Patents

Literature

179 results about "Saline mist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

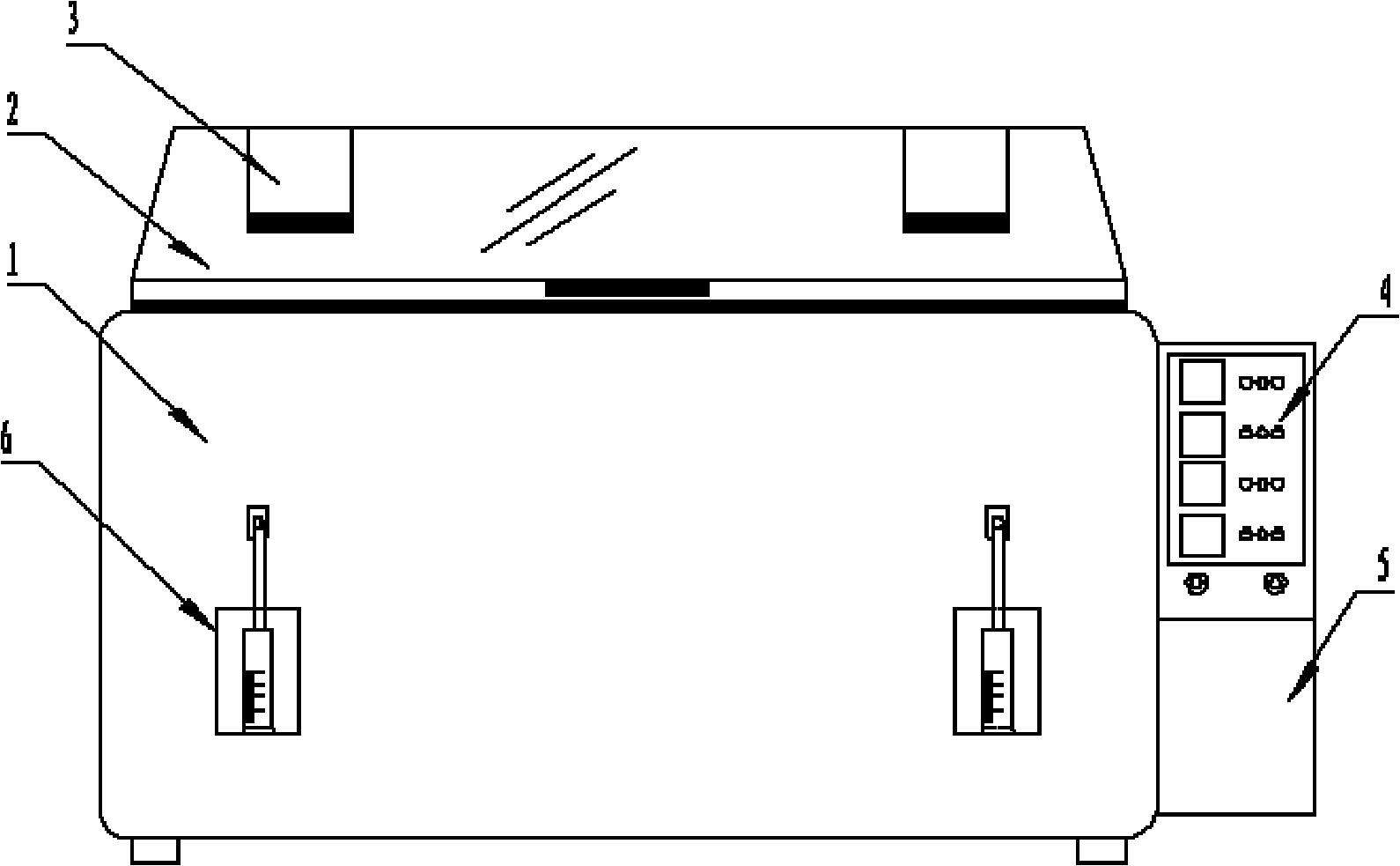

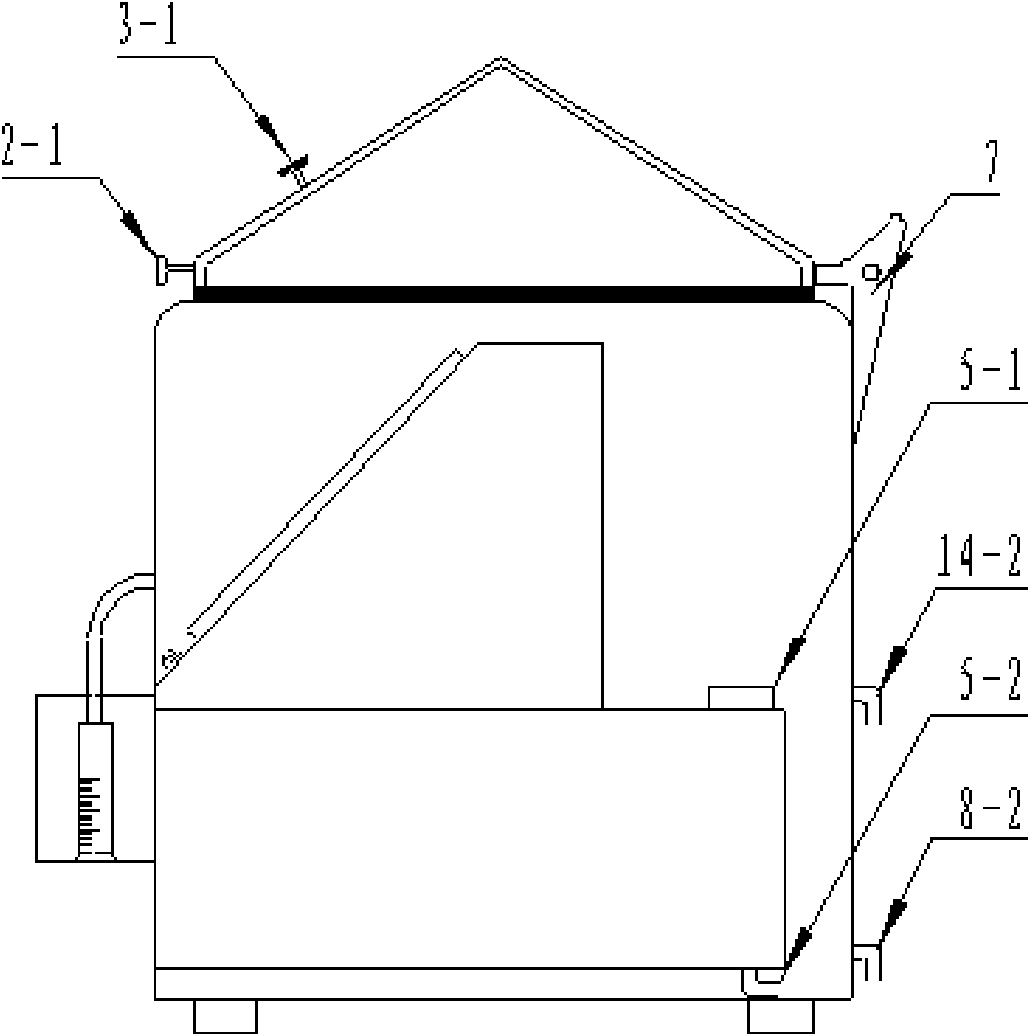

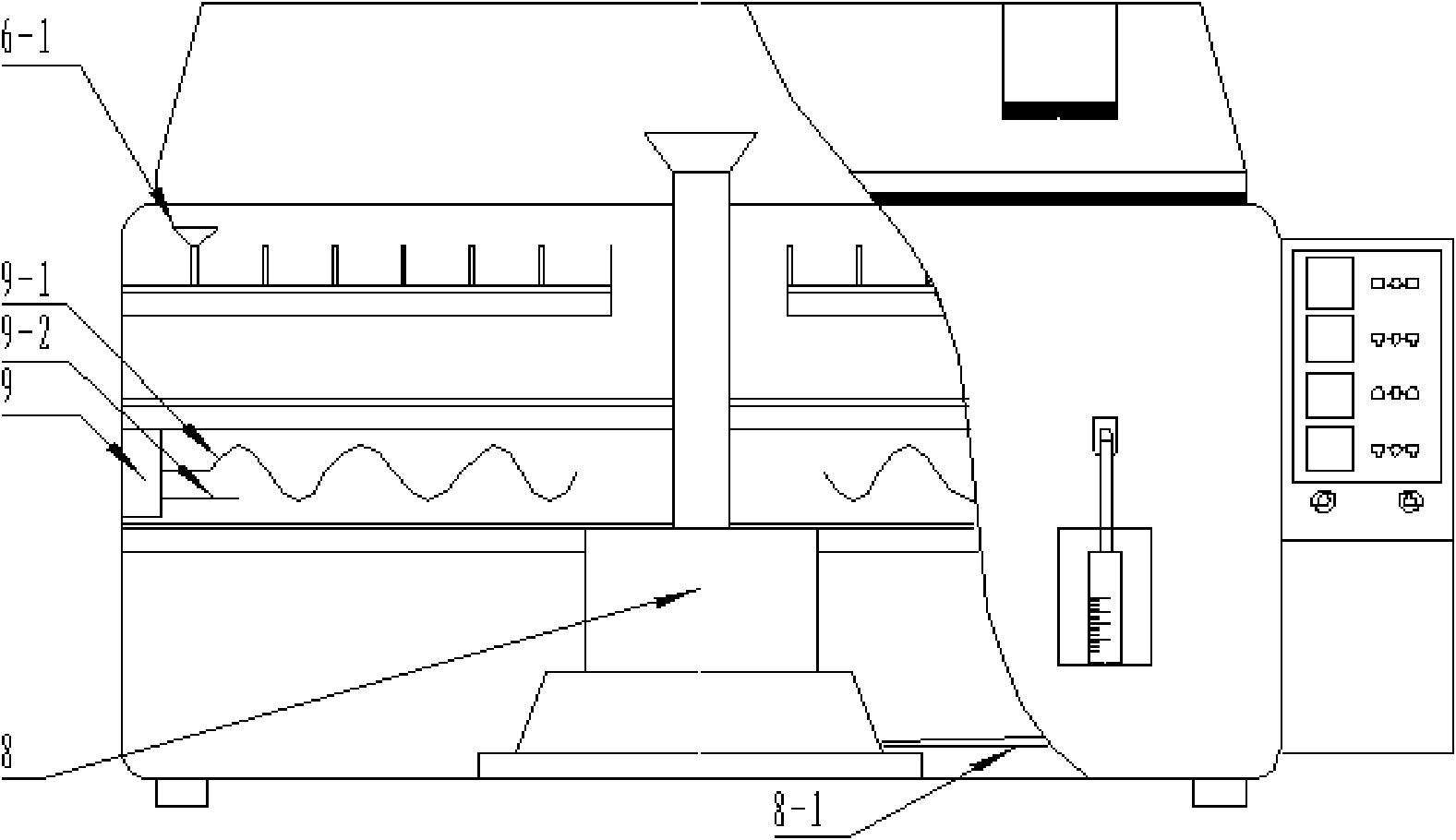

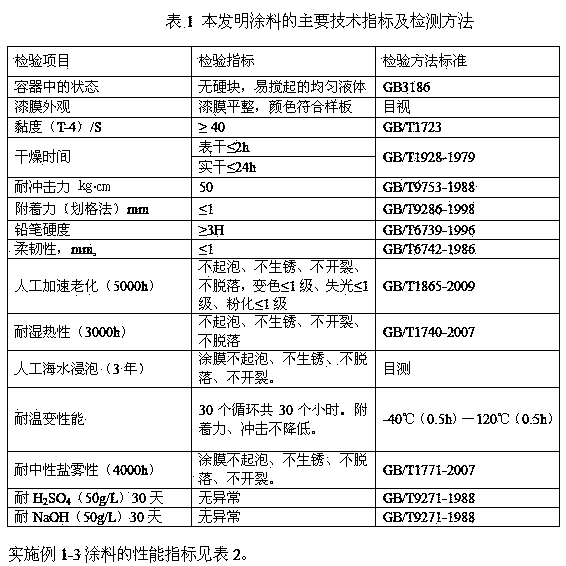

Multi-purpose salt fog test box

ActiveCN102156092ACorrosion Test AccelerationThe principle is simpleWeather/light/corrosion resistanceSaline mistDevice Panel

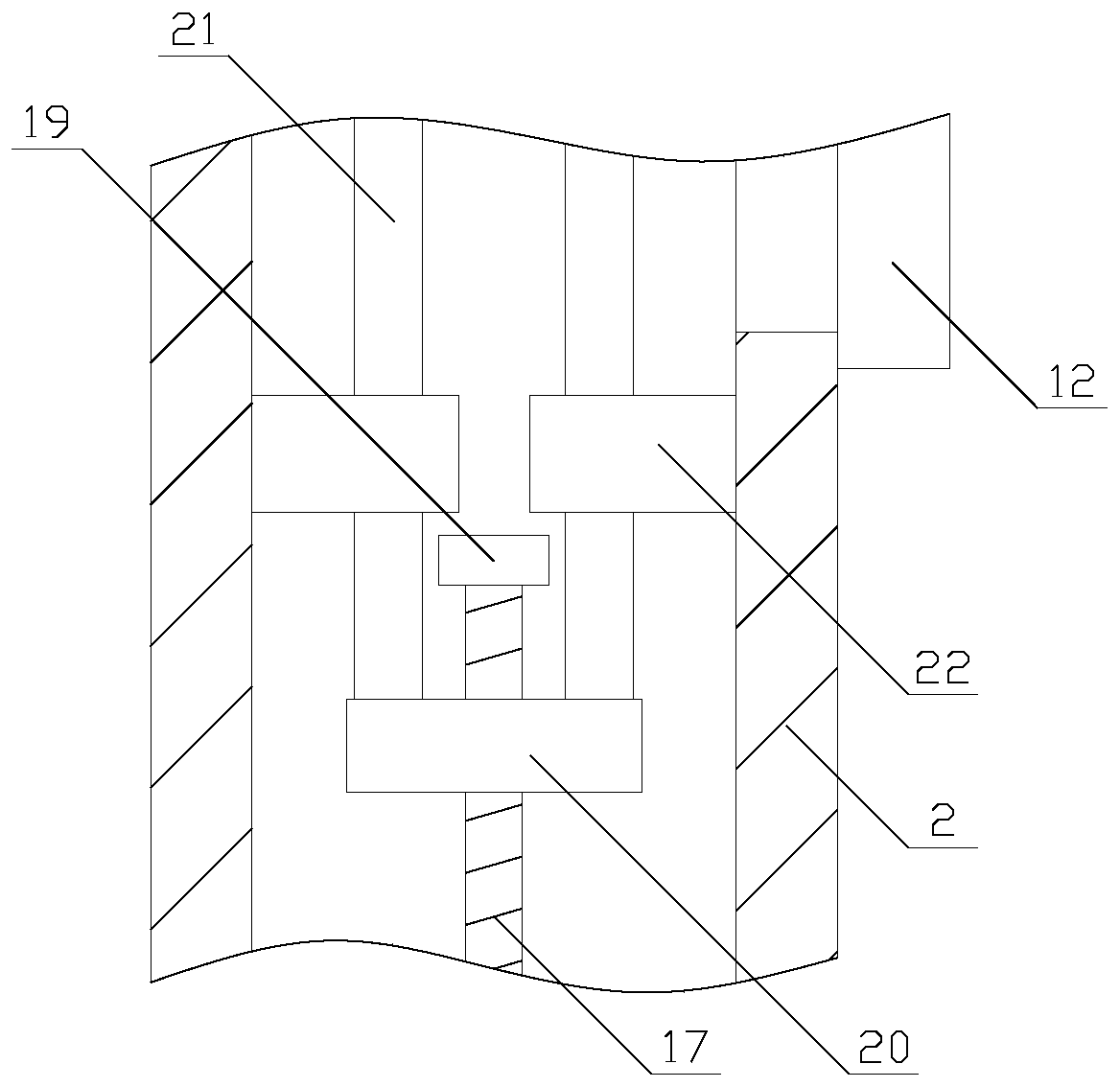

The invention relates to a multi-purpose salt fog test box belonging to the technical field of material analysis equipment. The multi-purpose salt fog test box comprises a main box body (1), a box cover (2), an observation cover (3), a salt water box (5) and a control device panel (4), wherein the main box body (1) is provided with a sealed water tank and internally comprises a salt fog collector(6-1), an ultrasonic salt fog generating device (8), a conduit (8-1), a heating and temperature warning device (9), a temperature sensor (10), a humidity sensor (11), support blocks (12-1), (13-1) and (14-1), a diaphragm (13), a sealing diaphragm (14) and a sample stage combination shelf (12); the external accessories of the test box comprise a box cover handle (2-1), a salt water box cover (5-1), a salt fog metering device (6), waste liquid drain pipes (5-2) and (8-2), a pipe (14-2) and a hinge part (7). The multi-purpose salt fog test box adopts the principle of the ultrasonic spray, omits the air compressor in the traditional salt fog test box, simplifies the test box and can be used for corrosion tests under constant-temperature-and-humidity conditions, alternating wetting and drying conditions and other conditions.

Owner:安科工程技术研究院(北京)有限公司

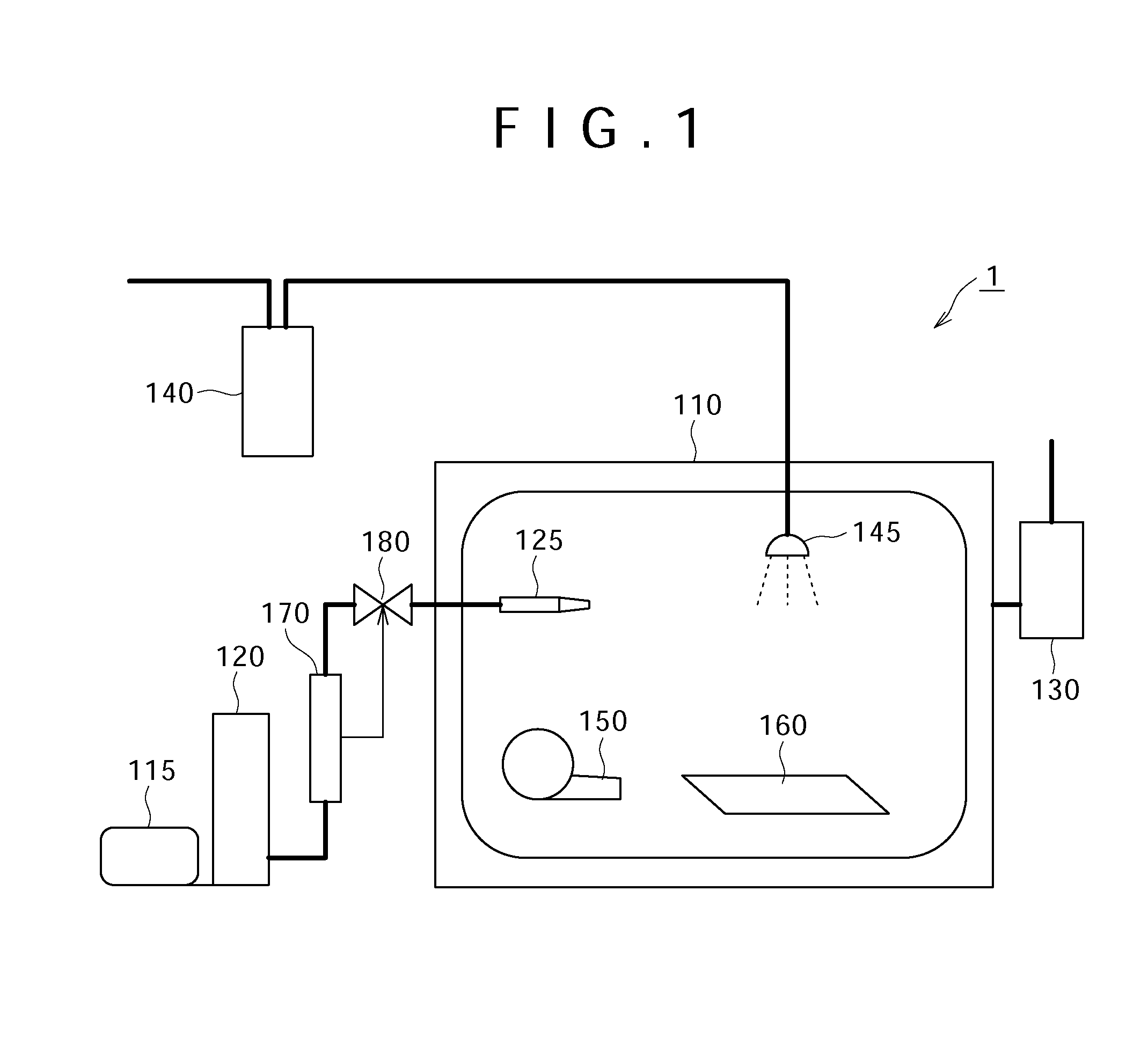

Atmospheric corrosion test procedure and its apparatus

InactiveUS20130164852A1Improve test accuracyReduce varianceWeather/light/corrosion resistanceBiological testingSaline waterSalt content

