Patents

Literature

37 results about "Yellow discoloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yellow Discoloration of the Skin. A yellow tinge in skin color may occur naturally in certain ethnic groups. However, a yellow skin (especially in conjunction with a yellowing of sclera and inner mouth) is usually caused by a disease. Jaundice is characterized by a yellowing of the skin that is caused by accumulation of bilirubin.

Polyamide resin composition

A polyamide resin composition comprising a polyamide (X) having a diamine constituent unit which is mainly composed of a m-xylylenediamine unit and a dicarboxylic acid constituent unit which is mainly composed of an adipic acid unit; and specific amounts of a phosphorus acid antioxidant and alkaline component. The polyamide (X) is characterized by a specific range of terminal-group concentration balance and a specific amino-group reaction rate. This composition can simultaneously achieve inhabitation of yellow discoloration and reduction of number of gels or fish eyes.

Owner:MITSUBISHI GAS CHEM CO INC

Polyamide resin composition

A polyamide resin composition comprising: a polyamide (X) having a diamine constituent unit which mainly comprises a metaxylylenediamine unit and a dicarboxylate constituent unit which mainly comprises an adipate constituent unit; and specific amounts of a phosphate-type antioxidant and alkaline component. The polyamide (X) is characterized by a specific terminal group concentration balance and a specific amino group reaction rate. By using the polyamide resin composition, both of the prevention of yellow discoloration and the reduction of gelatinization or fisheye formation can be achieved.

Owner:MITSUBISHI GAS CHEM CO INC

Paint for reduction of yellow discoloration of paper with high-yield bleaching pulp and coating method

InactiveCN101760991AReduce yellowingIncrease bulkPaper/cardboardInorganic compound additionUltraviolet lightsPigment

The invention relates to a paint for reduction of yellow discoloration of paper with high-yield bleaching pulp and a coating application method. The paint is coated on the surface of raw paper with the high-yield bleaching pulp. In addition to kaolin and calcium carbonate pigment conventionally used, titanium dioxide pigment which can absorb ultraviolet light is introduced in the paint, so as to reduce the yellow discoloration of paper with the high-yield bleaching pulp. The paper with the high-yield bleaching pulp produced by the invention has a low degree of yellow discoloration, and the color difference (delta E) is no higher than 3 after the paper is irradiated by ultraviolet light for 10 hours. Therefore, the paper fundamentally reaches the level of complete chemical pulp. Moreover, the method is simple, the raw materials are easily available, and the operating performance is good.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Polyamide resin composition

A polyamide resin composition comprising a polyamide (X) having a diamine constituent unit which is mainly composed of a m-xylylenediamine unit and a dicarboxylic acid constituent unit which is mainly composed of an adipic acid unit; and specific amounts of a phosphorus acid antioxidant and alkaline component. The polyamide (X) is characterized by a specific range of terminal-group concentration balance and a specific amino-group reaction rate. This composition can simultaneously achieve inhabitation of yellow discoloration and reduction of number of gels or fish eyes.

Owner:MITSUBISHI GAS CHEM CO INC

PC/ABS material composition for relieving yellow discoloration

ActiveCN101759979AReduce color differenceMeet the requirements of color differenceYELLOW DYEPolycarbonate

The invention discloses a PC / ABS material composition for relieving the yellow discoloration, which is prepared from the following ingredients in percentage by weight: 10 to 60 parts of acrylonitrile-butadiene-styrene graft copolymers, 30 to 85 parts of polycarbonate, 0 to 10 parts of acrylics graft rubber, 0.25 to 0.88 parts of coloring agents, 0 to 1 part of antioxidizers and 0 to 1 part of light stabilizers. Yellow dyes without light illumination resistance performance exist in a dye system, and the dyes can not influence the whole coloring process of plastics in the plastic coloring process, but in the light illumination process, the dyes gradually fade, the PC / ABS materials carry out yellow discoloration in the light illumination process, so the two mutually inconsistent processes have the mutual counteraction effect, and the color aberration of the whole PC / ABS composition is reduced after the light illumination. At the same time, the mechanical property of the composition material is not obviously reduced.

Owner:CHONGQNG PRET NEW MATERIAL +2

Method for producing negative ion silk quilt

The invention discloses a method for producing a negative ion silk quilt, which comprises the following steps: manufacturing a silk wadding comforter batt; fixing the silk wadding comforter batt in a coating plus material to perform check point quilting so as to sew a comforter batt; jacketing a quilt cover outside the comforter batt; and adhering negative ions to silk wadding. The method has the advantages of simple process, time saving and labor saving, and the negative ion silk quilt produced by the method has good softness and is comfortable to use, the silk has no yellow discoloration, and the releasing quantity of the negative ions is large.

