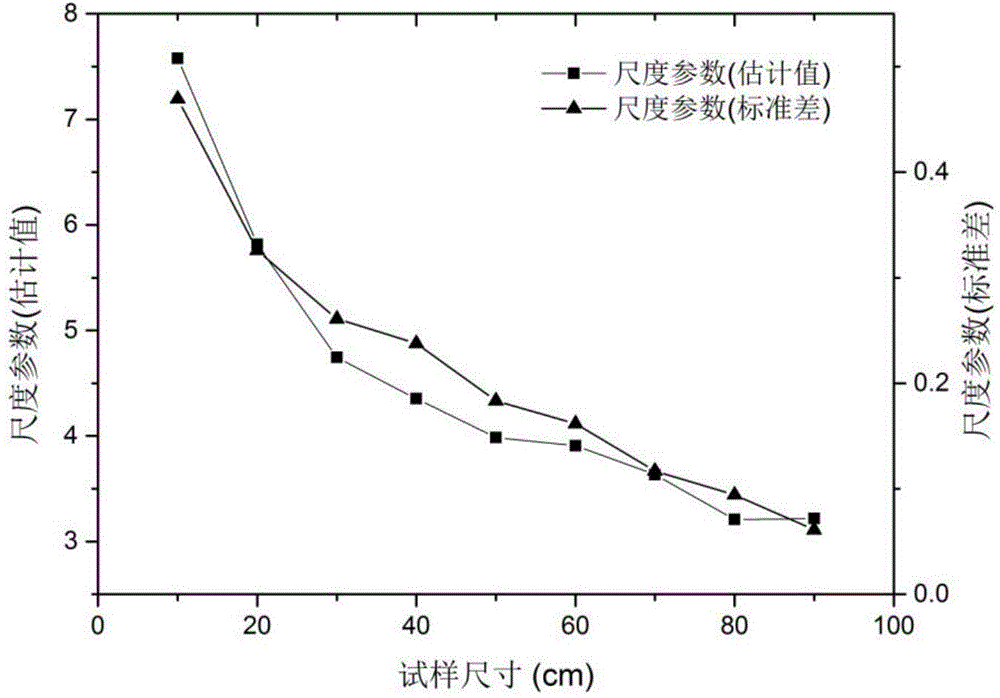

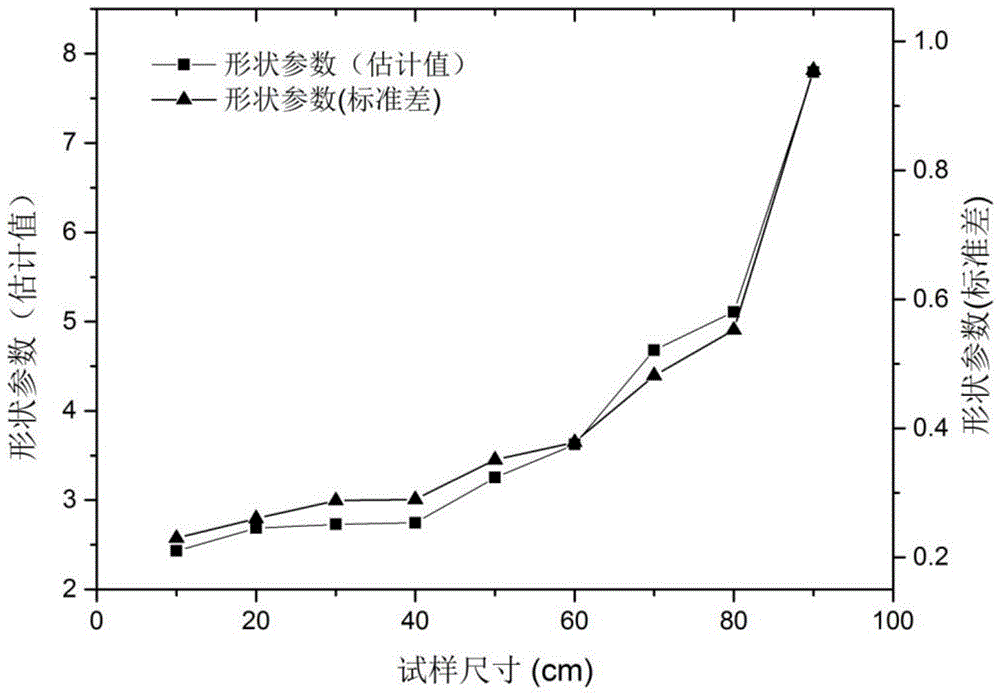

Establishing method of joint roughness coefficient size effect probability density function model

ActiveCN104881564AGood estimateQuick estimateSpecial data processing applicationsNormal densityFunctional relation

The invention relates to an establishing method of a joint roughness coefficient size effect probability density function model. The method includes the following steps: according to a joint contour line directional measurement result, adopting a large scanner to scan a drawing recording a joint contour line, and converting the drawing into picture format text; according to surface coordinate information of joint samples, adopting a Barton straight-edge simple formula to calculate roughness coefficient of a series of samples; based on phenomenological and significance test, respectively performing Weibull probability density function fitting (1) on general distribution of all size sample data; discovering functional relation among scale parameters a, shape parameter b and sample size 1 in Weibull distribution, and further establishing the joint roughness coefficient size effect probability density function model (2). By the method, influences of size effect on statistical laws of joint roughness coefficients can be described accurately, so that shear strength of joints in a series of sizes can be estimated conveniently and quickly.