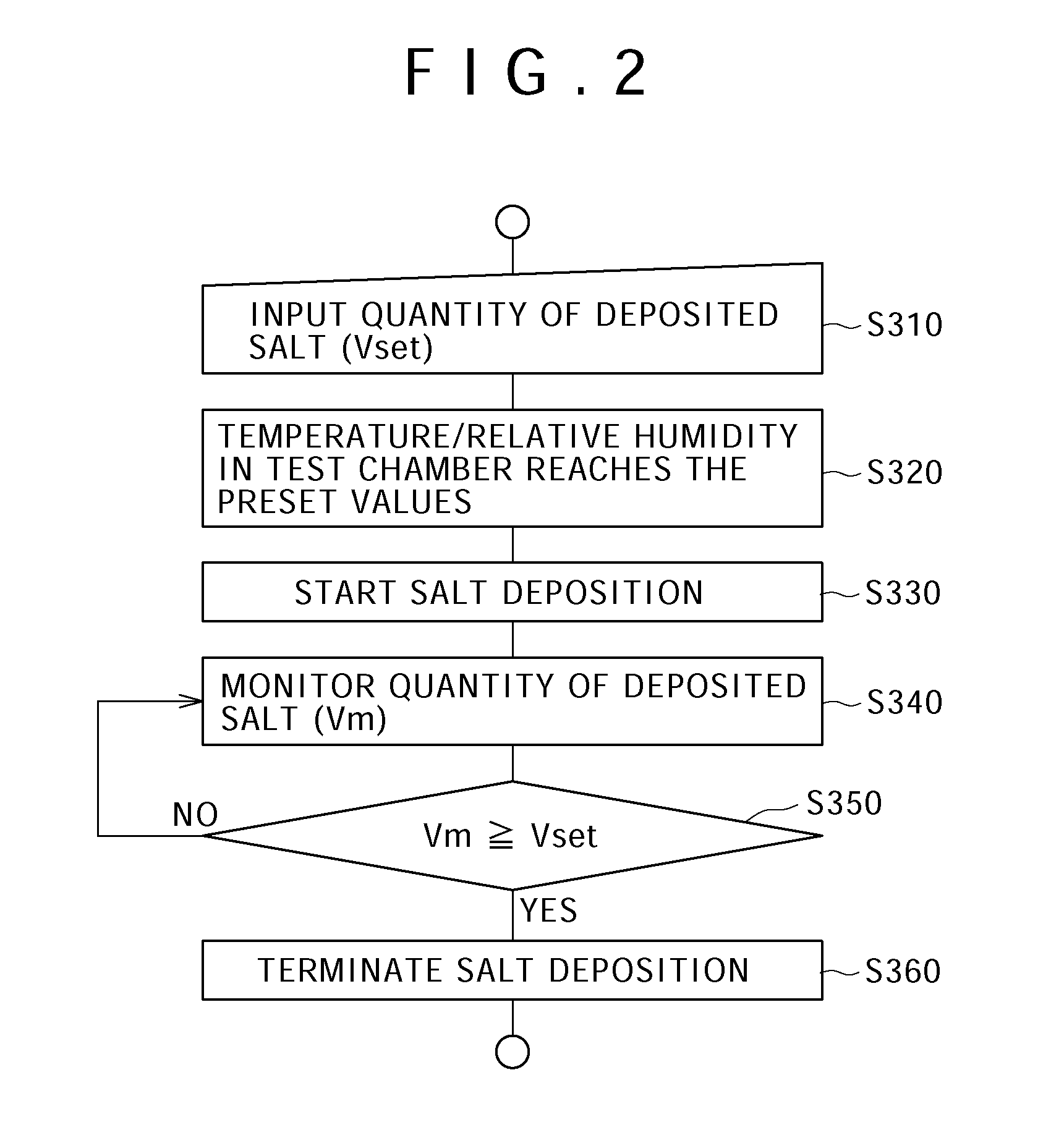

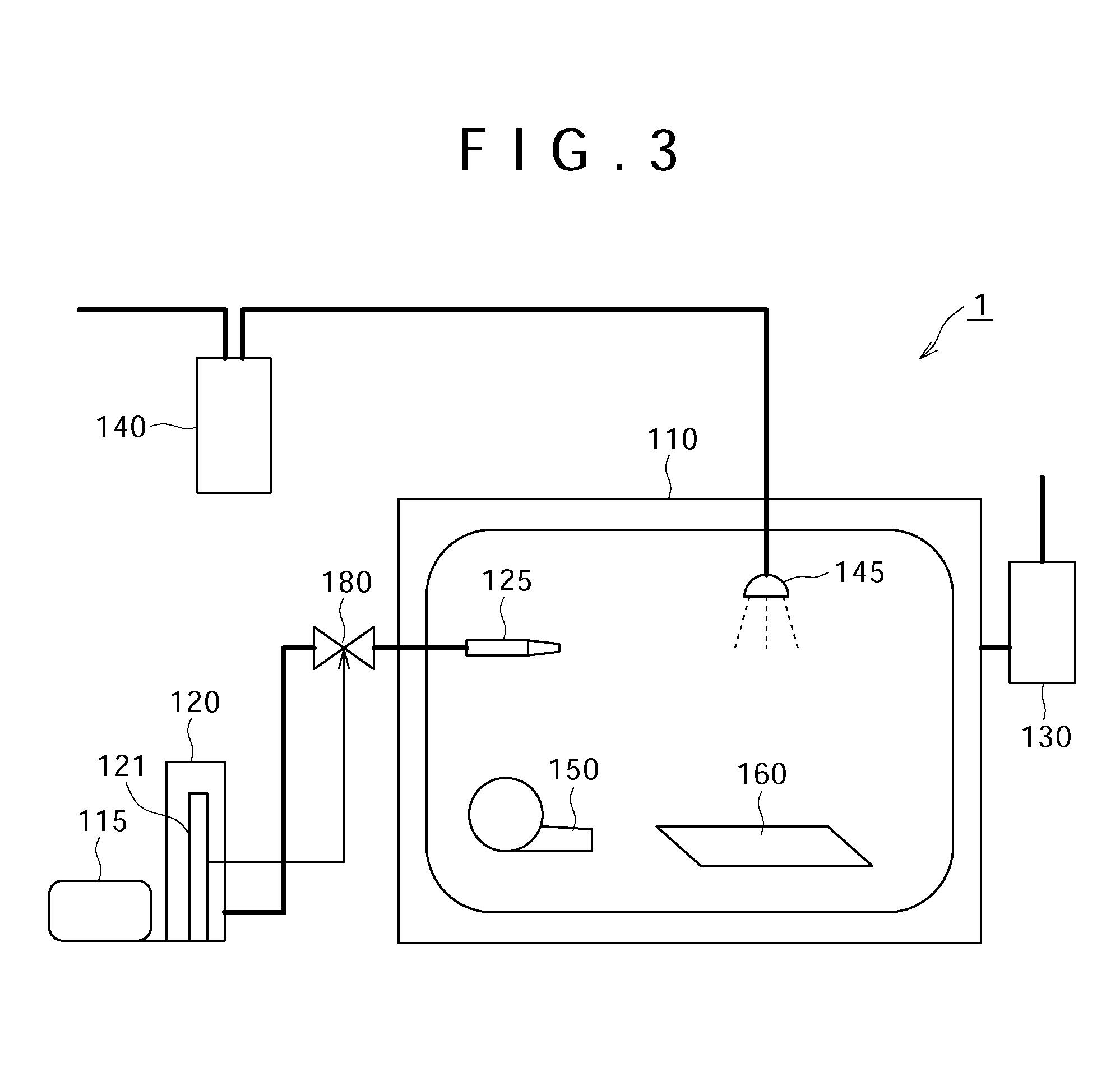

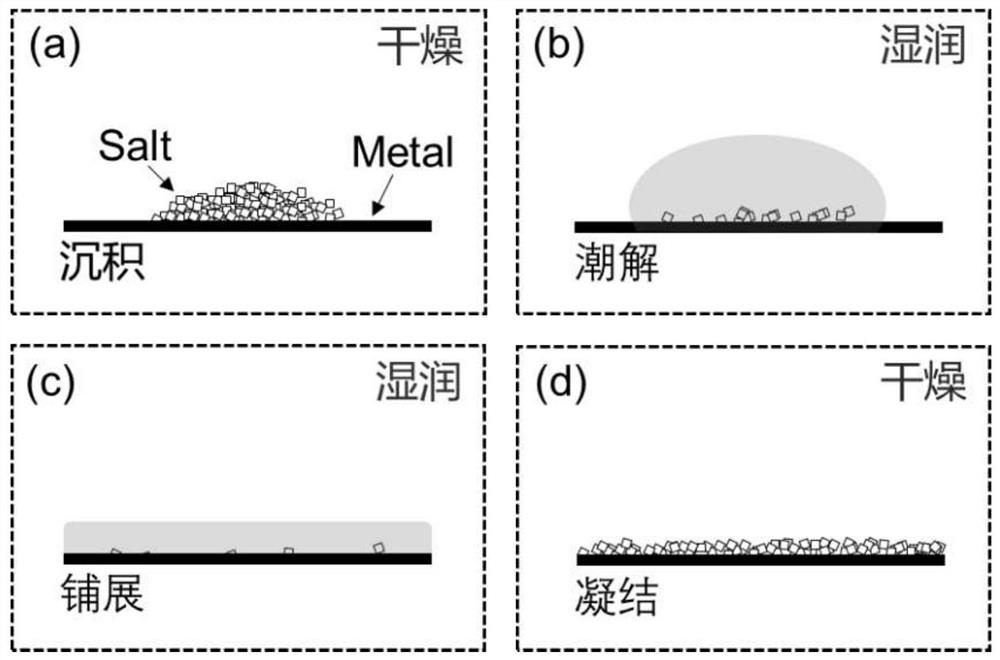

Provided are an atmospheric corrosion test procedure and an apparatus used for the test. The procedure involves a salt spray step for supplying salt content containing chloride ions on the surfaces of test pieces placed in a thermo-humidistat chamber and a subsequent dry-wet cyclic step including a dry sub-step for drying the surface of the test pieces in the thermo-humidistat chamber at a low relative humidity and a subsequent wet sub-step at a higher relative humidity than that in the dry sub-step, which are cycled. The salt content is supplied by spraying the salt water in the salt spray step. An exhaust step for removing the salt mist sprayed inside thermo-humidistat chamber is further inserted between the salt deposition step and the dry sub-step. The quantity of the salt content deposited on the surfaces of the test pieces is controlled by adjusting the quantity of the sprayed salt water.

Owner:HITACHI LTD

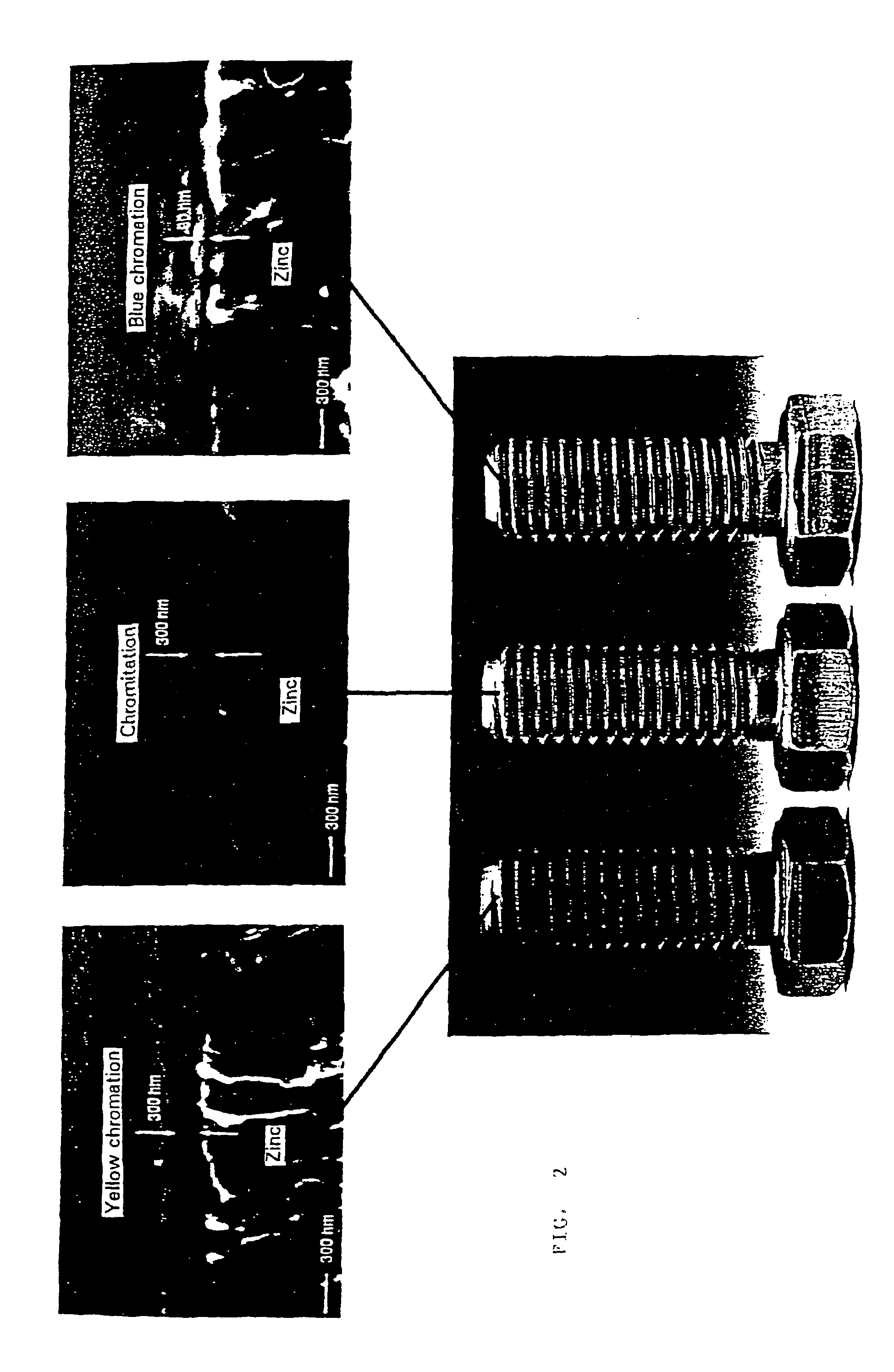

Chromium (VI)-free conversion layer and method for producing it

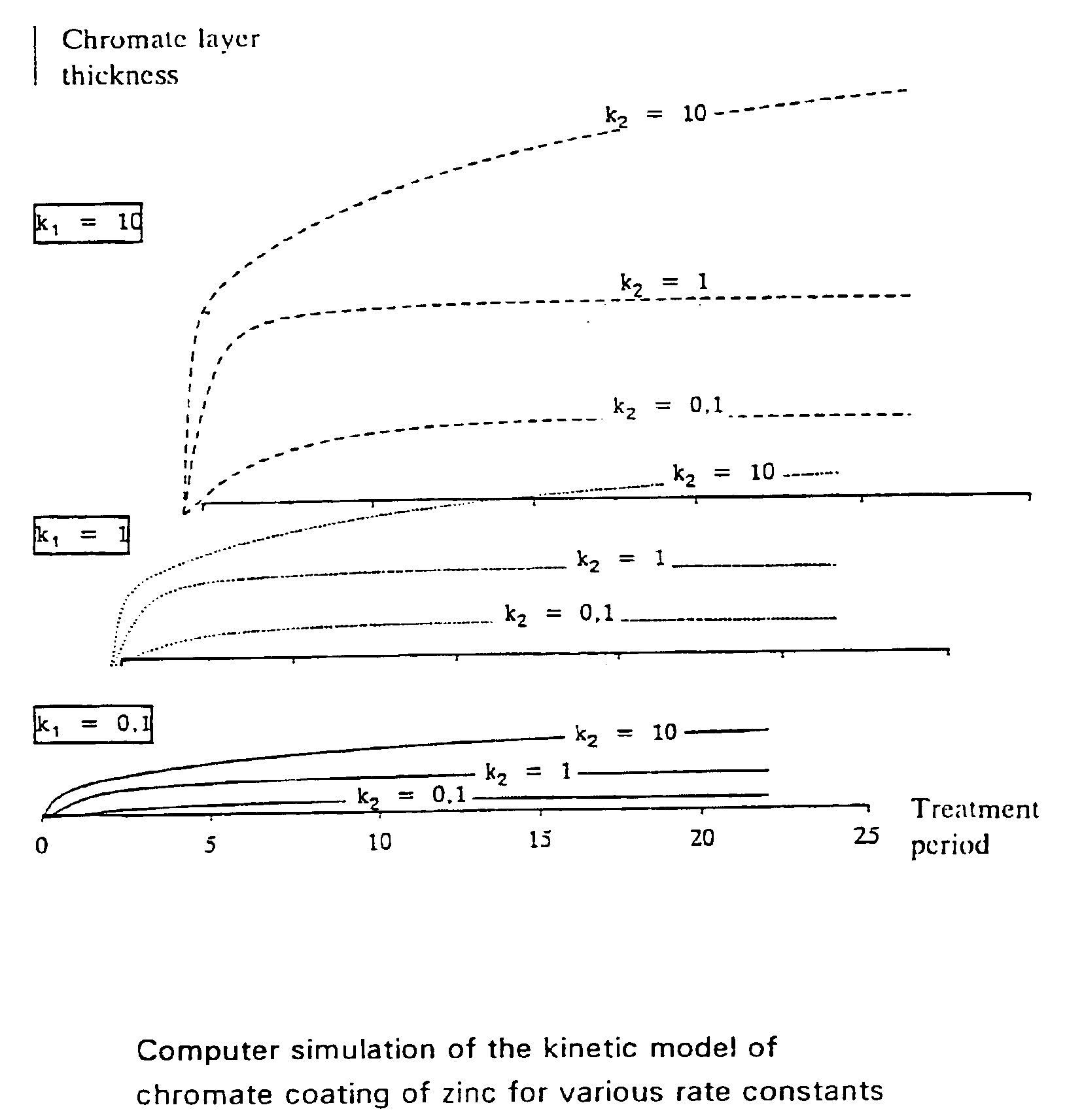

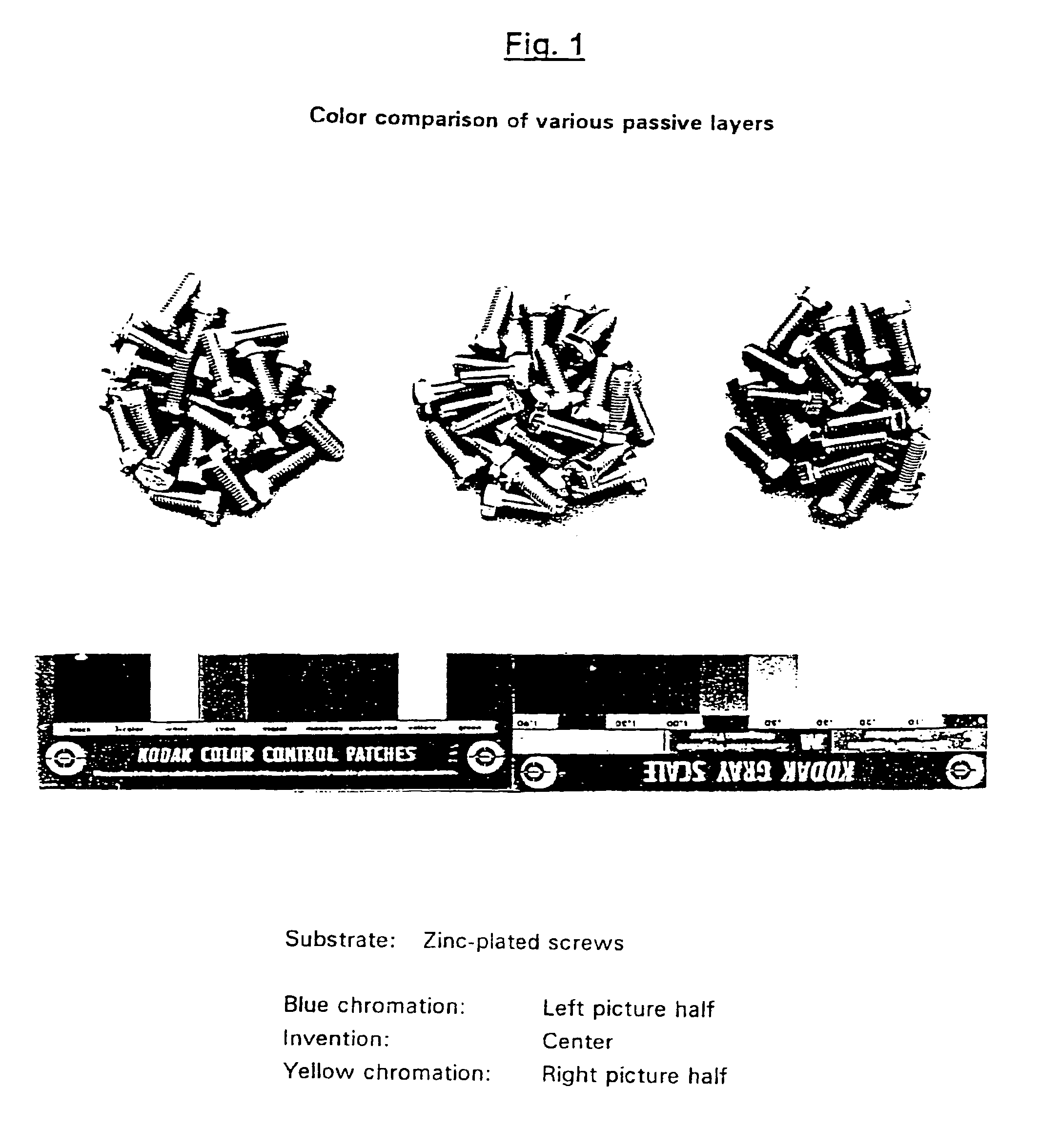

A chromium(VI)-free, chromium(III)-containing and substantially coherent conversion layer on zinc or zinc alloys presenting, even in the absence of further components such as silicate, cerium, aluminum and borate, a corrosion protection of approx. 100 to 1000 h in the salt spray test according to DIN 50021 SS or ASTM B 117-73 until first attack according to DIN 50961 Chapter 10; being clear, transparent and substantially colorless and presenting multi colored iridescence; having a layer thickness of approx. 100 nm to 1000 nm; and being hard, adhering well and being resistant to wiping.

