Water-based over-rust coating primer and preparation method thereof

A primer, water-based technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of easy peeling, high price, unstable effect, etc., and achieve the effect of excellent adhesion and strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

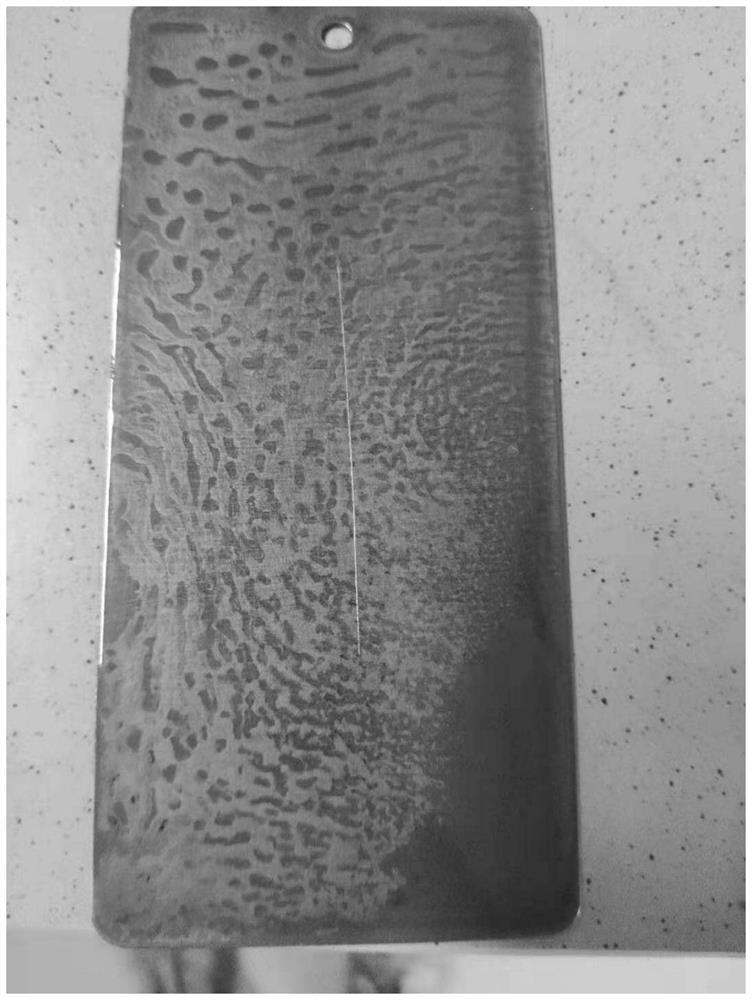

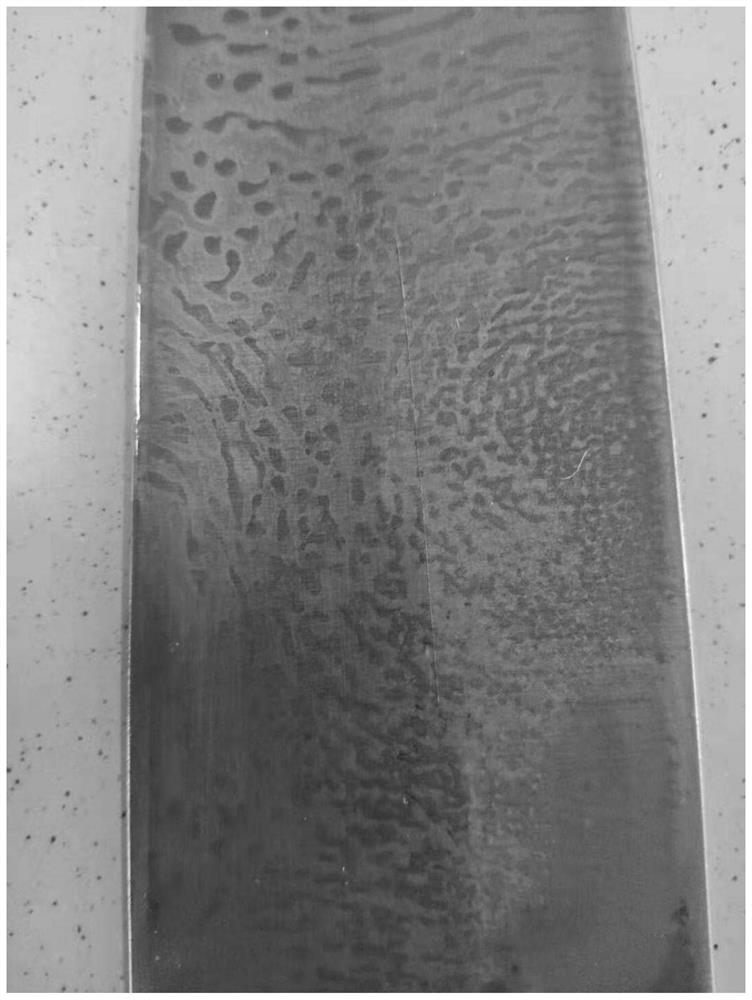

Image

Examples

preparation example Construction

[0038] Another aspect of the present invention provides a method for preparing the above-mentioned primer, the preparation method comprising: uniformly mixing a water-based acrylic emulsion, a film-forming aid, water and other additives to obtain the water-based rust-coating primer.