Owner:SHAOXING UNIVERSITY

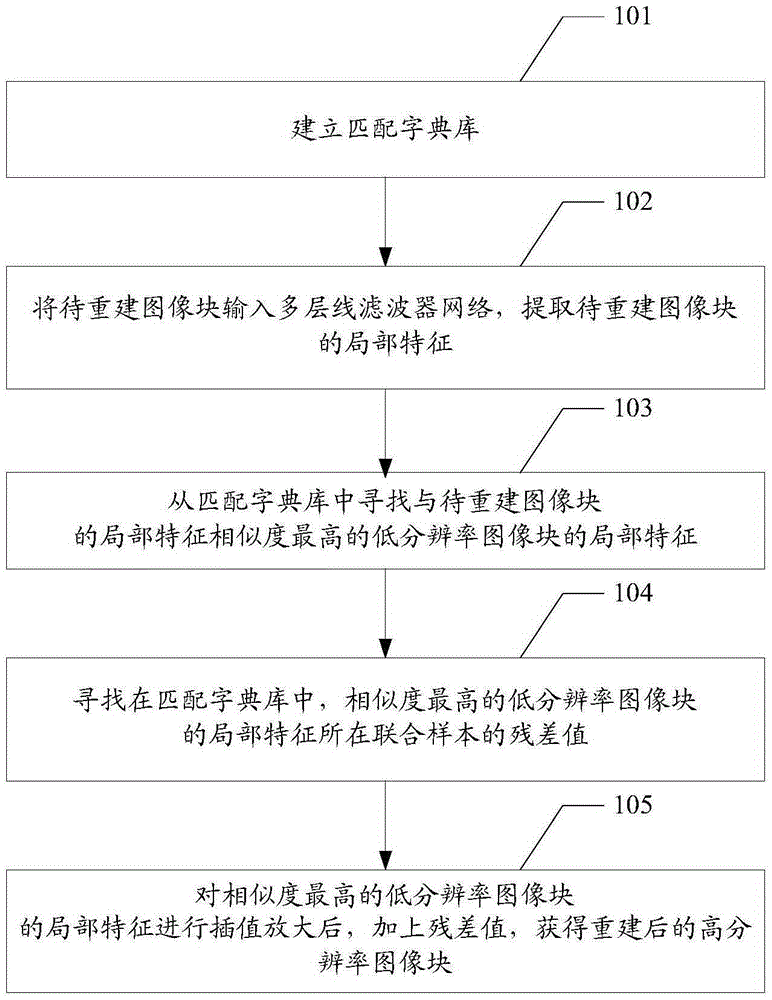

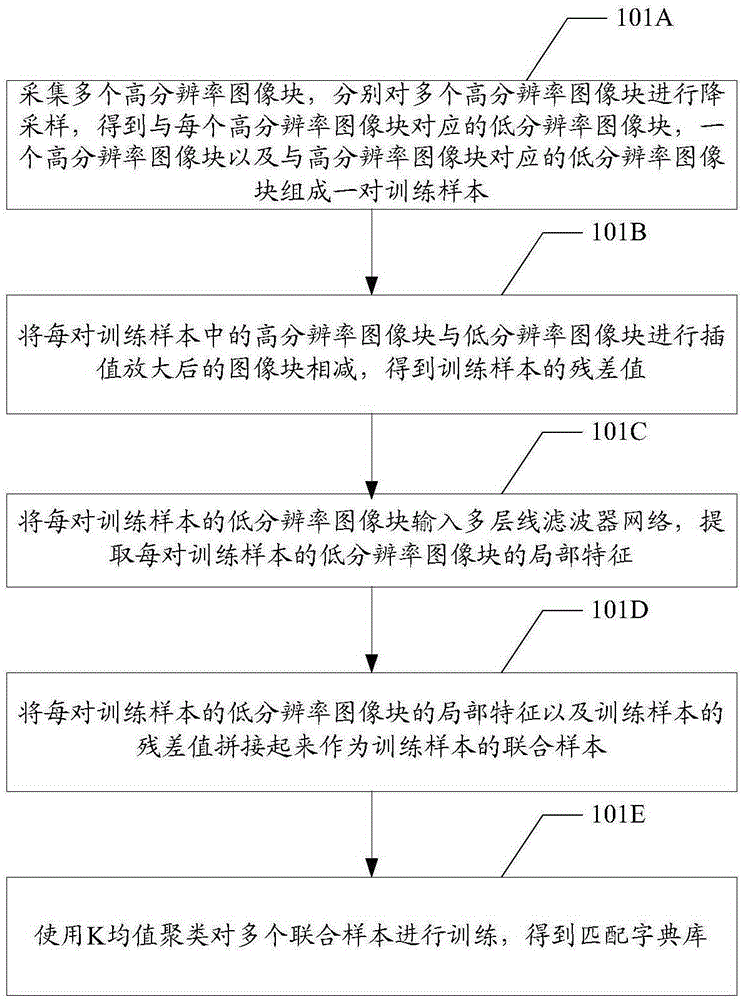

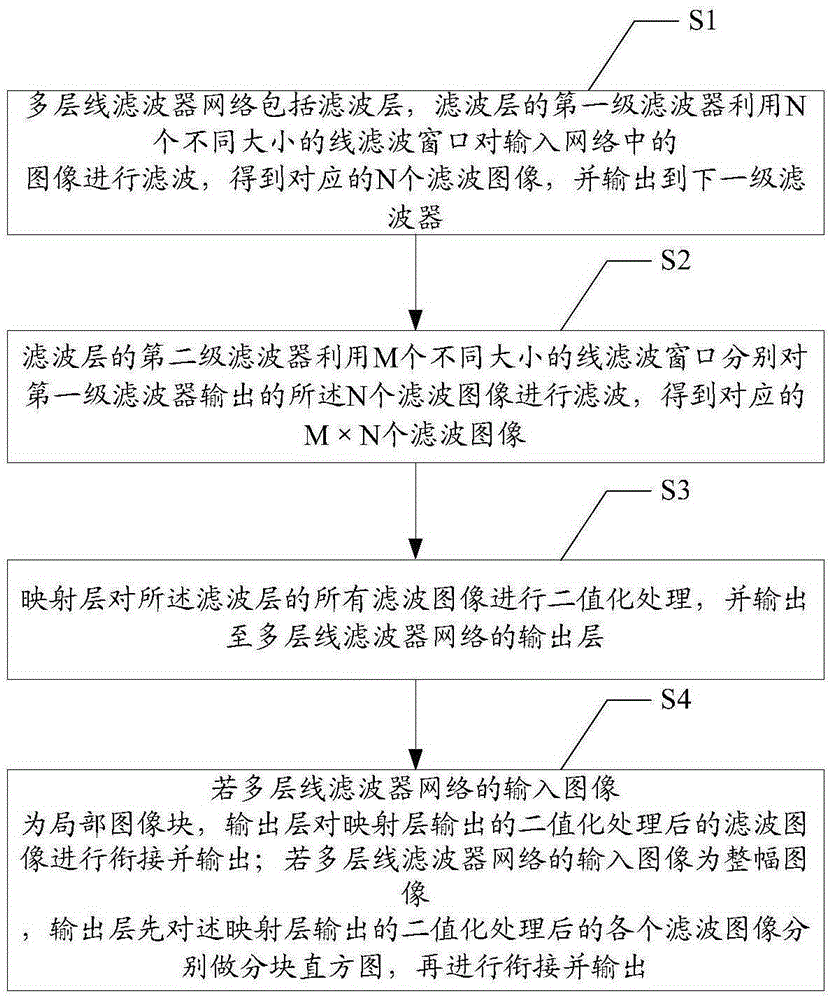

Image super resolution reconstruction method and device based on dictionary matching

ActiveCN105389778AQuality improvementHigh precisionGeometric image transformationPattern recognitionImage resolution

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Rock joint shearing test device

InactiveCN107014702AAvoid collisionSmooth goingMaterial strength using steady shearing forcesEngineeringJoint surface

The invention relates to a rock joint shearing test device. The device comprises an upper shear box and a lower shear box which are symmetrically arranged, wherein cavities for placing a rock joint sample are respectively formed in the middle part of the upper shear box and the lower shear box; the lower shear box is fixedly arranged on a base; a metal block presses on the top of the rock joint sample; grooves are arranged in the middle part of the upper shear box and the lower shear box and communicated with one ends of the cavities; the widths of the grooves are same as the widths of the cavities; and the lengths of the grooves in the shear direction are slightly greater than the shear displacement in the test. Compared with the prior art, the device has the beneficial effects that channels are arranged in places where the upper and the lower shear boxes are in contact and roller rows are placed in the channels, the upper shear box is elevated by utilizing the roller rows and space equivalent to the joint surface roughness between the upper and the lower shear boxes is left; and the contact area of the upper and the lower shear boxes can be reduced after arranging the roller rows, and the influence of the frictional resistance between the two shear boxes in the shear moving process on the test is reduced.

