Packaging structure of integrated fuel cell stack and assembling method thereof

A fuel cell stack and packaging structure technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of large volume and weight, poor cross-sealing effect of sealing surfaces, and difficulty in ensuring assembly tolerances, etc., to achieve volume and weight reduction , strong shock resistance, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

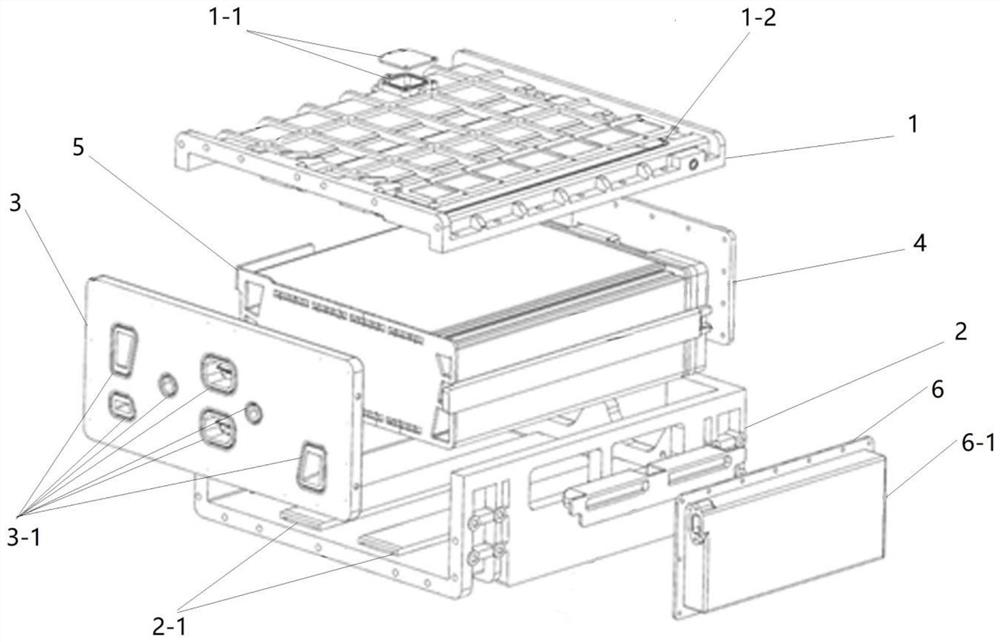

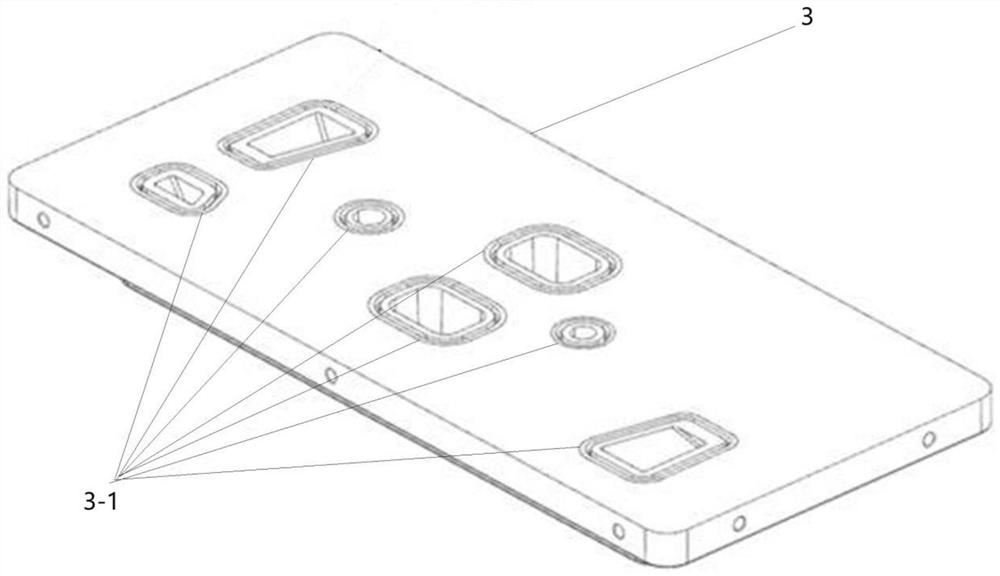

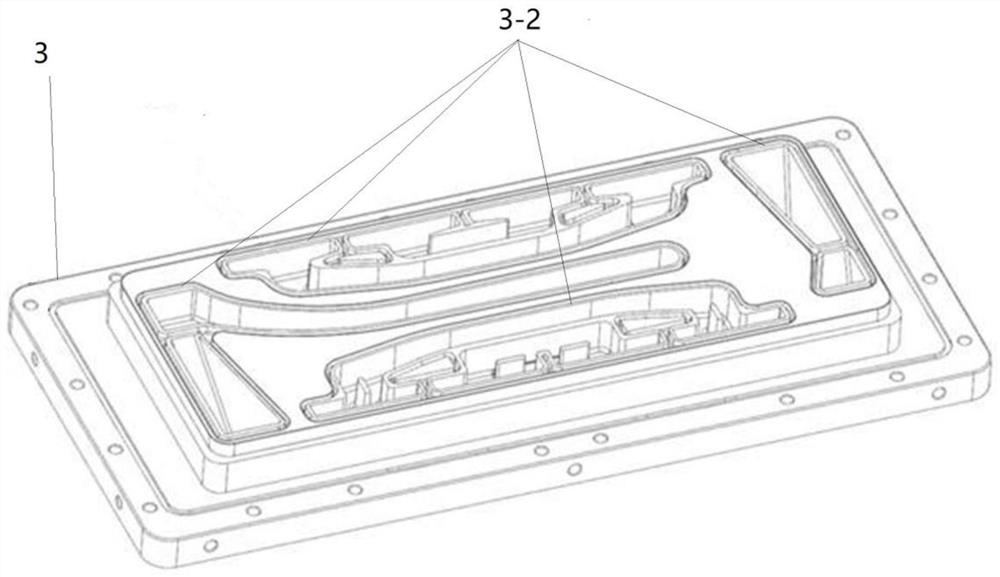

[0055] In a specific embodiment, as shown in the accompanying drawing Figure 1-Figure 8 As shown, a packaging structure of an integrated fuel cell stack includes an upper casing (1), a lower casing (2), a front end plate (3), a rear cover plate (4) and a core structure (5); The front end plate (3) is provided with gas ports (3-1) and flow channel structure (3-2); the front end plate (3) is located directly in front of the core structure (5), and is fixedly connected to the upper shell (1) and the lower shell (2); the upper casing (1) is located directly above the core structure (5), and is fixedly connected with the lower casing (2), the front end plate (3) and the back cover (4); the lower casing (2) is located in the stack directly below the core structure (5); the rear cover plate (4) is located directly behind the core structure (5), and is fixedly connected to the upper shell (1) and the lower shell (2); the core structure (5) is wrapped with insulating Guard plate; the...

Embodiment 2

[0067] In a specific embodiment, as shown in the accompanying drawing Figure 9-10 As shown, the specific steps are:

[0068] S1: Through the pre-positioning of the auxiliary tooling installed on the bottom plate (7-1) of the press, the press (7) needs to have a pressing function, and the upper part of the press (7) has a top plate (7-2) of the press; the press The top plate (7-2) is provided with positioning holes, which are used to locate the six positioning rod assemblies (7-3) used for core assembly and positioning; place the front end plate (3) on the bottom plate of the press (7-1) Inside; pass the positioning rod assembly (7-3) consisting of six positioning rods through the positioning hole of the press top plate (7-2) and the positioning hole of the auxiliary positioning block that is concentric with the corresponding positioning hole; adjust the front plate (3) position, so that it is close to the positioning rod assembly (7-3); according to the six-point positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com