[0039] In the present invention, preferably, the aqueous acrylic emulsion is filtered first, and then mixed with other raw materials.

[0040] As preferred version: preparation method of the present invention comprises the steps:

[0041] (1) Filter the water-based acrylic emulsion with a 200-mesh filter, then add it to the stirring tank, and rotate it at a low speed until there is a slight vortex;

[0042] (2) then drop into film-forming aid in step (1) gained material, fully stir, form homogeneous phase;

[0043] (3) Add defoamer, wetting agent, leveling agent and thickener to the material obtained in step (2) in order again, fully disperse and stir evenly;

[0044] (4) Finally, add the pure ...

Embodiment 1-3

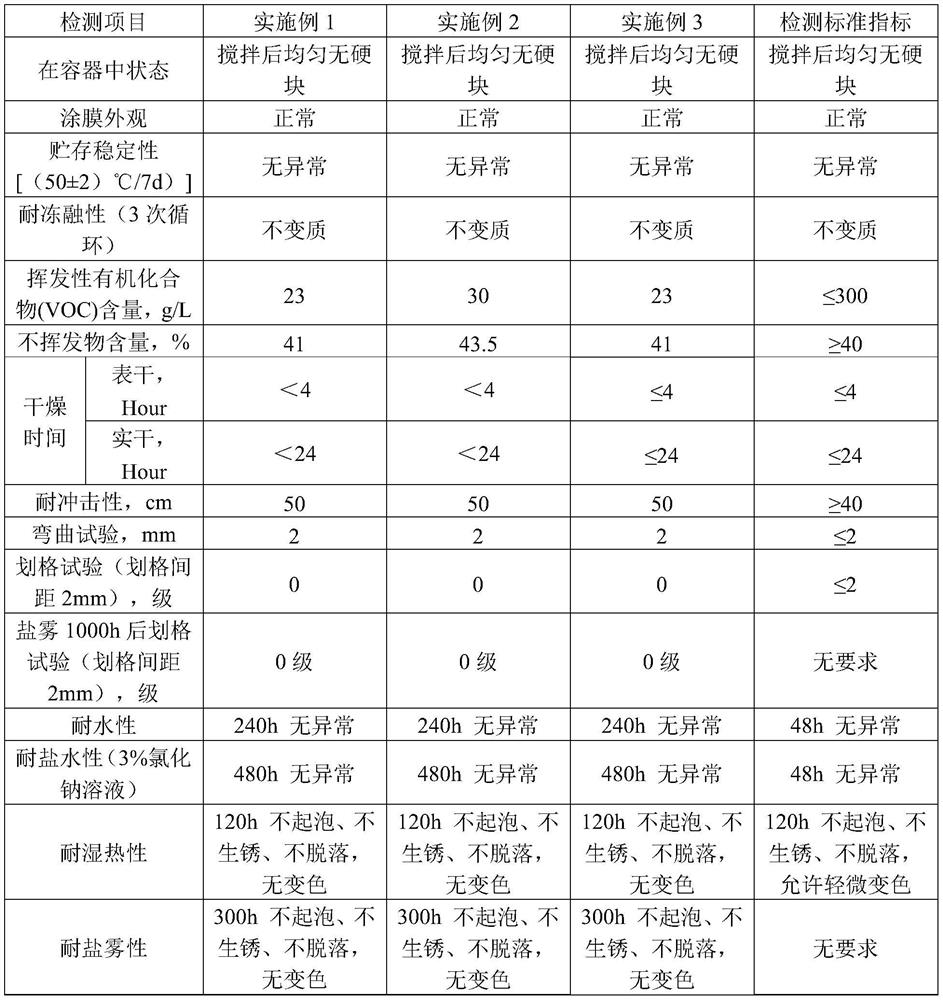

[0052] The specific formula of the water-based rusty coating primer prepared in Examples 1-3 is shown in Table 1, and the consumption of each component in Table 1 refers to parts by weight.

[0053] Table 1

[0054] name Example 1 Example 2 Example 3 Water-Based Acrylic Emulsion 80 85 80 Coalescing agent 1 0.8 0.8 0.8 Coalescing agent 2 4.6 5.0 4.6 Polyether modified silicone wetting agent 0.3 0.3 0.3 fungicide 0.2 0.2 0.2 Silicone leveling agent 0.2 0.2 0.2 Polyurethane thickener 1.3 2.3 2.3 Organic Polymer Defoamer 0.1 0.15 0.15 pure water 12.7 6.25 11.65

[0055] Wherein, film-forming aid 1 in Table 1 is DPM (dipropylene glycol methyl ether), and film-forming aid 2 is TEXANOL (dodecyl alcohol ester).

[0056] The concrete preparation method of the water-based band rust coating primer provided by above embodiment 1-3 is as follows:

[0057] (1) Filter the water-based acrylic emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com