Connector shear strength testing device

A technology of shear strength and testing device, which is applied in the direction of applying stable shear force to test the strength of materials, etc., which can solve the problems of difficult processing and manufacturing, time-consuming testing, and falling off of upper and lower clamps, and achieve the effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

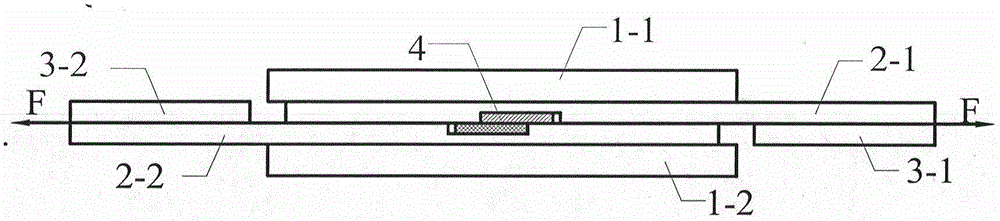

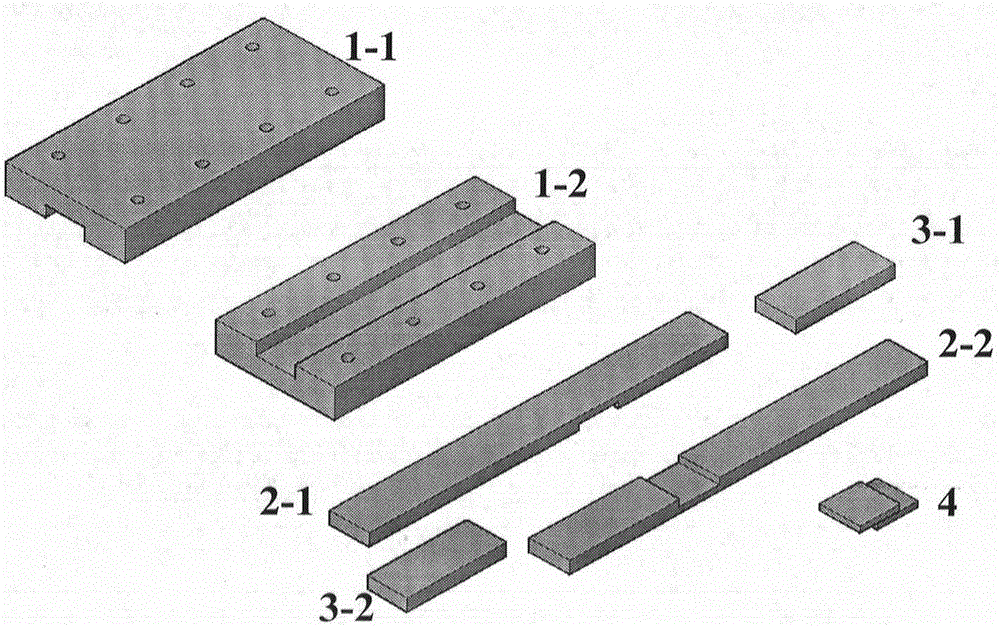

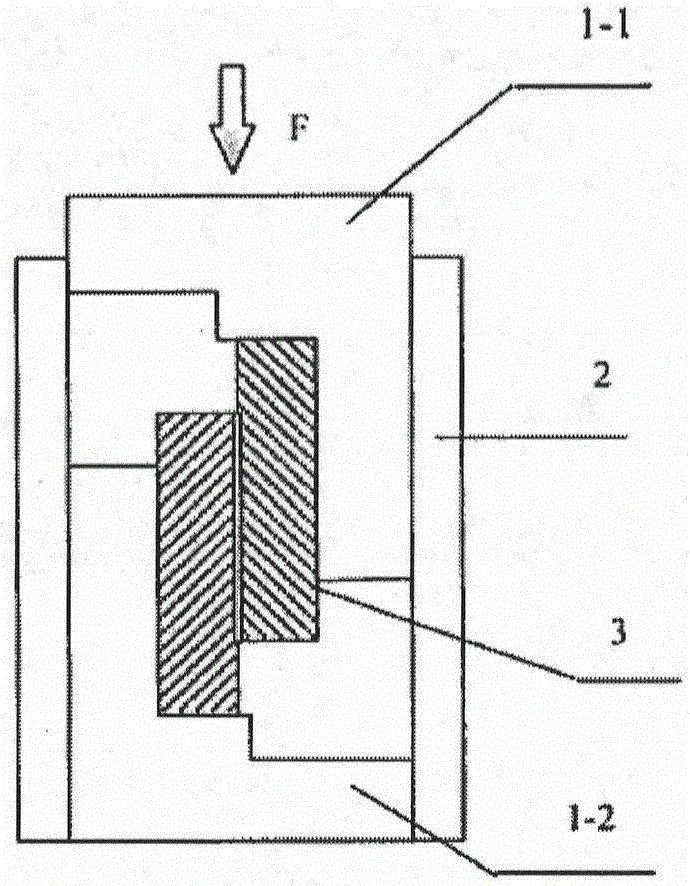

[0019] Such as figure 1 and figure 2 , the present invention comprises guide rail 1-1, guide rail 1-2, pull rod 2-1, pull rod 2-2, backing plate 3-1, backing plate 3-2, and guide rail 1-1 and guide rail 1-2 are square grooved guide rails The structure is exactly the same, and the rails are fixed by bolts. The pull rod 2-1 and the pull rod 2-2 have a square groove structure and are identical, and the depth of the groove is larger than the thickness of the connected material 4. The width of the pull rod 2-1 and the pull rod 2-2 is the same as that of the guide rail 1-1. Equal to the width of the groove of the guide rail 1-2, the thickness of the pull rod 2-1 and the pull rod 2-2 is equal to the depth of the groove of the guide rail 1-1 and the guide rail 1-2. The thickness of backing plate 3-1 and backing plate 3-2 is equal to the thickness of pull bar 2-1 and pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com