Loading robot arm control multipoint mapping intelligent control method and system

A robot arm, intelligent control technology, applied in general control systems, control/regulation systems, manipulators, etc., can solve the problems of neural network retraining, impracticality, inconvenient maintenance of robots, etc., to avoid modeling and solving process, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

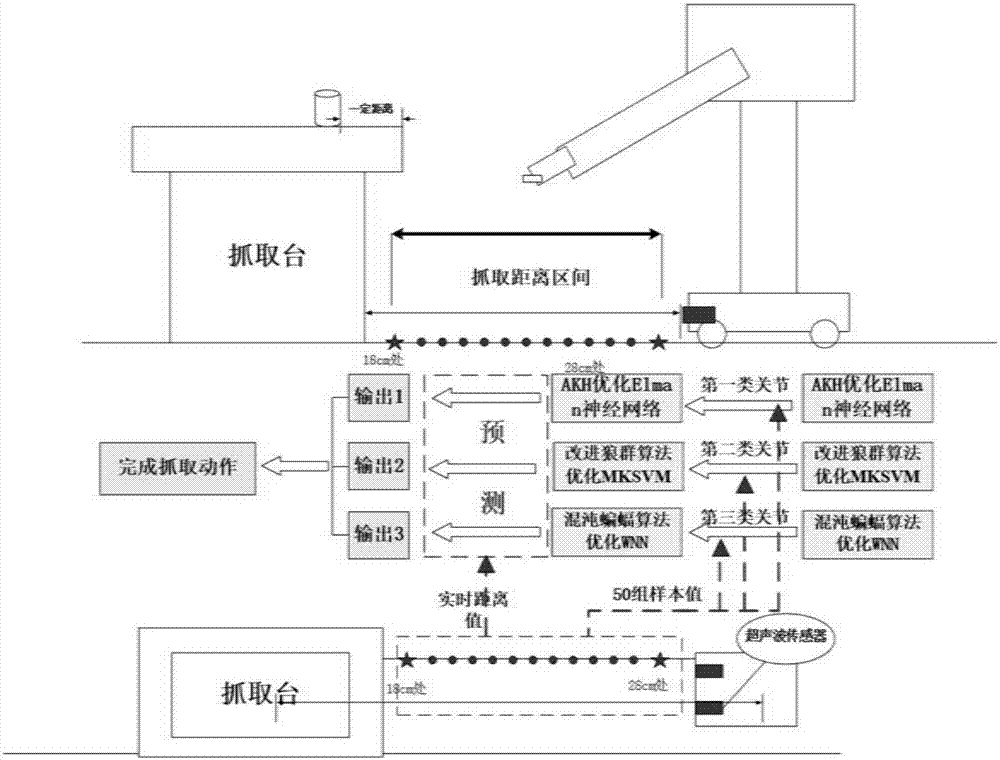

[0121] The schematic diagram of the grabbing process of the carrier robot is as follows: figure 1 Shown; the robot arm grasping control flow chart is shown in Figure 4 shown.

[0122] An intelligent control method for manipulating multi-point mapping of a carrier robot arm, comprising the following steps:

[0123] Step 1: When the carrier robot is at a fixed grabbing point within the specified grabbing distance interval, use the remote server to control the arm of the carrier robot to perform multiple grabbing training, and obtain 50 groups of carrier robots that complete the grabbing tasks at different fixed grabbing points. The sample set of grab samples;

[0124] Each grasping sample includes the distance between the fixed grasping point where the carrier robot base is located and the bottom edge of the grasping table and the control value matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com