Owner:SURTEC INT

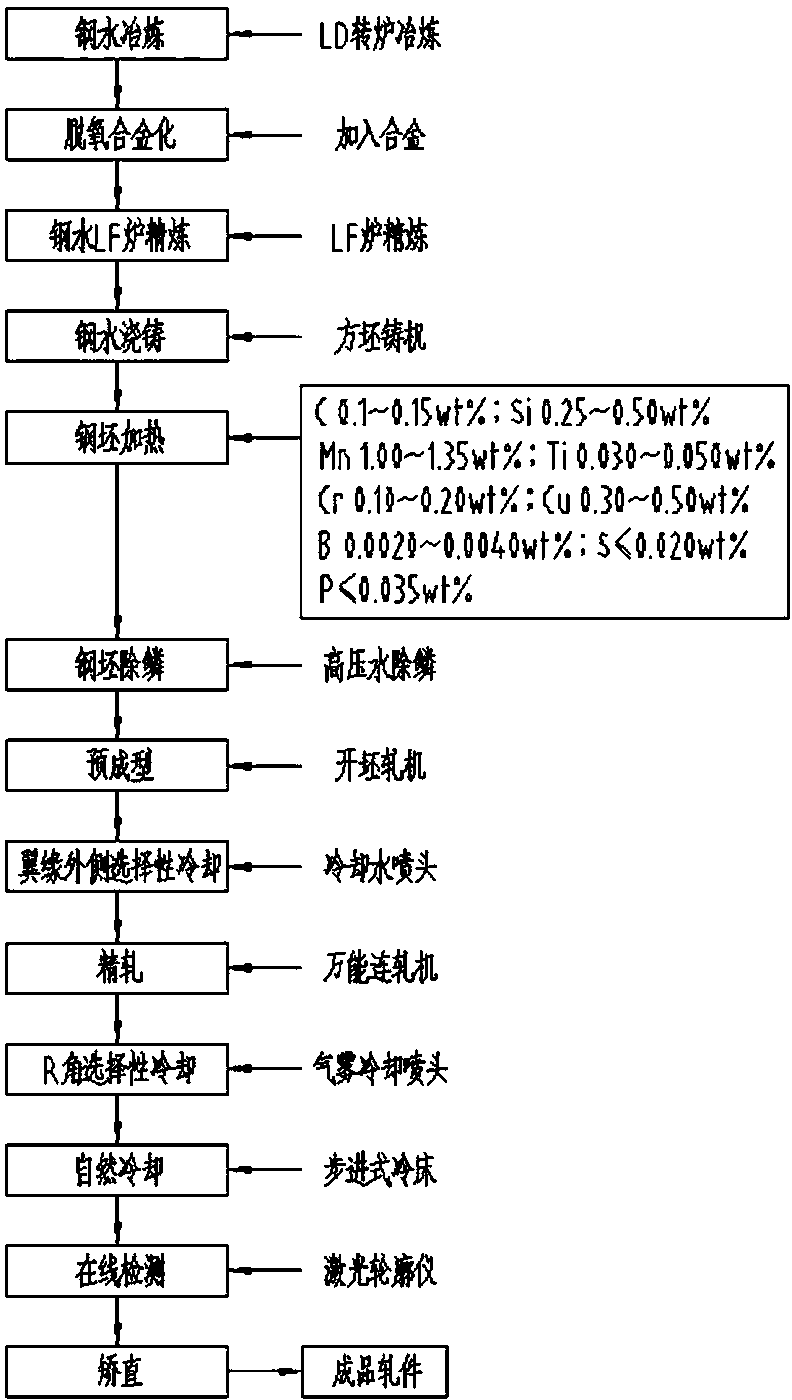

Quake-proof and corrosion-resistant H-shaped steel with high performance and processing method thereof

