Method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding

An aluminum-lithium alloy and laser welding technology, which is applied in the field of material analysis, can solve problems that do not involve process parameters, steps or key points, different proportions of electrolytic polishing liquid, and failure to provide grain orientation imaging maps, etc., achieving simple equipment, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

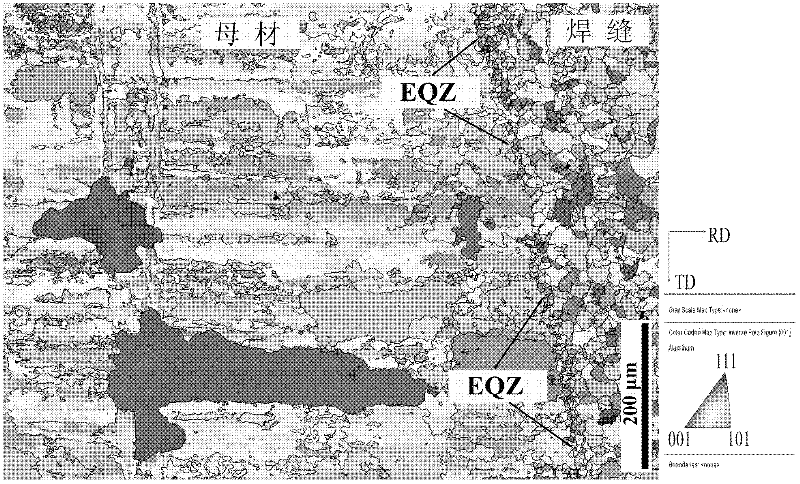

Embodiment 1

[0022] The horizontal section of the 5A90 aluminum-lithium alloy laser welded joint was sampled by wire cutting, and first mechanically polished: after cleaning with alcohol in an ultrasonic cleaner, the samples to be tested were passed through 200#, 400#, 600#, 800#, 1000# , 1200#, 1500#, 2000# water sandpaper for rough grinding, and then use woolen and polishing paste to polish until the surface of the sample is bright without scratches. Use an ultrasonic cleaner to clean in acetone solution for about 10 minutes, take out the sample, clean it with alcohol, dry it with a hair dryer, and then perform electrolytic polishing. The polishing solution is a mixed solution of nitric acid and methanol with a volume ratio of 3:7. The DC voltage is 20V, the polishing temperature is -25°C, the current is 1.0A, the polishing time is about 60s, and the electrolytic polishing is stirred with a glass rod. After the electropolished samples were cleaned by ultrasonic deionization in alcohol, t...

Embodiment 2

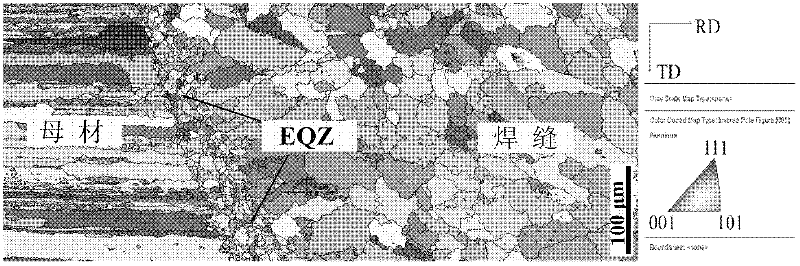

[0024] The cross-section of the 5A90 aluminum-lithium alloy laser welded joint was sampled by wire cutting, and first mechanically polished: after cleaning with alcohol in an ultrasonic cleaner, the samples to be tested were passed through 200#, 400#, 600#, 800#, 1000# , 1200#, 1500#, 2000# water sandpaper for rough grinding, and then use woolen and polishing paste to polish until the surface of the sample is bright without scratches. Use an ultrasonic cleaner to clean in acetone solution for about 10 minutes, take out the sample, clean it with alcohol, dry it with a hair dryer, and then perform electrolytic polishing. The polishing solution is a mixed solution of nitric acid and methanol with a volume ratio of 3:7. The DC voltage is 20V, the polishing temperature is -25°C, the current is 1.0A, the polishing time is about 60s, and the electrolytic polishing is stirred with a glass rod. After the electropolished samples were cleaned by ultrasonic deionization in alcohol, they w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com