Pressure stabilizing and pressure difference controlling system for rock joint whole-shear seepage coupling test

A technology for rock joints and control systems, applied in permeability/surface area analysis, measuring devices, suspension and porous material analysis, etc., can solve the problems of seepage pressure control, unable to provide stable water pressure, etc., and improve the efficiency of equipment operation , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

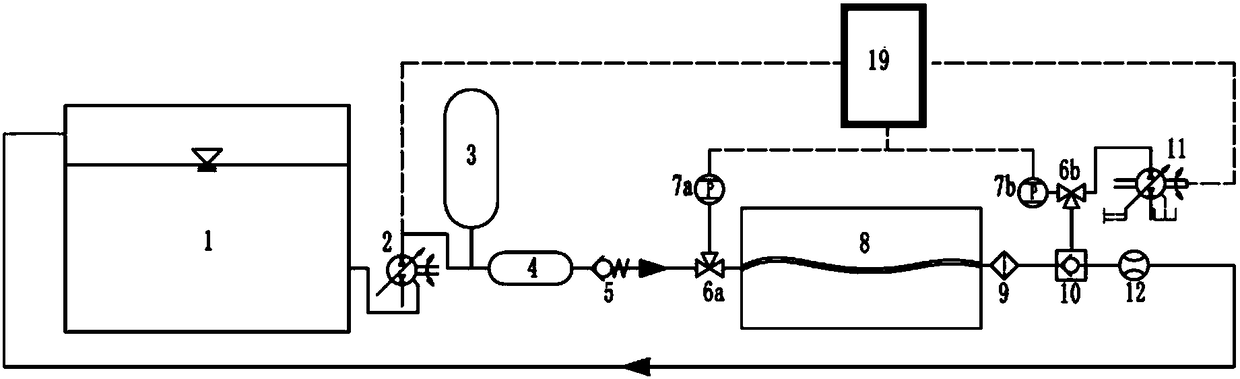

[0027] A new type of rock joint shear seepage test pressure difference control device and pressure stabilization system, its structure is as follows figure 1 As shown, it includes water tank 1, high-pressure plunger pump 2, accumulator 3, water storage tank 4, check valve 5, joint shear seepage box body 8, filter 9, back pressure valve 10, seepage pressure servo 11 , Flowmeter 12.

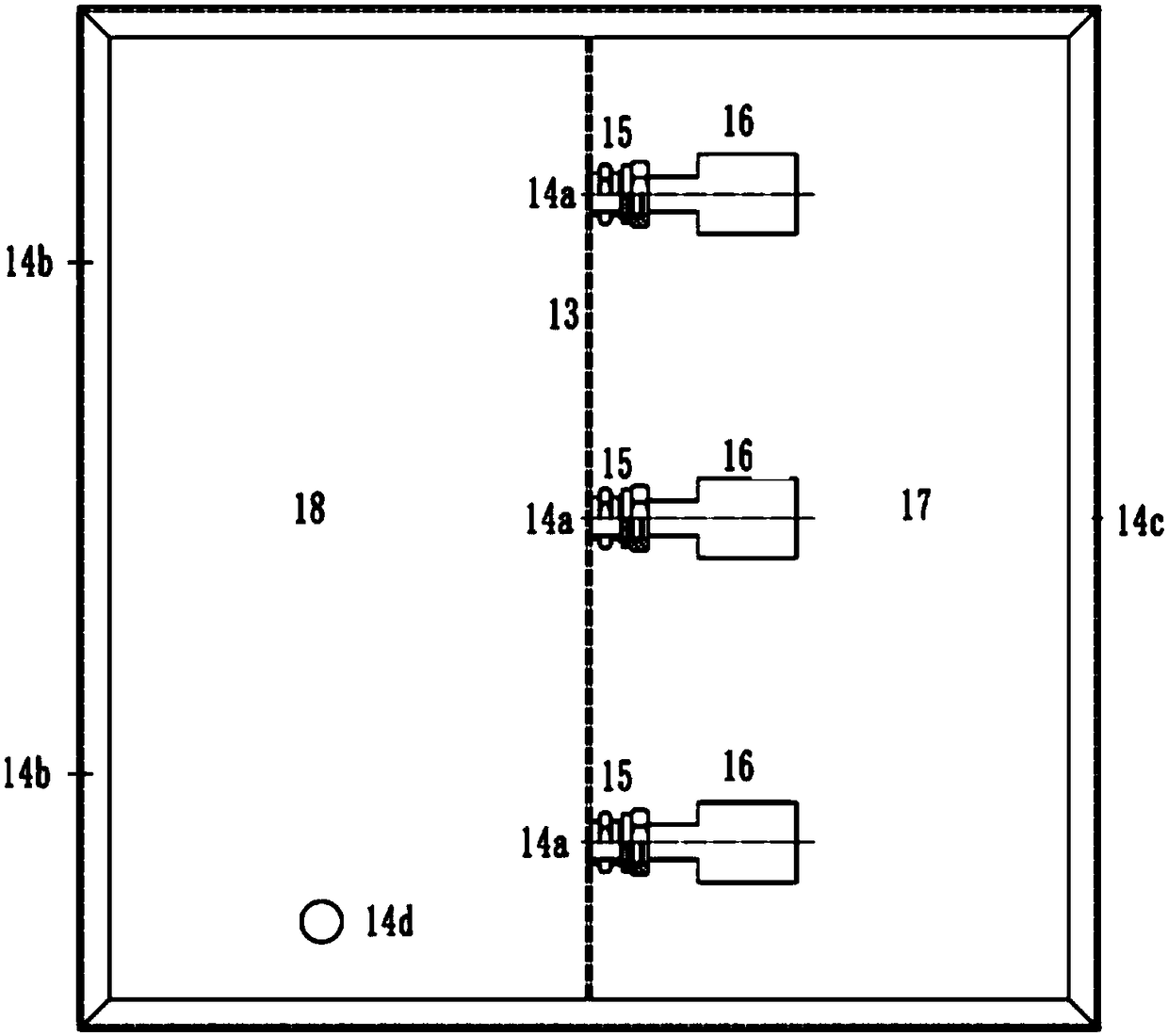

[0028] Water tank 1 adopts stainless steel material to make, adopts four-corner welding, and welding seam and polishing. In the middle of the water tank 1, a dividing plate 13 is added, and three through holes 14a of the same size are opened along the width of the water tank 1 at the middle height of the dividing plate 13, and the dividing plate 13 and the filter screen are connected by a ferrule-type copper pipe joint 15. The filter is connected with 16 threads, and the structure of the water tank is as follows figure 2 shown. The dividing plate 13 strengthens the strength of the water tank, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com