Owner:TONGJI UNIV

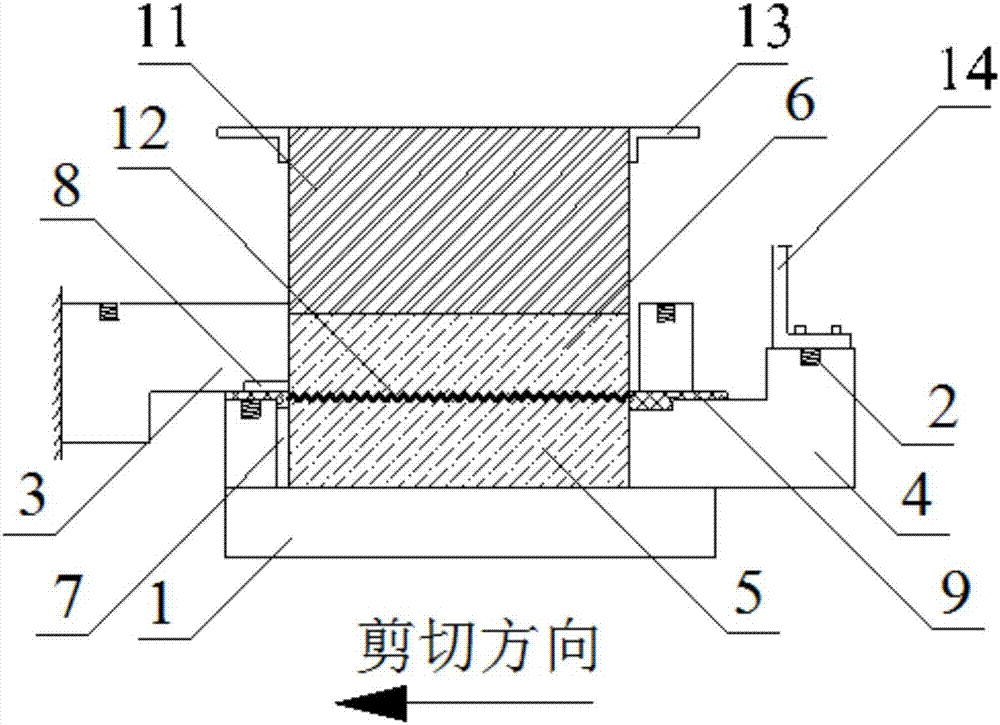

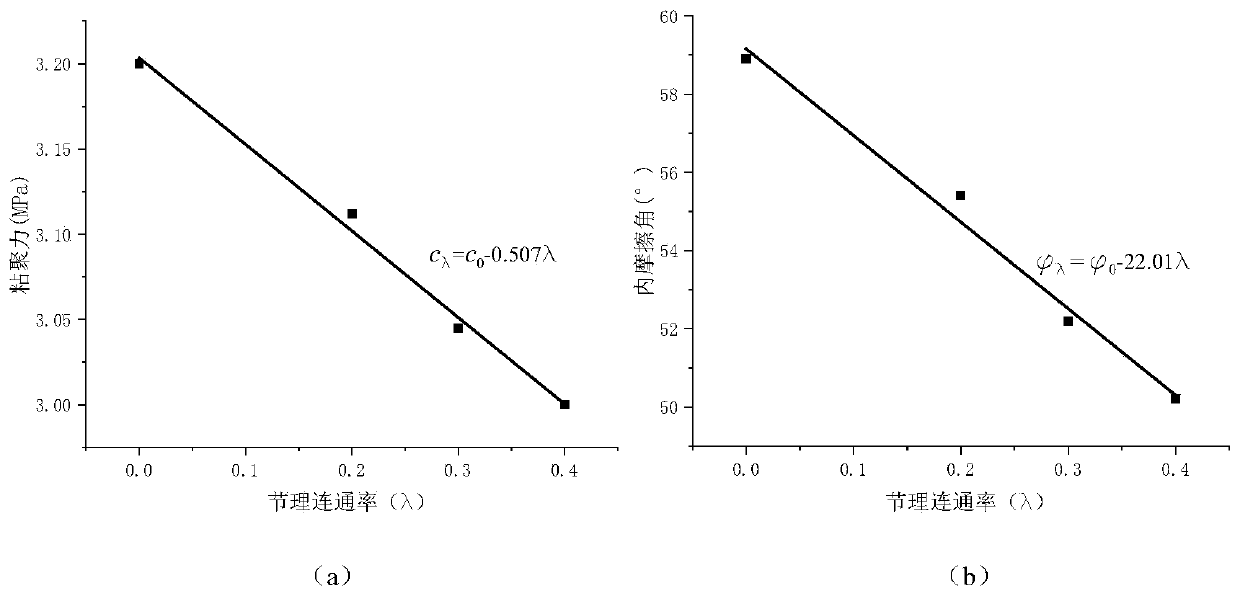

Method for determining joint shear strength considering freeze-thaw cycle damage

ActiveCN110987662AAccurate calculation of shear strengthImprove fitMaterial strength using steady shearing forcesFreeze thawingEngineering

The invention discloses a method for determining joint shear strength considering freeze-thaw cycle damage. Aiming at the complexity of rock mass joints in cold regions, the method provided by the invention deeply analyzes the relationship between the joint connectivity and the shear strength, and proposes a calculation formula of shear strength parameters changing along with the joint connectivity based on an indoor test, so that the shear strength of the complex joints can be conveniently and accurately calculated. According to the method, based on a freeze-thaw test and a direct shear testof a joint sample, a shear strength parameter damage evolution model is established; further an improved shear strength calculation formula is derived; according to the calculation formula, the damageaccumulation of freeze-thaw cycle and the influence of joint connectivity are considered at the same time; the degradation characteristics of the coupling effect of the freeze-thaw cycle and the joint connectivity on the shear strength parameters can be deeply analyzed, the high coincidence degree of the calculation result of the improved calculation formula and experimental data is obtained according to the subsequent test result, and the reasonability of the improvement criterion is shown.

