Method for testing sealing performance of metal hose in axial tension and corrosion state

A metal hose and sealing performance technology, used in fluid tightness testing, machine/structural component testing, and liquid/vacuum testing for liquid tightness. It can solve the problem of low reliability of test data and inability to simulate actual Status and other issues, to achieve the effect of safe and reliable testing and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

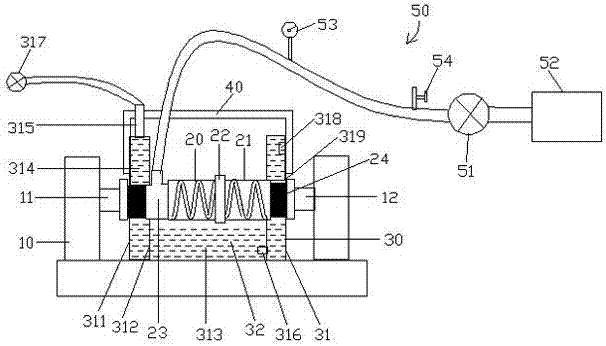

[0031] Such as figure 1 As shown, a metal hose multifunctional pressure test device includes a tensile machine 10 , a salt spray corrosion device 30 , an explosion-proof protective cover 40 and a sealing performance detection device 50 .

[0032] The tensile machine includes a left stretching head 11 and a right stretching head 12 coaxially arranged.

[0033] The two ends of the pressure test metal hose 20 are respectively connected with the left stretching head and the right stretching head.

[0034] The pressure test metal hose includes a metal hose segment 21 , an intermediate joint 22 , a tee joint 23 and an end sealing joint 24 . The number of metal hose segments is at least two, and the two adjacent metal hose segments are sealed and connected by an intermediate joint; the three-way joint is set at one end of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com