Owner:LIAONING YIXING FLOSS SILK

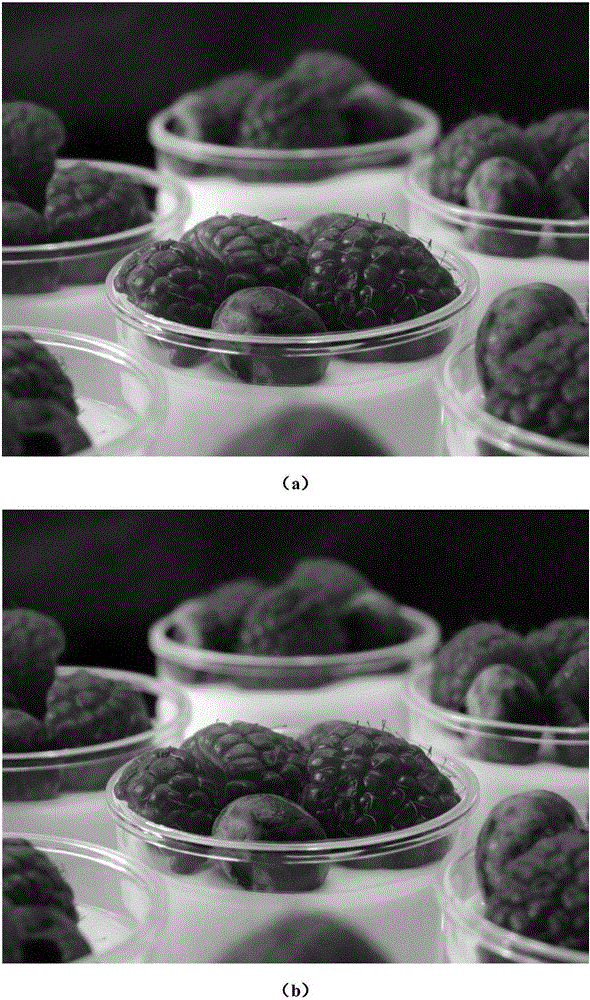

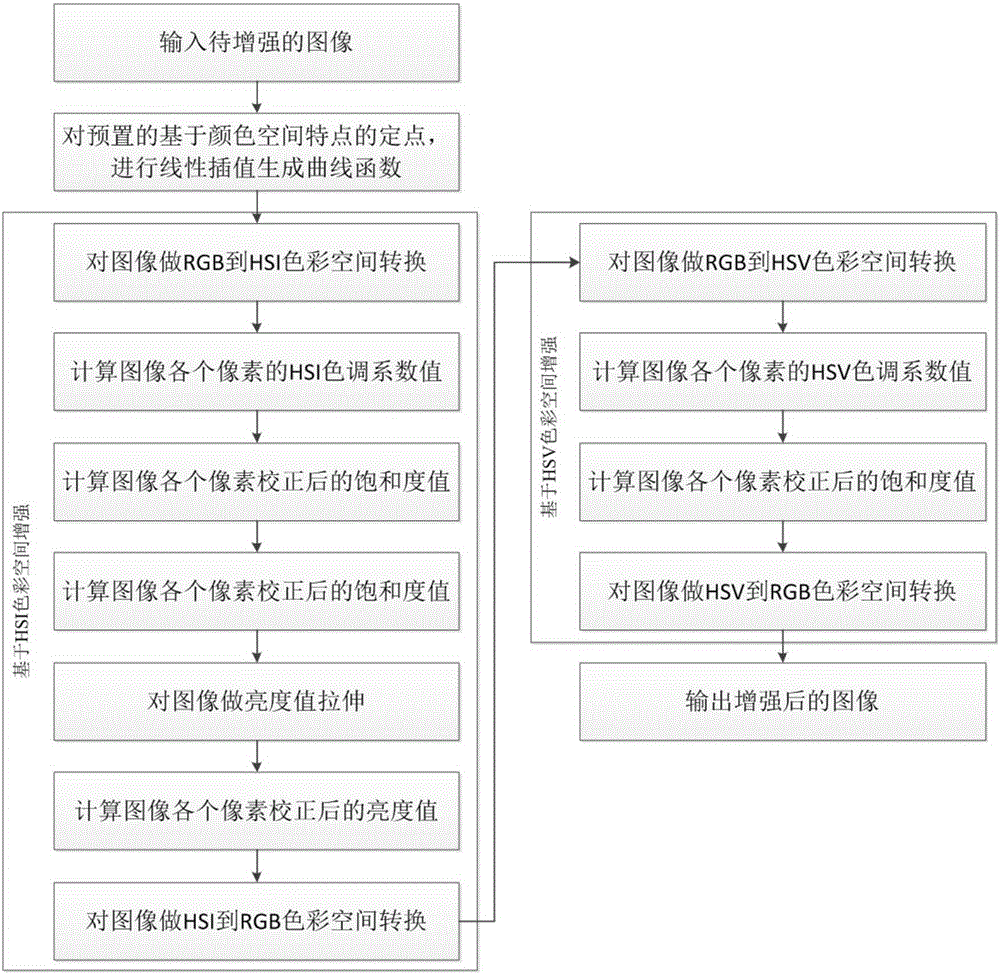

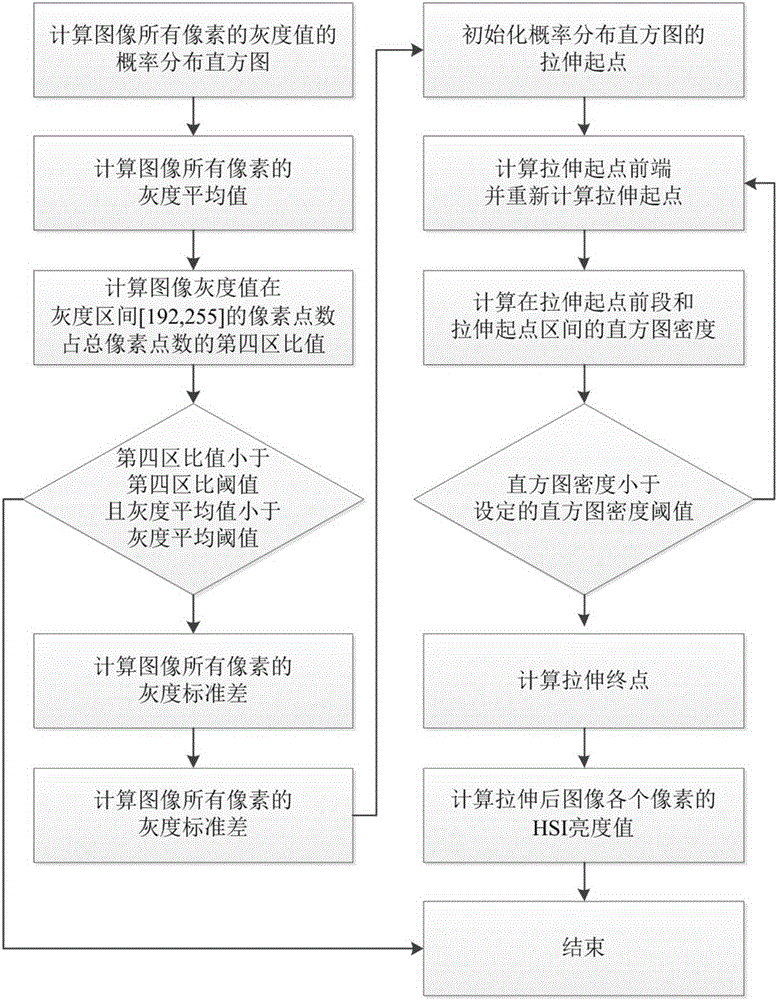

Food image color enhancement method based on color space characteristics

ActiveCN105184757AIncrease concentrationAvoid yellowingImage enhancementBrightness perceptionLightness

The invention discloses a food image color enhancement method based on color space characteristics. The method comprises steps that, (1), an image is inputted, and fixed points are preset; (2), for preset HSI and HSV color space fixed point sequences, linear processing is carried out to generate corresponding functions; (3), tone coefficient value calculation based on the HSI color space is carried out; (4), saturation value rectification based on the HSI color space is carried out; (5), luminance value rectification based on the HSI color space is carried out; (6), tone coefficient value calculation based on the HSV color space is carried out; and (7), saturation value rectification based on the HSV color space is carried out. Dual processing on the image is carried out in combination with HIS and HSV color space characteristics, color concentration increase is not only realized, but also the color brightening effect is further realized. According to the color space and food color characteristics, a corresponding saturation and brightness rectification curve is designed, a corresponding tone coefficient curve is further designed, problems of yellow discoloration generation and color cast are avoided, and the excellent food color enhancement effect is realized.

