High-ductility hollow building block and fabrication method thereof

A hollow block and production method technology, applied in the field of building materials, can solve the problems of ordinary block bearing capacity, deformation capacity not meeting the requirements, brittleness, poor crack resistance and seismic performance, and improved seismic fortification requirements, etc. Mechanical properties, the effect of improving seismic performance, improving bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

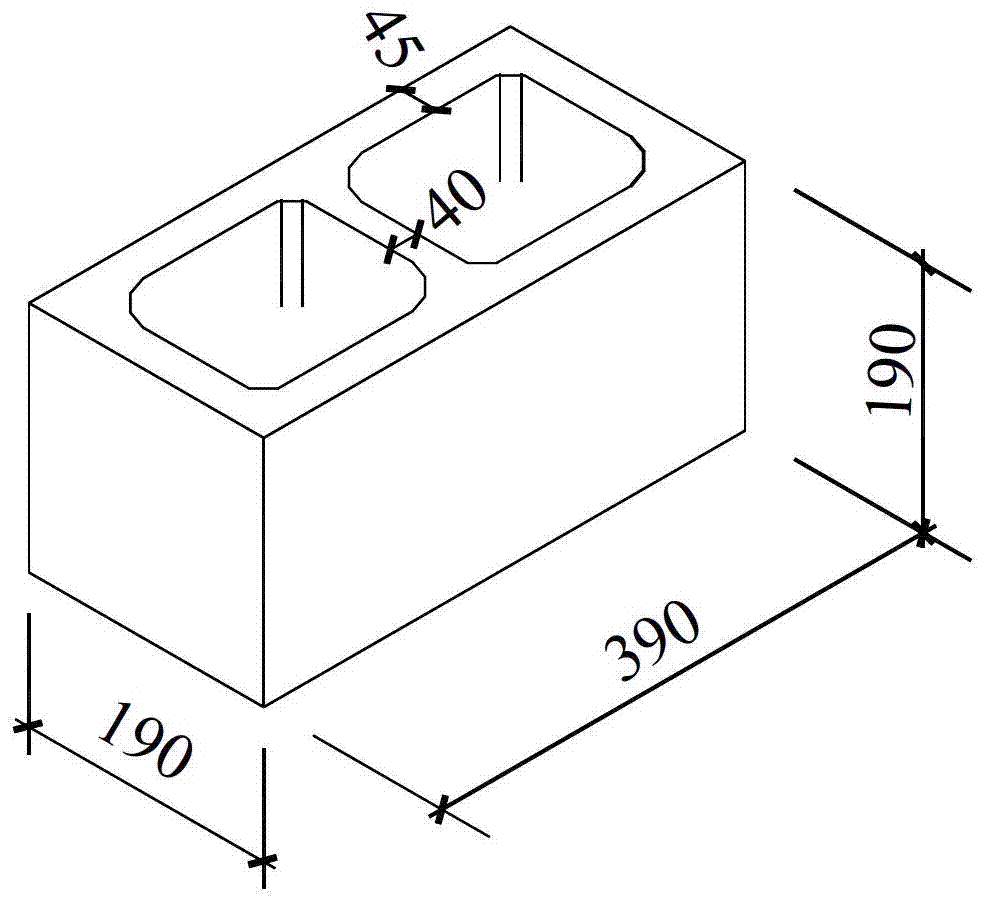

[0026] Follow the technical scheme of the present invention, such as figure 1 As shown, the size of the high ductility hollow block in this example is 390mmx190mmx190mm, the outer wall thickness is 45mm, the rib is 40mm, and the hollow rate is 35.09%.

[0027] Its specific production process is:

[0028] Step 1, preparation of high ductility fiber concrete:

[0029] The components of the high ductility fiber concrete of this embodiment are cement, fly ash, silica fume, sand, PVA fiber and water, wherein, by mass percentage, cement: fly ash: silica fume: sand: water=1: 0.9: 0.1: 0.76: 0.58; based on the total volume of cement, fly ash, silica fume, sand and water mixed uniformly, the volume content of PVA fiber (polyvinyl alcohol fiber) is 1.5%; the cement used is P.O. 52.5R Portland cement, the fly ash is Class I fly ash, the silica fume has an ignition loss of 5%, a silica content of 88%, and a specific surface area of 18,000m 2 / kg of silica fume; the maximum particle s...

