Method for preparation of columnar jointed rock mass similar material sample by 3D printing technology

A technology of columnar joints and similar materials, applied in the field of rock mechanics and engineering, can solve the problems such as the impossibility of carrying out a large number of tests and the inability to accurately control the porosity of samples, and achieve high yield, environmental protection and resource saving, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

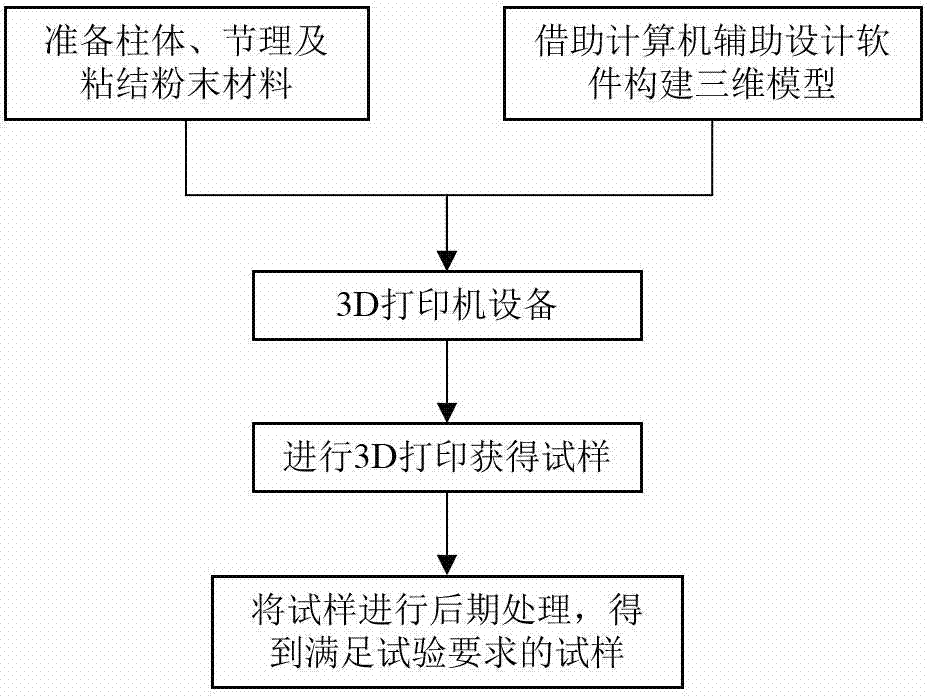

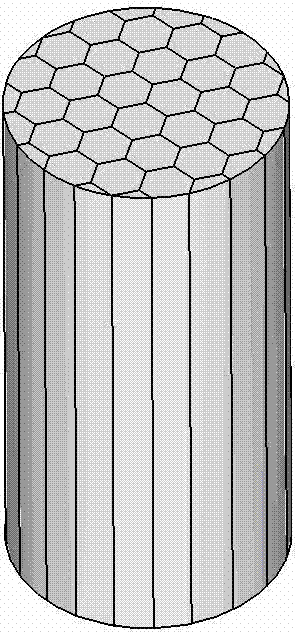

[0025] Taking printing a completely filled cylindrical sample as an example, the operation flow of this embodiment is as follows figure 1 As shown, including the following steps:

[0026] Step 1: First, prepare the powdered raw materials required for printing of similar material samples of columnar jointed rock mass. The powdered raw materials mainly include columnar jointed columnary powder materials and jointed powder materials. In addition, the powdered materials used for cementing and bonding are provided. Connect the glue.

[0027] The above-mentioned powdery materials can use similar materials such as concrete materials, resin materials and other composite materials, or collect on-site columnar jointed rock masses (joint fillers) from the site and grind them into a powder shape that a 3D printer satisfies. The powdery adhesive material acts as a bonding agent. Columnar joints, column powder materials and joint powder materials are cemented and bonded with different strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com