Wheel bolt electroplating process

An electroplating process and bolt technology, which is applied in the field of wheel bolt electroplating process, can solve the problems such as the risk of hydrogen embrittlement, and achieve the effects of reducing the risk of hydrogen embrittlement, improving product quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

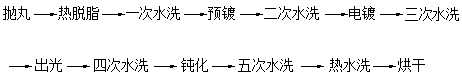

[0023] Such as figure 1 As shown, a kind of wheel bolt electroplating process of the present invention comprises the process steps that are carried out in the following order:

[0024] For shot blasting, put the processed and formed bolts into the shot blasting chamber, and the weight of each loading should not exceed 120kg. Too much loading at a time will lead to incomplete removal of the shot blasting scale; the diameter of the steel shot in the shot blasting chamber is 0.1~ 0.2mm, the hardness of the steel shot is 45~50HRC, and the shot blasting time is 5~8min; in the shot blasting process, when the shot blasted bolts are taken out of the shot blasting chamber, the vibration blanking method can be used, and a slope can be set at the blanking port. A vibration motor is installed on the slope. When the vibration motor vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com