Owner:XIDIAN UNIV

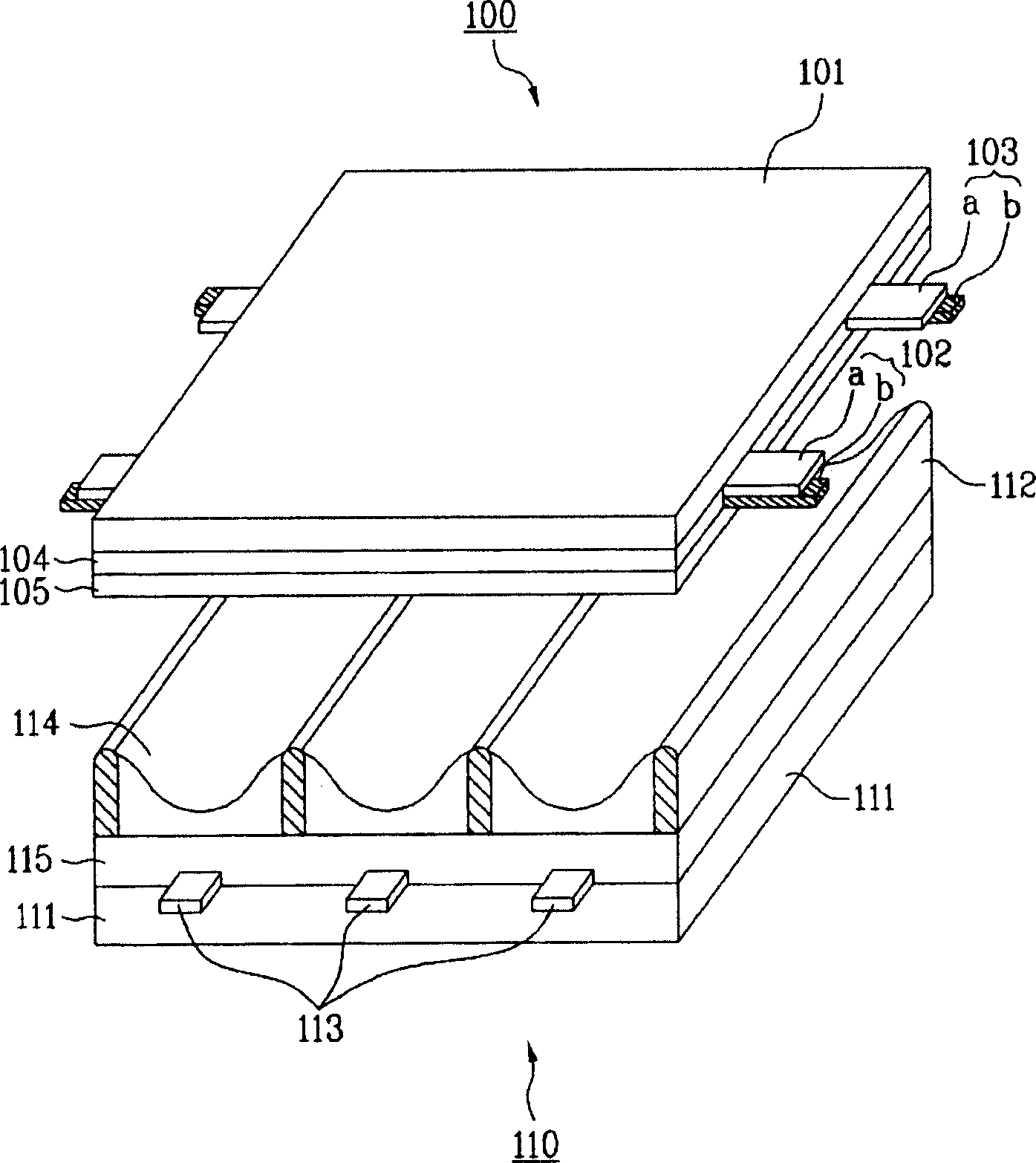

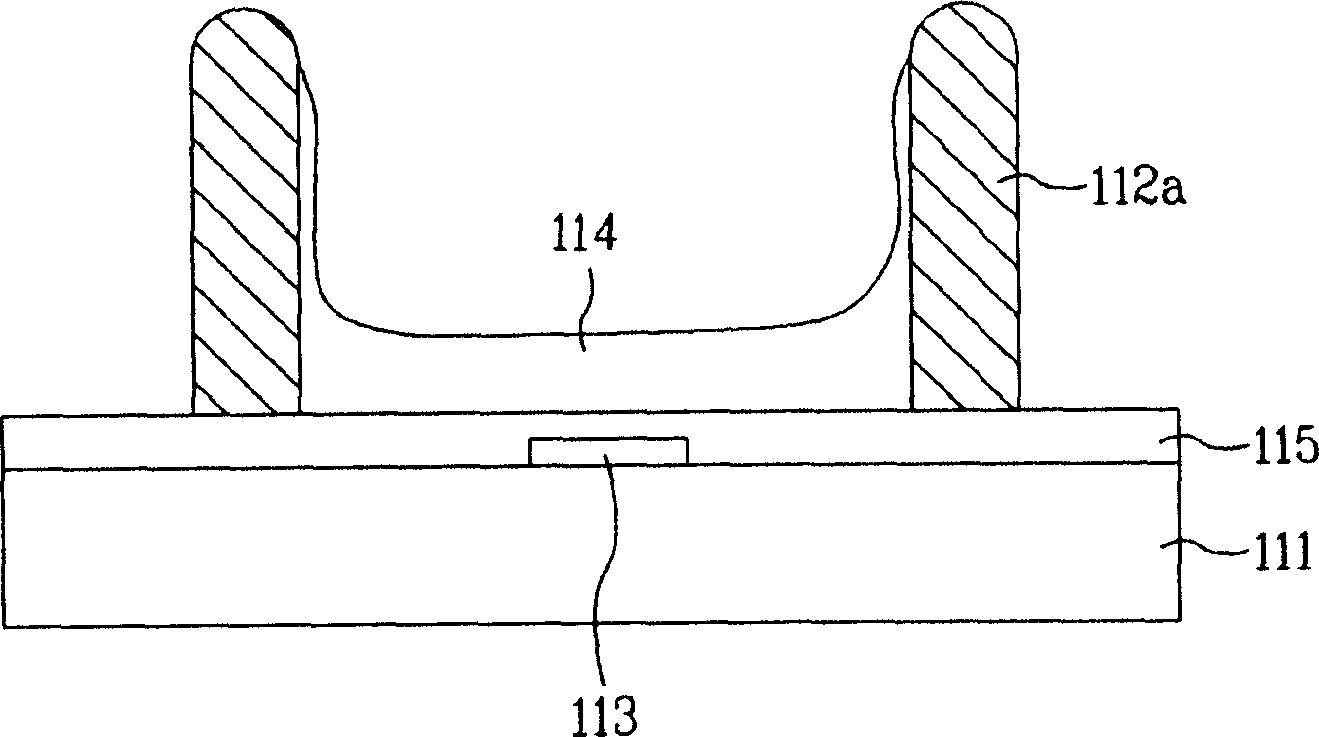

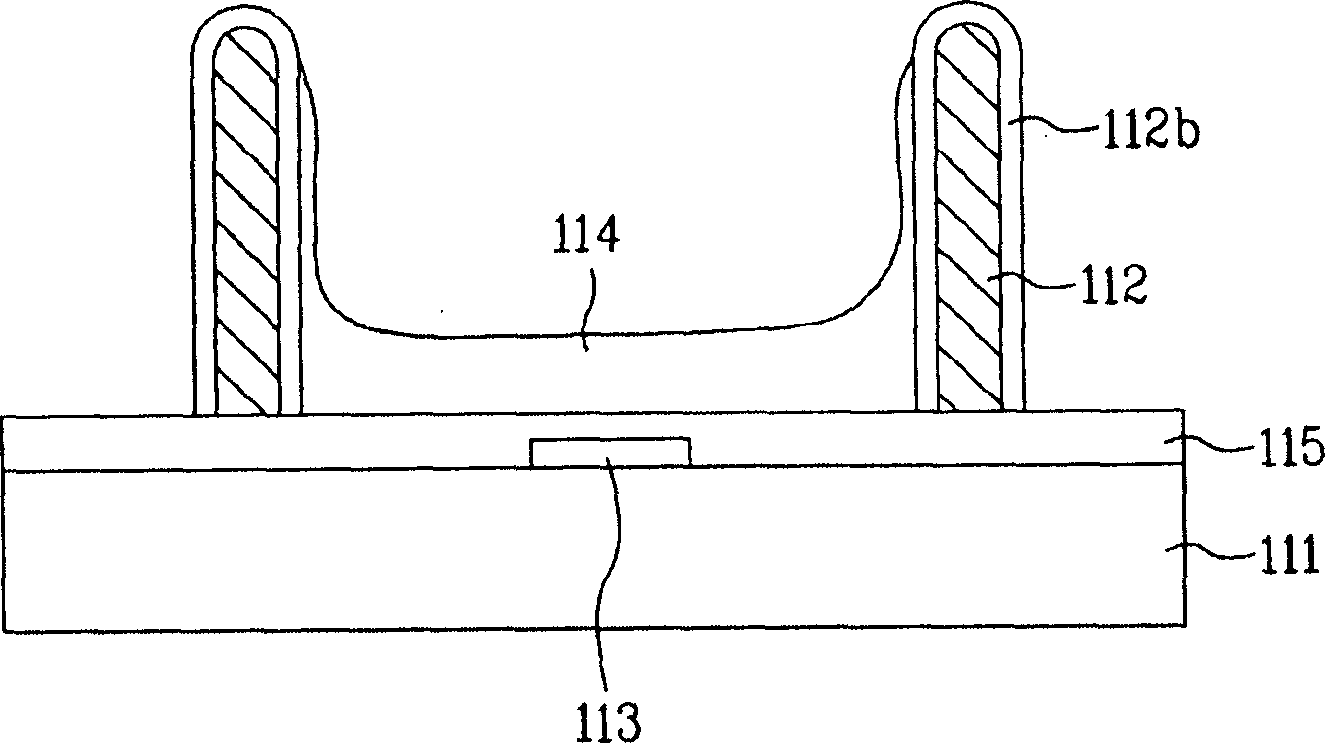

Plasma display panel, method of manufacturing the same, and composition of partitions thereof

InactiveCN1877777AImprove color temperatureQuality improvementAddress electrodesSustain/scan electrodesInorganic ionsOptoelectronics

A plasma display panel includes an upper plate having a sustain electrode, a lower plate having an address electrode, and a partition formed between the upper plate and the lower plate and having an inorganic ion exchanger. The yellow discoloration of the partition is prevented to improve color brightness and light permeability.