Owner:WUKUN STEEL

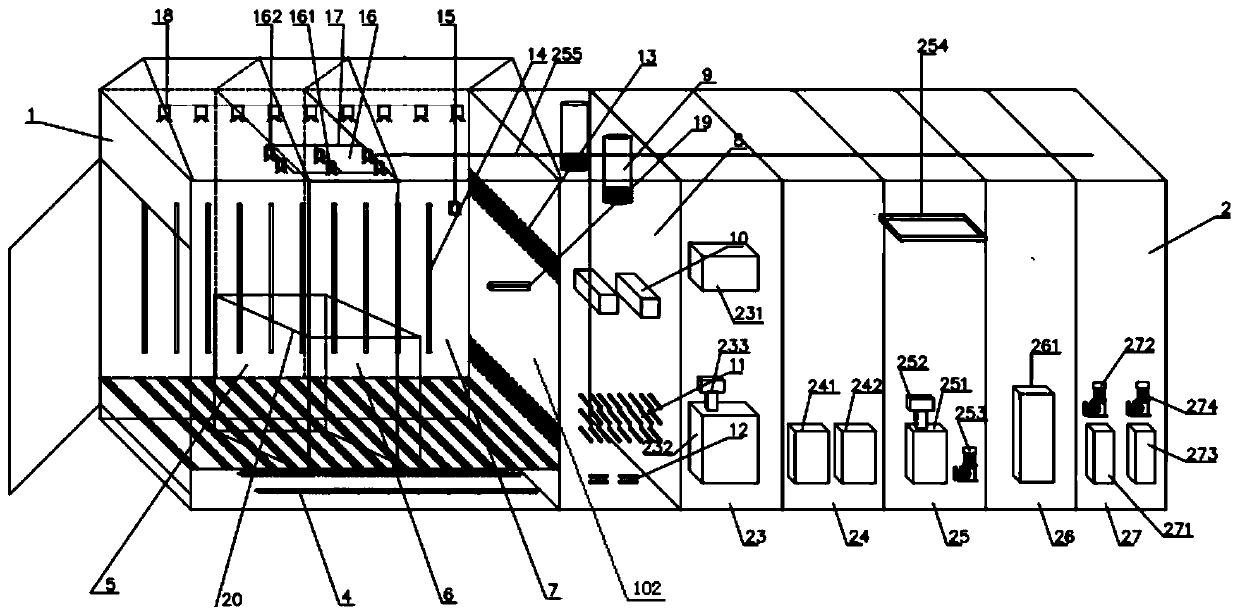

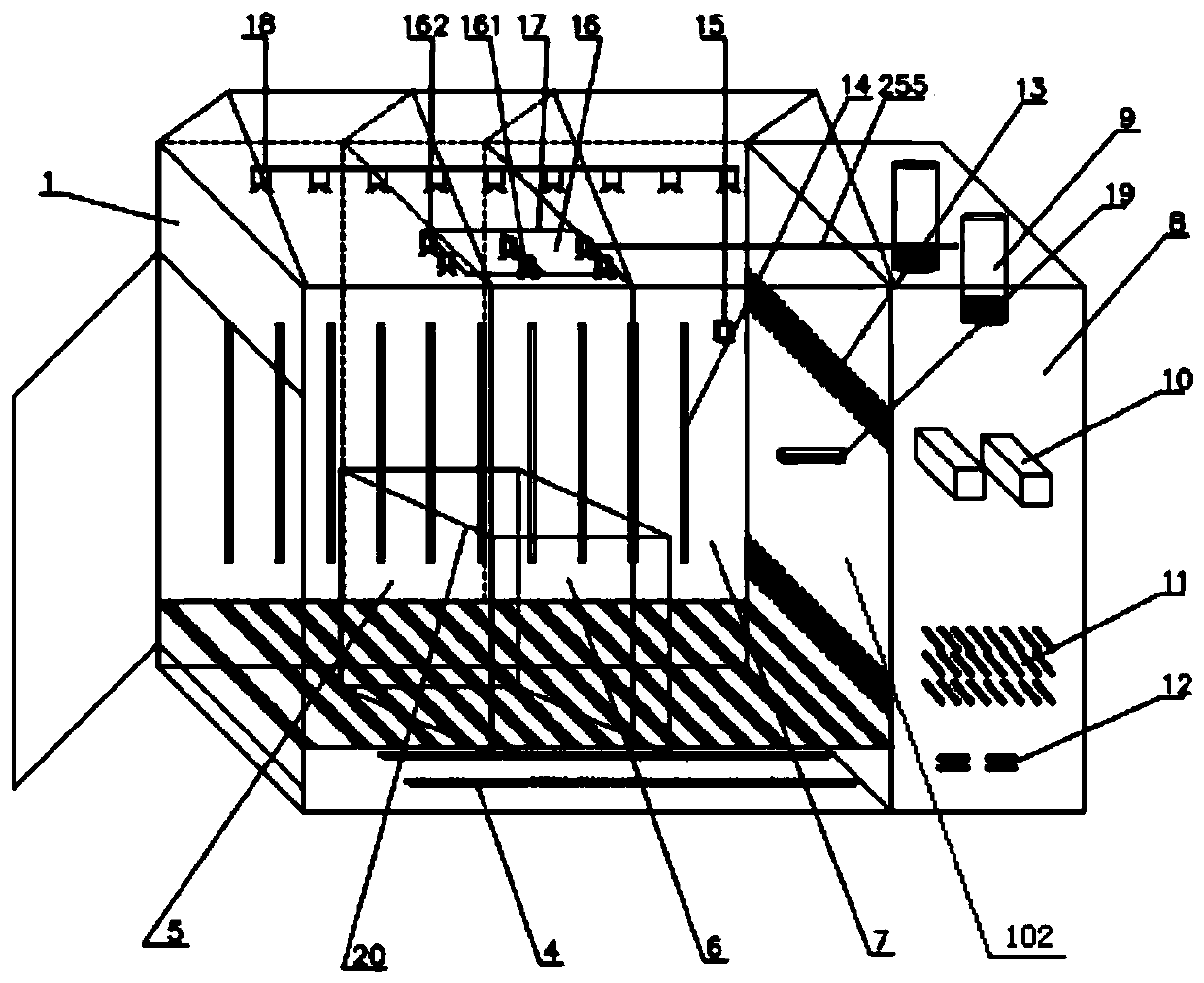

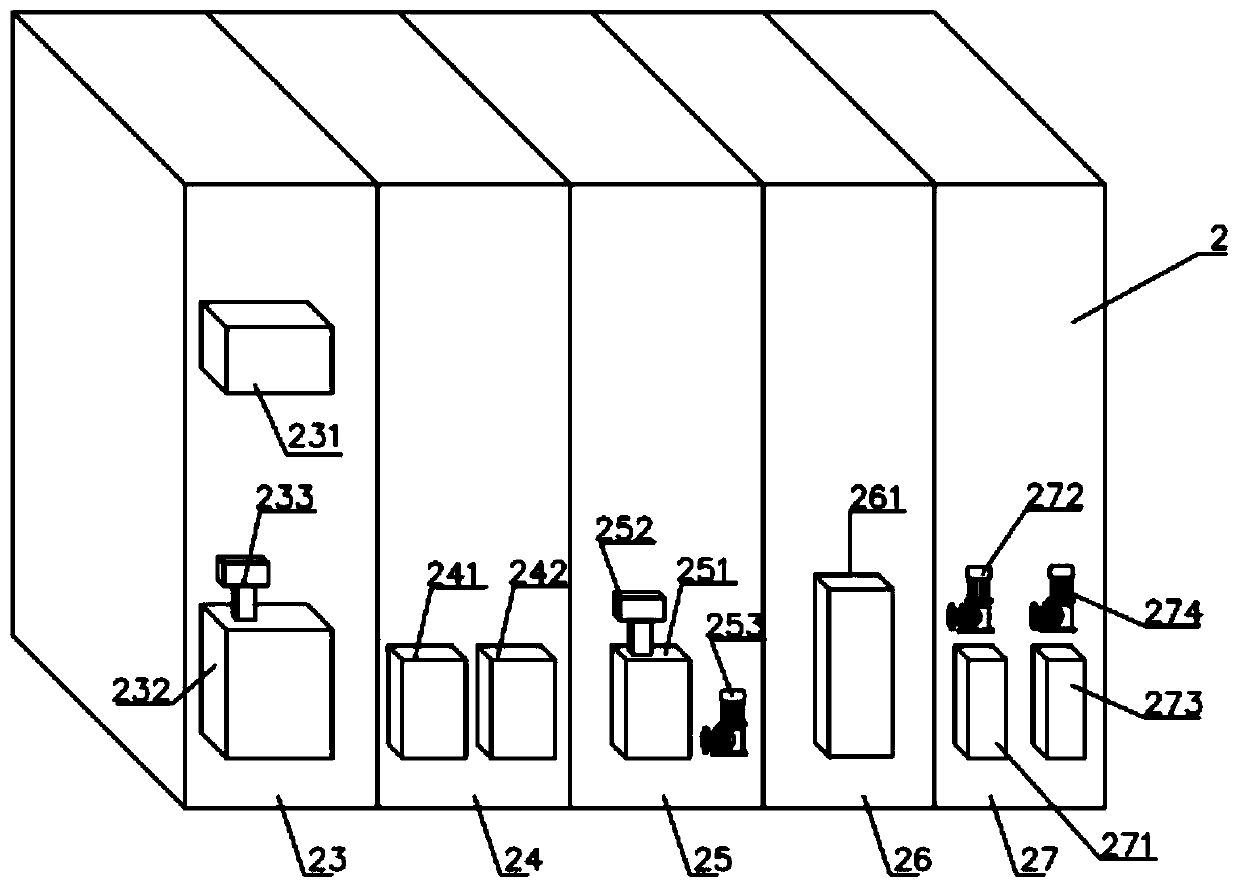

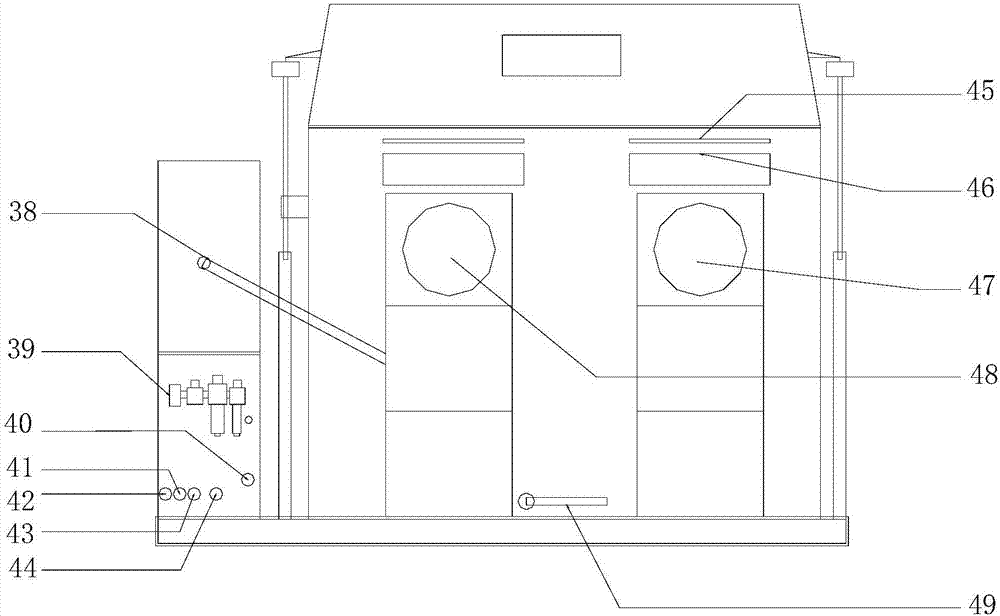

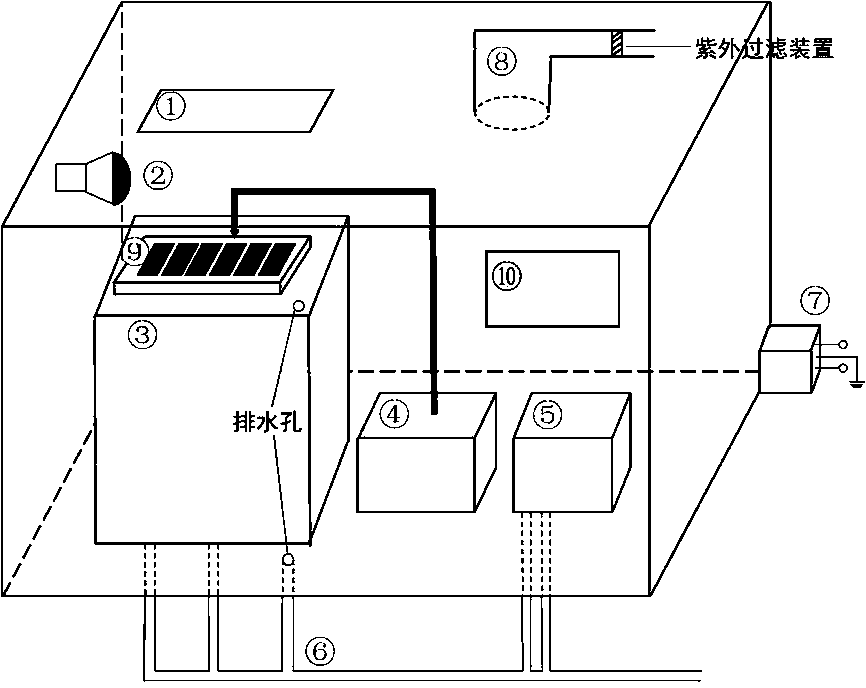

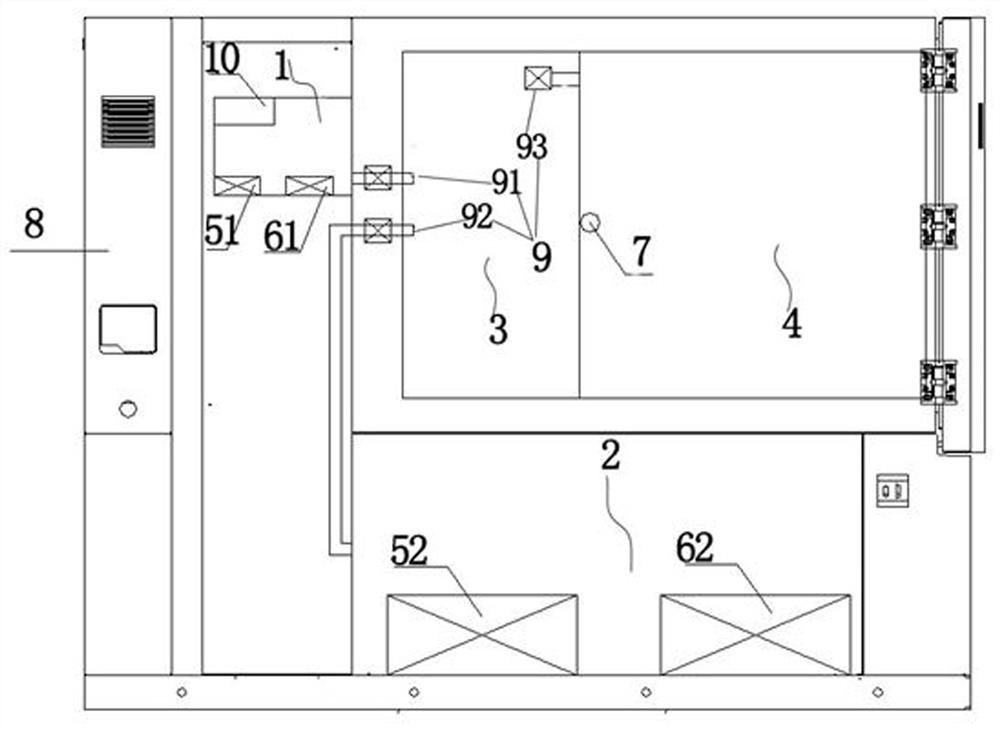

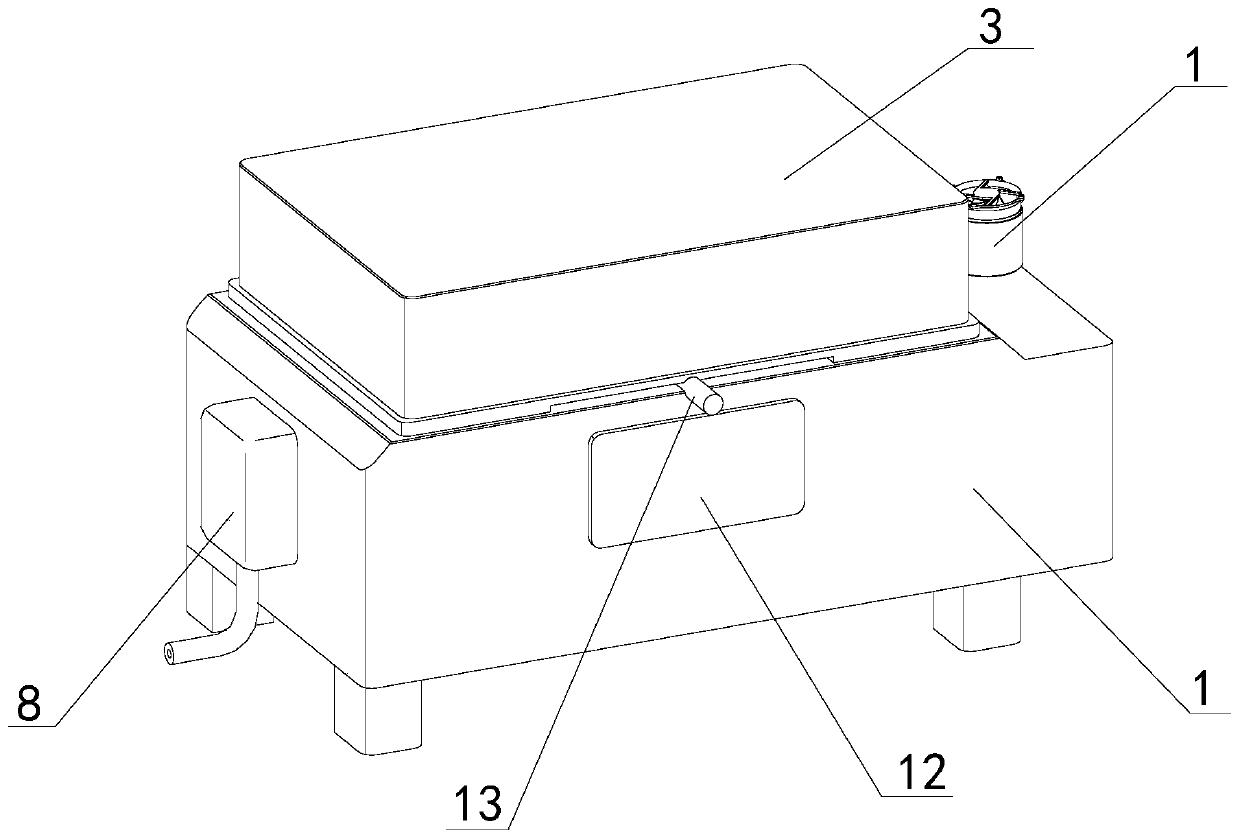

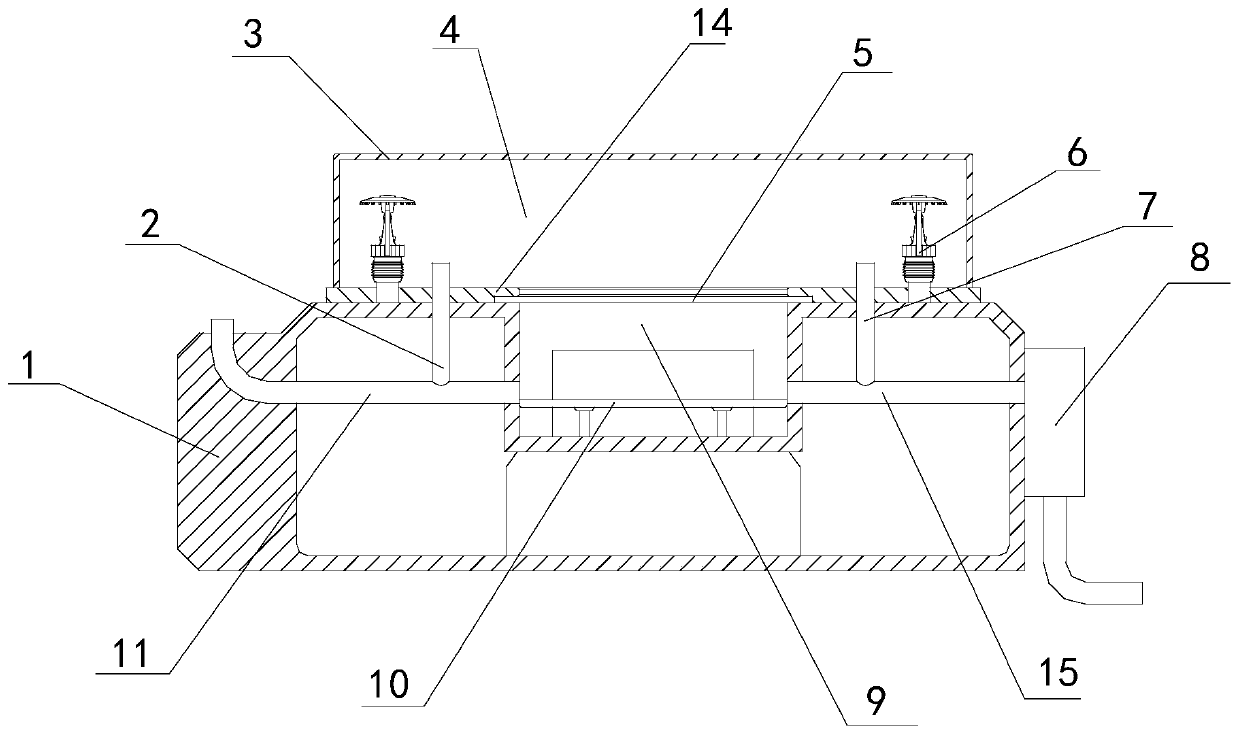

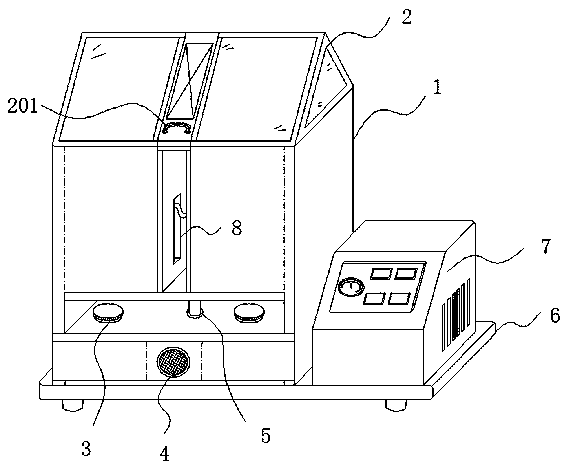

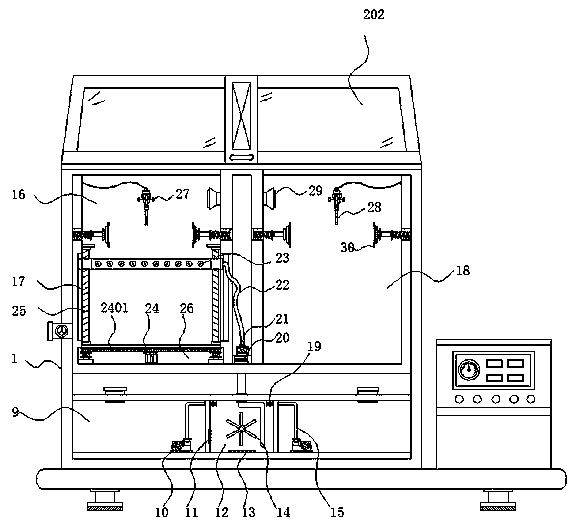

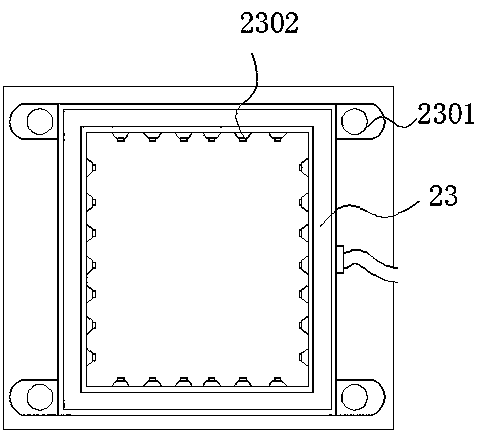

Multifunctional composite environment test device

PendingCN110470591AAvoid pollutionAvoid Loss of Humidity Measurement AccuracyWeather/light/corrosion resistanceStructural/machines measurementSaline mistSalt spray test

A multifunctional composite environment test device is composed of a main box body, a function box and a control system. The main box body and the function box are provided with a salt spray test system, a dampness-heat test system, an ultraviolet test system, a spray test system and a wetting test system. The device can provide a nine-factor composite environment of salt spray, dampness-heat, dryness, high temperature, low temperature, spray, ultraviolet, wet and dry alternating, and baking. Through the coupling design and the coupling control of the test box, the composite test of the abovevarious functions and the superimposed cycle test can be carried out. The device can comprise a mobile rain matrix, a telescopic humidity measurement system, a transmission type dry-wet alternating system and the like to achieve a variety of composite environments, thereby effectively avoiding the mutual interference and cross contamination problems between various combinations of factors.

Owner:国合通用测试评价认证股份公司

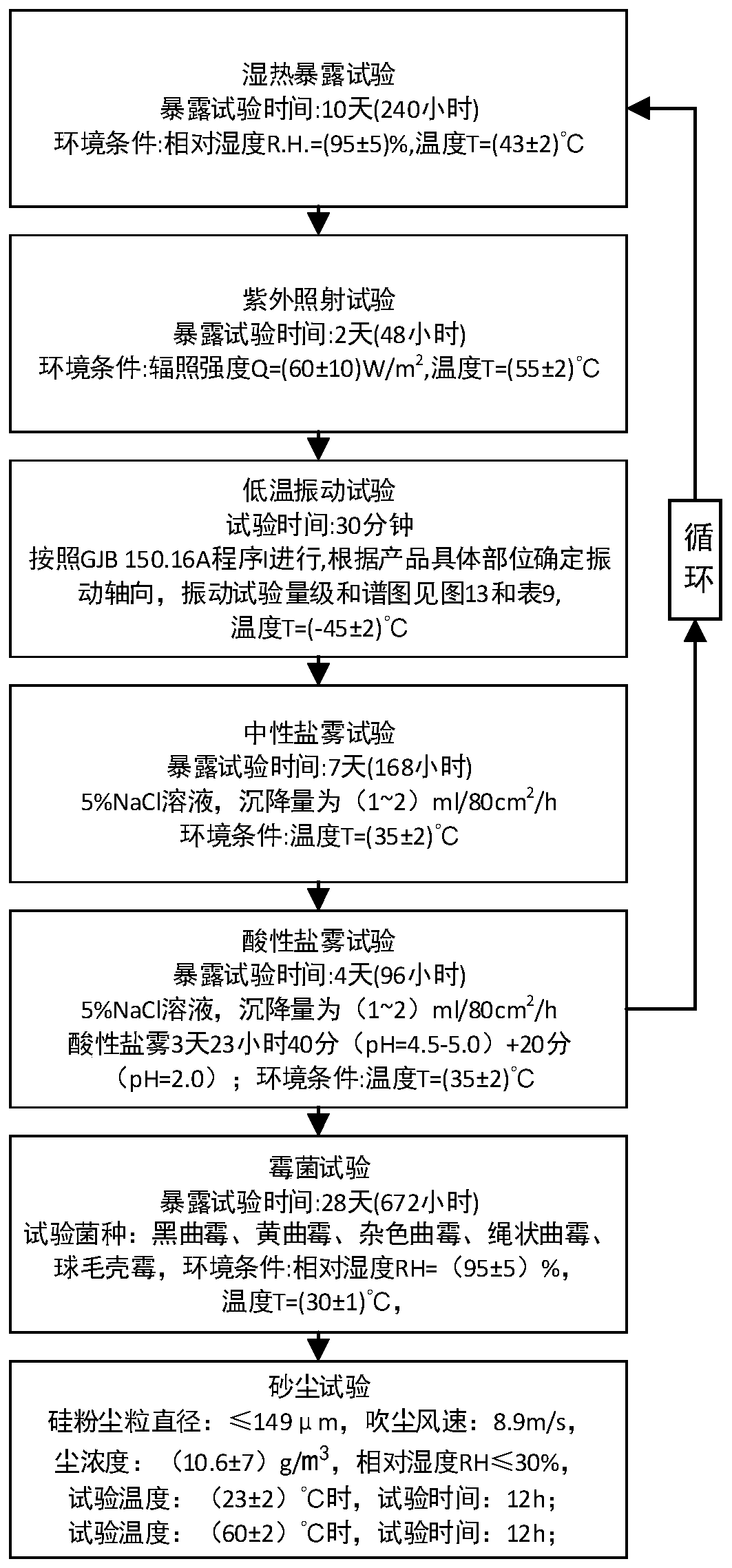

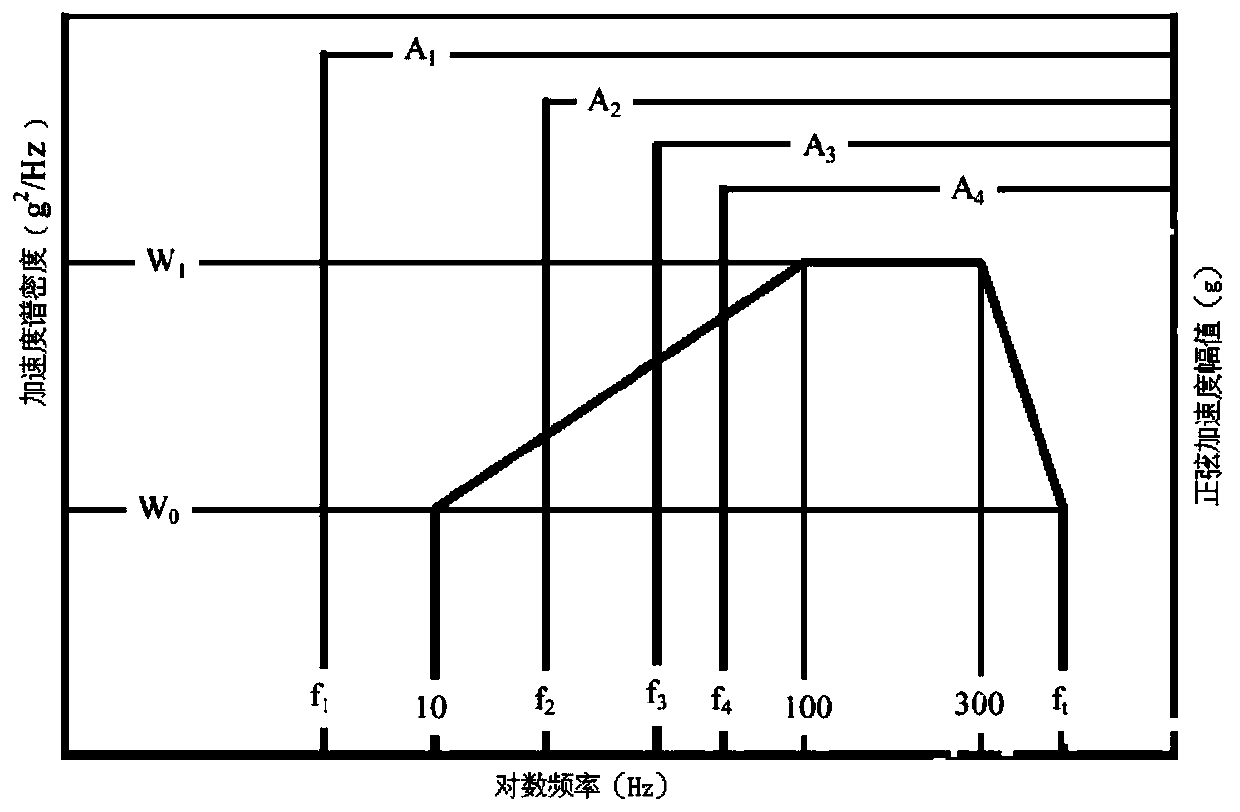

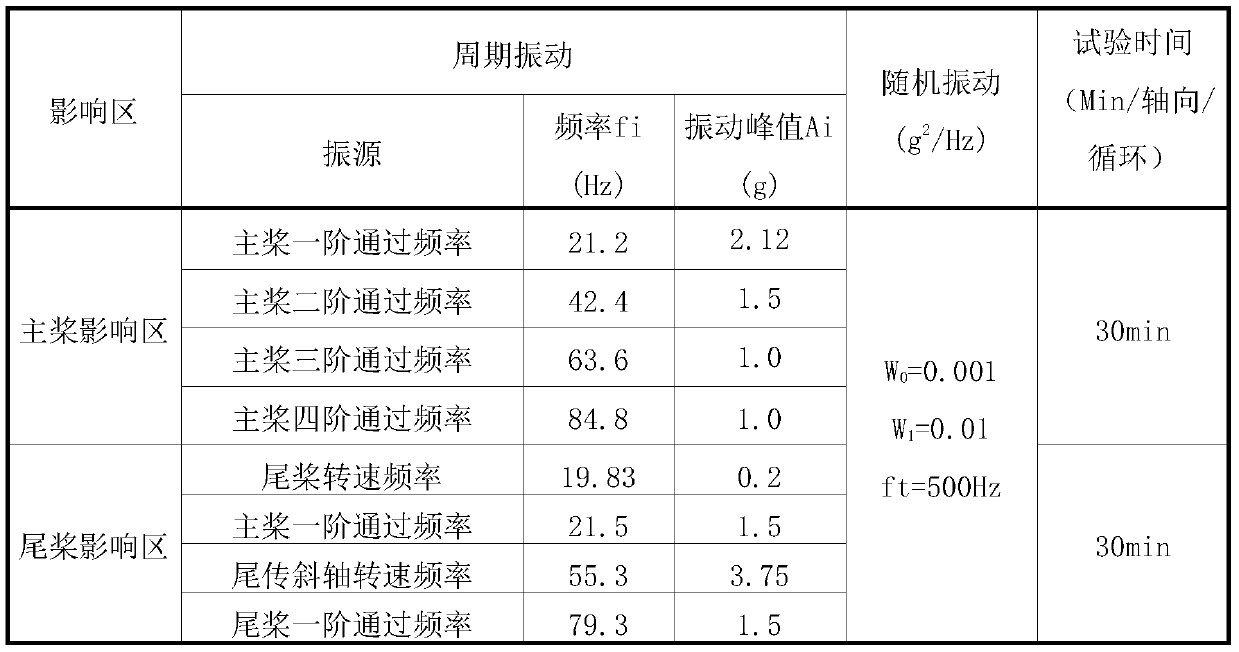

Laboratory acceleration test method for ship-based helicopter coating under marine atmospheric condition

The invention belongs to a helicopter coating laboratory acceleration test method, and discloses a laboratory acceleration test method for a ship-based helicopter coating under a marine atmospheric condition. The method comprises the following steps: S1, sequentially performing a damp and hot exposure test, an ultraviolet irradiation test, a low-temperature vibration test, a neutral salt spray test and an acidic salt spray test on the ship-based helicopter coating; S2, circularly executing the S1 according to a preset period; S3, after the S2 is completed, sequentially performing a mold test and a sand dust test on the ship-based helicopter coating; and S4, after the S3 is completed, performing environmental adaptability assessment on the ship-based helicopter coating according to the characteristics of the ship-based helicopter coating, and forming a laboratory acceleration test method by adding a helicopter vibration test and an acidic salt spray test, so that the coating of the ship-based helicopter is more accurately assessed.

Owner:CHINA HELICOPTER RES & DEV INST

Alkaline chloride galvanizing additive and preparation method thereof

The invention discloses an alkaline chloride zinking primer, wherein the primer comprises following components based on mass percent: 9.6% to 14.5% sodium hydroxide, 5.0% to 7.0% potassium chloride, 0.6% to 0.9% zinc oxide, 0.35% to 0.45% DPE-3 adjuvant, 0.35% to 0.45% ZB-80 lustre-coating agent and 76% to 84% water. The preparation method of the alkaline chloride zinking primer is provided. The invention has advantages that the plating layer has high combination ratio, high depositing speed, bright and fined plated products without brittleness, coarse skin and color change when baking temperature is at 250 deg. C, great anti-impurity capacity, without fogging and bubbling phenomena. The salt spray test uses 150 hours to 200 hours with low cost. The invention saves energy and is easy to processes waste.