Owner:CENT SOUTH UNIV

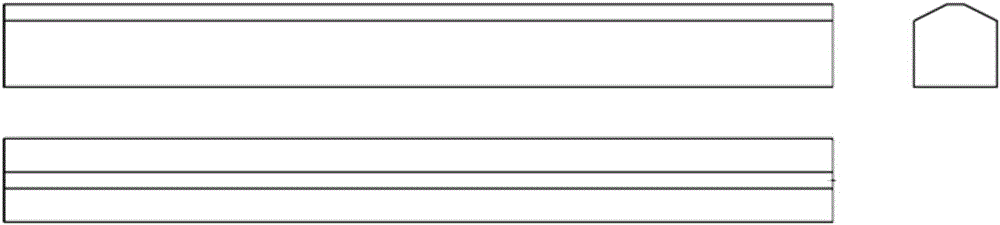

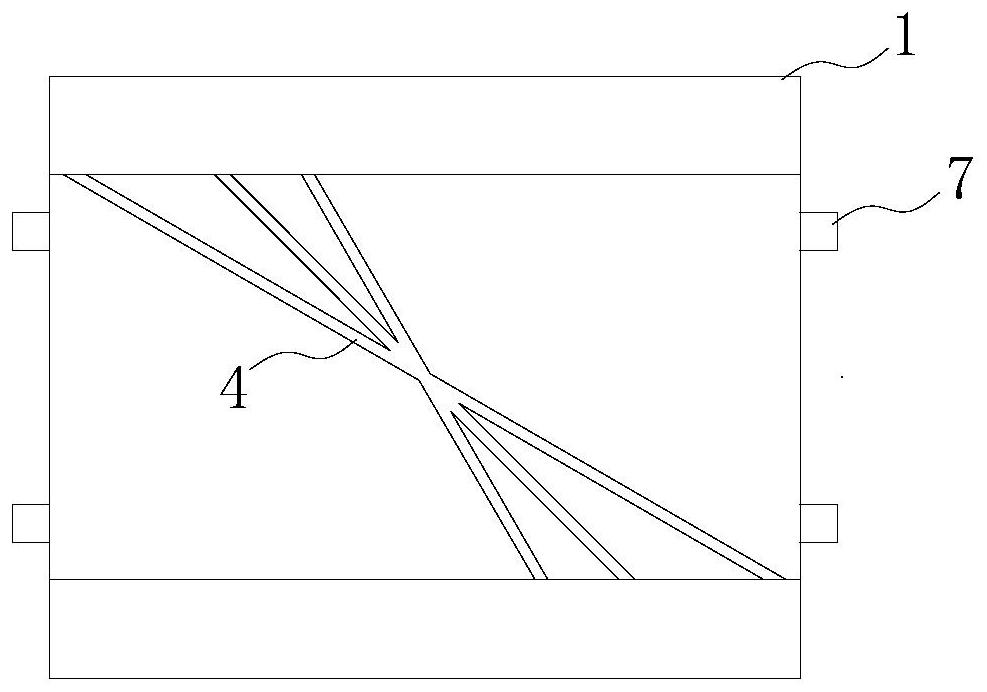

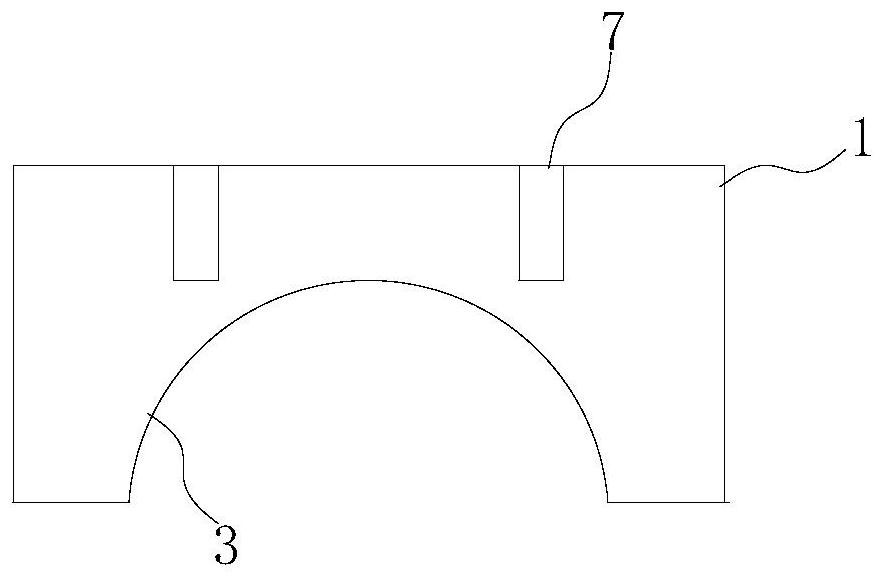

Mold for splitting to form multi-angle rock joint surface and joint sample manufacturing method

PendingCN111999139AAvoid joint problemsLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesStructural engineeringRock sample

The invention provides a mold for forming a multi-angle rock joint surface through splitting and a joint sample manufacturing method, relates to the field of rock mechanics tests, and can be used formanufacturing a multi-angle joint surface of a cylindrical rock sample. The mold comprises an upper box body and a lower box body which are used for bearing pressure, semi-circular grooves are formedin the lower end face of the upper box body and the upper end face of the lower box body respectively, and arc-shaped grooves with the included angles of 30 degrees, 45 degrees and 60 degrees with theaxes of the semi-circular grooves can be formed in the inner walls of the semi-circular grooves respectively. Spring fixing holes perpendicular to the bottom face of the lower box body are symmetrically formed in the bottoms of the semicircular grooves of the lower box body and used for containing springs. Two rectangular guide columns are symmetrically arranged on the outer walls of the left side and the right side of the upper box body respectively, and two rectangular guide grooves are symmetrically formed in the inner sides of the outer walls of the left side and the right side of the lower box body respectively. The mold can be used for manufacturing fresh joint surfaces which form multiple angles of 30 degrees, 45 degrees, 60 degrees and the like with the axis direction of a cylindrical rock sample and have complex three-dimensional morphological characteristics.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

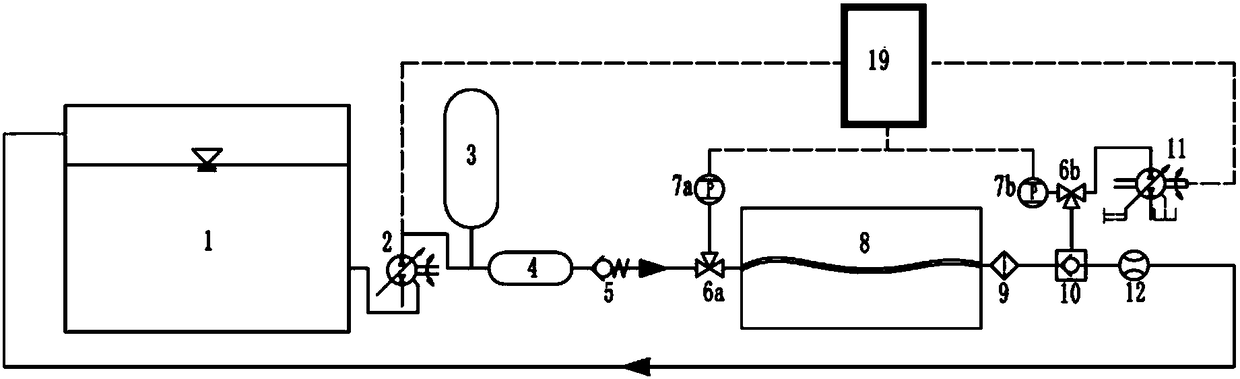

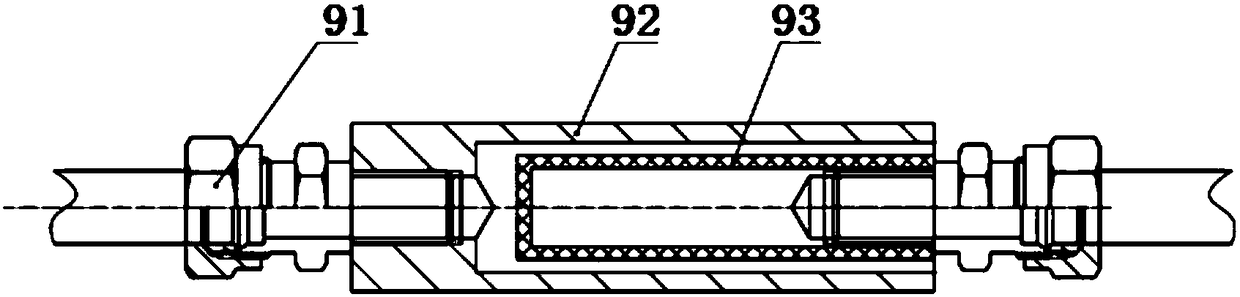

Pressure stabilizing and pressure difference controlling system for rock joint whole-shear seepage coupling test