Owner:LG ELECTRONICS INC

Polycarbonate resin composition and medical appliances comprising thereof

The present invention relates to a polycarbonate resin composition which comprises an aromatic polycarbonate resin (A) and a colorant (B) and which has such a property that a molded test specimen comprising said polycarbonate resin composition and having a thickness of 3 mm is exposed to 25 kGy of a cobalt-60 gamma radiation, and the b value of test specimen measured by the Hunter's Lab method after 7 days from the exposure is not more than 2. A molded product comprising the said polycarbonate resin composition is invisible in the yellow discoloration and excellent in the transparency even though it is exposed to 25 kGy of a cobalt-60 gamma radiation for sterilization, especially excellent in such a transparency that the fluid level and color of content such as a medicinal solution or blood in a medical appliance can be easily confirmed, and also is small in mechanical properties deterioration. Therefore, the molded product is suitably used for medical appliances.

Owner:MITSUBISHI ENG PLASTICS CORP

Polyester film

InactiveUS20110054090A1Avoid yellowingImprove adhesionGroup 5/15 element organic compoundsPolyesterPrism

An object of the present invention is to provide a polyester film which is reduced in yellow discoloration, has a high quality and can be suitably used for optical filters (for example AR films, NIR films and EMI films), films for liquid crystal applications (for example diffraction films and prism films), materials for electric appliance, films for packaging, materials for graphic appliance (photograph materials), plate making films, OHP films or the like.The aspect of the present invention is a polyester film comprising at least one polyester layer comprising reclaimed resin of polyester film having a coating layer, which polyester layer comprising a phosphorus-based antioxidant having a starting temperature of loss on heat of not lower than 290° C.

Owner:MITSUBISHI PLASTICS INC

Curable Silicone Composition, Cured Product Thereof, And Optical Semiconductor Device

ActiveUS20150376344A1Little yellow discolorationImprove flame retardant performanceSolid-state devicesLuminescent compositionsCeriumHydrosilylation

This invention relates to a curable silicone composition comprising: (A) a straight-chain organopolysiloxane having at least two alkenyl groups in a molecule; (B) an organopolysiloxane represented by the following average unit formula: (R1SiO3 / 2)a (R12SiO2 / 2)b(R13SiO1 / 2)c(SiO4 / 2)d(XO1 / 2)e wherein, R1 each independently represent an alkyl group having from 1 to 12 carbons, an alkenyl group having from 2 to 12 carbons, an aryl group having from 6 to 20 carbons, an aralkyl group having from 7 to 20 carbons, or a group in which some or all of the hydrogen atoms of these groups are substituted with halogen atoms, with the proviso that at least two R1 in a molecule are the alkenyl groups, X is a hydrogen atom or an alkyl group, a is a number from 0 to 0.3, b is 0 or a positive number, c is a positive number, d is a positive number, e is a number from 0 to 0.4, a+b+c+d=1, c / d is a number from 0 to 10, and b / d is a number from 0 to 0.5; (C) an organopolysiloxane having at least two silicon-bonded hydrogen atoms in a molecule; (D) a cerium-containing organopolysiloxane; and (E) a hydrosilylation reaction catalyst. The curable silicone composition does not develop cracks due to thermal aging and can form a cured product having little yellow discoloration.

Owner:DOW CORNING TORAY CO LTD +1

Process for preparing silicate green fluorescent powder

InactiveCN1664056ASimple preparation processEasy to implementLuminescent compositionsCruciblePhosphor

A method for preparing silicate green emitting phosphor with small grain size, and the chemical expression of the silicate green emitting phosphor is Zn2-2xMn2xSiO4, 0.0025<=x<=0.08.The method comprises the following steps: (1) weighing needed stock and small quantity of fluxing agent according to the phosphor chemical proportion and mixing, (2) weighing silica dioxide and fluxing agent with the weight 5-40% of the mixture, and calling it preset material, (3) putting the mixture into the pot which taking up 1 / 2-2 / 3 of the pot, loading the preset material, then loading the mixture, (4) igniting the pot in air or inert atmosphere at 1200-1400 DEG C, quenching and taking it up at about above 1000 DEG C or cooling under the protection of inert atmosphere and then taking it up,(5)disintegrating the ignited product, washing, drying, sifting and getting the silicate green emitting phosphor. The process is simple and can get clear white powder only ignited for one time, eliminating the problem of yellow discoloration.

Owner:SOUTHEAST UNIV

Liquid Crystal Display Device

ActiveUS20130083272A1Increase the differenceImprove the level ofNon-linear opticsLiquid-crystal displayEngineering

In a liquid crystal display device, there is provided a liquid crystal display panel in which a TFT substrate and a counter substrate are bonded together by a sealing material, with a liquid crystal sandwiched between the substrates. Further, a front window with a black border print formed in the periphery is bonded to the liquid crystal display panel by a UV curable resin. The liquid crystal, is filled by a drop method. The thickness of the TFT substrate and the counter substrate is reduced to about 0.2 mm toy polishing. An inner end of the black border print of the front window is inside an inner end or the sealing material, to prevent the counter substrate of the liquid crystal display panel from being deformed by stress generated In the curing of the UV curable resin, thereby preventing yellow discoloration in the periphery of the display area.