Owner:唐军

Water-based high-temperature-resistant anti-corrosion composition

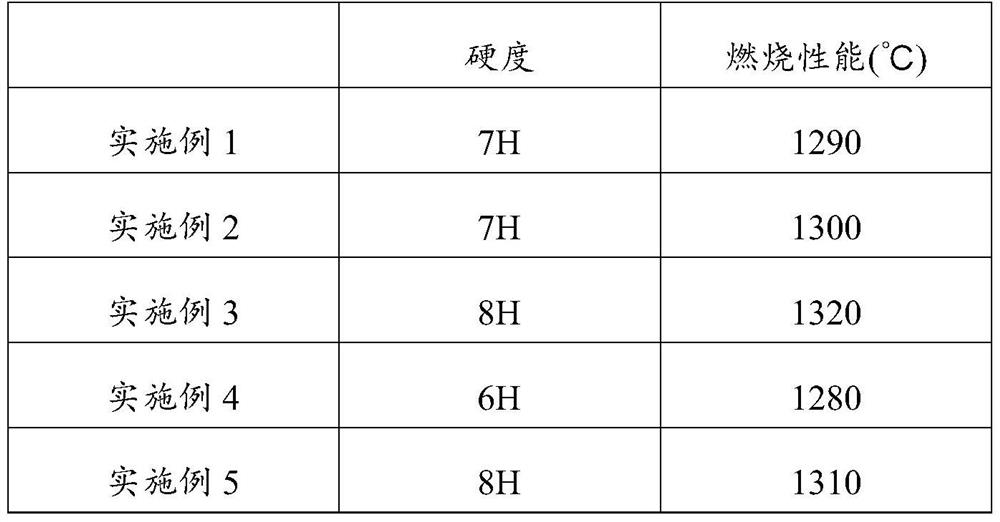

PendingCN112831252AImprove anti-corrosion performanceImprove performanceFireproof paintsAntifouling/underwater paintsAdhesive cementMischmetal

The invention discloses a water-based high-temperature-resistant anti-corrosion composition which comprises the following components in parts by weight: 45-90 parts of a polymer matrix, 15-70 parts of compact filling powder, 0.5-4 parts of rare earth metal, 5-40 parts of a dispersing agent, 2-25 parts of a flatting agent and 10-30 parts of an inorganic adhesive. The water-based high-temperature-resistant anti-corrosion composition is good in anti-corrosion performance, does not re-rust in a high-salt environment and particularly has more outstanding performance in corrosion environments such as salt mist and acid rain, the ultraviolet aging resistance is 3-5 times that of a traditional coating, the salt mist test can reach 2400 h or above, and the service life of the water-based high-temperature-resistant anti-corrosion composition meets the requirement of Centennial Project. The water-based high-temperature-resistant anti-corrosion composition disclosed by the invention is high-temperature-resistant and non-combustible, is an A-grade fireproof non-combustible material, has ultrahigh surface hardness which can reach 4-9H, particularly outstanding scratch resistance and good impact resistance, and can meet the requirements of various special environments.

Owner:烟台万华新材料技术有限公司

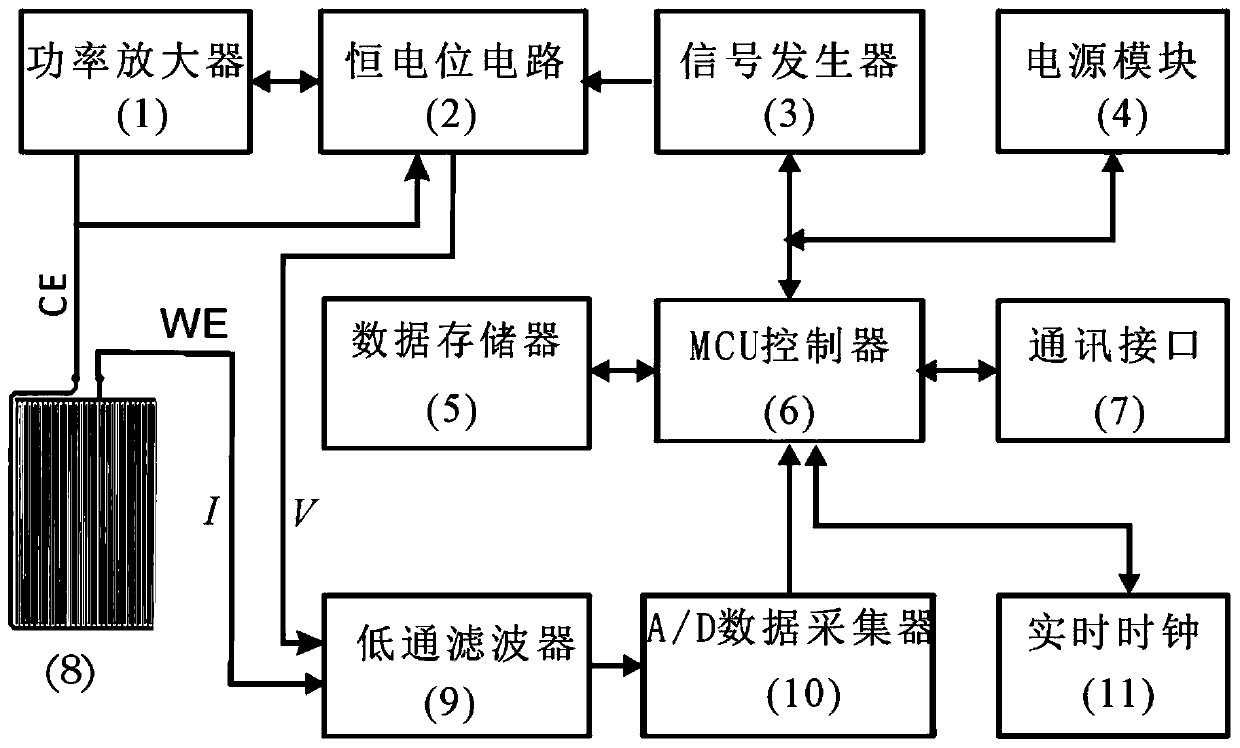

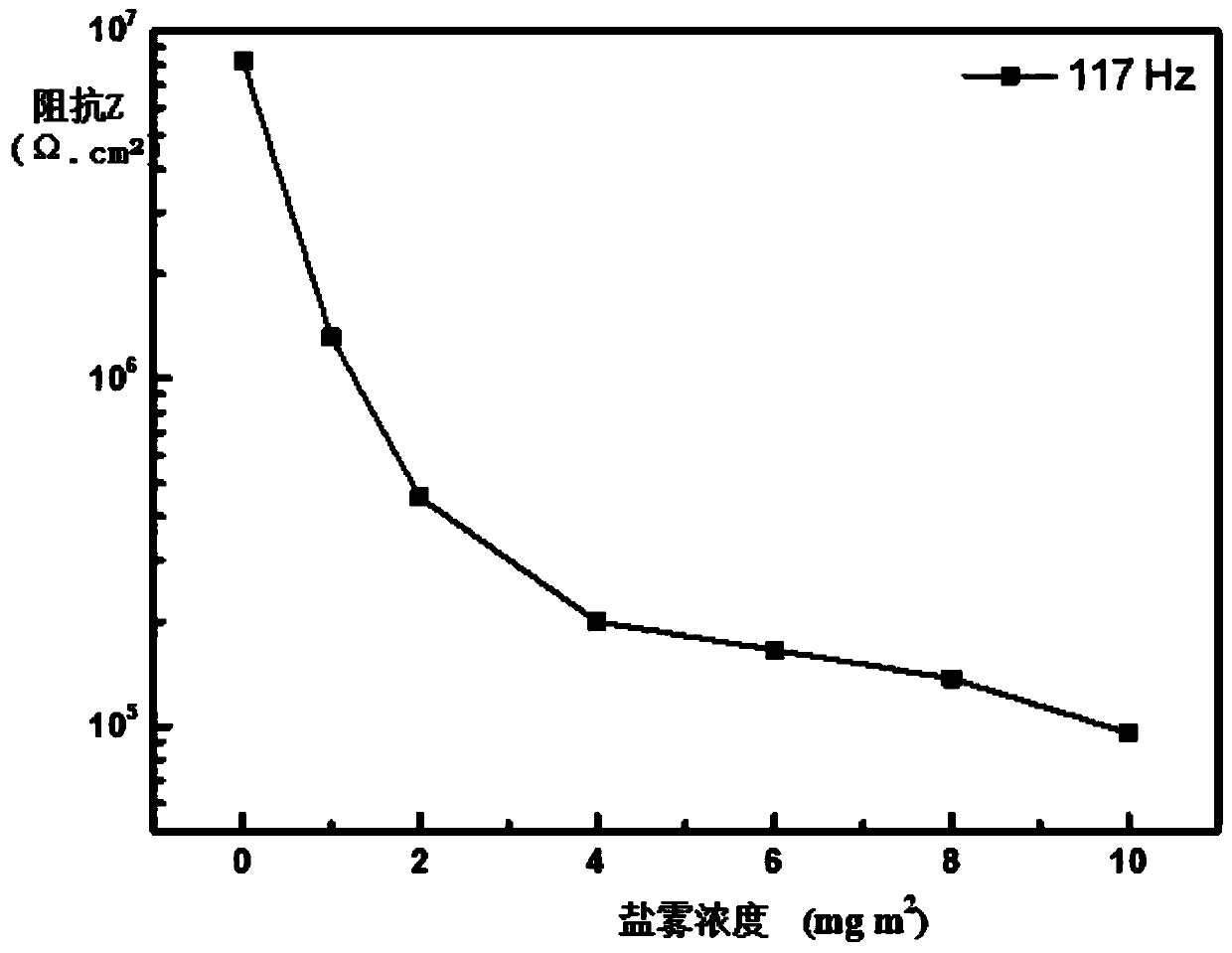

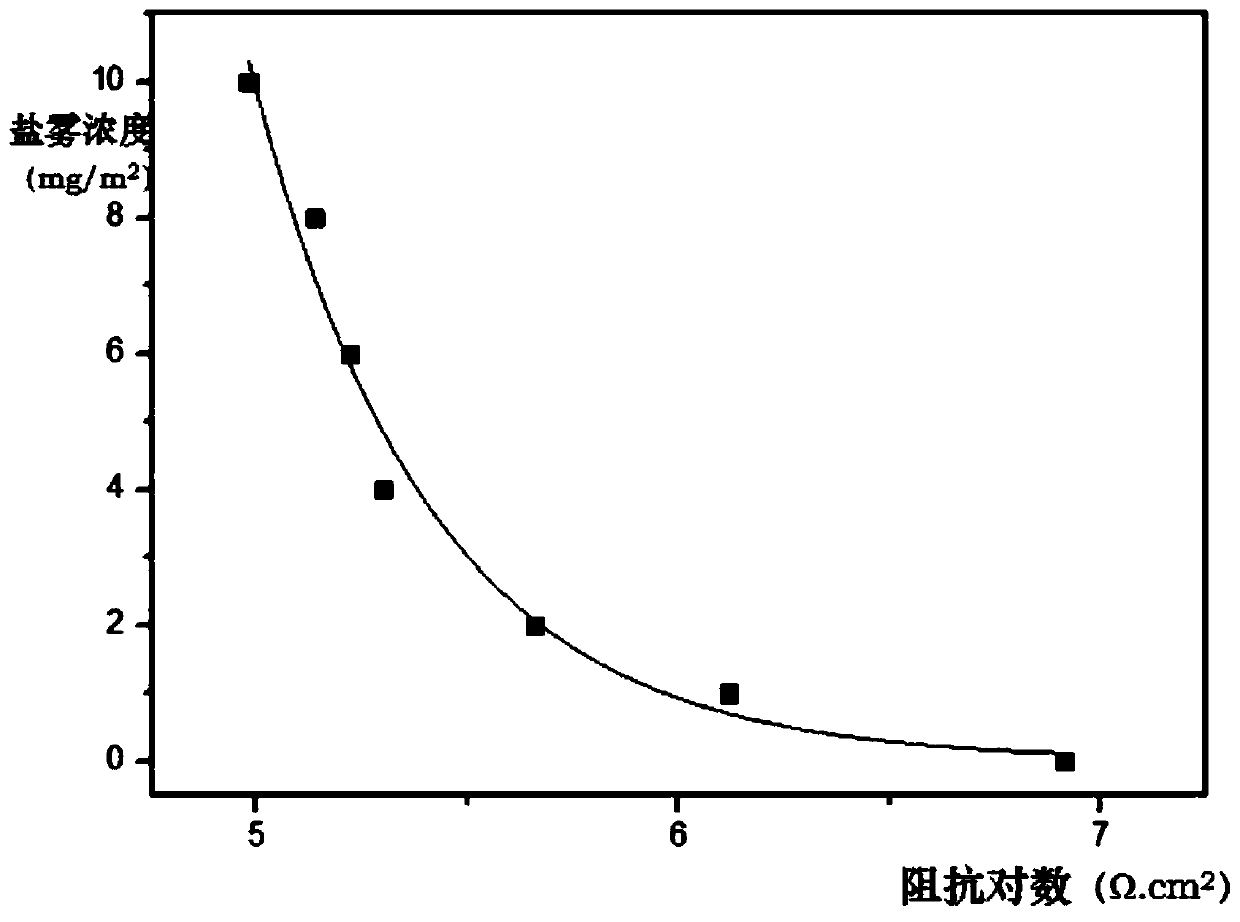

Atmospheric environment salt fog concentration monitoring device and testing method

PendingCN110426331AEasy to measureSave manpower and material costsParticle suspension analysisPhysicsConstant frequency

The invention relates to an atmospheric environment salt fog concentration monitoring device and a testing method. The testing method specifically includes the following steps of S1, exposing a sensorpart of a corrosion monitoring probe in a corrosion environment to be detected; S2, measuring a liquid film impedance value of the surface of a sensor of the corrosion monitoring probe under a certain salt fog concentration; S3, adjusting the salt fog concentration, and measuring constant frequency impedance values of the sensor part of the corrosion monitoring probe under different salt particledeposition amount conditions; S4, establishing a corresponding relation curve between the salt fog concentration and the liquid film impedance value of the surface of the corrosion monitoring probe,carrying out exponential attenuation fitting on the change relation between the salt fog concentration and the impedance value, and obtaining a calculation relation between the impedance value of thecorrosion monitoring probe under the excitation of constant frequency alternating current signals and the environmental salt fog concentration. According to the atmospheric environment salt fog concentration monitoring device and the testing method, the purpose of measuring the salt fog concentration in real time is achieved by establishing the corresponding relation between the impedance value ofthe probe under the excitation of the constant frequency alternating current signals and the environmental salt fog content.

Owner:WUHAN CORRTEST INSTR

Salt mist physical-therapy room

A salt fog physiotherapy center is composed of the mineral salt solution and salt fog vapor room, and features that the humidity, temp and the granularity of atomized salt solution are controlled for playing the full physiotherapeutic function.

Owner:成都卓成健康管理有限公司

Method for testing sealing performance of metal hose in axial tension and corrosion state

ActiveCN107884008AEasy to operateTest securityMeasurement of fluid loss/gain rateWeather/light/corrosion resistanceSaline mistProcess engineering

The invention discloses a method for testing the sealing performance of a metal hose in axial tension and corrosion state. The method comprises a step 1 of injecting a corrosive medium; a step 2 of installing a pressure test metal hose; a step 3 of installing an explosion-proof protective cover; a step 4 of detecting performance testing; a step 41 of detecting sealing performance; a step 42 of detecting tensile performance; a step 43 of detecting sealing performance under a corrosion condition; and a step 44 of detecting tensile performance under a corrosion condition. The method can separately or jointly detect the tensile performance, the sealing performance and the corrosion resistance of the metal hose, can simulate a performance test under an extreme condition where the tension forceand the salt spray corrosion are combined, and is easy to operate and safe and reliable in test.

Owner:WUXI YONGXING METAL HOSE

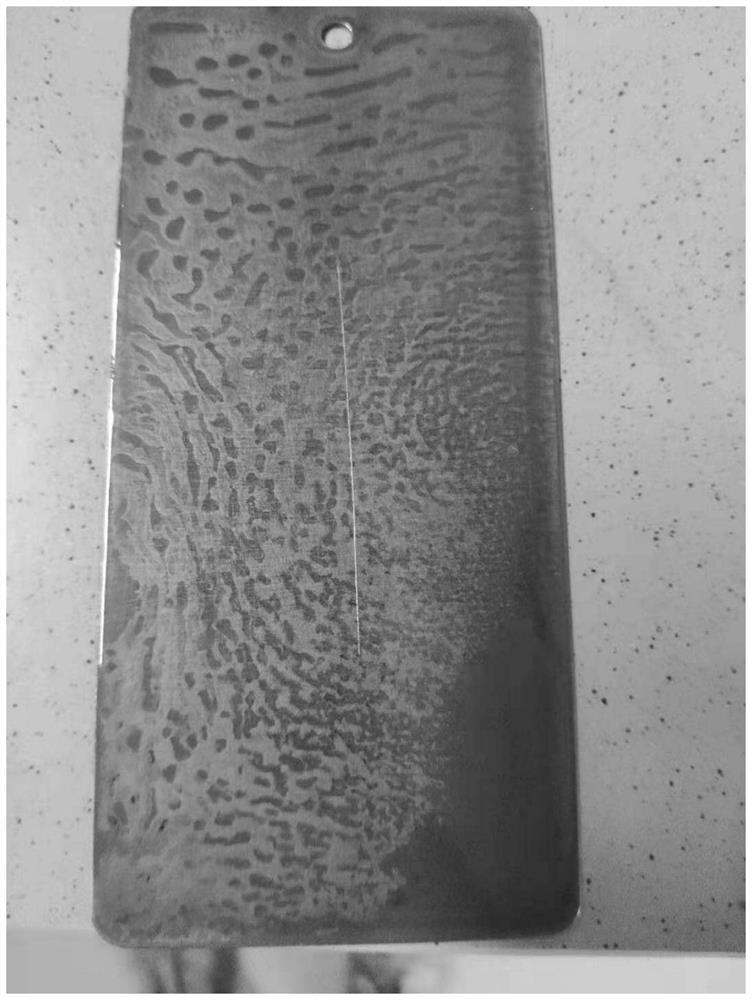

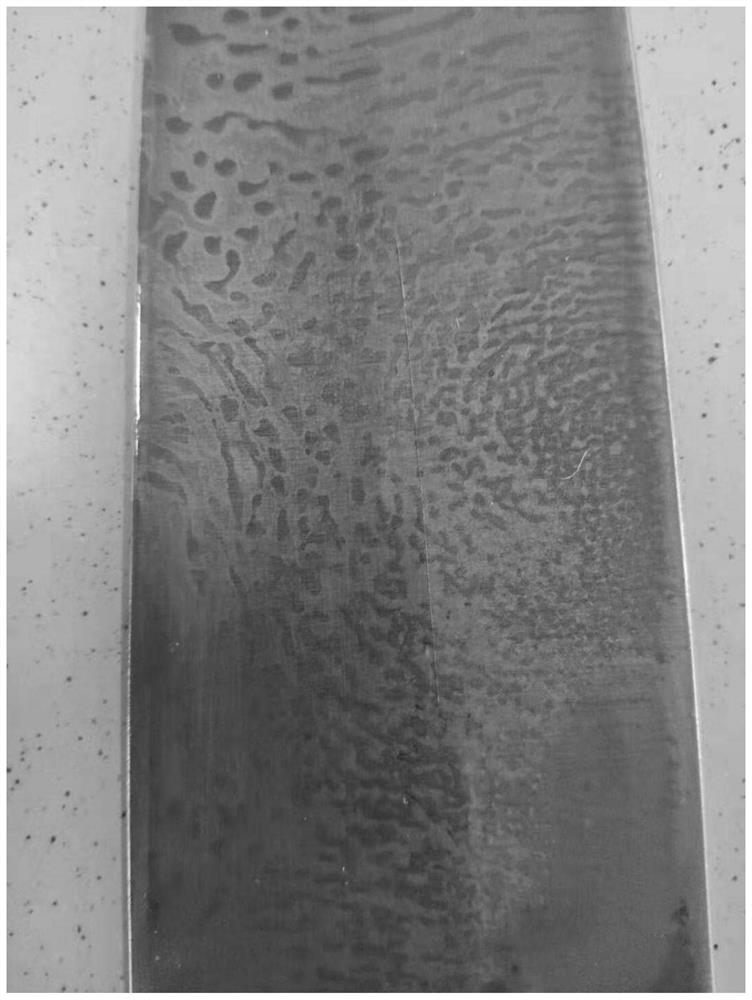

Quick evaluation test method of anti-corrosion performance of tin-plated board

InactiveCN105241806AQuick Quantitative RatingQuantitative rating is convenientWeather/light/corrosion resistanceCold airSaline mist

The invention relates to a quick evaluation test method of anti-corrosion performance of a tin-plated board. The quick evaluation test method is characterized by comprising the following steps: 1) selecting a tin-plated board being 1.1 g / m<2> in tin layer thickness and 4 mg / m<2> in passivated film thickness and pre-treating the tin-plated board; 2) placing the test sample in a salt fog corrosion test box, wherein the test sample is hanged on a hanging rod in the box body; 3) selecting a NaCl solution being 2% in mass concentration as a basic corrosion medium with a NaHSO3 solution in a certain concentration matched therewith, successively adjusting six dimensions of four test parameters comprising corrosion medium concentration, corrosion medium settlement quantity, temperature and test period to carry out a corrosion test; 4) when the corrosion test is finished, taking out the test sample and washing the sample through deionized water at 20-30 DEG C for 30-60 s, and air-drying the sample with cold air; and 5) comparing the test sample with six test result legends under the six dimensions, and evaluating and recording a result according to two characteristic parameters comprising corrosion area and corrosion point diameter to achieve quantitative evaluation of the anti-corrosion performance of the tin-plated board.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