InactiveCN108375533AImprove operational efficiencyImprove cleanlinessPermeability/surface area analysisDifferential pressurePore water pressure

The invention relates to a pressure stabilizing and pressure difference controlling system for a rock joint whole-shear seepage coupling test. The system comprises a water tank, an incoming water pressure adjusting unit for adjusting incoming water pressure, a to-be-tested joint sample shear seepage box, an outgoing water pressure adjusting unit for adjusting water pressure at an outlet of the joint sample shear seepage box and a flow meter and further comprises a control unit, wherein both the incoming water pressure adjusting unit and the outgoing water pressure adjusting unit are connectedwith the control unit. During testing, the incoming water pressure adjusting unit and the outgoing water pressure adjusting unit are controlled through the control unit, so that incoming water pressure, outgoing water pressure and pressure difference of a joint sample shear seepage box can be regulated accurately. Compared with the prior art, the system has the advantages that a high-pressure plunger pump is adopted at a water inlet, so that high permeation pressure can be provided for the rock joint shear seepage test; a water inlet pressure stabilizing system is utilized to solve the problemof unstable inlet pressure caused by pulse wave of inlet pressure of the high-pressure plunger pump, and equipment running efficiency is improved greatly.

Owner:TONGJI UNIV +2

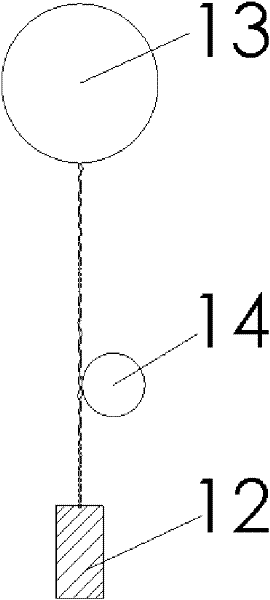

Interpolation type device for measuring resistance of superconducting joint

InactiveCN102243273AMagnetic measurementsTransformersElectrical resistance and conductanceTransformer

The invention discloses an interpolation type device for measuring the resistance of a superconducting joint. The device comprises two parts, namely an in-tank sample chamber and an out-tank operating area, wherein the in-tank sample chamber consists of a superconducting transformer (1), a magnetic-field measuring seat (2) and a back-field superconducting magnet (4); during measurement, the superconducting joint (12) is placed in an inner hole of the back-field superconducting magnet (4), and the back-field superconducting magnet (4) generates a background magnetic field; a single-turn sensing ring (13) of a superconducting joint sample is sleeved on outer layers of coils of the superconducting transformer (1), and the superconducting transformer (1) senses a current in the superconducting joint sample; a single-turn measuring ring (14) of the superconducting joint sample is embedded in a middle groove of the magnetic-field measuring seat (2); a magnetic-field measurement probe which is arranged in a central hole of the magnetic-field measuring seat (2) measures the size of a central magnetic field of the single-turn measuring ring (14) of the superconducting joint and calculates the current in the superconducting joint sample; and during operation, the in-tank sample chamber is completely inserted into a liquid helium storage tank (15) and soaked and cooled in liquid helium.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

