Shearing seepage box for full shearing-seepage coupling test for rock joint under high permeability pressure

A technology of rock joints and high permeability, which is applied in the fields of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc. It can solve the problems of poor sealing effect, inability to achieve sealing effect, and low accuracy of test results, etc., and achieve good results. simulated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

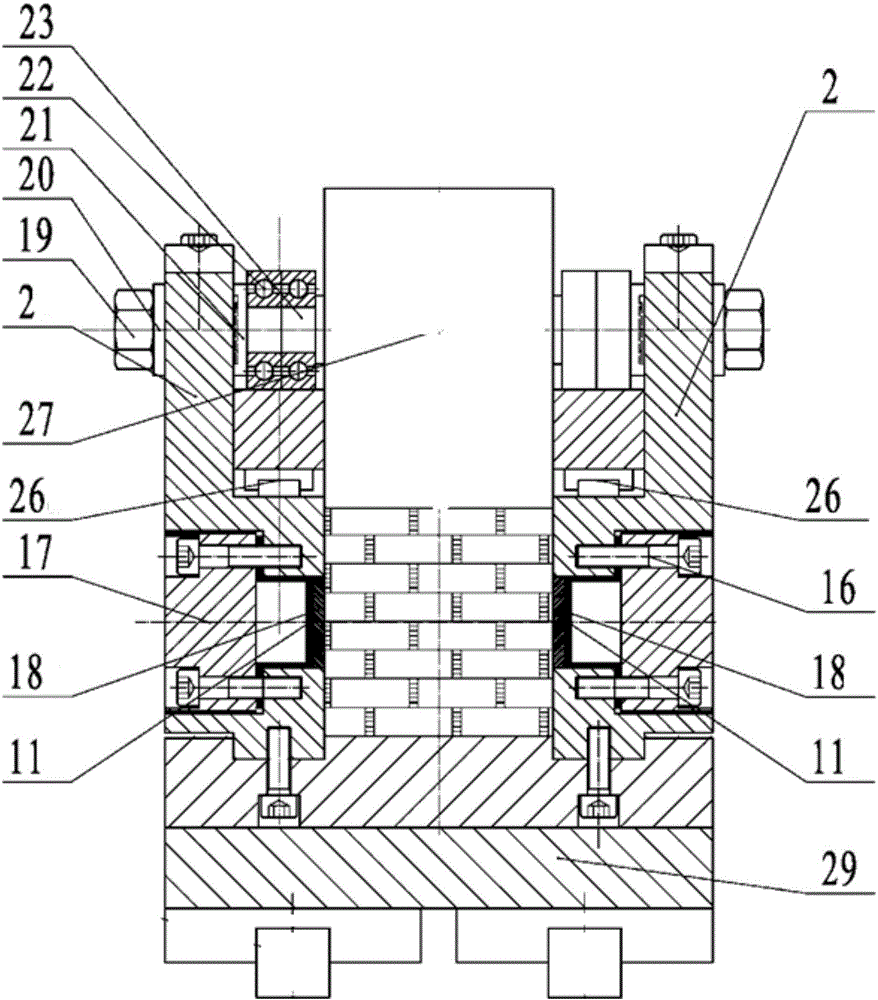

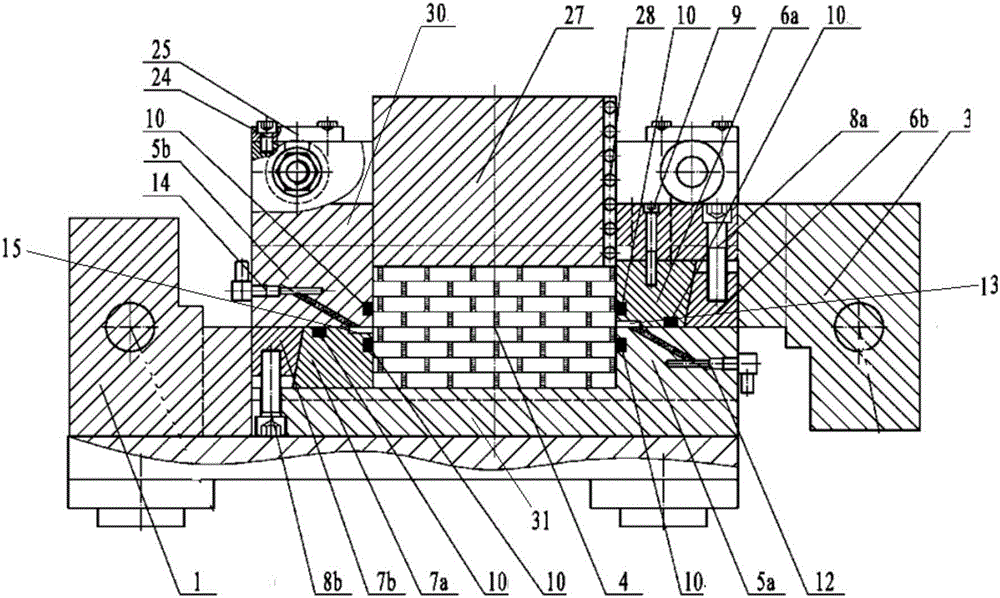

[0033] A full shear-seepage coupling test shear seepage box for rock joints under high permeability pressure, such as figure 1 with figure 2 As shown, it includes a lower shear box 1, two side plates 2 which are arranged on both sides of the lower shear box 1 and are vertically fixed to the lower shear box by hexagon socket screws, and an upper shear box 3. The lower shear box 1, the two side plates 2 and the upper shear box 3 form a cavity for placing the rock sample 4, and upper fixed shear blocks 5a for fixing the rock sample 4 are provided at both ends of the cavity. Lower fixed shear block 5b and No. 1 upper wedge cut block 6a, No. 2 upper wedge cut block 6b, No. 1 lower wedge cut block 7a and No. 2 lower wedge cut block 7b that can be horizontally displaced; The fixed cut block 5a, the lower cut box 1 and the lower bottom plate 31 are processed into a whole, and the upper fixed cut block 5b, the upper cut box 3 and the upper top plate 30 are processed into a whole. The N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com