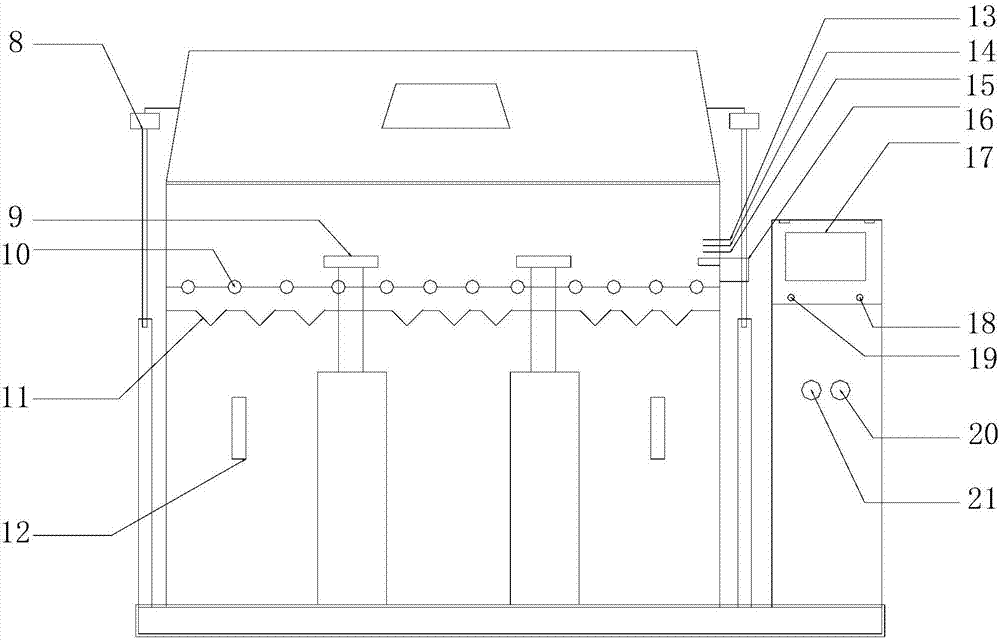

Temperature, humidity and salt fog comprehensive test chamber

ActiveCN106979923AWeather/light/corrosion resistanceSimultaneous control of multiple variablesSaline waterSaline mist

The invention discloses a temperature, humidity and salt fog comprehensive test chamber which comprises a salt fog test machine and a constant-temperature and constant-humidity system. The salt fog test machine comprises a salt fog box, salt fog spray towers, hang rods, a V-shaped slotted storage rack and salt water collectors are arranged in the salt fog box, and a salt fog box cover is arranged on the top of the salt fog box; a control box is arranged on the right side of the salt fog box and is connected with the salt fog spray towers by a salt solution delivery pipeline; the constant-temperature and constant-humidity system comprises a constant-temperature and constant-humidity box, a temperature adjusting system and a humidifying system, the temperature adjusting system comprises a refrigerating system and a heating system, the refrigerating system comprises a condenser, an evaporator, a compressor and a refrigerant liquid storage tank which are connected with one another, and the heating system comprises a heating pipe. The temperature, humidity and salt fog comprehensive test chamber has the advantages that the temperature, humidity and salt fog comprehensive test chamber is provided with the constant-temperature and constant-humidity system, accordingly, complicated corrosion environments can be simulated by means of unified adjustment and control, corrosion tests under comprehensive temperature and humidity conditions can be completed, and the temperature, humidity and salt fog comprehensive test chamber is worthy of being energetically popularized.

Owner:广东艾思荔检测仪器有限公司

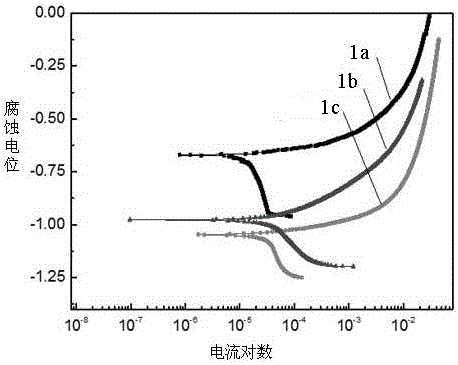

Method for testing anti-corrosion performance of metallic equipment under island environment

The invention discloses a method for testing anti-corrosion performance of metallic equipment under an island environment. The method specifically comprises the following steps: A, testing a potentiodynamic polarization curve of a metal sample with a coating, and fitting an alternate-current impedance spectrum and a self-corrosion potential of the metal sample with the coating; B, carrying out a salt fog simulation experiment on the metal sample with the coating and recording the corrosion status of the surface of the coating; C, comprehensively evaluating and analyzing the anti-corrosion performance of the metal sample with the coating according to the step A and the step B. According to the method disclosed by the invention, the metallic equipment with the coating is subjected to electrochemical performance testing of the anti-corrosion performance by adopting potentiodynamic polarization and the electrochemical impedance spectrum, and the corrosion process of the metallic equipment with the coating under the island environment is simulated by adopting a salt fog experiment; a most suitable coating of the metallic equipment under different island environments may be selected according to experiment results of the two steps, thereby providing guarantee for reliable operation of a transformer substation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

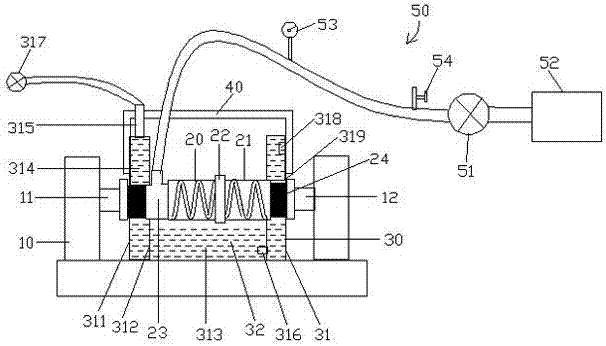

In-situ test detection device and method for simulating corrosion and aging of multi-factor atmospheric environment material

PendingCN111398144AAchieving continuous lossless trackingRapid identificationWeather/light/corrosion resistanceMetallic materialsEngineering

The invention provides an in-situ test detection device and method for simulating corrosion and aging of a multi-factor atmospheric environment material. The in-situ test detection device is combinedwith technologies such as salt spray, electric heating, environment temperature and humidity control and ultraviolet radiation control. The method comprises: putting a metal material on a silicone rubber heating sheet in the experimental device, closing an optical path channel, heating the heating stage to a predetermined temperature by electrifying and heating the silicone rubber heating sheet, and sensing and controlling the temperature in real time through a temperature sensor; meanwhile, using the atmosphere temperature and humidity control device for realizing preset temperature and humidity in a test environment; quantitatively spraying salt mist to a sample at a fixed frequency in the test process, and an ultraviolet lamp irradiating the sample according to set radiation intensity and radiation frequency, so that the control simulation of five environmental factors including environmental temperature and humidity, sample temperature, salt mist and radiation is realized at the same time, the corrosion state of the sample in various atmospheric environments is reproduced, and real-time monitoring and detection conditions are provided.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

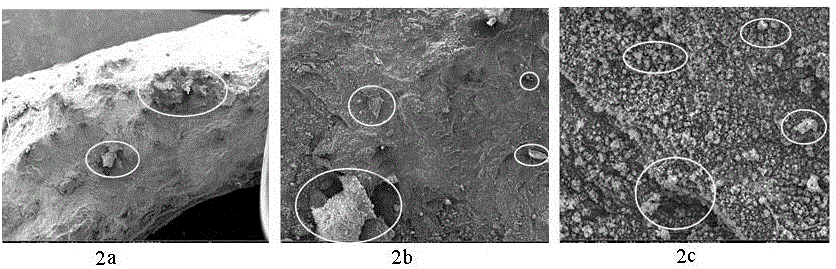

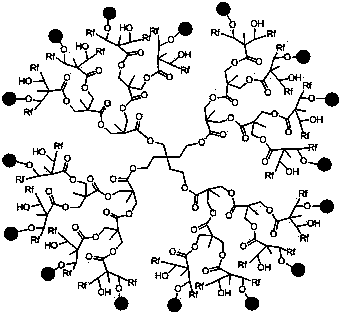

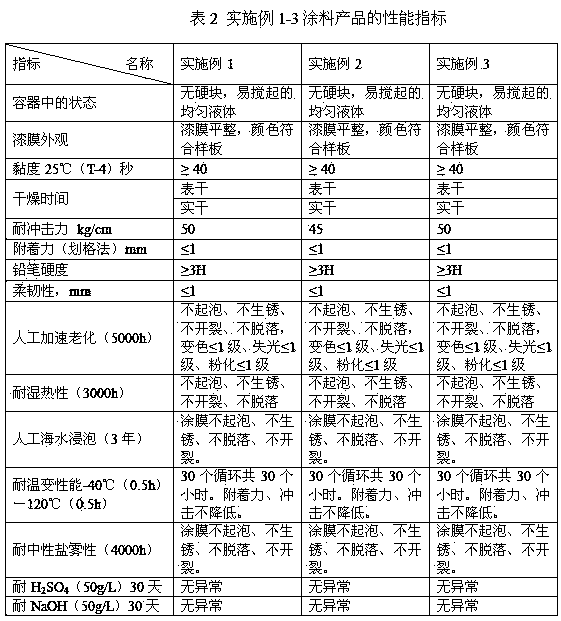

High-corrosion-resistant coating prepared from nano-silica loaded hyperbranched fluroresin

ActiveCN103897572AHigh hardnessExcellent resistance to seawater immersionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a high-corrosion-resistant coating prepared from nano-silica loaded hyperbranched fluroresin. The coating is prepared by mixing a component A and a component B according to the mass ratio of (8-11):1, wherein the component A is formed by mixing a main material and auxiliary materials, the main material is nano-silica loaded hyperbranched fluroresin, and the auxiliary materials include a mixed solvent, a flatting agent, a catalyst, pigment and filler; the component B is one of a mixture of HDI (Hexamethylene Diisocyanate) biuret and HDI tripolymer. The coating disclosed by the invention has excellent performances such as weather resistance, seawater soaking resistance, damp and hot resistance, temperature change resistance, salt fog resistance, pollution resistance and the like and can resist to the corrosion of a marine environment for a long term; in addition, the service life of a film can be up to more than 25 years after the coating is coated. The preparation method of the high-corrosion-resistant coating disclosed by the invention is simple in operation and low in equipment cost.

Owner:湘江涂料科技有限公司

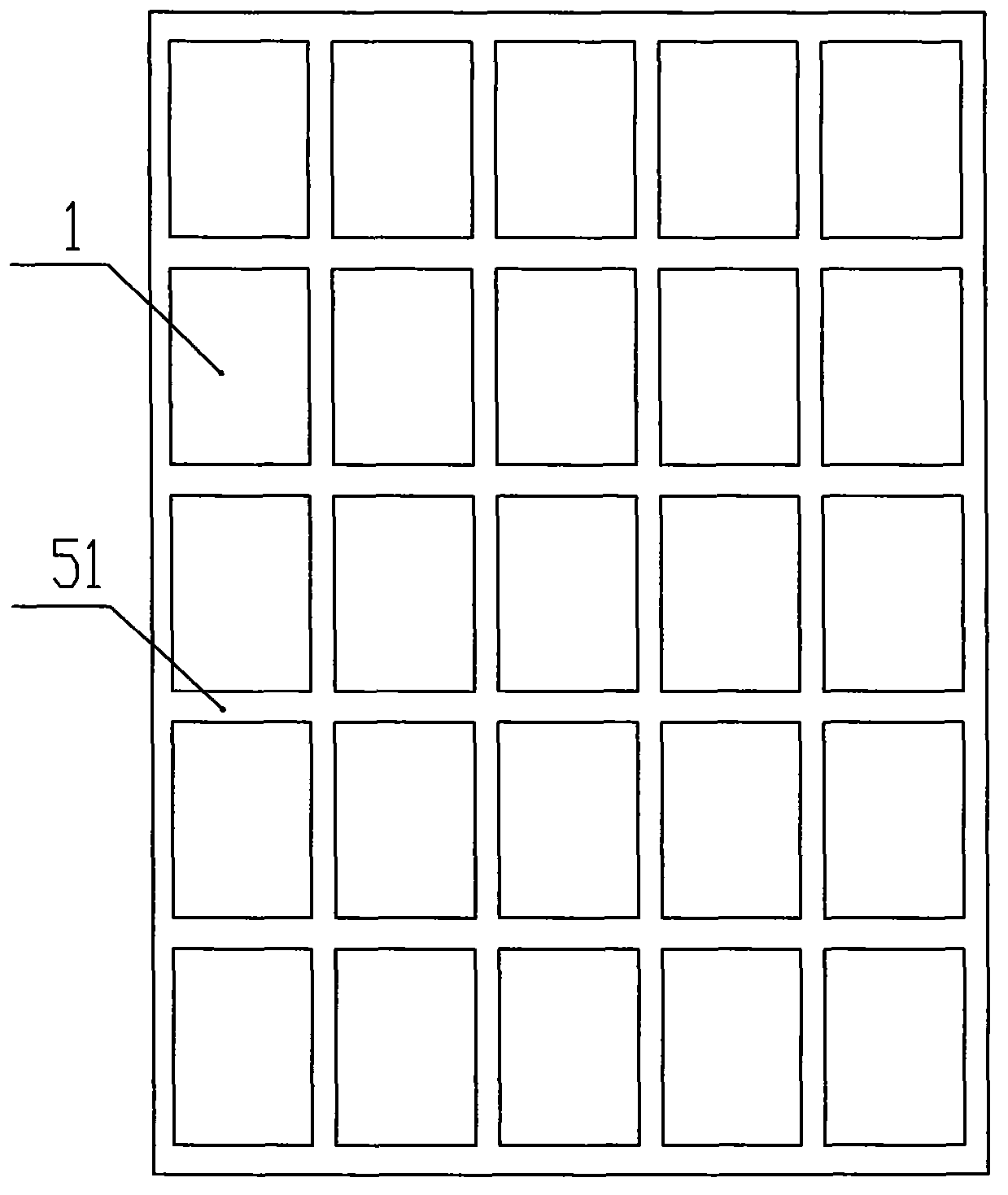

Piece-shaped thermal shrinkage mark and installation method thereof

PendingCN103680299ASolve the problem of not being able to dressSolving Heat Shrink Marking IssuesStampsIdentification meansDamp environmentHeat-shrink tubing

The invention discloses a piece-shaped thermal shrinkage mark and an installation method thereof. The piece-shaped thermal shrinkage mark can be used under the conditions of various severe environments such as an outdoor environment, a vibration environment, a damp environment and a salt mist environment. According to the piece-shaped thermal shrinkage mark and the installation method of the piece-shaped thermal shrinkage mark, thermal shrinkage marking of a large-diameter product is achieved, a traditional thermal shrinkage sleeve mark cannot be installed in a penetrated mode for the large-diameter product, the piece-shaped thermal shrinkage mark can be subject to thermal shrinkage on the product in a mode of two-end adhesion of the mark, thermal shrinkage without penetration is achieved, and the problem that a pipe-shaped mark of a large-diameter connector cannot perform installation in a penetrated mode is solved. According to the piece-shaped thermal shrinkage mark, installing efficiency is improved, and batch manufacturing and installation are facilitated. An installation process of the mark is simplified, the installation method is simple, the piece-shaped thermal shrinkage mark only needs heating, and the installation cost is reduced. According to the piece-shaped thermal shrinkage mark, an outer layer mark protection layer and an inner layer mark locating piece can be arranged.

Owner:许小明

Epoxy glass flake anticorrosive paint as well as preparation method and application thereof

InactiveCN109207022AImprove corrosion resistanceImprove performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyCoconut diethanolamide

The invention provides epoxy glass flake anticorrosive paint which is characterized by comprising the following components in parts by weight: 95%-99.8% of a component A and 0.2%-5% of a component B;the component A comprises the following components in parts by weight: 8-10 parts of epoxy resin, 4.2-4.5 parts of glass flakes, 1-3 parts of a pigment, 0.5-1 part of a dispersing agent, 1-1.2 parts of a silane coupling agent, 0.1-0.2 part of a defoaming agent, 1-1.5 parts of an assistant and 1-2 parts of a solvent, wherein the component B comprises the following components in parts by weight: 10-30 parts of graphene slurry, 2-4 parts of nano calcium carbonate, 1-2 parts of coconut diethanolamide and 1-2 parts of aluminum dihydrogen tripolyphosphate; the salt spray test can reach more than 5000h, and the epoxy glass flake anticorrosive paint has a good electrostatic conduction effect, has the characteristics of strong adhesive force and high mechanical strength of the same type of anti-corrosion paint, and is anticorrosive paint with excellent performance.

Owner:ZHEJIANG FEIJING PAINT

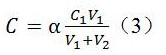

Environmental test equipment for cooperatively controlling salt mist concentration and relative humidity

ActiveCN113515157ASolve concentrationSolve Humidity ProblemsSimultaneous control of multiple variablesTest chamberAir conditioning

The invention discloses environment test equipment for cooperatively controlling salt mist concentration and relative humidity, which comprises a dry salt mist generation system, an air conditioning system, a mixing chamber, a test chamber and an electric control cabinet. The environment test equipment is adopted for obtaining salt mist concentration relational expression and relative humidity relational expression among environment parameters in a test room, dry salt mist environment parameters in a dry salt mist generation system and environment parameters of conditioning air in an air conditioning system base on the salt content and water content conservation principle before and after mixing, and after determining the environment test parameters required in the test room, obtaining a temperature parameter and a relative humidity parameter which need to be set in the dry salt mist generation system and a temperature parameter and a relative humidity parameter which need to be set in the air conditioning system through the salt mist concentration relational expression and the relative humidity relational expression; meanwhile, the equipment can adjust the dry salt mist generation system and the air conditioning system through deviation feedback of monitoring data, and dynamic balance of the laboratory environment is achieved.

Owner:CHINA NAT ELECTRIC APP RES INST

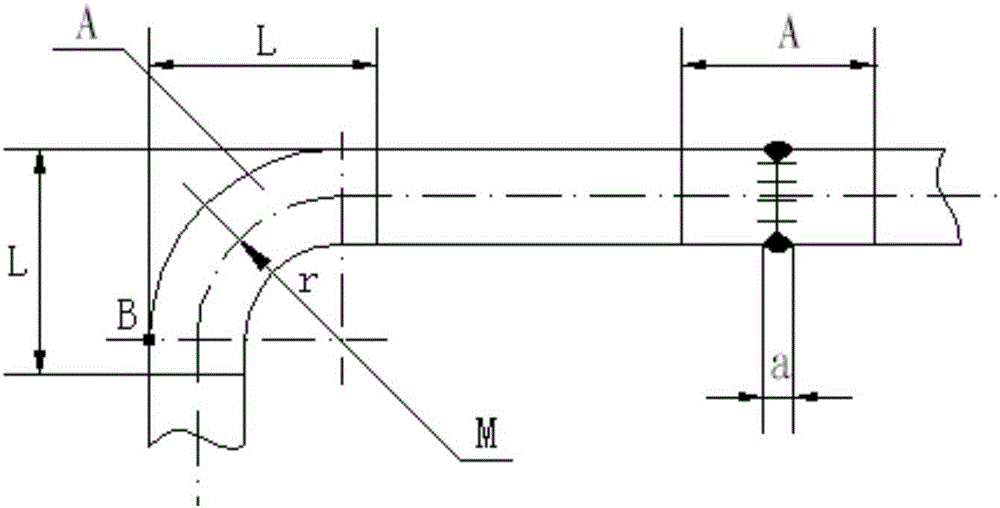

Corrosion prevention method of stainless steel weld joint or bent area

InactiveCN106181586AImprove corrosion resistanceAvoid intergranular corrosionWelding/cutting auxillary devicesAuxillary welding devicesMachiningCorrosion prevention

The invention belongs to surface treatment technology, and relates to an anticorrosion method for stainless steel weld seams or bending areas. It is characterized in that the anti-corrosion steps are as follows: determine the intergranular corrosion area A of the material; perform mechanical grinding on the intergranular corrosion area A of the material; grind the intergranular corrosion area A of the material; carry out pickling and passivation treatment on the parts. The invention proposes an anti-corrosion method for stainless steel welds or bending areas, which greatly increases the anti-corrosion ability of 1Cr18Ni9Ti stainless steel in salt spray and hot and humid environments, avoids intergranular corrosion of parts again, and improves the use of parts life.

