Preparation method of columnar joint rock sample with filled pores in columnar surface

A columnar joint and sample preparation technology, which is applied in the preparation of test samples, sampling, and measuring devices, can solve the seepage governing equation Reynolds equation and N-S equation. Difficult and inapplicable classic cubic law, etc., to achieve the effect of overcoming large environmental impact, high yield rate, and reliable method support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

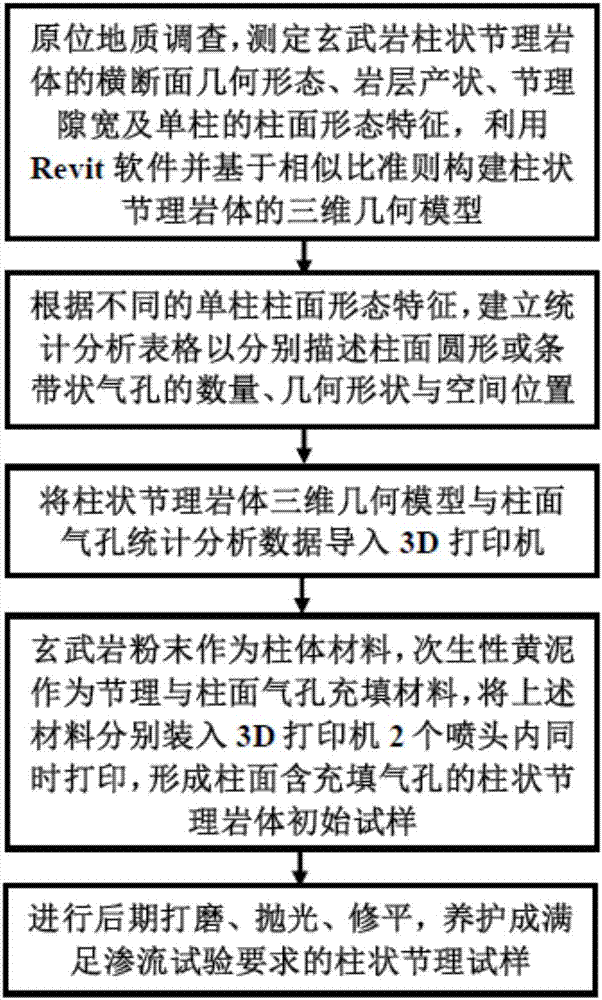

[0033] like Figure 1 to Figure 2 As shown, a method for preparing a columnar jointed rock sample with a columnar surface containing pores filled, comprising the following steps:

[0034] (1) Using in-situ geological surveys to determine the cross-sectional geometry, rock formation, joint gap width, and cylindrical shape characteristics of a single column of basalt columnar joint rock mass, and use Revit software to construct columnar joint rock mass based on the similarity ratio criterion 3D geometric model of

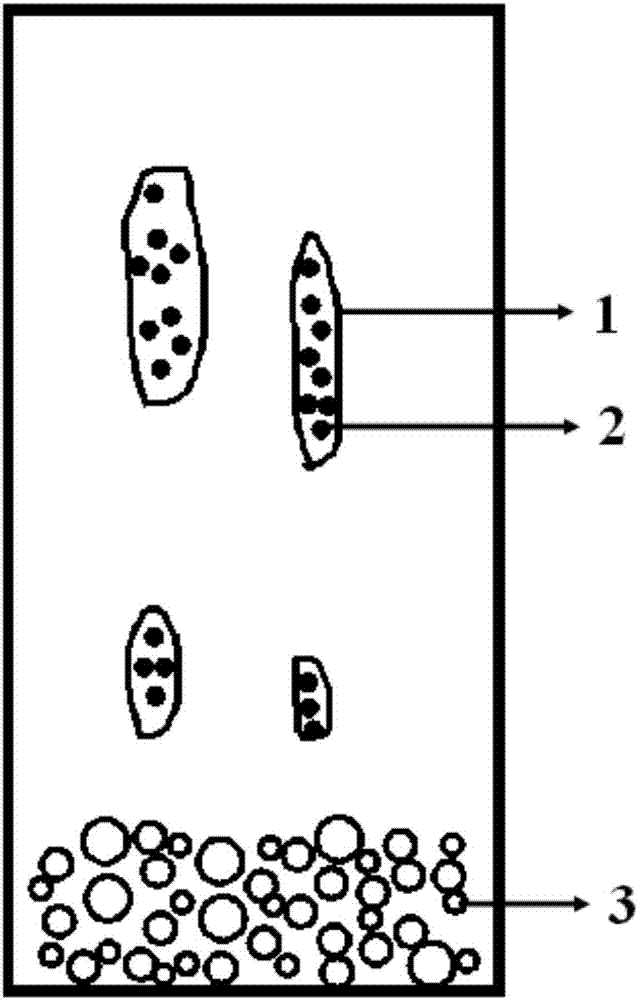

[0035] (2) According to the different single-column cylindrical shape characteristics of the columnar joint rock mass, establish a data statistical analysis form to qualitatively and quantitatively describe the quantity, geometric shape and spatial position of the columnar air pores of the columnar joint rock mass, and the columnar joint rock mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com