Rock joint shearing test device

A technology for rock joints and shear testing, which is applied to measuring devices, using a stable shear force to test the strength of materials, instruments, etc. It can solve the problems of shearing phenomenon, inconvenient handling and installation, and heavy shear box weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

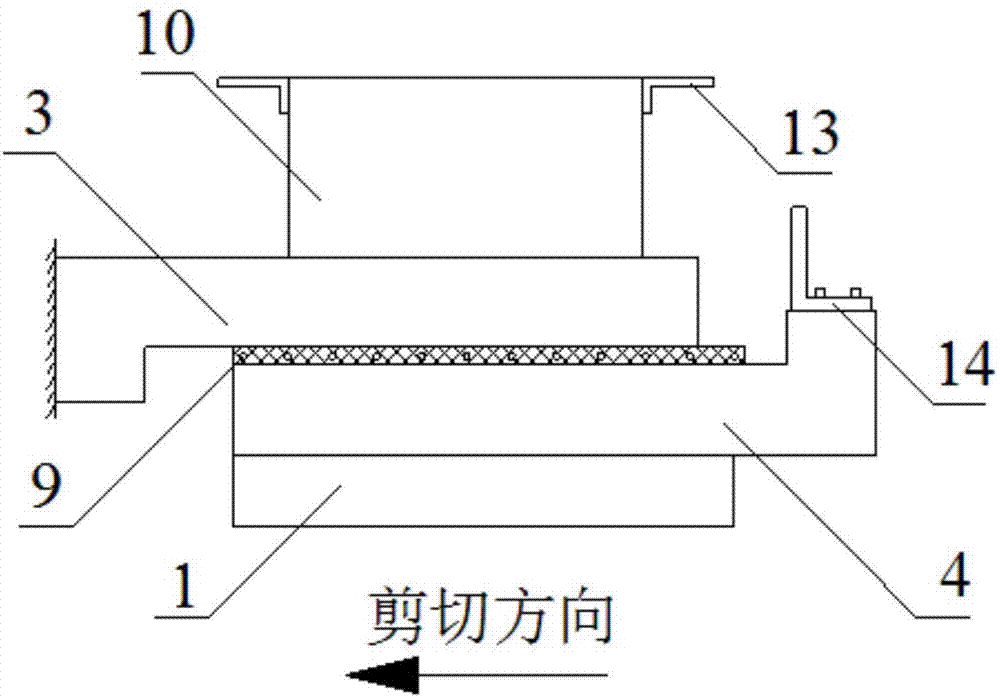

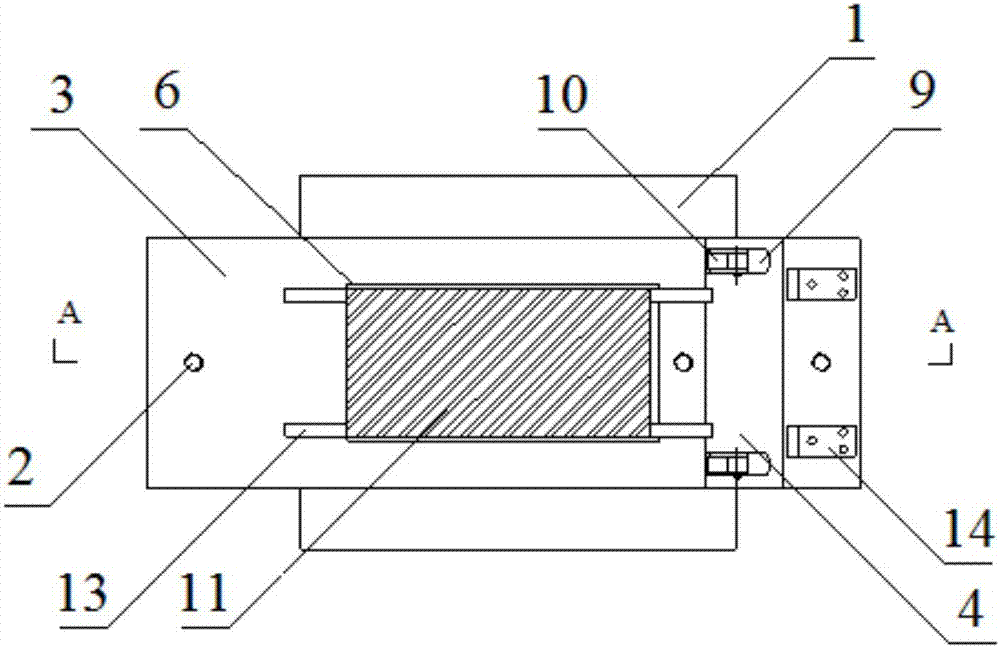

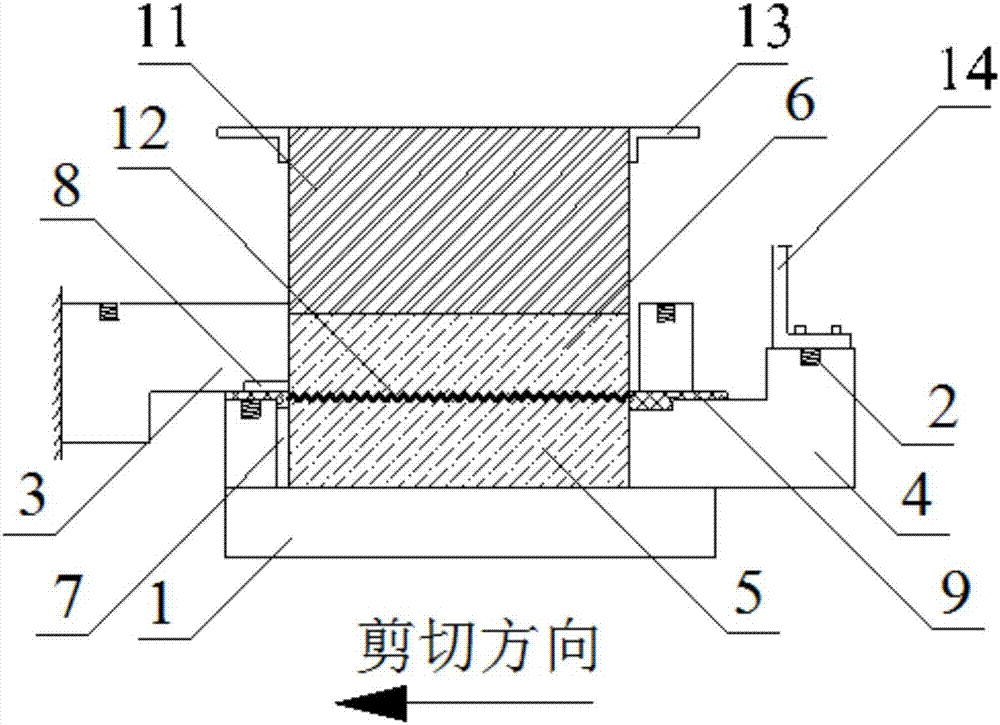

[0029] A kind of rock joint shear test device, its structure is as follows Figure 1 to Figure 6 As shown, the rock joint shear test device includes a base 1, which is arranged below the lower shear box 4, and the two are made into a rigid body by machining. The upper shear box 3 covers the top of the lower shear box 4, and the middle part of both is provided with a cavity 7, which is used to place rock joint samples after overlapping, and a piece of metal block 11 is pressed above the rock joint samples. The central axis of the rock joint sample is a joint surface 12 , and the rock joint sample is divided into a rock joint upper shear block 5 and a rock joint upper shear block 6 . Two internally threaded holes 2 are provided at the two ends of the central axis of the upper surface of the upper shear box 3 and the lower shear box 4, and the bolts with lifting holes are screwed into the internally threaded holes 2 to fix them, and the upper and lower shear boxes can be moved by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com