Owner:SHAANXI AIRCRAFT CORPORATION

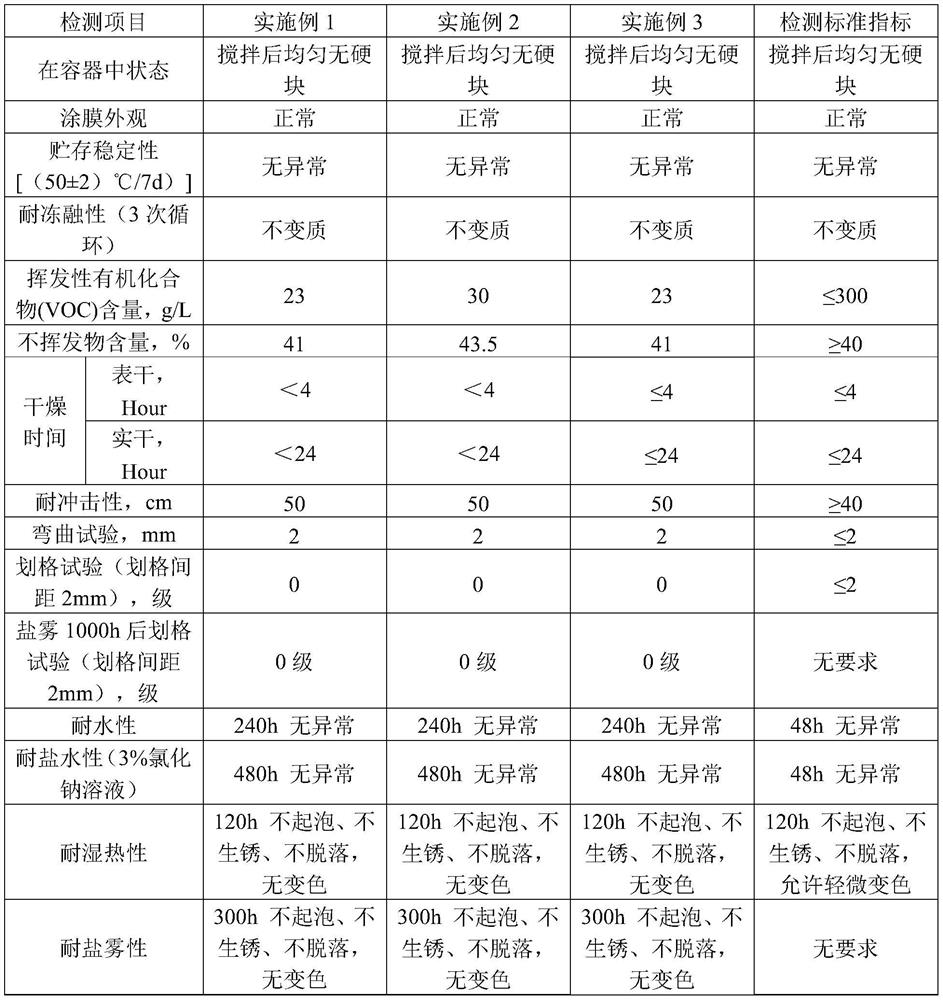

Water-based over-rust coating primer and preparation method thereof

InactiveCN111925680AFast packPlay the role of passivation rust spotsAnti-corrosive paintsPolymer scienceFree form

The invention discloses a water-based over-rust coating primer and a preparation method thereof. The primer comprises, by weight, 70-95 parts of a water-based acrylic emulsion, 1.5-6 parts of a coalescing agent, 5-30 parts of water and 0.3-8 parts of other auxiliaries. The primer disclosed by the invention does not use an antirust pigment with heavy metals any more, does not use an antirust pigment containing a zinc element any more, and is thus environment-friendlier; the primer disclosed by the invention does not use tannic acid and other organic acids any more, so no acidic substance residue in any free form exists in a paint film; and the primer disclosed by the invention is excellent in adhesive force, an adhesive force test shows that the adhesive force of the primer is grade 0 (seea scratch test), so the problem of poor adhesive force of a rust conversion coating is solved. The test adhesive force of the primer is still grade 0 after 1000 hours of exposure to salt spray (see adivision test after 1000 hours of exposure to salt spray).

Owner:德爱威(中国)有限公司

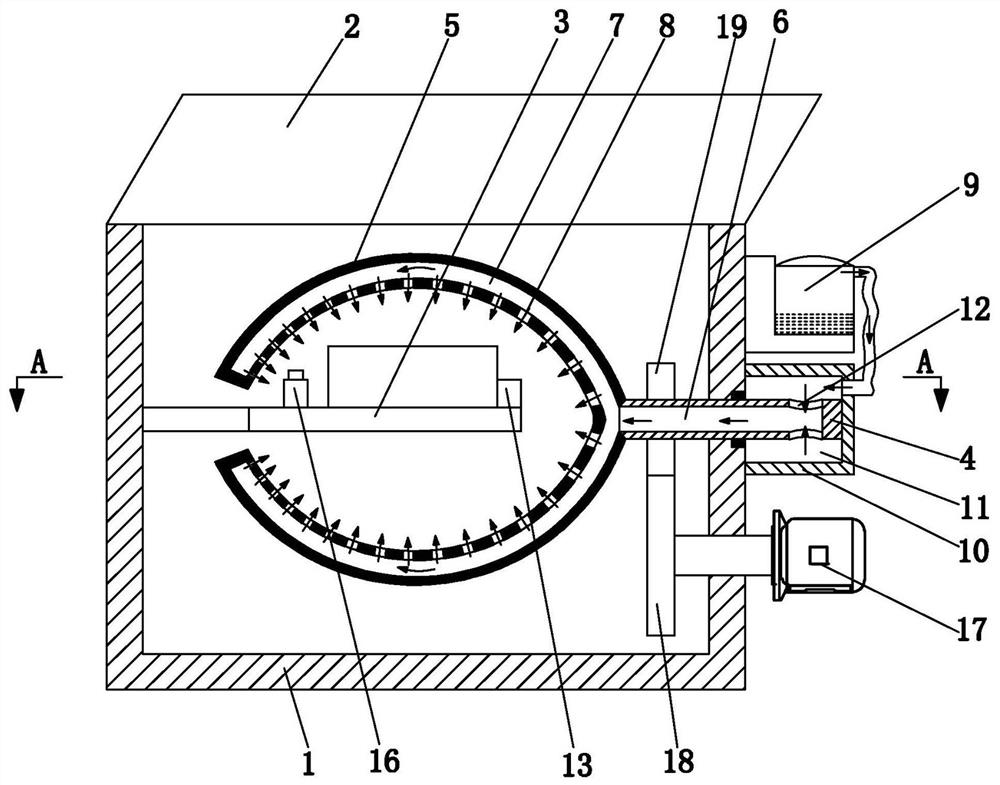

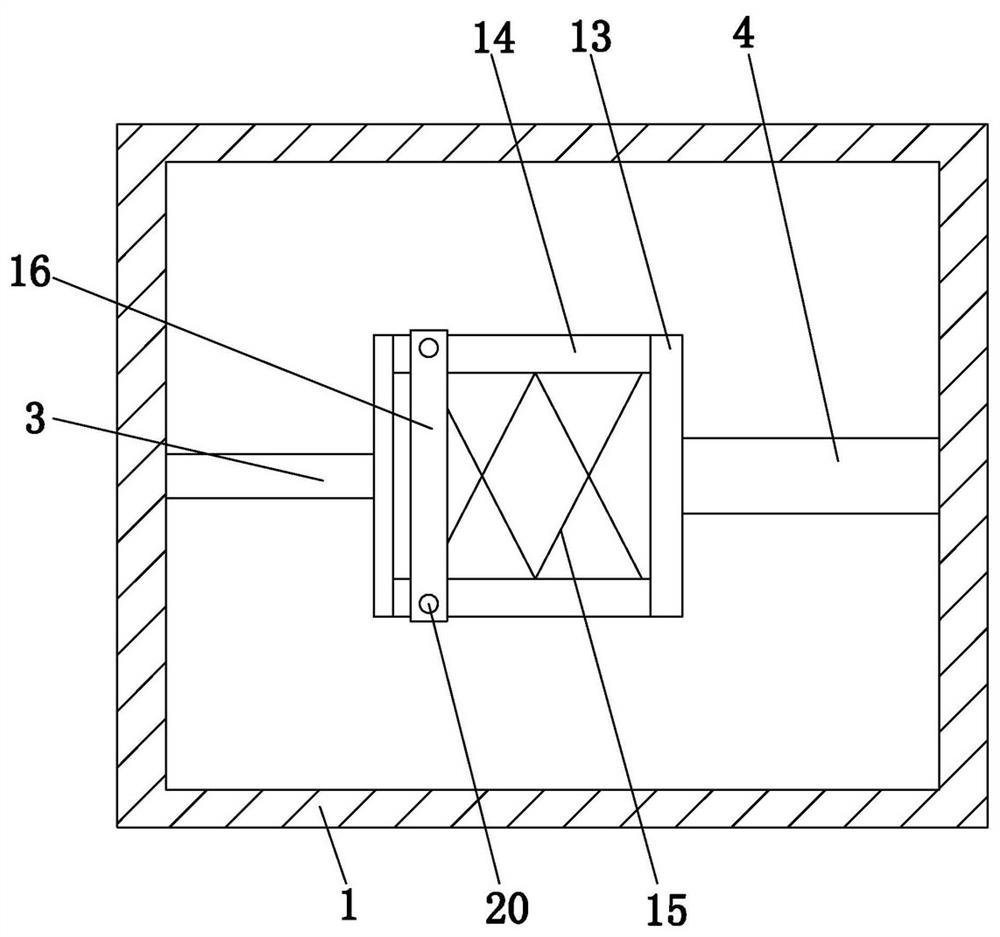

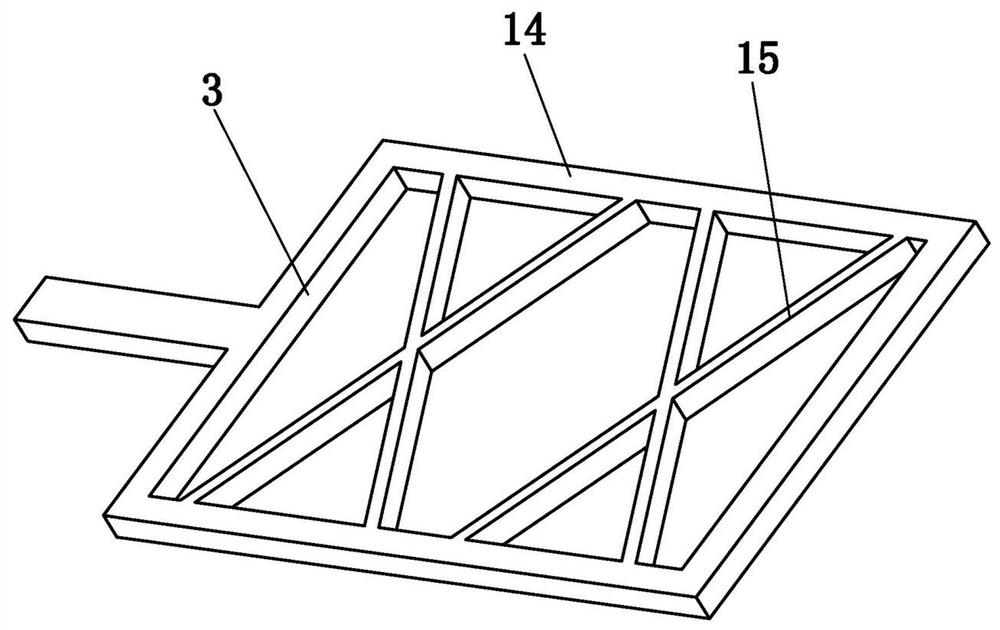

Multifunctional salt spray test device

PendingCN111948126AIngenious structureEasy to operateWeather/light/corrosion resistanceWork holdersSaline mistSalt spray test

A multifunctional salt spray test device effectively solves the problems of incomplete salt spray coverage, non-uniform spraying, influence on test data and the like, and comprises a cabinet body, a cabinet door hinged to the cabinet body, a support frame fixed in the cabinet body, a rotating shaft rotationally connected in the cabinet body, and two arc-shaped pipes fixed at the left end of the rotating shaft, the two arc-shaped pipes are vertically symmetrical about the center of the rotating shaft, the supporting frame is located between the two arc-shaped pipes, a hollow pipe is arranged inthe rotating shaft, arc-shaped channels communicated with the hollow pipe are formed in the arc-shaped pipes, a plurality of first through holes facing the supporting frame are evenly distributed inthe arc-shaped pipes, and the first through holes are communicated with the arc-shaped channels. An atomizer and a box body are fixed to the right end of the cabinet body, the right end of the rotating shaft is rotationally connected with the box body, a cavity is formed in the box body, a plurality of second through holes communicated with the cavity are formed in the rotating shaft, a hose communicated with the cavity is arranged on the atomizer, the structure is ingenious, operation is easy, and the test effect is good.

Owner:上海志勤环境技术有限公司

Salt spray testing machine

PendingCN111458284AAvoid affecting air qualityAvoid contactWeather/light/corrosion resistanceSaline mistSalt spray test

The invention discloses a salt spray testing machine, and belongs to the field of salt spray tests. The salt spray testing machine comprises: a detachable box cover arranged above a box body, whereina discharge port is formed in the side wall of an objective table, and a box door is arranged on the discharge port; a workbench which is horizontally and fixedly mounted in the box body, an opening is formed in the upper portion of the workbench, and the workbench, the box cover and the box body form a working cavity; an inner cavity which is arranged below the workbench, wherein the inner cavityis communicated with the workbench through the opening, and the inner cavity is communicated with the workbench through the discharge port; a salt mist spraying system which is mounted on the workbench; the objective table which is arranged above the inner cavity; an air inlet channel, wherein one end of the air inlet channel extends out of the box body and is provided with an air blower, and theother end of the air inlet channel is communicated with the inner cavity; and an air outlet channel, wherein one end of the air outlet channel is extended out of the box body. Compared with the priorart, the salt spray testing machine has the advantages that salt spray can be discharged after testing, and operators are prevented from making contact with the salt spray.

Owner:安徽中腾汽车零部件有限公司

5G communication equipment with long service life

ActiveCN111509360AImprove wind resistanceIncrease the difficultyAntenna supports/mountingsHollow article cleaningSaline mistStructural engineering

The invention relates to 5G communication equipment with a long service life. The equipment comprises a bottom plate, a supporting tube and an antenna, the bottom plate is horizontally arranged, the supporting tube is perpendicular to the bottom plate, the antenna is cylindrical and is coaxial with the supporting tube; the diameter of the antenna is smaller than the inner diameter of the supporting tube; the bottom end of the supporting pipe and the top of the bottom plate are sealed and fixedly connected, the antenna is arranged on one side, far away from the bottom plate, of the supporting tube; an auxiliary mechanism and a maintenance mechanism are arranged on the supporting tube; the auxiliary mechanism comprises a moving disc, a suction pump, a water pipe, a sealing assembly and a transmission assembly. The sealing assembly comprises a sealing disc, a moving plate, two auxiliary rods and two reset units. The 5G communication equipment with the long service life achieves the salt mist cleaning function through the auxiliary mechanism, the equipment is prevented from being corroded by salt mist, the service life of the equipment is prolonged, and in addition, the maintenance convenience is improved through the maintenance mechanism.

Owner:李雪华

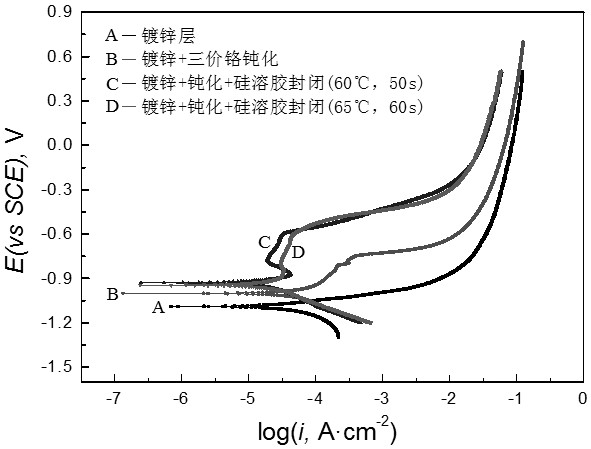

Method for improving acid salt spray corrosion resistance of zinc coating

ActiveCN113463141AImprove bindingUniform colorMetallic material coating processesSaline mistSalt spray test

The invention discloses a method for improving acid salt spray corrosion resistance of a zinc coating. The method comprises the following steps of sequentially carrying out pretreatment, alkaline zinc plating, bright dipping treatment, trivalent chromium passivation treatment, air stop treatment, water-based silica sol sealing treatment and vacuum drying treatment on a part, so that an excellent colored passivation film which is good in binding force, uniform in color distribution and good in acid resistance and salt spray corrosion resistance is prepared on the surface of the zinc coating of the part, and a neutral salt spray test of 1440 h or above and an acid salt spray test of 864 h or above can be past. By meas of the method, a novel trivalent chromium passivation technology and water-based silica sol sealing composite treatment are adopted, the corrosion resistance of the zinc coating in the acid salt mist environment is greatly improved, the technology is green and environmentally friendly, waste water treatment is simple, and good practicability is achieved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

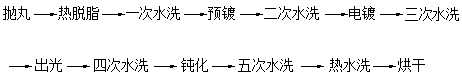

Wheel bolt electroplating process

InactiveCN111074313AReduced risk of hydrogen embrittlementMetallic material coating processesSaline mistSalt spray test

The invention relates to a wheel bolt electroplating process. The process comprises the following process steps of thermal debinding, primary water washing, pre-plating, secondary water washing, electroplating, third water washing, glaring, fourth water washing, passivation, fifth water washing, hot water washing and drying. An electroplated product obtained after shot blasting has the same surface quality and salt fog testing as an electroplated product after acid pickling, a shot blasting product does not need acid pickling, the hydrogen embrittlement risk is reduced, shot blasting does notonly replaces one acid pickling procedure, neutralization and hydrogen removal after acid pickling are not needed, in addition, the production cost can be consumed by waste acid treatment caused by acid pickling, shot blasting is free of the problem, the product quality is improved through process improvement, and in addition, the production cost is reduced.

Owner:山东九佳紧固件股份有限公司

Detection device for detecting corrosion resistance of shell

InactiveCN111595767AEasy to analyze and troubleshootEliminate distractionsWeather/light/corrosion resistanceLiquid spraying apparatusThermodynamicsSaline mist

The invention discloses a detection device for detecting corrosion resistance of a shell. The device specifically comprises a host, a bottom plate, a control box, a mixing box and a plug-in probe, andthe host is installed on one side of the top of the bottom plate. A control box is fixed to the other side of the top of the bottom plate; a box cover is mounted at the top end of the host; a handleis mounted in the middle of the bottom of one end of the box cover; liquid storage tanks are arranged on the two sides of the bottom end of the interior of the host correspondingly. Themixing box is arranged in the middle of the bottom end in the host; a water pump is mounted at the bottom of the interior of each liquid storage tank; and water pipes are fixed at the output ends of the water pump.According to the detection device for detecting the corrosion resistance of the shell, adetection bin and acontrast bin are arranged, salt mist and humid and hot air are introduced into the detection bin, and humid and hot air is introduced into the contrast bin, so that the corrosion condition of the shell is conveniently analyzed and checked, the interference of external environment air on detection is eliminated, and obtained data is more reliable and effective.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

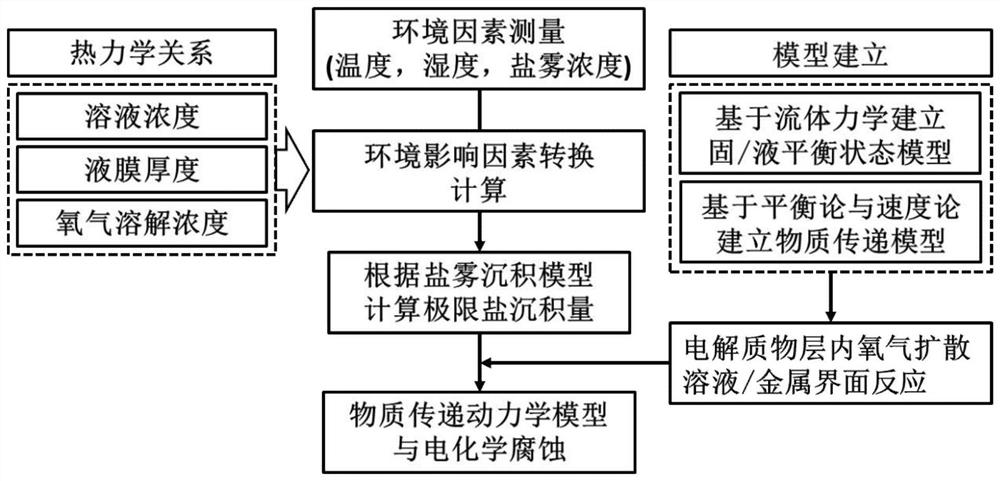

Metal atmospheric corrosion rate prediction algorithm based on material transfer kinetic model

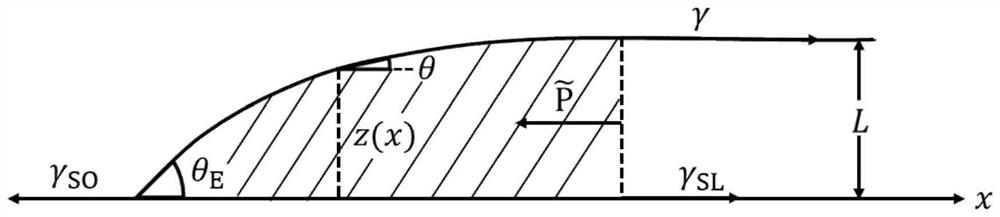

ActiveCN112735538AEffective guidanceWeather/light/corrosion resistanceChemical processes analysis/designChemical reactionReaction rate

The invention discloses a metal atmospheric corrosion rate prediction algorithm based on a material transfer kinetic model, which is suitable for metal atmospheric corrosion rate prediction taking environmental factors such as temperature, humidity and salt spray concentration as main influence factors, and comprises the following steps of: S1, measuring and calculating key environmental factors influencing a corrosion rate; S2, performing conversion calculation on the environmental factors to obtain theoretical values of the related parameters in the step S3; and S3, speculating and calculating the corrosion electrochemical reaction rate according to the dissolution and diffusion model of the oxygen under the liquid film, namely a substance transfer kinetic model. The dynamic model between metal atmospheric corrosion and meteorological factors is established on the basis of the existing mature metal corrosion electrochemical theory and thermodynamic law, the atmospheric corrosion of each region can be calculated according to meteorological environment data, and theoretical support is provided for drawing a corrosion map; and effective guidance can be provided for metal corrosion prediction, corrosion prevention and other aspects.

