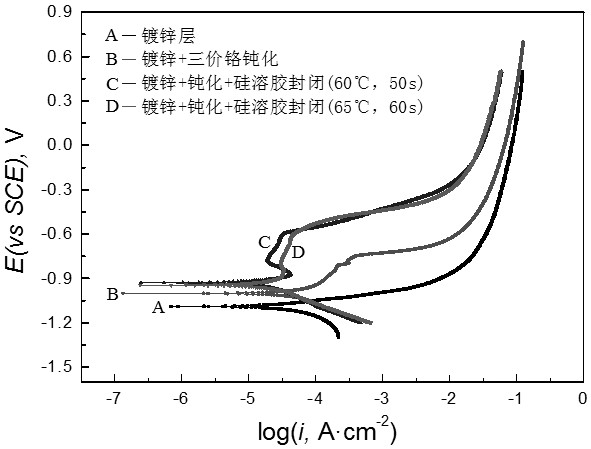

Method for improving acid salt spray corrosion resistance of zinc coating

A technology of salt spray corrosion and galvanized layer, which is applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance, great difference in corrosion resistance of galvanized layer, lack of etc., and achieve excellent corrosion resistance, Good binding force and uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for improving the acid salt spray corrosion resistance of galvanized coating, comprising the following steps:

[0037] 1) Chemical degreasing. Prepare a chemical degreasing solution with 30g / L sodium hydroxide, 45g / L sodium carbonate, and 25g / L sodium silicate; put the Q235 steel sheet in the chemical degreasing solution at 50-70°C for 5-15 minutes. After the parts are degreased, they are thoroughly washed with warm water. It is necessary to ensure that the surface of the entire part is hydrophilic. If the continuous water film lasts for more than 60 seconds, the degreasing is considered qualified.

[0038]2) activation. The sample treated in step 1) is subjected to activation treatment, and the process parameters are: 50-100 g / L hydrochloric acid, 40-50 g / L urotropine, soaking at room temperature for 1-2 minutes. After activation, the samples were thoroughly washed with deionized water.

[0039] 3) Neutralization. The samples treated in steps 1) and 2) wer...

Embodiment 2

[0051] A method for improving the acid salt spray corrosion resistance of galvanized coating, comprising the following steps:

[0052] 1) Chemical degreasing. Prepare a chemical degreasing solution with 30g / L sodium hydroxide, 45g / L sodium carbonate, and 25g / L sodium silicate; put the Q235 steel sheet in the chemical degreasing solution at 50-70°C for 5-15 minutes. After the parts are degreased, they are thoroughly washed with warm water. It is necessary to ensure that the surface of the entire part is hydrophilic. If the continuous water film lasts for more than 60 seconds, the degreasing is considered qualified.

[0053] 2) activation. The sample treated in step 1) is subjected to activation treatment, and the process parameters are: 50-100 g / L hydrochloric acid, 40-50 g / L urotropine, soaking at room temperature for 1-2 minutes. After activation, the samples were thoroughly washed with deionized water.

[0054] 3) Neutralization. The samples treated in steps 1) and 2) we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com