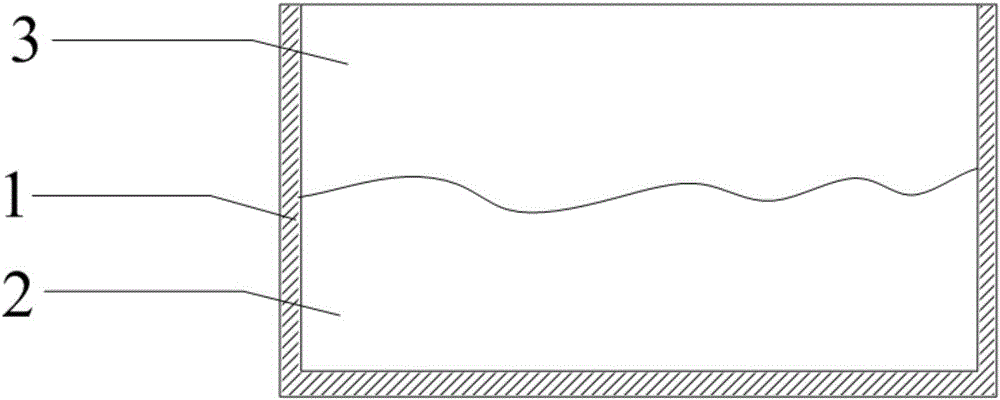

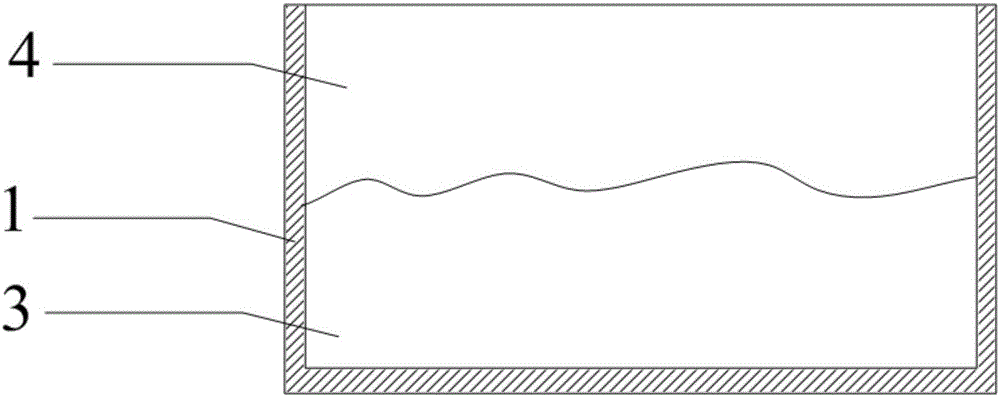

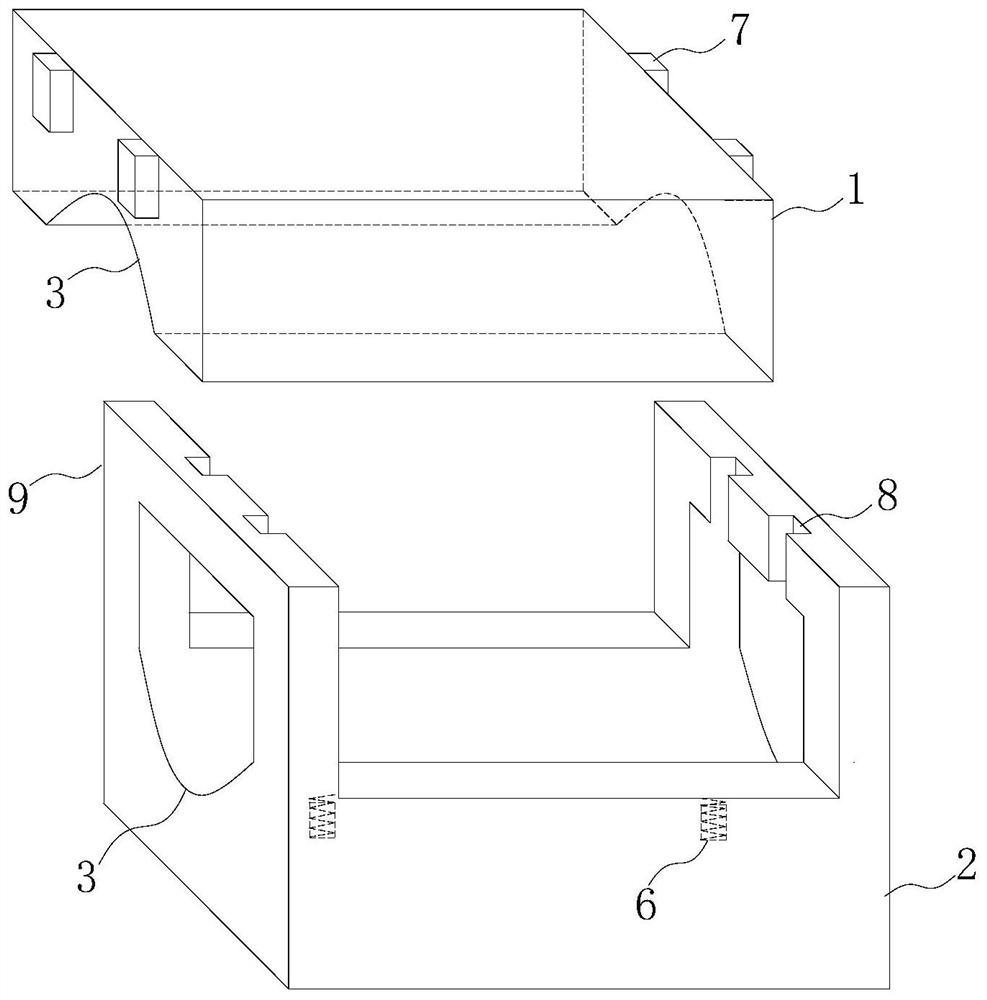

Mold and method for making joint sample for shear and seepage coupling test

InactiveCN108414304AMade preciselyOperational securityPreparing sample for investigationEthylenediamineEpoxy

The invention relates to a mold and a method for making a joint sample for shear and seepage coupling test. The mold comprises a base plate, a side enclosure body arranged on the base plate and a cover plate covering the top of the side enclosure body, the side enclosure body comprises four side baffle plates which are sequentially abutted, one end of every side baffle plate is abutted against themiddle part of the adjacent side baffle plate, the side baffle plates are fixed by screws and positioning pins, and the cover plate is fixedly connected with the tops of the four side baffle plates through screws. The material of the finally obtained joint sample is resin concrete, and the resin concrete contains epoxy resin, cement, sands, dibutyl ester and ethylenediamine according to a mass ratio of 1:(1.1-1.3):(2.0-3.0):(0.08-0.15):(0.04-0.1). The mold and the method can be used to accurately produce the rock joint sample with a required size; the joint manufacturing method has the advantages of safety and simplicity in operation, and realization of large-batch production of samples; and the produced sample has the advantages of good effect, short producing and curing period, and highjoint strength.

