Environmental test equipment for cooperatively controlling salt mist concentration and relative humidity

A relative humidity and environmental test technology, applied in the direction of simultaneous control of multiple variables, non-electric variable control, control/regulation system, etc., can solve the problems of electrical equipment parts corrosion, equipment failure, high relative humidity, etc., and achieve dynamic balance , easy automation, simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test example 1

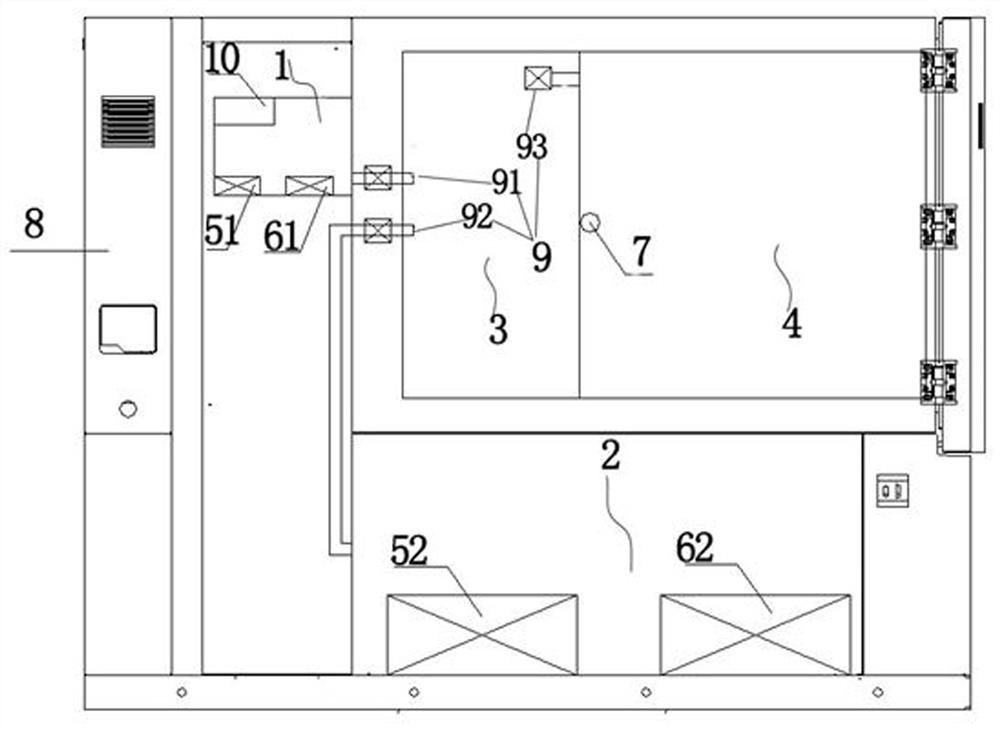

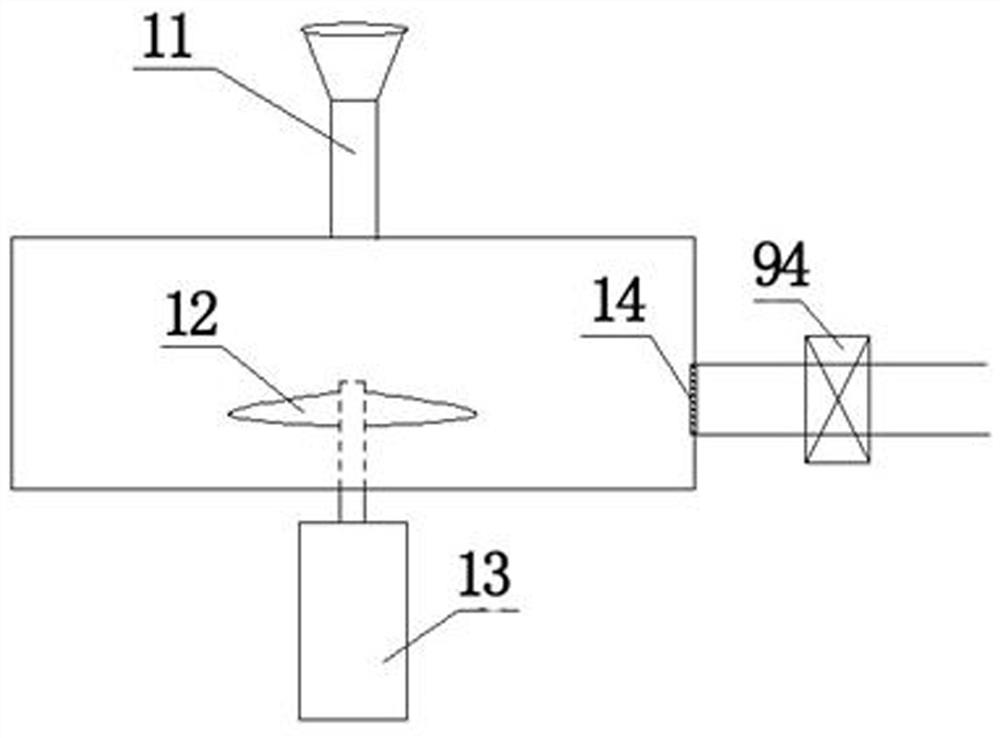

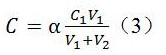

[0052] When the environmental test equipment is working, the fixed dry salt fog concentration is 3000mg / m 3 The relative humidity is 40%. Setting the laboratory requires environmental parameters: temperature is 35 ° C, relative humidity is 80%, salt fog concentration is 500 mg / m 3 . The relative humidity of the adjustment air should be set to 88%, the dry salt fog atmosphere and the adjustment of the air volume ratio of 1: 5. When launching an environmental test equipment, the device first produces a fixed concentration of 4000 mg / m by using a dry salt fog occurrence system 1. 3 The dry salt mist atmosphere, the dry salt fog occurrence system 1, by the first temperature adjustment module 51, the temperature is controlled to 35 ° C, and the relative humidity of the first humidity adjustment module 61 is adjusted; at the same time by air conditioning system 2 The second temperature control module 52 sets the temperature of the adjustment air to 35 ° C, and the relative humidit...

test example 2

[0054] The same environmental test equipment is used and the test case 1, the same fixed dry salt fog concentration is 3000mg / m 3 The relative humidity is 40%. When the environment is required to have a temperature of 40 ° C, the relative humidity is 85%, the salt fog concentration is 600 mg / m 3 . According to Equation 1 and Equation 2, the relative humidity of the adjustment air should be controlled to 96%, the amount of the dry salt fog atmosphere flow and the adjustment of the air flow rate are 1: 4.

[0055] When launching an environmental test equipment, the device first produces a fixed concentration of 4000 mg / m by using a dry salt fog occurrence system 1. 3 Dry salt fog atmosphere, in the dry salt fog occurrence system, the temperature is controlled to 40 ° C by the first temperature adjustment module 51, and the relative humidity of the first humidity adjustment module 61 is adjusted; at the same time, the air conditioning system 2 is used. The second temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com