Water-based high-temperature-resistant anti-corrosion composition

A technology of high temperature resistance and composition, applied in the field of water-based high temperature resistant and anti-corrosion compositions, can solve problems such as poor anti-corrosion effect, and achieve the effects of not easy to discolor, simple and convenient construction, and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

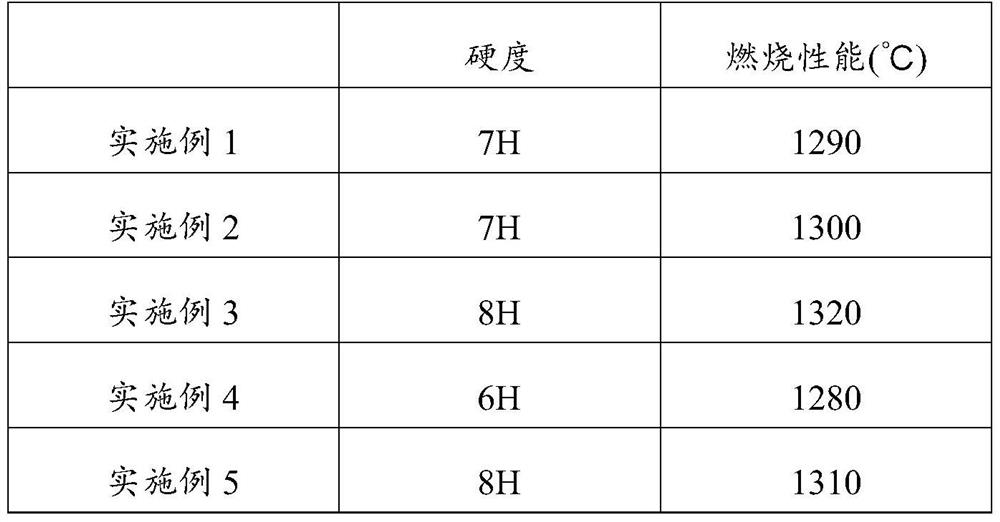

Examples

Embodiment 1

[0021] A water-based high temperature resistant anticorrosion composition, comprising the following components by weight:

[0022] 90 parts of modified epoxy resin, 5 parts of nano-alumina, 5 parts of nano-titanium dioxide, 5 parts of nano-magnesium oxide, 0.5 part of scandium, 40 parts of polyethylene glycol 200, 2 parts of silicone resin, 10 parts of water glass and 10 parts of silica gel share.

Embodiment 2

[0024] A water-based high temperature resistant anticorrosion composition, comprising the following components by weight:

[0025] 50 parts of water-based silicone resin, 10 parts of nano-silica, 5 parts of nano-yttrium oxide, 1 part of nano-cerium oxide, 7 parts of nano-zinc hydroxide, 1 part of lanthanum, 20 parts of polyaspartic acid, 20 parts of dipropylene glycol methyl ether , 2 parts of carboxymethyl cellulose, 20 parts of silica gel and 5 parts of titanium dioxide.

Embodiment 3

[0027] A water-based high temperature resistant anticorrosion composition, comprising the following components by weight:

[0028] 60 parts of high temperature resistant silicone resin, 15 parts of nano-alumina, 1 part of nano-zinc oxide, 22 parts of nano-magnesia, 14 parts of nano-silicon dioxide, 5 parts of nano-yttrium oxide, 13 parts of nano-cerium oxide, 4 parts of lanthanum, polyethylene 10 parts of glycol 400, 5 parts of polyaspartic acid, 12 parts of dipropylene glycol methyl ether, 13 parts of propylene glycol methyl ether, 25 parts of polyether modified polysiloxane (number average molecular weight 12000) and 15 parts of silica gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com