Mold and method for making joint sample for shear and seepage coupling test

A joint and seepage technology, which is applied in the field of rock mechanics and seepage mechanics, can solve problems such as troublesome disassembly, inaccurate test results, and poor side sealing, and achieve safe operation and good sample results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

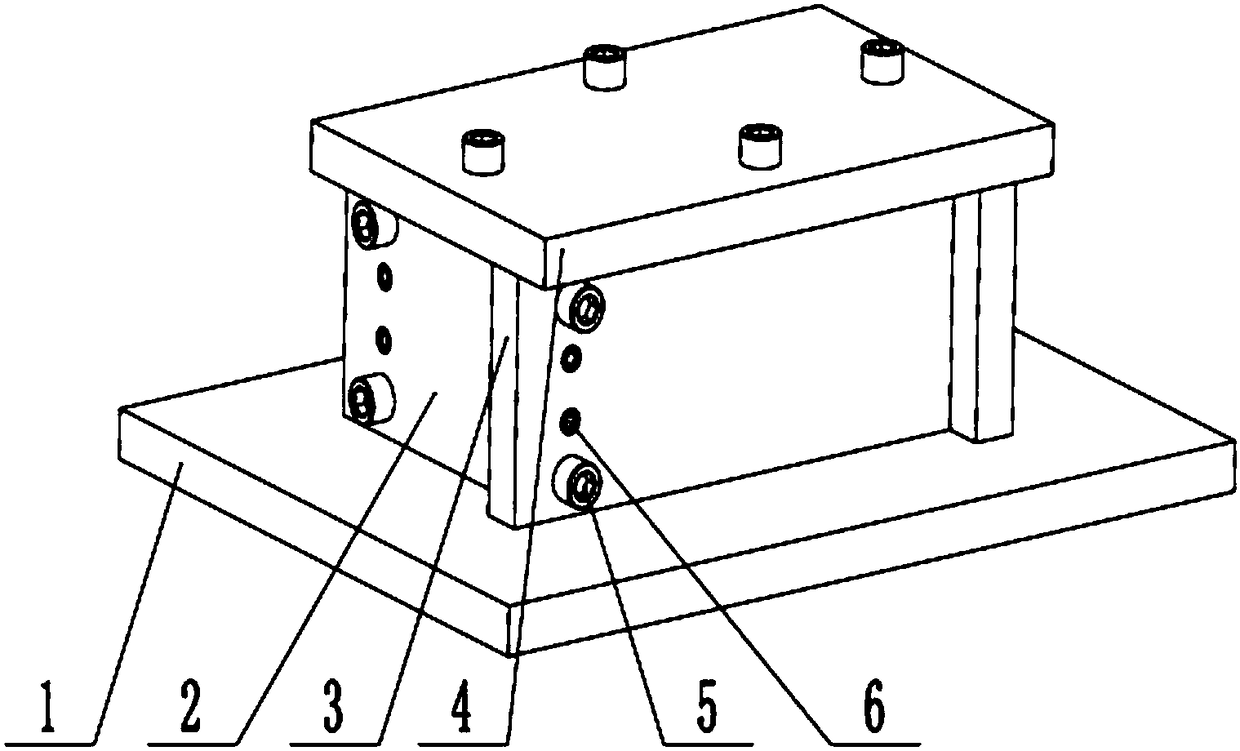

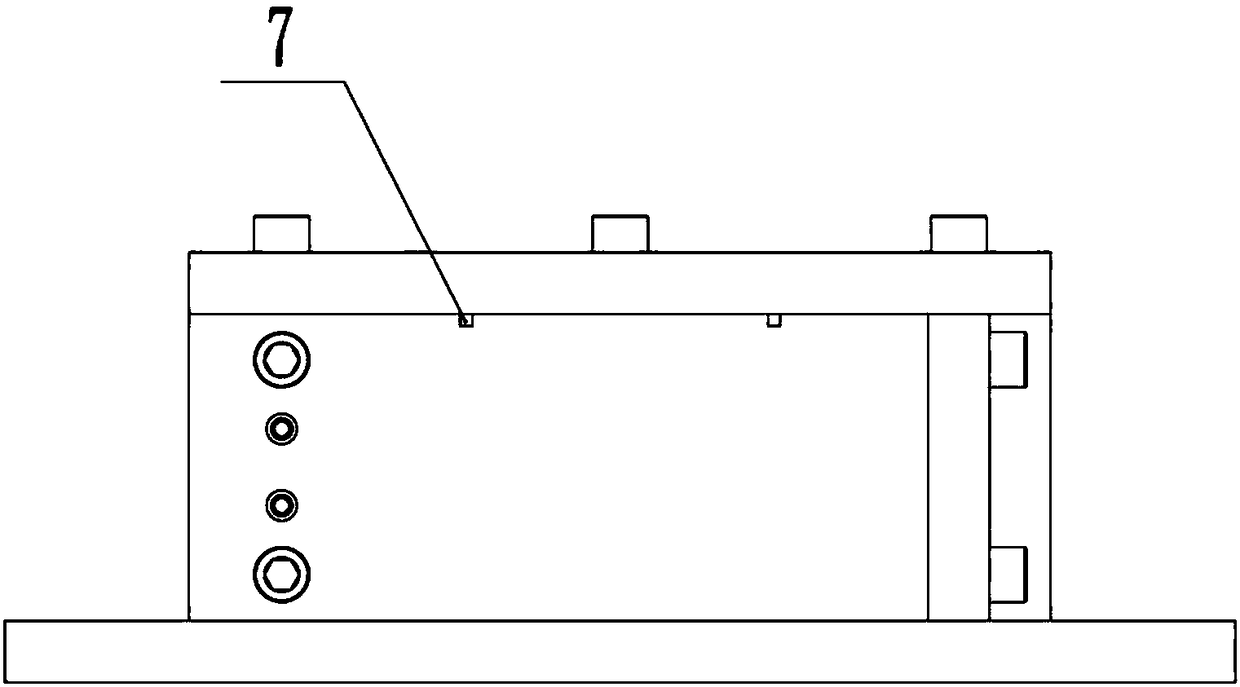

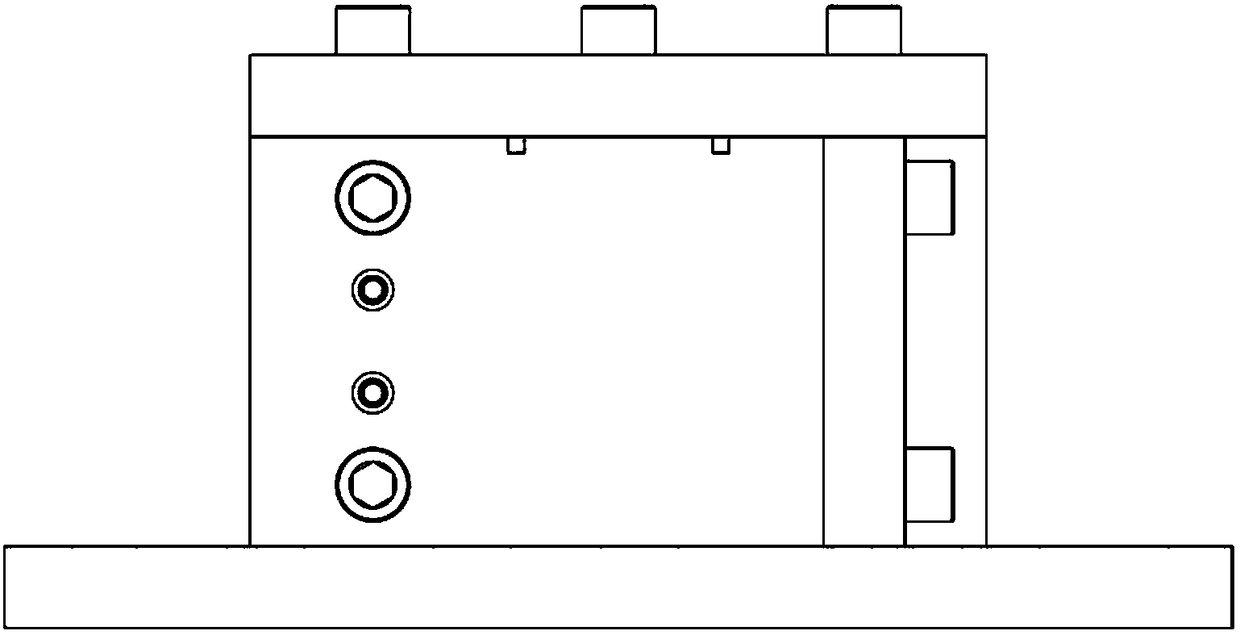

[0032] A mold for making joint specimens for shear-seepage coupling tests, such as Figure 1~4 As shown, it includes a bottom plate 1 , two short side baffles 2 , two long side baffles 3 , a cover plate 4 , screws 5 , positioning pins 6 and square slots 7 . When assembling, first fix a short side baffle 2 and a long side baffle 3 with two positioning pins 6, and then fix the other short side baffle 2 and a long side baffle 3 with two positioning pins 6 , and then place the matching joint replication silica gel plate and rectangular iron block in the cavity of the above-mentioned combined long and short boards, and then install the other four positioning pins 6 and eight screws 5 so that they are fastened as a whole, on the long and short side boards Apply a special release agent for epoxy resin mortar around the inner side of the cover and the bottom of the cover, so that you can start to make the upper half of the rock joint.

[0033] In order to pull out the positioning pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com