Embodiment 2

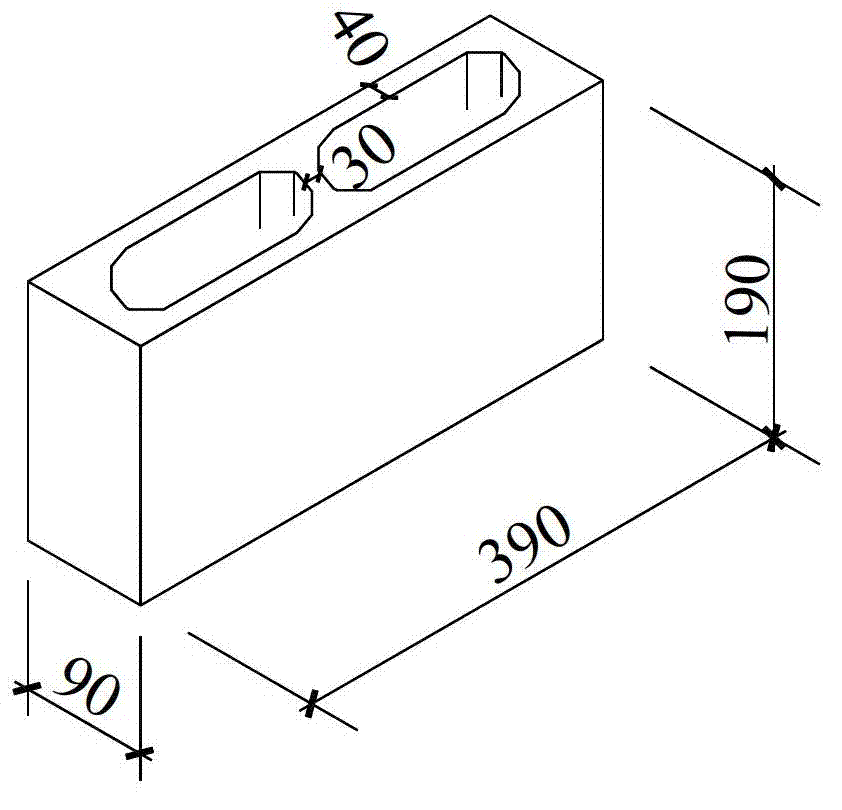

[0040] Such as figure 2 As shown, the difference from Example 1 is that the block size of this example is 390mmx190mmx90mm, the outer wall thickness is 40mm, the rib is 30mm, and the hollow ratio is 41.57%. Other manufacturing methods are the same as Example 1.

Embodiment 3

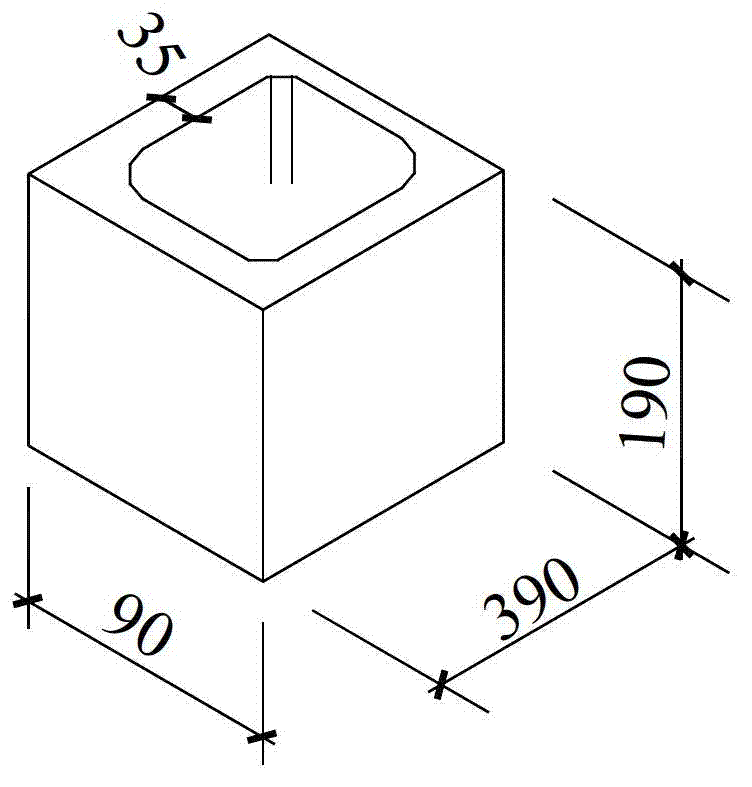

[0042] Such as image 3As shown, the difference from embodiment 1 is that the block size of this embodiment is 190mmx190mmx190mm, the outer wall thickness is 35mm, and the hollow ratio is 39.89%. Other manufacturing methods are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com