Owner:TONGJI UNIV +2

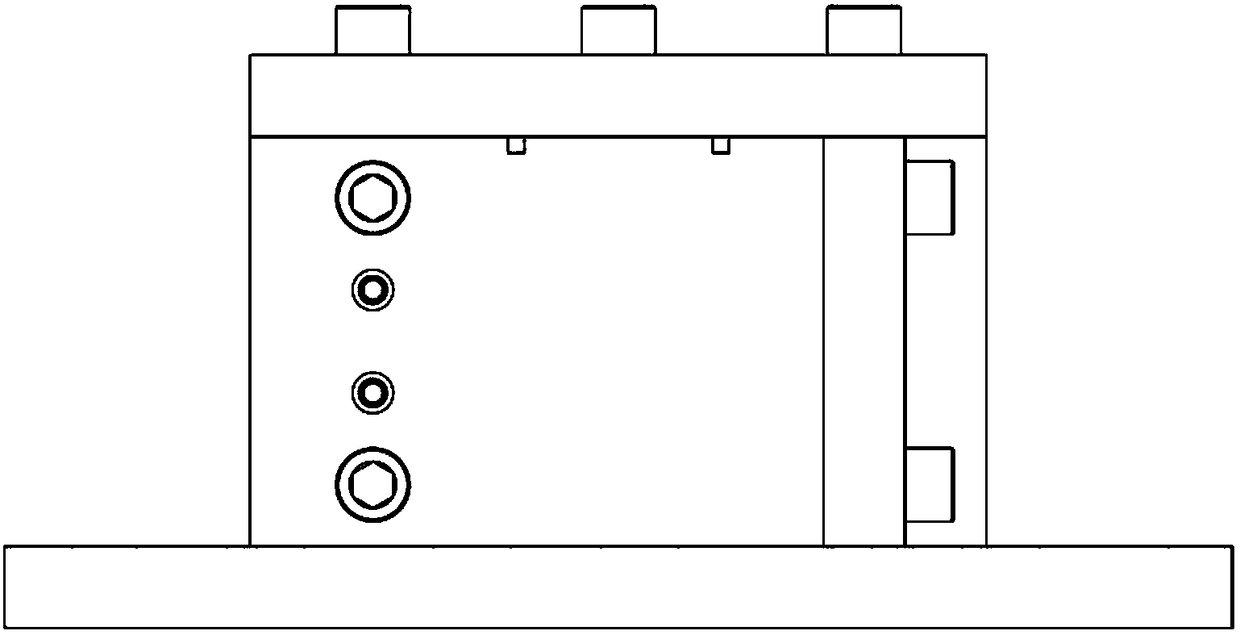

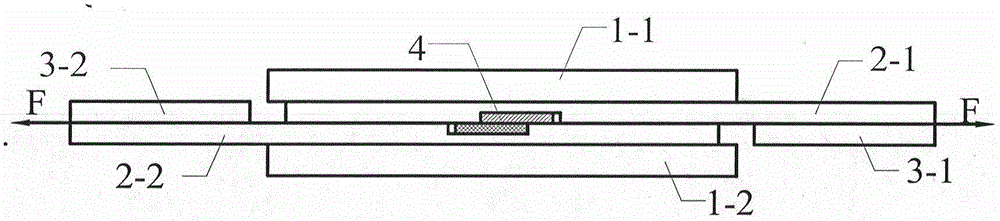

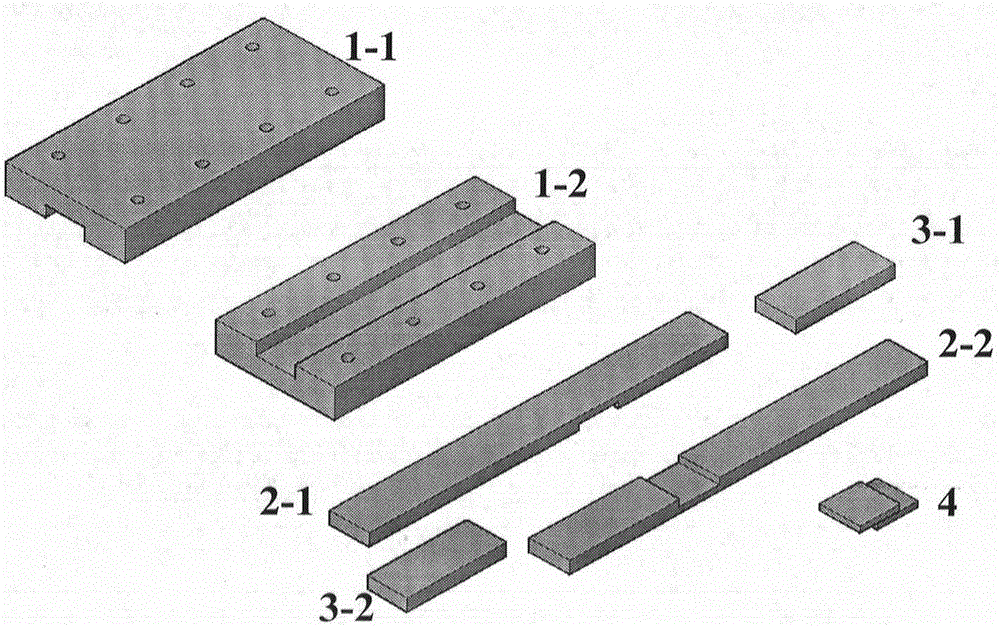

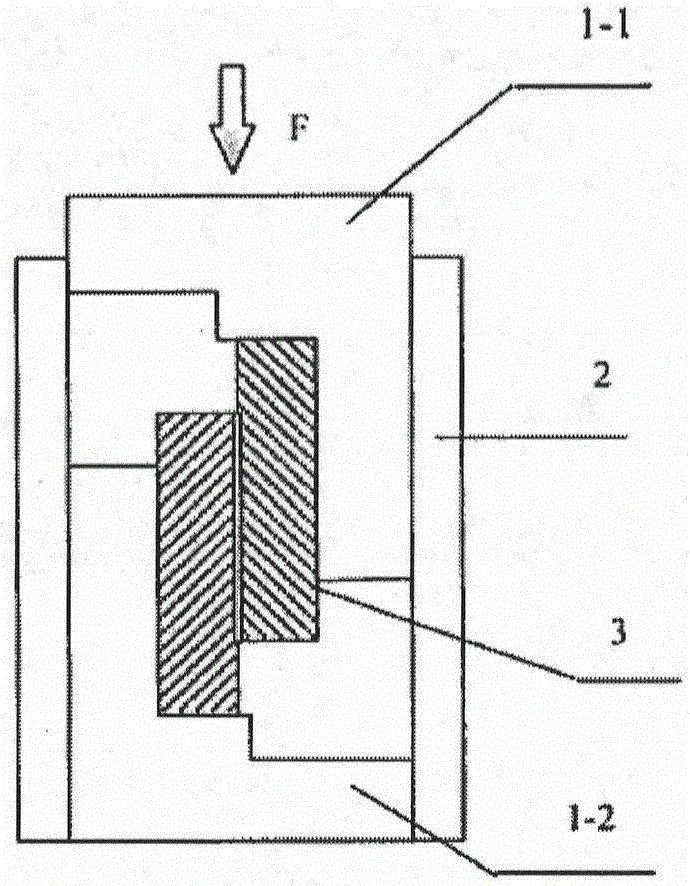

Connector shear strength testing device

InactiveCN104990810AEasy to processMaterial strength using steady shearing forcesEngineeringUltimate tensile strength

The invention discloses a connector shear strength testing device. The connector shear strength testing device comprises a guide rail 1-1, a guide rail 1-2, a pull rod 2-1, a pull rod 2-2, a base plate 3-1 and a base plate 3-2. The pull rod 2-1 and the pull rod 2-2 are symmetrically distributed in a square cavity formed by the guide rails. A tested overlapped joint sample 4 is placed in a cavity formed by the pull rod 2-1 and the pull rod 2-2. Due to the fact that the pull rods can only move in the cavity formed by the guide rails, connecting materials cannot be separated from the pull rod 2-1 and the pull rod 2-2 due to tensile force in the testing process, the device is simple and easy to implement, and working efficiency can be improved obviously. The device is completely composed of panel structural components, and thus processing and manufacturing are easy. Moreover, the shear strength can be detected in a stretched mode.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

