In-situ test detection device and method for simulating corrosion and aging of multi-factor atmospheric environment material

An atmospheric environment, in-situ test technology, applied in the field of revealing the atmospheric corrosion behavior, laws and mechanisms of metal materials, to achieve the effect of continuous non-destructive tracking and avoiding the influence of the electrochemical state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

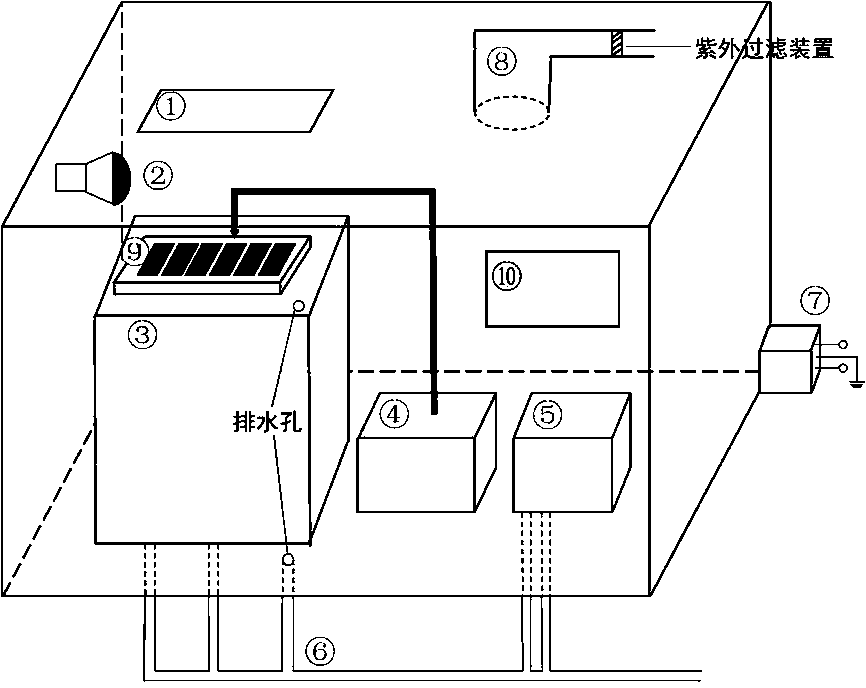

[0058] Based on the device in Embodiment 1, the present invention provides an in-situ test and detection method for simulating the corrosion and aging of materials in a multi-factor atmospheric environment. Sample 9 is placed on the heating plate in the detection device, the optical path channel is closed, and the heating plate is energized to heat the heating plate to a predetermined temperature, and the temperature is controlled by real-time sensing through the temperature sensor; at the same time, the test environment is realized by using the atmospheric temperature and humidity control device 5 hours. Preset the temperature and humidity, and spray salt mist on the sample 9 at a quantitative and fixed frequency during the test. Control simulation of 5 environmental factors, salt spray and radiation, to reproduce the corrosion state of sample 9 in various atmospheric environments;

[0059] When performing in-situ monitoring and detection, the detection device is placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com