Owner:CHINA NAT ELECTRIC APP RES INST

Water-based metal rust-proof varnish and preparation method thereof

The invention relates to water-based metal rust-proof varnish and a preparation method thereof, and belongs to the field of coating. The water-based metal rust-proof varnish comprises the following components in parts by weight: 5 to 15 parts of deionized water, 70 to 80 parts of water-based polymer emulsion, 1 to 2 parts of a salt-mist-resistant agent, 0.5 to 1 part of a corrosion inhibitor, 0.1 to 0.3 part of a wetting and leveling agent, 2 to 3 parts of wax emulsion, 4 to 6 parts of alcohol ester-12, 0.2 to 0.4 part of a pH regulator and 0.2 to 0.5 part of an associative thickener. The water-based metal rust-proof varnish can form a paint film quickly at room temperature, has high transparency, light color, high glossiness and good plumpness, is smooth and fine, and perfectly takes on the metal effect of a substrate. High-performance materials are selected, so that the paint film has strong ultraviolet-resistant ability, good adhesive force, high weather resistance, yellowing resistance, water tolerance, scraping resistance, high hardness and long rust-proof time, and is bright and clean as new after being washed by rain. The product is non-toxic and odorless, does not contain components which are harmful to a human body and the environment, and is real environment-friendly water-based corrosion-resistant coating. The water-based metal rust-proof varnish is convenient to construct and high in self-drying speed, improves the efficiency and reduces the energy.

Owner:徐州市水性漆厂

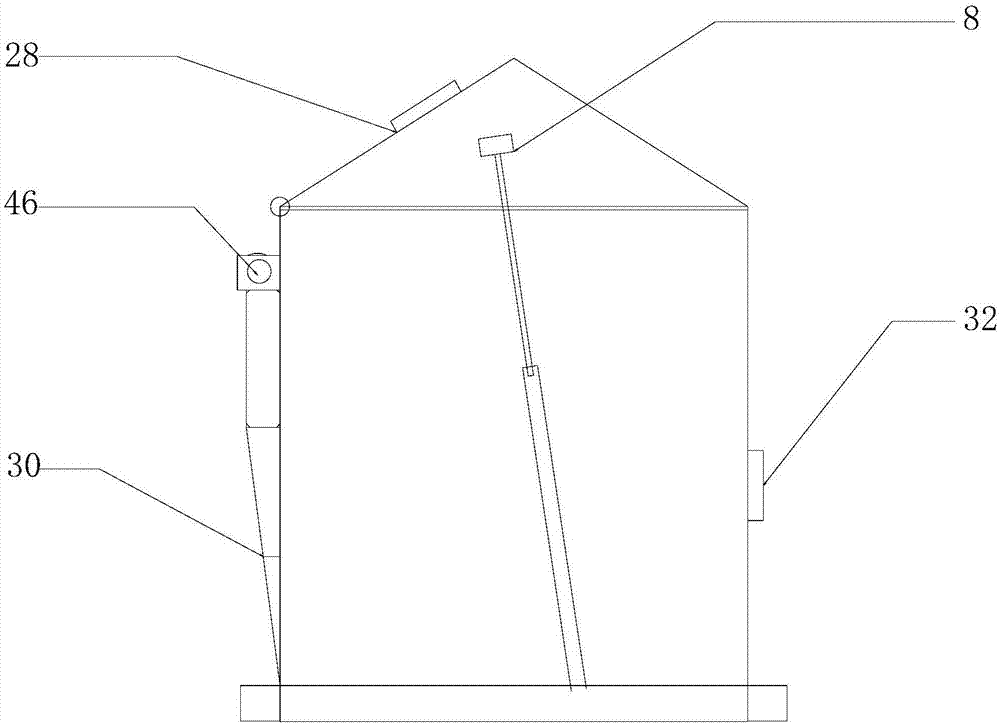

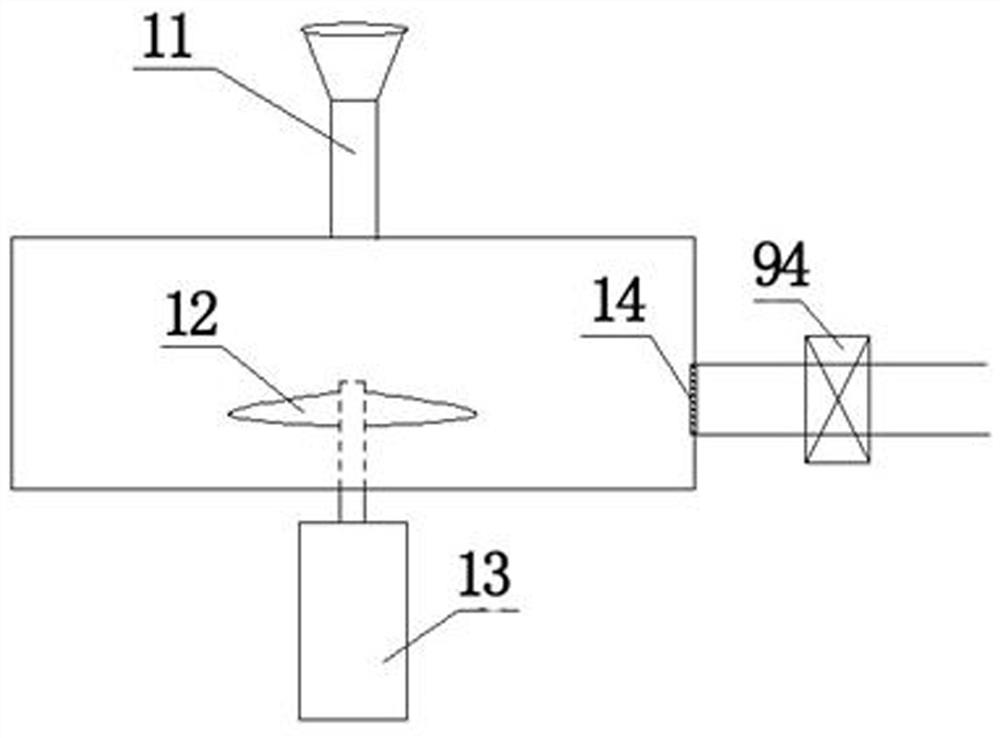

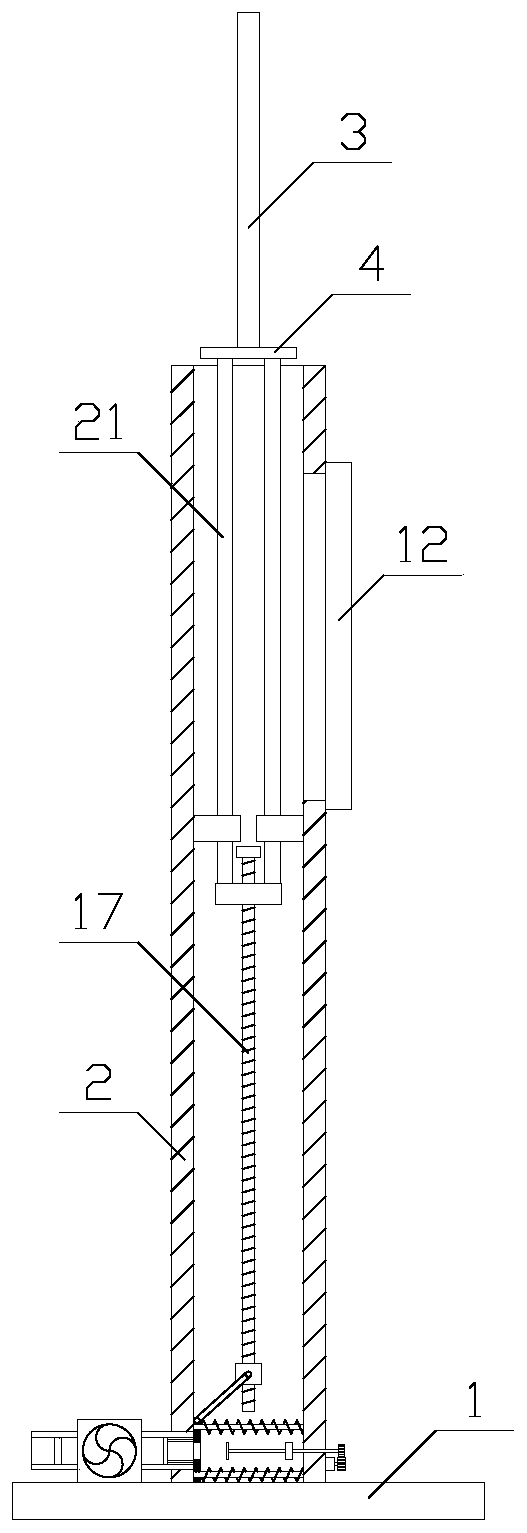

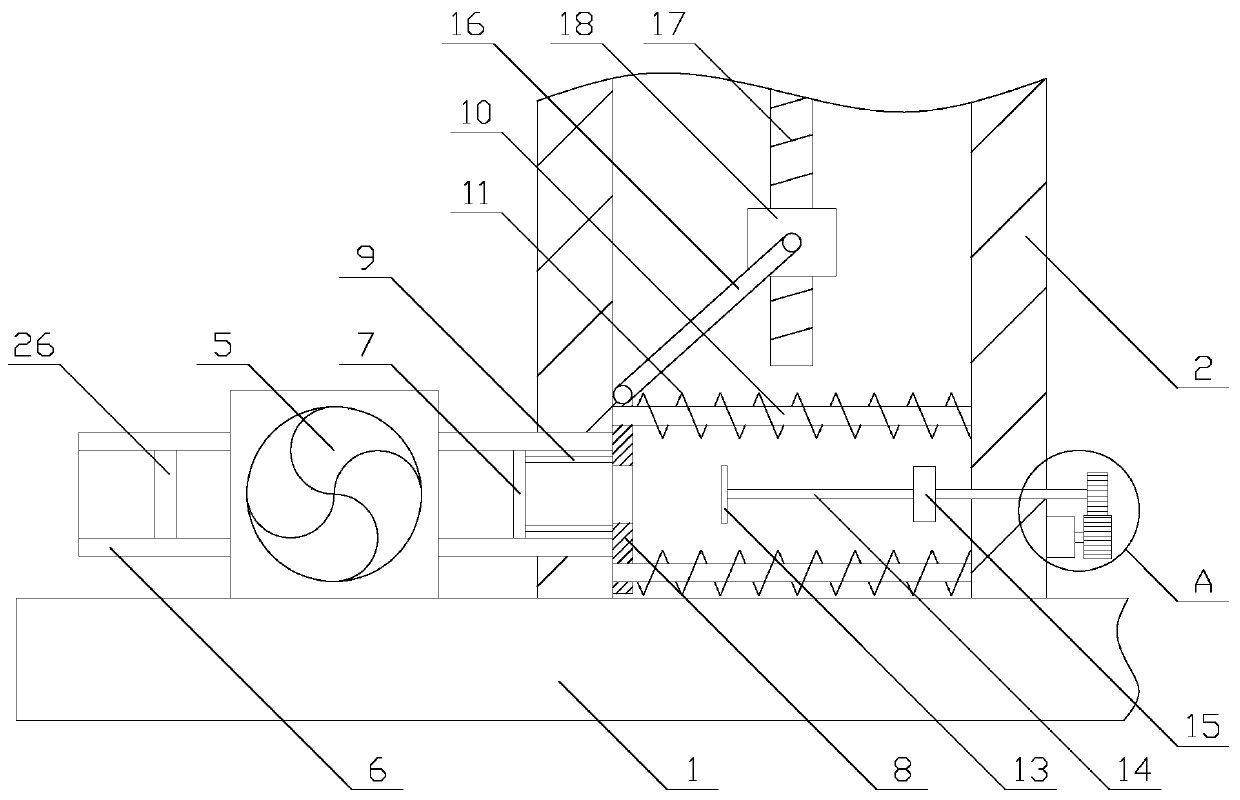

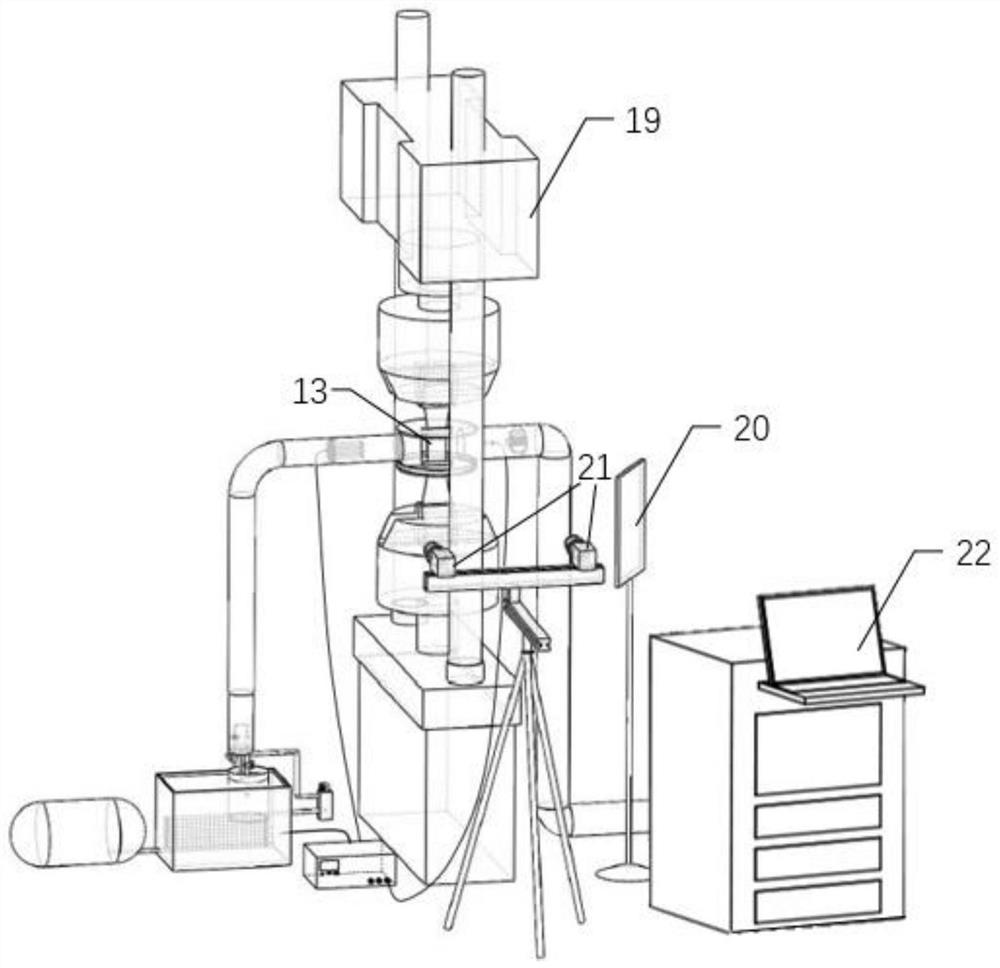

Semi-open type in-situ salt spray corrosion device suitable for optical measurement mechanics

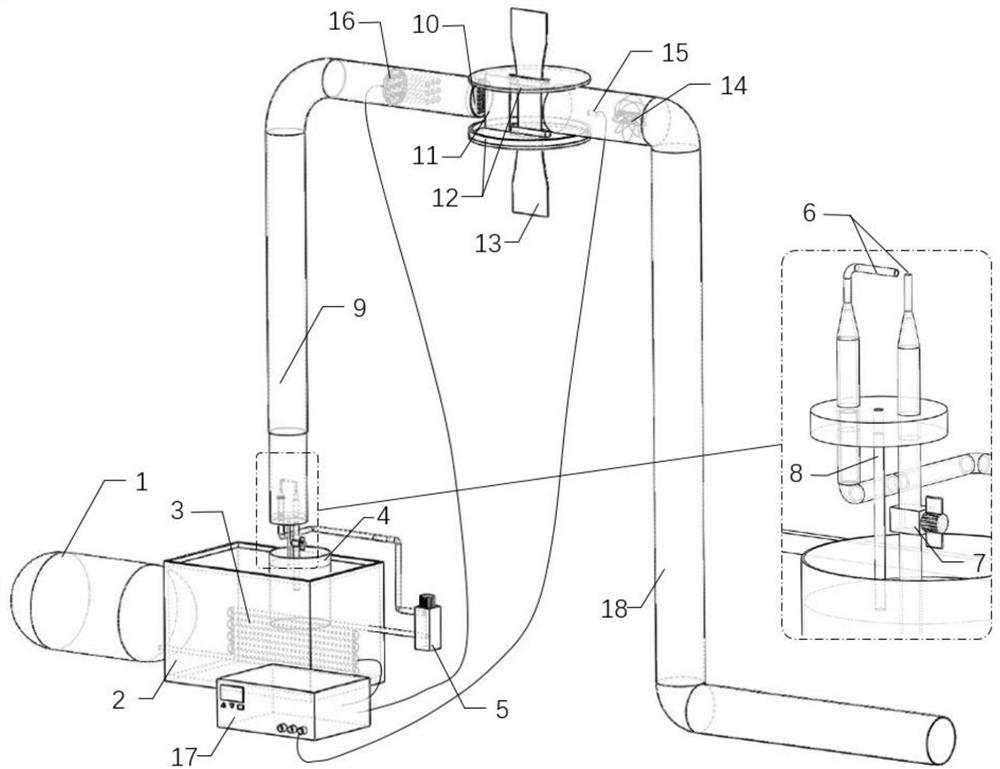

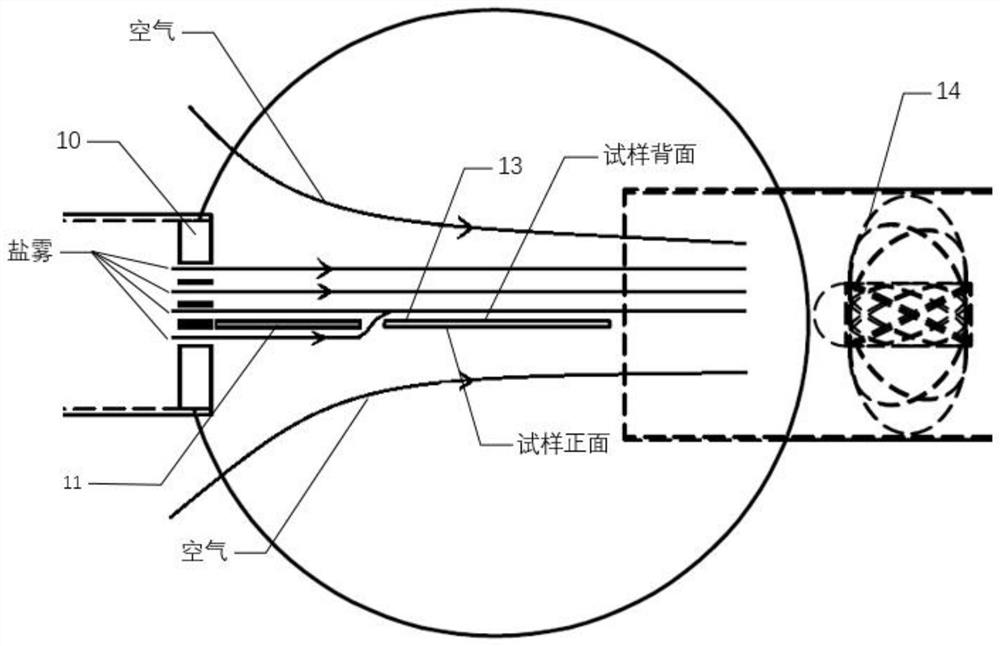

ActiveCN111879687AAdjustable flow rateAdjustable temperatureWeather/light/corrosion resistanceSaline mistMaterials testing

The invention relates to the technical field of material testing devices, in particular to a semi-open type in-situ salt spray corrosion device suitable for optical measurement mechanics. The device comprises a temperature adjusting module, a salt spray generating module and a semi-open type corrosion cavity, and can generate salt spray through the salt spray generating module and control the flowrate and concentration of the salt spray. The temperature adjusting module adjusts the temperature of salt mist generated by the salt mist generating module, and the generated salt mist passes through the semi-open corrosion cavity to conduct a salt mist corrosion experiment on one side of a sample, so a salt mist environment with the adjustable temperature and flow speed is provided for the sample, and the semi-open corrosion cavity is adopted, so salt mist or liquid drops condensed by the salt mist can be prevented from interfering with optical measurement mechanical methods such as digitalimage related technologies while the salt mist is prevented, the surface of the sample is allowed to be observed in real time in the mechanical test process, and the information data such as the surface appearance, displacement and deformation of the sample is collected.

Owner:CIVIL AVIATION UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com