Manufacturing and measuring method for low temperature resistance measurement system of CICC superconductive joint

A technology of superconducting joints and measurement methods, which is applied in the direction of measuring electrical variables, measuring devices, and measuring resistance/reactance/impedance, etc., can solve the problems of reducing test costs and lack of low-temperature resistance performance of superconducting joints, and achieve reliable measurement and low-temperature resistance. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

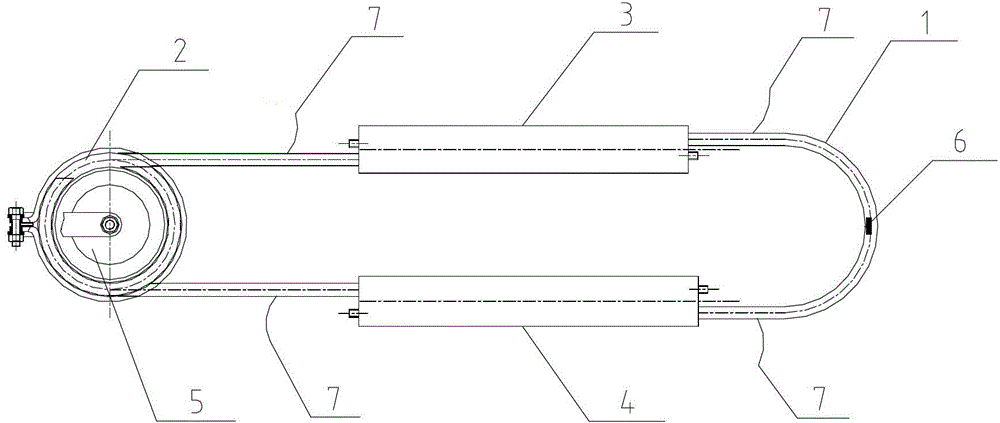

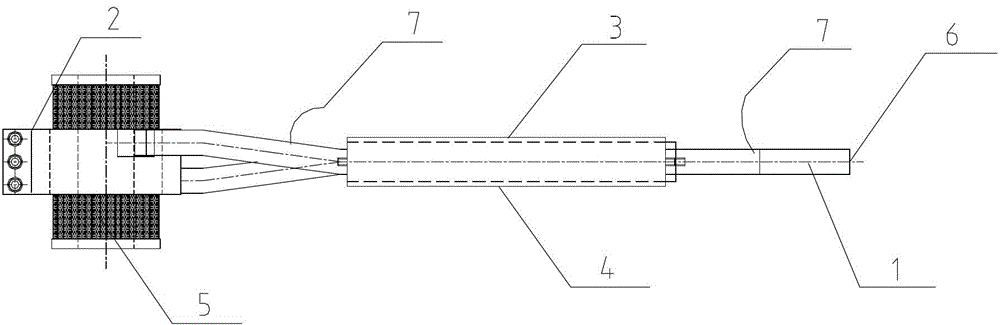

[0022] see figure 1 , 2 , a kind of making and measuring method of the low-temperature resistance measuring system of CICC superconducting joint, it is characterized in that, comprises the following steps:

[0023] (1) A U-shaped CICC conductor 1 and a U-shaped CICC conductor 2 with two coils are made by using an inner cable conductor composed of a NbTi or Nb3Sn superconducting material; the two-turn coil of the CICC conductor 2 During production, the surface is wrapped with 0.1mm thick glass cloth tape to form 0.5mm thick inter-turn insulation;

[0024] (2) CICC conductor 1 and CICC conductor 2 are connected by two CICC superconducting joints to form a racetrack-shaped coil, which constitutes the secondary coil of a superconducting transformer; the two CICC superconducting joints to be tested are inner joint samples 3, External joint sample 4;

[0025] (3) If the superconducting material is Nb3Sn material, the entire racetrack-shaped coil needs to be placed in a heat treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com