Owner:JAPAN DISPLAY INC

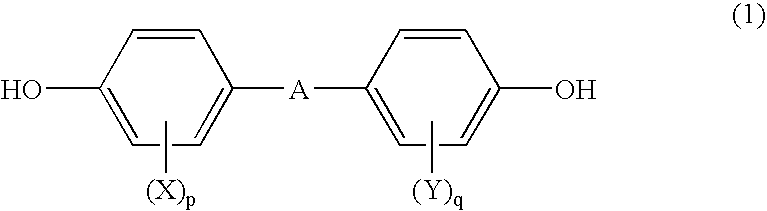

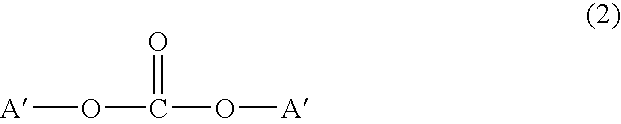

Polycarbonate resin composition, and molded article produced from the resin composition

Disclosed are: a polycarbonate resin composition comprising 100 parts by mass of a polycarbonate, 0.01 to 0.15 part by mass of a phosphorous acid ester represented by general formula (I) or the like, and 0.01 to 0.15 part by mass of an organopolysiloxane compound having a phenyl group, a methoxy group and a vinyl group; and a molded article such as a light guide plate, a film or a sheet, which is produced by molding the resin composition. In the polycarbonate resin composition, the occurrence of yellow discoloration or the generation of silver can be reduced and the sticking of the resin composition onto a mold can also be reduced. The polycarbonate resin composition has excellent mold release properties. The molded article can be produced from the resin composition. (In the formula, R1's independently represent an aryl group or an alkyl group and may be the same as or different from each other.)

Owner:IDEMITSU KOSAN CO LTD

Compositions and methods for improved solar cells

InactiveUS20150325715A1Conductive materialSemiconductor/solid-state device manufacturingSiliconPhysical property

Disclosed are aluminum paste compositions for silicon photovoltaic cells, that display reduced blistering, reduced yellow discoloration, reduced bowing, increased (or maintained) open-circuit voltage (Voc), and possess an increased firing window, through modification of the organic binder and / or addition of pigments. The present invention relates to the improvement of cosmetic and physical properties of silicon photovoltaic cells. The present invention also relates to the use of pigment to reduce the discoloration of fired aluminum pastes on silicon wafers for use as photovoltaic cells.

Owner:SUN CHEM CORP

Aluminum paste for back electrode of solar cell

ActiveCN102576578AAvoid warpingImprove efficiencyNon-conductive material with dispersed conductive materialCarbon-silicon compound conductorsCalcinationSilicon

Disclosed herein is an aluminum paste for a back electrode of a solar cell, comprising: aluminum powder in which aluminum powder having an average particle size (D50) of 4 ~ 6 [mu]m and aluminum powder having an average particle size (D50) of 2 ~ 4 [mu]m are mixed in a ratio of 6:4 ~ 9.5:0.5 by weight. The aluminum paste is advantageous in that since the contact between aluminum paste and a silicon wafer textured using two or more kinds of aluminum powder having a different average particle size is improved, the warpage of a solar cell can be prevented or the formation of aluminum bubbles or bumps and the occurrence of yellow discoloration can be minimized during a calcination process, the values of short circuit current (Isc) and open circuit voltage (Voc) can be greatly increased, and the efficiency of a solar cell can be remarkably improved

Owner:DONGWOO FINE CHEM CO LTD

Curable silicone composition, cured product thereof, and optical semiconductor device

ActiveUS9902811B2Little yellow discolorationImprove reliabilitySolid-state devicesLuminescent compositionsCeriumHydrosilylation

This invention relates to a curable silicone composition comprising: (A) a straight-chain organopolysiloxane having at least two alkenyl groups in a molecule; (B) an organopolysiloxane represented by the following average unit formula: (R1SiO3 / 2)a(R12SiO2 / 2)b(R13SiO1 / 2)c(SiO4 / 2)d(XO1 / 2)e wherein, R1 each independently represent an alkyl group having from 1 to 12 carbons, an alkenyl group having from 2 to 12 carbons, an aryl group having from 6 to 20 carbons, an aralkyl group having from 7 to 20 carbons, or a group in which some or all of the hydrogen atoms of these groups are substituted with halogen atoms, with the proviso that at least two R1 in a molecule are the alkenyl groups, X is a hydrogen atom or an alkyl group, a is a number from 0 to 0.3, b is 0 or a positive number, c is a positive number, d is a positive number, e is a number from 0 to 0.4, a+b+c+d=1, c / d is a number from 0 to 10, and b / d is a number from 0 to 0.5; (C) an organopolysiloxane having at least two silicon-bonded hydrogen atoms in a molecule; (D) a cerium-containing organopolysiloxane; and (E) a hydrosilylation reaction catalyst. The curable silicone composition does not develop cracks due to thermal aging and can form a cured product having little yellow discoloration.

