Method for testing anti-corrosion performance of metallic equipment under island environment

A test method and metal sample technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as metal structure damage, reduce the strength and reliability of metal equipment, and damage the metal itself to achieve reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] A test method for anticorrosion performance of metal equipment in an island environment, which is used to test the corrosion of different coatings in different environments, so as to provide a theoretical basis for selecting a suitable coating for metal equipment in a specific island environment. The method specifically includes the following steps:

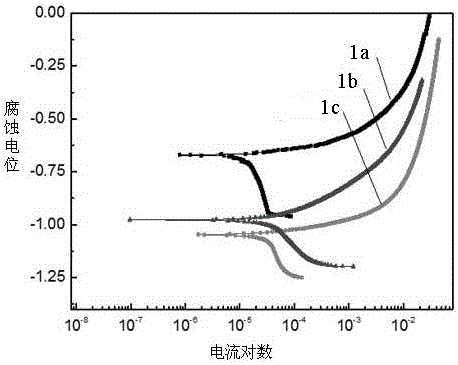

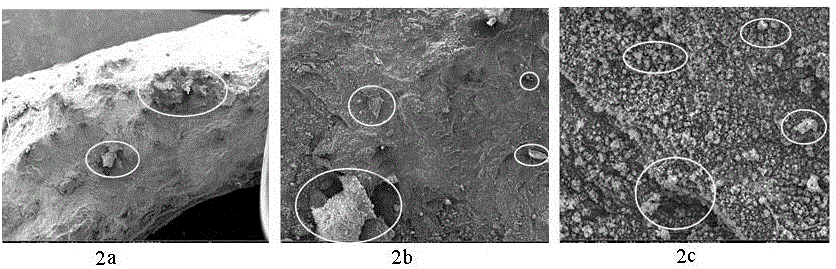

[0029] A. Test the potentiodynamic polarization curve of coated metal equipment, and fit the AC impedance spectrum and self-corrosion potential of coated metal equipment. In this embodiment, metal equipment with three different coatings are selected for testing, and the three coatings include hot-dip aluminizing, hot-dip galvanizing and hot-dip aluminizing.

[0030] This step specifically includes the following:

[0031] A1. Place the coated metal sample in the three-electrode t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com