Mold for splitting to form multi-angle rock joint surface and joint sample manufacturing method

A technology for rock joints and rock samples, which is applied in the field of rock mechanics test, can solve the problems of large difference in properties, low success rate, and difficulty in fixing rocks, and achieves the effect of simple steps and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

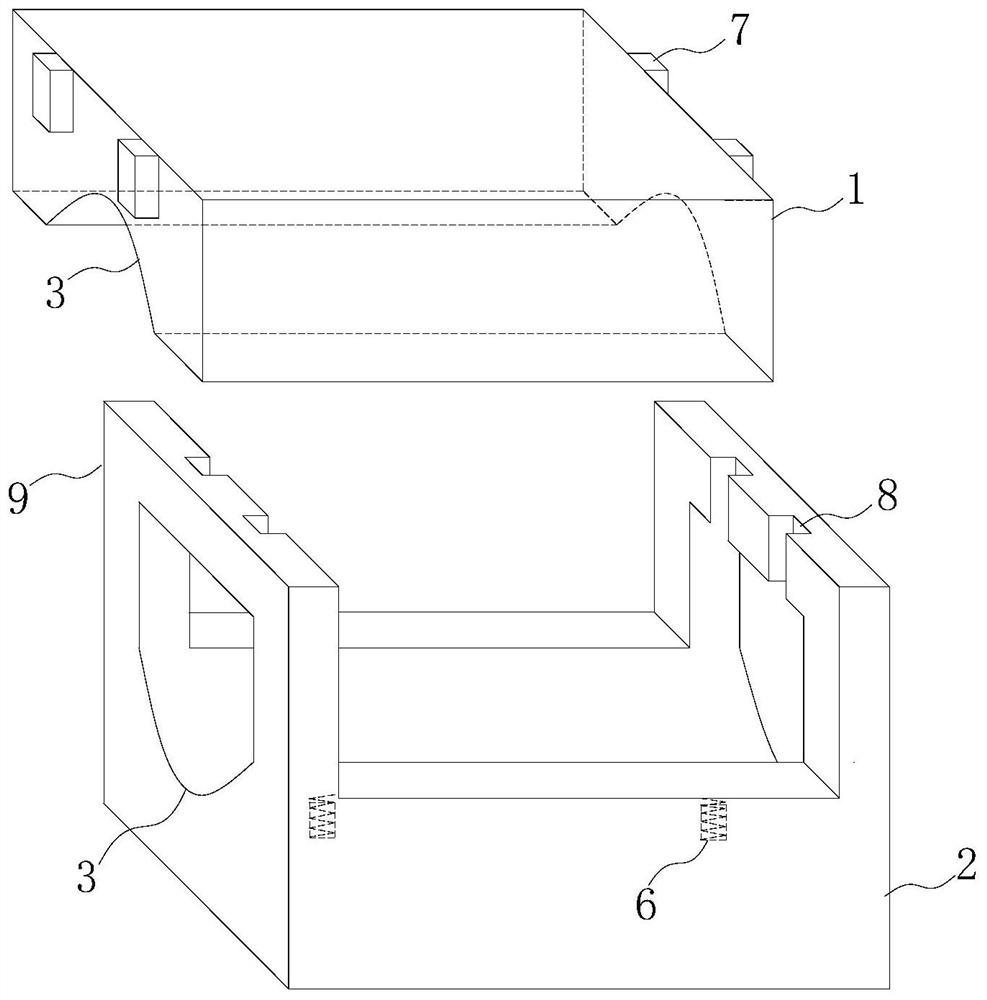

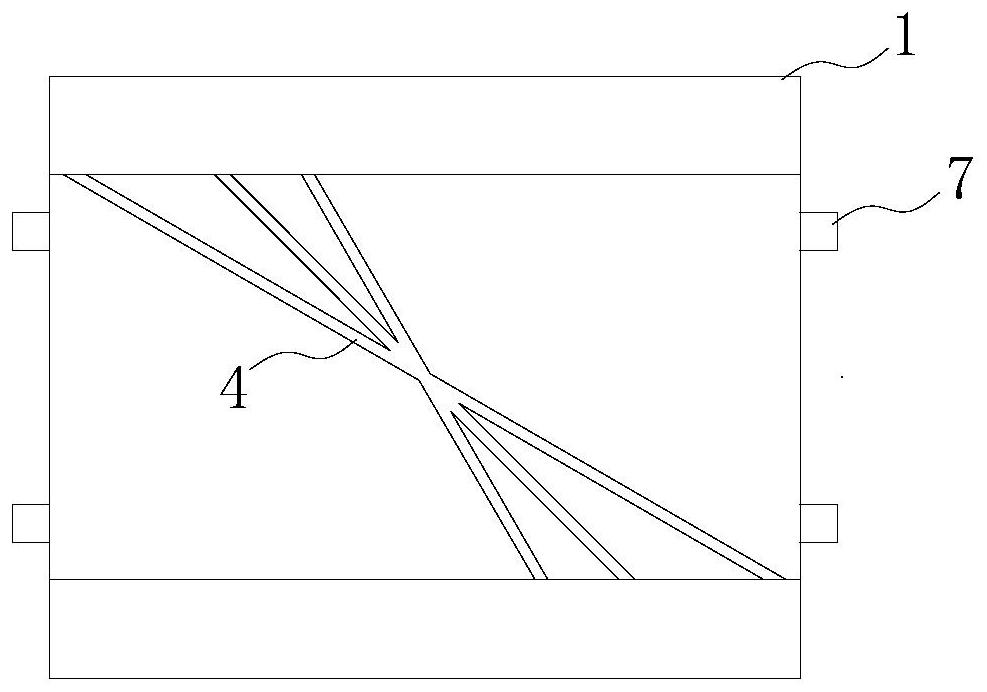

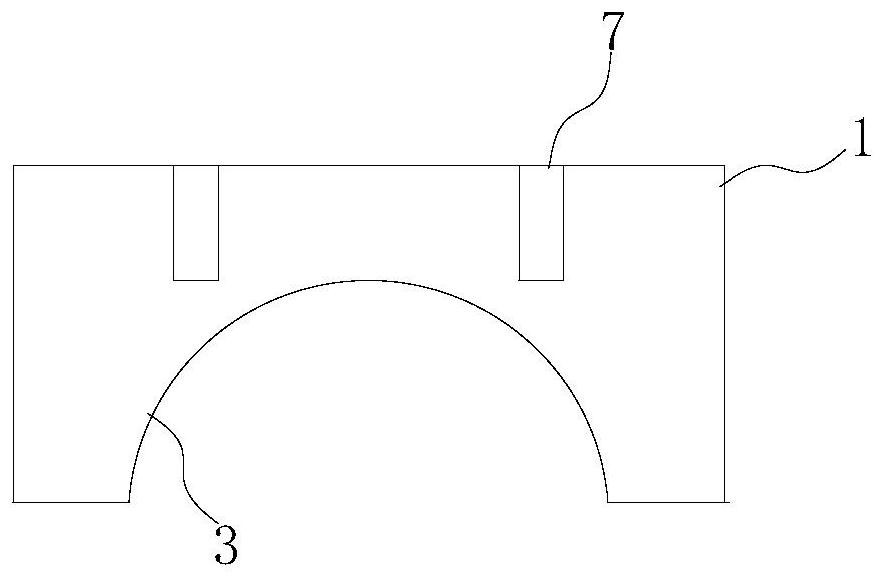

[0032] to combine Figure 1 to Figure 7 As shown, a mold for splitting and forming a multi-angle rock joint surface provided by the present invention and a method for making a joint sample are described in detail.

[0033] A mold for splitting to form multi-angle rock joint surfaces, used to make samples of different rock joint surfaces, which specifically includes an upper box body 1 and a lower box body 2 for bearing loads, and an upper box body 1 and a lower box body 2 The upper and lower end faces are flat, which is convenient for loading by the Brazilian splitting test machine. The lower end surface of the upper box body 1 and the upper end surface of the lower box body are respectively provided with semicircular grooves, and the semicircular grooves 3 of the upper box body and the lower box body cooperate to form a cylindrical sample cavity, and the rock sample is placed in the sample cavity. On the inner wall of the semicircular groove 3 of the upper box body and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com