Autoclaved flyash-lime brick prepared from waste incineration flyash and preparation method for autoclaved flyash-lime brick

A technology of waste incineration fly ash and autoclaved fly ash bricks, which is applied in the field of building materials, can solve problems such as waste of resources and secondary pollution, and achieve the effects of saving resources, reducing the use of cement, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

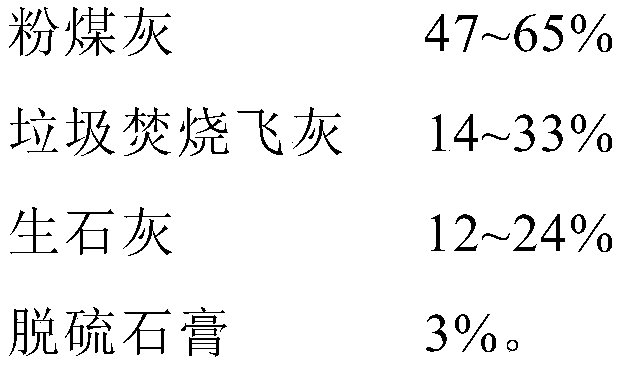

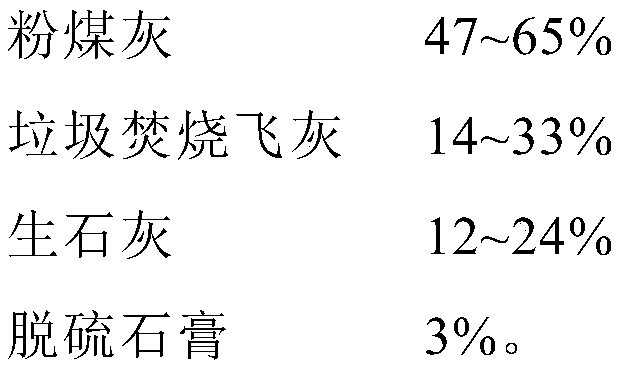

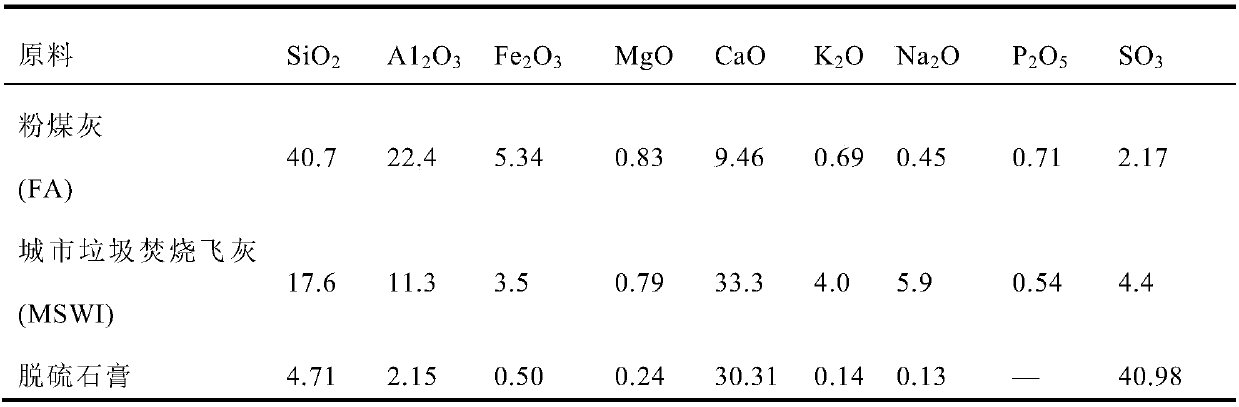

[0032] A method for preparing autoclaved fly ash bricks by using waste incineration fly ash, comprising the following steps:

[0033] S1: Set Ca / Si to 1.26, weigh 5.30g of fly ash, 2.60g of municipal waste incineration fly ash, 1.80g of quicklime and 0.30g of desulfurized gypsum. The raw materials are fully dry mixed and mixed evenly;

[0034] S2: Put the uniformly mixed raw materials in S1 into an agate mortar, weigh 2g of deionized water, pour it into the agate mortar, and grind to make the water fully contact with the raw materials;

[0035] S3: put the ground raw material in S2 into a mould, press and form it on a tablet press (compression molding pressure 20MPa) and demould, to obtain a formed test block;

[0036] S4: Weigh 50g of deionized water and add it into a 500ml reaction kettle. Put a bracket higher than the water surface in the reactor; put the test block obtained in S3 on the bracket in the reactor for hydrothermal reaction, the reaction temperature is 220°C, ...

Embodiment 2

[0041] A method for preparing autoclaved fly ash bricks by using waste incineration fly ash, comprising the following steps:

[0042] S1: Set Ca / Si to 1.20, weigh 5.26g of fly ash, 2.94g of municipal waste incineration fly ash, 1.50g of quicklime and 0.30g of desulfurized gypsum. The raw materials are fully dry mixed and mixed evenly;

[0043] S2: Put the uniformly mixed raw materials in S1 into an agate mortar, weigh 2g of deionized water, pour it into the agate mortar, and grind to make the water fully contact with the raw materials;

[0044] S3: put the ground raw material in S2 into a mould, press and form it on a tablet press (compression molding pressure 20MPa) and demould, to obtain a formed test block;

[0045] S4: Weigh 50g of deionized water and add it into a 500ml reaction kettle. Put a bracket higher than the water surface in the reactor; put the test block obtained in S3 on the bracket in the reactor for hydrothermal reaction, the reaction temperature is 220°C, ...

Embodiment 3

[0050] A method for preparing autoclaved fly ash bricks by using waste incineration fly ash, comprising the following steps:

[0051]S1: Set Ca / Si to 1.10, weigh 5.71g of fly ash, 2.89g of municipal waste incineration fly ash, 1.40g of quicklime and 0.30g of desulfurized gypsum, and dry mix the raw materials fully and evenly;

[0052] S2: Put the uniformly mixed raw materials in S1 into an agate mortar, weigh 2g of deionized water, pour it into the agate mortar, and grind to make the water fully contact with the raw materials;

[0053] S3: put the ground raw material in S2 into a mould, press and form it on a tablet press (compression molding pressure 20MPa) and demould, to obtain a formed test piece;

[0054] S4: Weigh 50g of deionized water and add it into a 500ml reaction kettle. Put a bracket higher than the water surface in the reactor; put the test block obtained in S3 on the bracket in the reactor for hydrothermal reaction, the reaction temperature is 220°C, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com