Quake-proof and corrosion-resistant H-shaped steel with high performance and processing method thereof

A processing method and technology of H-beam, applied in the field of metal material processing and forming, can solve the problem that H-beam cannot meet the high strength of earthquake resistance, corrosion resistance, weather resistance, etc. low stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

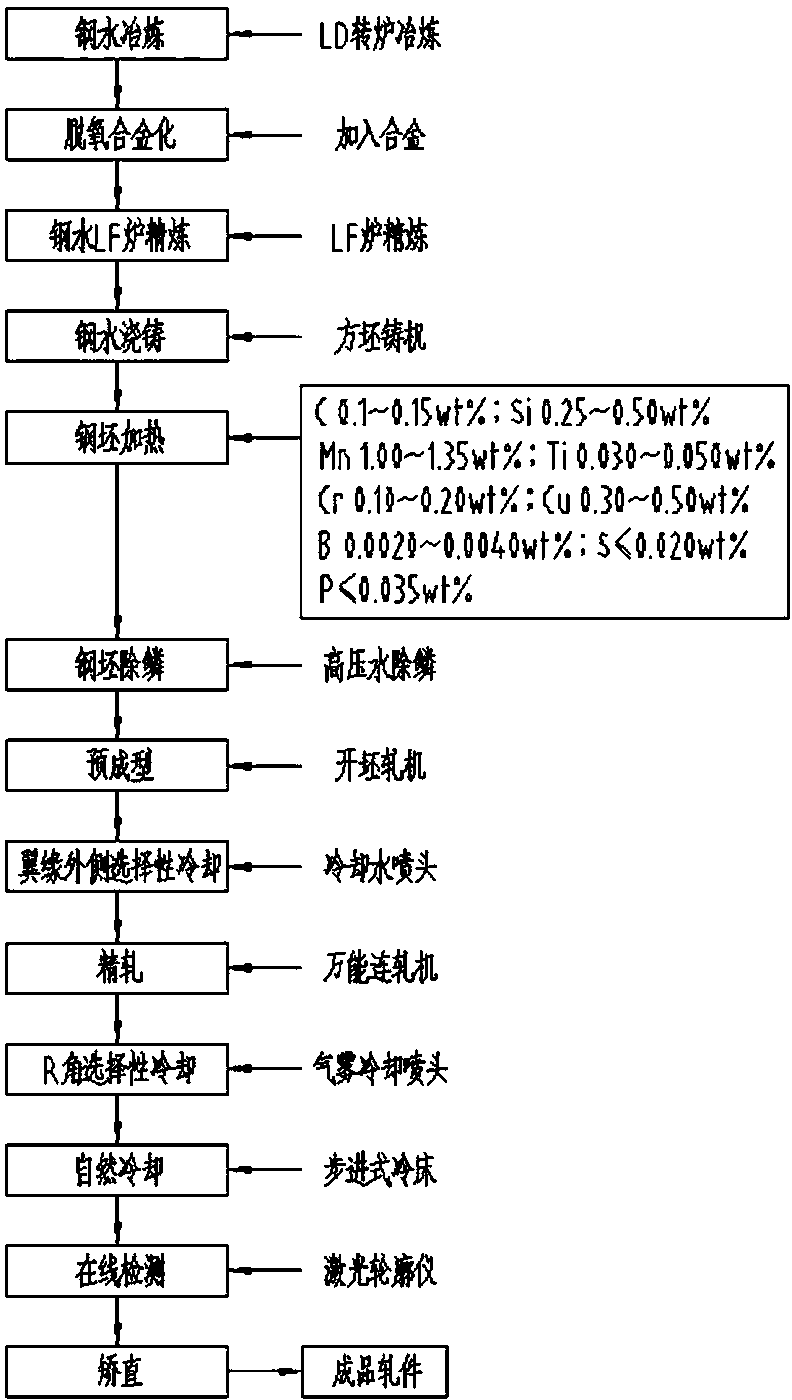

Method used

Image

Examples

Embodiment 1

[0041] The high-performance anti-shock and corrosion-resistant H-shaped steel has the following chemical composition in weight percentage: C 0.10wt%, Si 0.25wt%, Mn 1.00wt%, Ti 0.030wt%, Cr 0.10wt%, Cu 0.30wt%, B 0.0020 wt%, S 0.020 wt%, P 0.035 wt%, the rest is Fe and unavoidable impurities. Processed through the following processes, billet section: 320mm×410mm:

[0042] Described molten steel smelting is molten iron (chemical composition C 4.0wt%, Si 0.30wt%, Mn 0.35wt%, P 0.100wt%, S0.020wt%, the rest is Fe and unavoidable impurity), steel scrap ( Chemical composition C 0.20wt%, Si 0.30wt%, Mn 0.30wt%, P 0.030wt%, S 0.025wt%, the rest is Fe and unavoidable impurities) and pig iron (chemical composition C 3.0wt%, Si 0.50 wt%, Mn 0.40wt%, P 0.090wt%, S 0.020wt%, and the rest are Fe and unavoidable impurities) into the LD converter, and at the same time add copper plates (chemical composition Cu 99.3wt%, the rest is Fe and unavoidable impurity), and then carry out convention...

Embodiment 2

[0057] The high-performance anti-shock and corrosion-resistant H-shaped steel has the following chemical composition in weight percentage: C 0.12 wt%, Si 0.35 wt%, Mn 1.20 wt%, Ti 0.040 wt%, Cr 0.15 wt%, Cu 0.40 wt%, B 0.0030 wt%, S 0.016 wt%, P 0.031 wt%, the rest is Fe and unavoidable impurities; processed by the following procedures, billet section: 320mm×410mm:

[0058] Described molten steel smelting is that molten iron (chemical composition C 4.3wt%, Si 0.48wt%, Mn 0.52wt%, P 0.160wt%, S0.017wt%, the rest are Fe and unavoidable impurities), steel scrap ( Chemical composition C 0.20wt%, Si 0.44wt%, Mn 0.39wt%, P 0.038wt%, S 0.034wt%, the rest is Fe and unavoidable impurities) and pig iron (chemical composition C 3.0wt%, Si 0.68 wt%, Mn 0.59 wt%, P 0.107 wt%, S 0.034 wt%, the rest is Fe and unavoidable impurities) into the LD converter, and at the same time add copper plate (chemical composition Cu 99.3wt%, and the rest is Fe and unavoidable impurities), and then carry ou...

Embodiment 3

[0072] The high-performance anti-shock and corrosion-resistant H-shaped steel has the following chemical composition in weight percentage: C 0.15 wt%, Si 0.50 wt%, Mn 1.35 wt%, Ti 0.050 wt%, Cr 0.20 wt%, Cu 0.50 wt%, B 0.0040 wt%, S 0.014 wt%, P 0.033 wt%, the rest is Fe and unavoidable impurities; processed by the following procedures, billet section: 320mm×410mm:

[0073] Described molten steel smelting is molten iron (chemical composition C 4.5wt%, Si 0.60wt%, Mn 0.60wt%, P 0.200wt%, S 0.015wt%, the rest is Fe and unavoidable impurity), steel scrap ( Chemical composition C 0.40wt%, Si 0.60wt%, Mn 0.60wt%, P 0.045wt%, S 0.040wt%, the rest is Fe and unavoidable impurities) and pig iron (chemical composition C 4.0wt%, Si 0.80 wt%, Mn 0.70 wt%, P 0.120wt%, S 0.045wt%, the rest is Fe and unavoidable impurities) into the LD converter, and at the same time add copper plates (chemical composition Cu 99.3wt%, and the rest is Fe and unavoidable impurities), followed by conventional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com