Machine-made sand and pitch adhesion evaluation method

An evaluation method and technology of machine-made sand, applied in the direction of using mechanical devices, instruments, measuring devices, etc., can solve problems such as low safety, complicated operation, and long time consumption, and achieve reliable results, simple operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

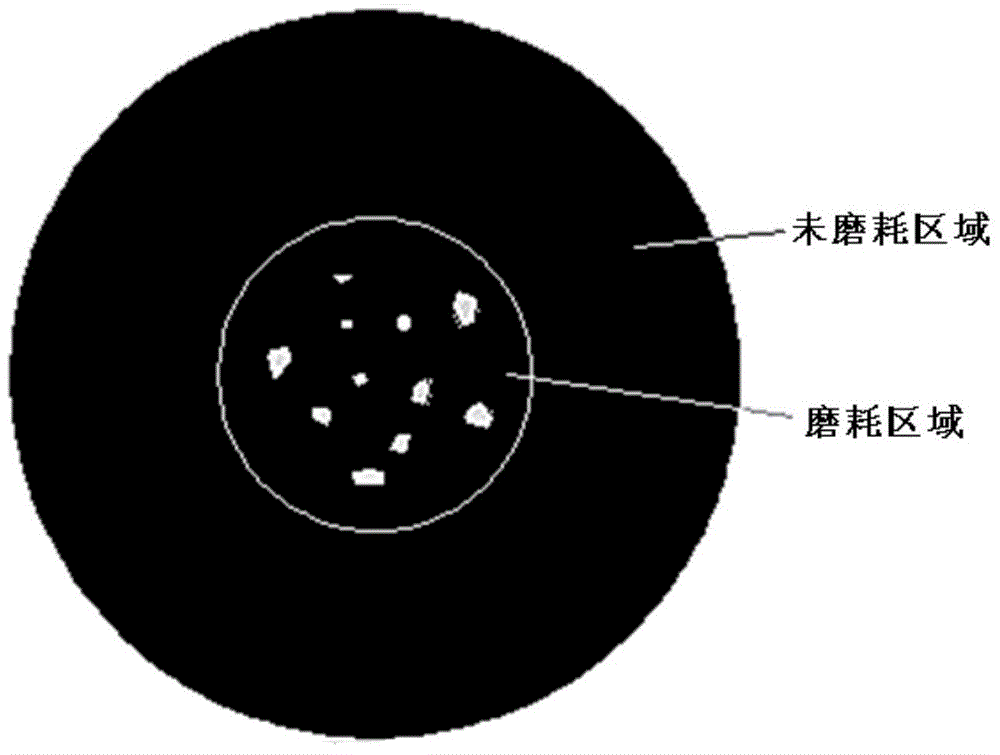

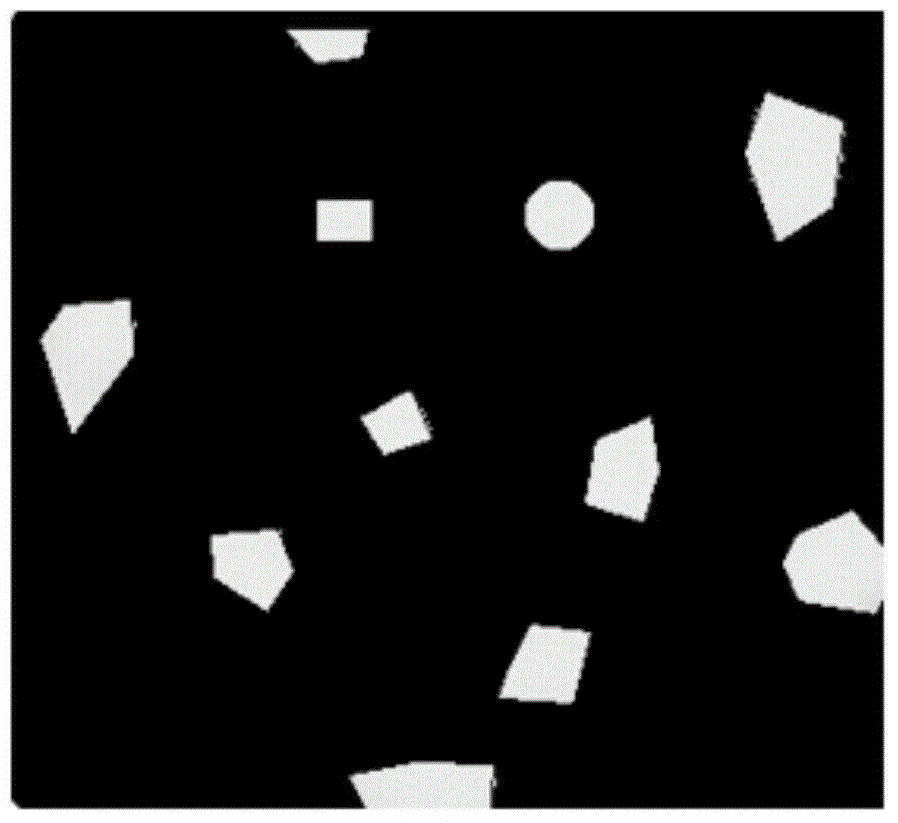

Image

Examples

Embodiment 1

[0023] Embodiment 1: A method for evaluating the adhesion of machine-made sand and asphalt, mainly comprising the following steps:

[0024] (1) Prepare machine-made sand according to the gradation requirements in Table 1; bake the prepared machine-made sand in an oven at 180°C for at least 4 hours;

[0025] Table 1: Grading of machine-made sand

[0026]

[0027] (2) Prepare No. 90 base asphalt and heat it in a small oven at 150° C., wherein the No. 90 base asphalt oil-stone ratio is 9%;

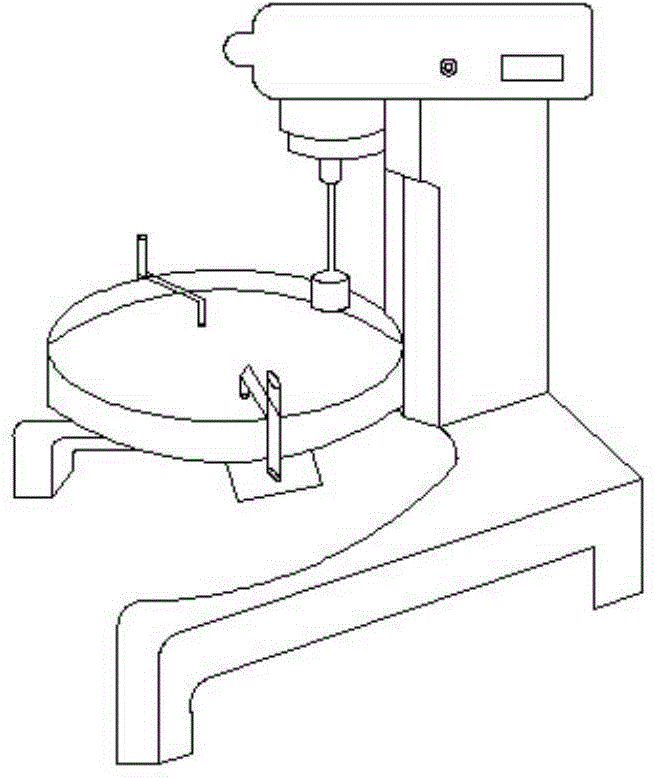

[0028] (3) Heat the mixing pot to 150°C in advance; prepare the linoleum disc, template, and scraper in advance, spread the linoleum disc on the operating table, and then place the template on the flat linoleum in the center;

[0029] (4) Take machine-made sand with a total mass of 1000g and put it into a mixing pot, add No. 90 base asphalt with a quality of 85g for mixing, and the mixing time is 90s;

[0030] (5) Pour the well-mixed asphalt mortar into the test mold and scrape it quickl...

Embodiment 2

[0045] A method for evaluating the adhesion of machine-made sand and asphalt, mainly comprising the following steps:

[0046] (1) Prepare machine-made sand according to the gradation requirements in Table 1; bake the prepared machine-made sand in an oven at 180°C for at least 4 hours;

[0047] Table 1: Grading of machine-made sand

[0048]

[0049] (2) prepare No. 90 base bitumen, heat in the small baking oven of 150 ℃, wherein No. 90 base bitumen bitumen ratio is 9%;

[0050] (3) Heat the mixing pot to 150°C in advance; prepare the linoleum disc, template, and scraper in advance, spread the linoleum disc on the operating table, and then place the template on the flat linoleum in the center;

[0051] (4) Take machine-made sand with a total mass of 1000g and put it into a mixing pot, add No. 90 base asphalt with a quality of 85g for mixing, and the mixing time is 90s;

[0052](5) Pour the well-mixed asphalt mortar into the test mold and quickly level it. The whole operatio...

Embodiment 3

[0063] Embodiment 3: a method for evaluating the adhesion of machine-made sand and asphalt, mainly comprising the following steps:

[0064] (1) Prepare machine-made sand according to the gradation requirements in Table 1; bake the prepared machine-made sand in an oven at 180°C for at least 4 hours;

[0065] Table 1: Grading of machine-made sand

[0066]

[0067] (2) Prepare No. 90 base asphalt and heat it in a small oven at 150° C., wherein the No. 90 base asphalt oil-stone ratio is 9%;

[0068] (3) Heat the mixing pot to 150°C in advance; prepare the linoleum disc, template, and scraper in advance, spread the linoleum disc on the operating table, and then place the template on the flat linoleum in the center;

[0069] (4) Weigh the machine-made sand with a total mass of 1000g and put it into the mixing pot, add 90g of No. 90 base asphalt for mixing, and the mixing time is 90s;

[0070] (5) Pour the well-mixed asphalt mortar into the test mold and scrape it quickly. The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com