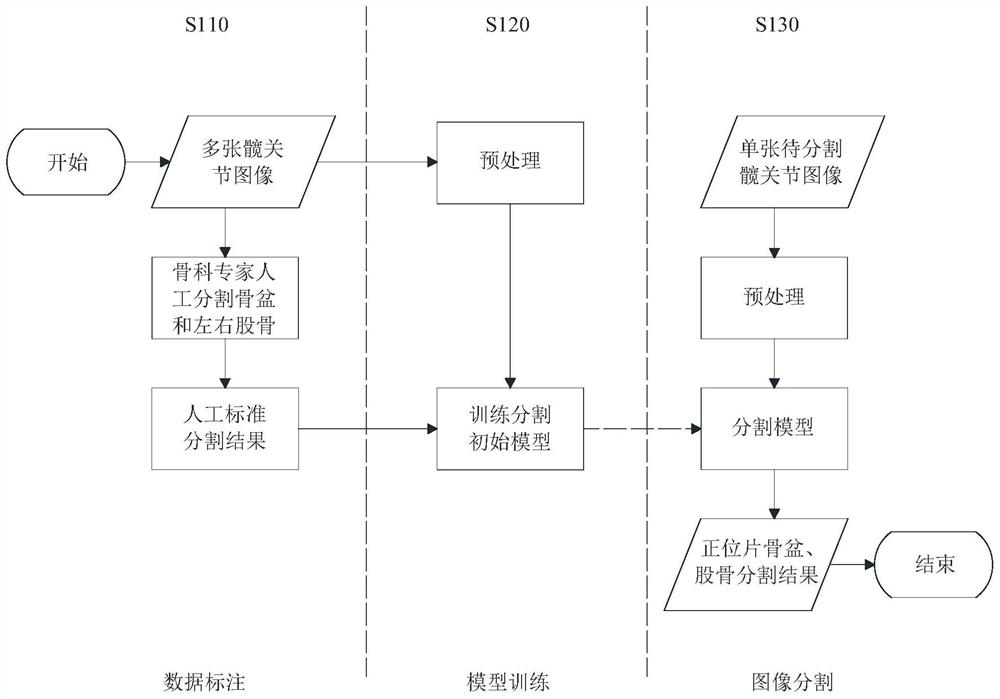

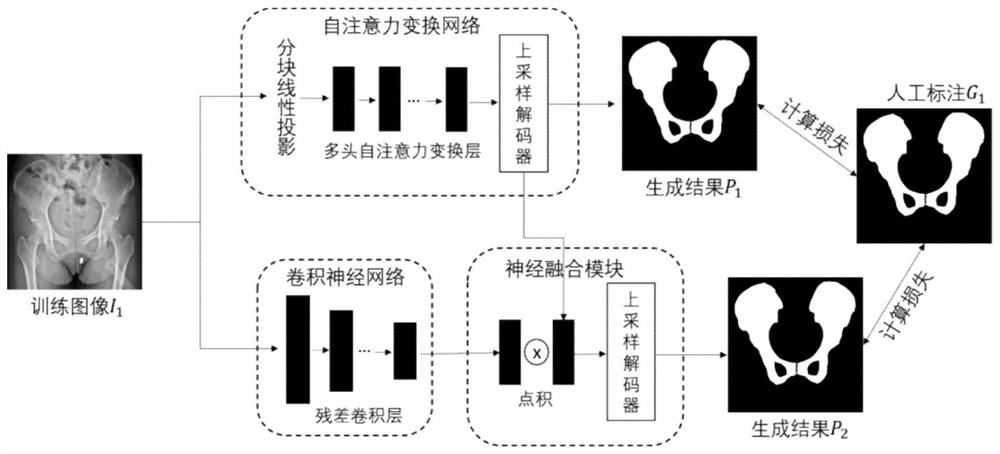

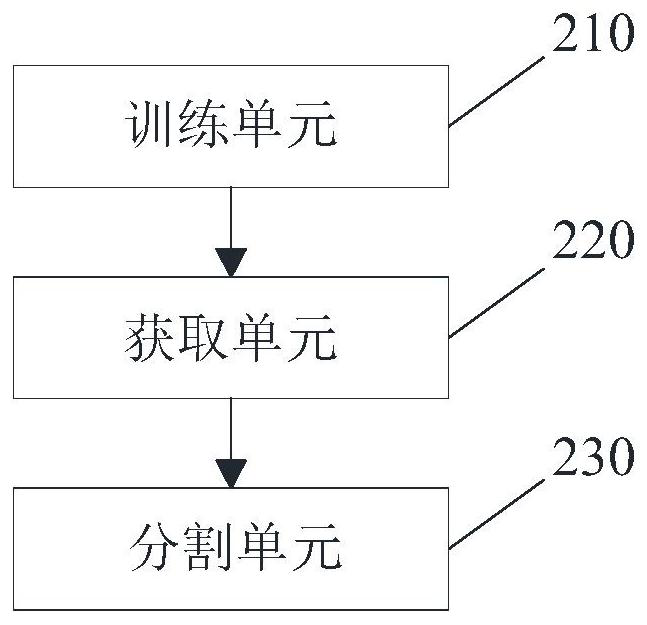

Bone segmentation method in hip joint image, electronic equipment and storage medium

ActiveCN113012155AEfficient extractionReduce the amount of parametersImage enhancementImage analysisBone structureNerve network

The embodiment of the invention relates to the field of image processing, and discloses a bone segmentation method in a hip joint image, electronic equipment and a storage medium. The method comprises the steps: obtaining a to-be-segmented hip joint image; inputting the to-be-segmented hip joint image into a pre-trained segmentation model, and outputting a segmentation result, wherein a method for obtaining the segmentation model through pre-training comprises the following steps: creating an initial segmentation model, and obtaining a plurality of artificially labeled hip joint sample images to obtain a mask image; inputting the hip joint sample images into a self-attention transformation initial model and a convolutional neural network initial model to respectively obtain a first segmentation result and a second segmentation result; and calculating training loss, and returning the training loss to the initial segmentation model to obtain a final segmentation model. According to the embodiment of the invention, the segmentation result is accurate, the robustness is realized, and bone structures in the hip joint images can be efficiently and automatically segmented, so that clinical doctors are assisted in surgical planning, intraoperative navigation and postoperative evaluation.

Owner:刘慧烨 +1

Method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding

InactiveCN102507619BEasy to operateMaterial analysis using wave/particle radiationPreparing sample for investigationLithiumElectron

The invention discloses a method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding, belonging to the technical field of material analysis. The method comprises the following steps of mechanical polishing of a joint sample, preparation of electrolytes, electrolytic polishing, EBSD (Electron Back Scattering Diffraction) test and the like. The method disclosed by the invention has the advantages of successfully solving the difficult problem of displaying the EQZ textures of the welded joints and the fusion zones of the 5A90 aluminum-lithium alloy laser welding, and clearly displaying the characteristics, such as form, size and grain orientation, of the EQZ textures of the welded joints and the fusion zones of the 5A90 aluminum-lithium alloy laser welding. The method disclosed by the invention has the advantages of simpleness in equipment, convenience for operation, and capability of being applied to observation of the EQZ textures of fusion zones of various types of aluminum alloy welded joints.

Owner:BEIJING UNIV OF TECH

Joint geotechnical triaxial test sample preparation method

ActiveCN107144454AImprove efficiencyImprove accuracyPreparing sample for investigationMaterial strength using tensile/compressive forcesTriaxial shear testTest sample

The invention relates to a joint geotechnical triaxial test sample preparation method. Due to the fact that a target sample is composed of child samples divided through joints, the joint geotechnical triaxial test sample preparation method comprises selecting a first child sample in an edge position, and selecting mold test blocks identical in shape and size to other child samples, wherein the mold test blocks are single blocks or combined blocks; placing the mold test blocks and soil materials in position into a mold sleeve and performing compression; extracting shaped samples and taking the samples as mold test blocks, repeating the steps above to manufacture a next child sample neighboring to the first child sample until manufacturing the target sample. During the manufacturing processes, deburring treatment on the natural contact surfaces where the joints among the child samples are positioned is saved, namely, every pair of natural contact surface can serve as joint surfaces. By means of a static-pressure layered manufacturing mode and through different combination of the mold test blocks, the joint geotechnical triaxial test sample preparation method can be applied to manufacturing through type or non-through type joint samples with different inclinations ranging between 0 and 90 degrees and different numbers of joints.

Owner:SEISMOLOGICAL BUREAU OF GANSU PROVINCE CHINA EARTHQUAKE ADMINISTRATION

Shear cell and test method suitable for rock joint shear-seepage coupling test

InactiveCN102944665BFully study the variation law of permeability characteristicsGood sealing water boundaryEarth material testingCouplingWater flow

The invention relates to a shear box applicable to rock joint shearing, seepage and coupling tests and a test method. By the aid of the test box, water can be sealed strictly during shearing, and stable seepage water streams can be formed among joints. The shearing box is mainly composed of a bottom plate, a side plate, a lateral water sealing bag and a water inlet and outlet device. The shear box is characterized by the design of the lateral sealing bag and the method of water injection at the front end and water accumulation at the rear end. By the aid of the rock joint shearing, seepage and coupling test box, the shearing displacement within 20mm can be achieved, the seepage characteristic variation caused by dilation and contraction during rock joint shearing can be studied fully, a water head of 0.05-3.0MPa can be provided to provide conditions for studying the influence of water pressure on joint seepage fully, a minitype servo water pump is used for injecting water, stable water streams can be formed at one ends of joints, the seepage situation conforms to natural conditions, and shearing and seepage tests of joint samples under the effect of complex loads can be finished through the shearing box.

Owner:WUHAN UNIV

Radiation protection device for CT scanning rock joint shear tests

InactiveCN109975106AEasy to observeAvoid radiationMaterial strength using steady shearing forcesComputed tomographyX-ray

The invention belongs to the technical field of geotechnical engineering, and provides a radiation protection device for CT scanning rock joint shear tests. The radiation protection device comprises ashear chamber, a mainframe framework, a loading device, a rotating device, a CT scanning device and a lead-rich glass X-ray protection device. The shear chamber is a hollow cylindrical shear chamber,and a rock joint sample is positioned in the shear chamber. An action end of the loading device is connected with a rotating gasket which is connected with a pressure block, the pressure block penetrates the outer wall of the shear chamber to abut against the upper surface of one side and the lower surface of one side of the rock joint sample, and the other side of the rock joint sample is fixedin the shear chamber. The rotating device comprises a rotating mechanical supporting frame and a stepping motor, and the rotating mechanical supporting frame is in linkage with the shear chamber. TheCT scanning device comprises a radioactive source and a detector which are arranged on two opposite sides of the shear chamber. A piece of cylindrical high-lead glass surrounds the outside of the shear chamber to contain the CT scanning device inside. The radiation protection device effectively overcomes the radiation problem caused by CT scanning in the long-term testing process.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com