Mold of plastic density sheet for molding test

A technology of density sheets and plastics, applied in the preparation of test samples, measuring devices, strength characteristics, etc., can solve problems such as inaccurate results, low work efficiency, and affecting production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

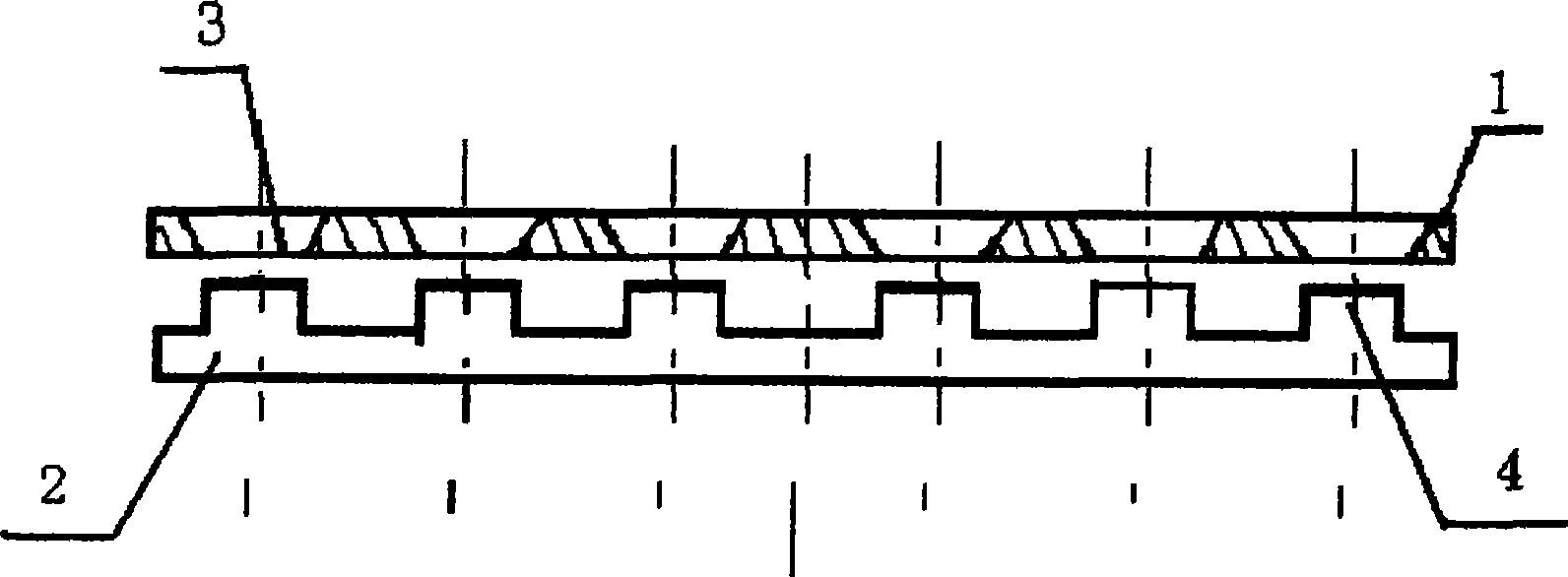

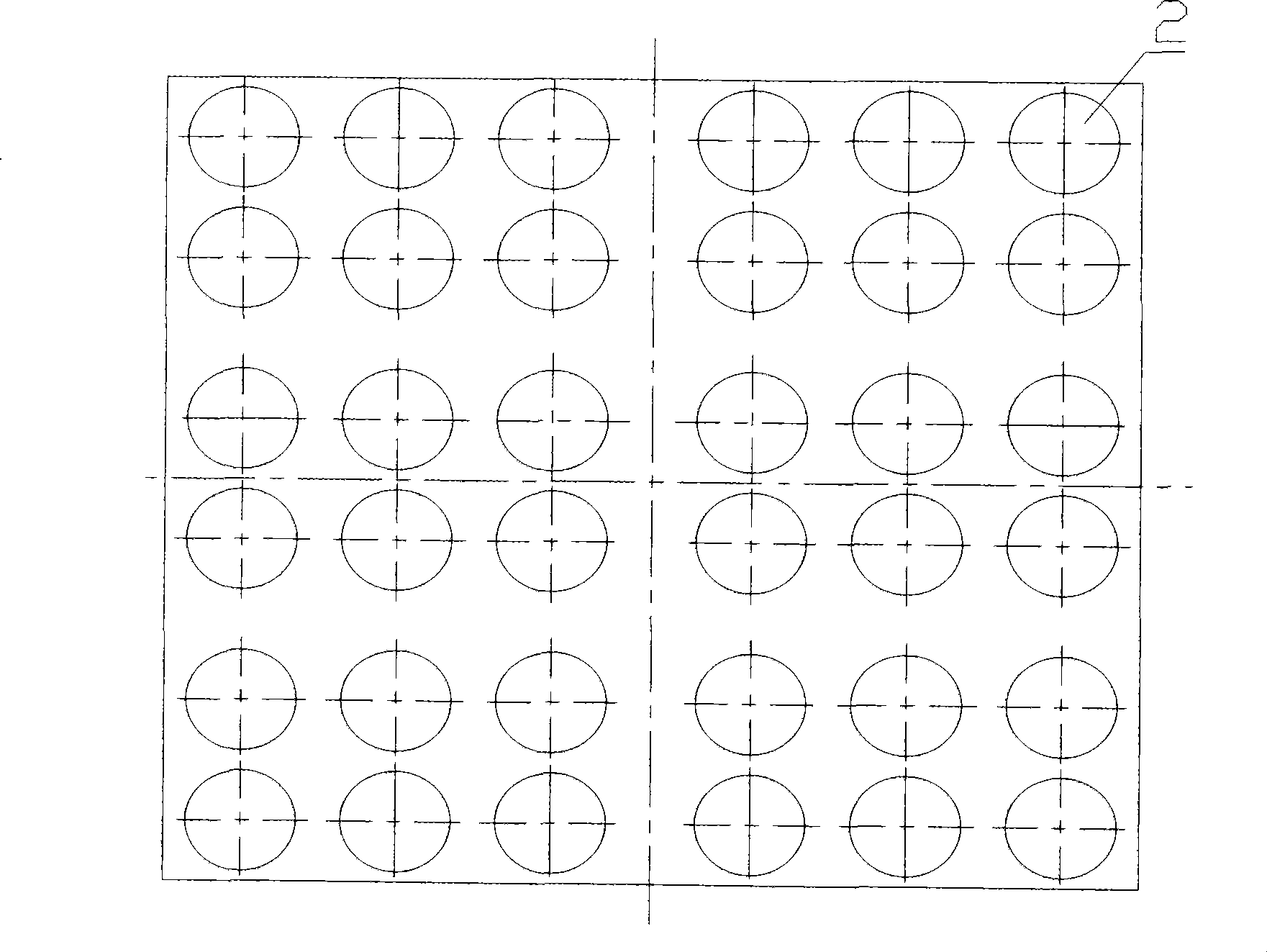

[0009] As shown in the figure, the mold of the plastic density sheet for the tablet forming test is a mold plate 1 with a plurality of circular holes 3 of the same size and regular distribution, and a matching demoulding base plate 2; The circular hole 3 is in the shape of an inverted truncated cone, and the demoulding bottom plate 2 is provided with a boss 4 matching the circular hole 3 .

[0010] How to use: Put a solid steel plate under the mold plate 1, and put plastic particles into the round holes 3 respectively. Then put a solid steel plate on top of the mould, put it into an electric vulcanization forming machine for tablet forming. After the molding is completed, as long as the demoulding bottom plate 2 is placed on the lower part, and the bosses 4 on all the demoulding bottom plates 2 are aligned with the round holes 3 on the corresponding abrasive plate 1, the pressed sample can be removed from the round hole 3 break away.

[0011] In actual use, the mold can form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com