Owner:DOW CORNING TORAY CO LTD +1

Sealing method for direct-insert type light-emitting diode (LED) lamp

The invention discloses a sealing method for a direct-insert type light-emitting diode (LED) lamp. The sealing method comprises the following steps: firstly, setting the heights of a mold strip and a sticking point, and selecting a diffusant and a coloring agent; secondly, heating epoxy resin A, mixing the epoxy resin with epoxy resin B at a certain ratio, adding the diffusant and the coloring agent, stirring the diffusant and the coloring agent, and carrying out vacuum-pumping treatment on stirred mixed glue; thirdly, fixing the bound LED bracket on a loading rack; fourthly, adjusting the glue-pouring quantity, the glue-extruding speed, the sticking time and the sticking distance; and finally starting a pouring machine and carrying out sealing treatment on the bound LED bracket. The epoxy resin A is heated and then is mixed with the epoxy resin B at the certain ratio, so that the mixing viscosity is reduced; the diffusant and the coloring agent are added and stirred, so that the problem of yellow discoloration of the baked LED lamp is avoided by controlling the mixing ratio and the mixing time; and the quality and the yield of the LED lamp are improved, so as to improve the cost performance of an LED display screen.

Owner:苏州市英富美欣科技有限公司

Method for preparing catalysts for manufacturing polycarbonate diols

InactiveCN105085892AImprove catalytic performanceGood reaction selectivityCarbonate esterOrganic synthesis

The invention relates to the field of organic synthesis, and discloses a method for preparing catalysts for manufacturing polycarbonate diols. The method includes steps of preparation phases, hydrotalcite preparation and Lewis base loading. The method has the advantages that Lewis base is immobilized on the basis of hydrotalcite, and accordingly the catalysts can be applied to generating the polycarbonate diols by the aid of a small-molecule carbonate ester exchange process and are high in catalytic efficiency, good in reaction selectivity and free of oligomerization; the catalysts prepared by the aid of the method can be applied to generating the polycarbonate diols, obtained products are high in purity, and accordingly the technical problem that generation of polycarbonate diols can be affected by other impurities in catalysts produced in the prior art can be solved; the products are free of mixed colors, and accordingly the technical problem of discoloration (such as yellow discoloration) of products in the prior art can be solved; the obtained products do not need to be further treated, and the catalysts remain in polyols without affecting follow-up reaction.

Owner:宁波诺尔丽化学科技有限公司

Release film for producing synthetic leather and preparing method of release film

PendingCN107722323AImprove peel forceImprove adhesionPolyurea/polyurethane coatingsTextiles and paperPhotosensitizerPolymer chemistry

The invention relates to release film for producing synthetic leather and a preparing method of the release film. The release film for producing the synthetic leather comprises a PET film layer and apress pattern layer which are laminated in sequence, and the press pattern layer is prepared from, by mass, 65%-75% of UV resin, 15%-25% of flatting agent and 5%-15% of photosensitizer. The release film for producing the synthetic leather is good in temperature resistance, can resist high temperature of 140-155 DEG C in the producing process of the synthetic leather, cannot curl, is not easily brittle and not easily tore, resists yellow discoloration and can be repeatedly utilized 80-100 times.

Owner:广州林云木新材料有限公司

Polarizing plate and liquid crystal display device

InactiveUS20170031072A1Increased durabilityLight transmittanceOptical filtersSynthetic resin layered productsTectorial membraneIn plane

It is an object of the present invention to provide a polarizing plate which can suppress display unevenness and yellow discoloration even when being applied to a liquid crystal panel and prevent a change in oblique hue, and a liquid crystal display device including the polarizing plate. A polarizing plate includes: a polyvinyl alcohol-based polarizer; a transparent protective film provided on one surface of the polyvinyl alcohol-based polarizer with an adhesive layer interposed therebetween; and a retardation film provided on the other surface of the polarizer with an adhesive layer interposed therebetween. The transparent protective film contains a (meth)acrylic resin and an ultraviolet absorber. The retardation film contains a cellulose resin and has an in-plane retardation of 5 nm or less and a thickness-direction retardation of 10 nm or less.

Owner:NITTO DENKO CORP

Liquid crystal display device

ActiveUS9250461B2Reduce distortionBlocking may occurNon-linear opticsLiquid-crystal displayEngineering

In a liquid crystal display device, there is provided a liquid crystal display panel in which a TFT substrate and a counter substrate are bonded together by a sealing material, with a liquid crystal sandwiched between the substrates. Further, a front window with a black border print formed in the periphery is bonded to the liquid crystal display panel by a UV curable resin. The liquid crystal, is filled by a drop method. The thickness of the TFT substrate and the counter substrate is reduced to about 0.2 mm toy polishing. An inner end of the black border print of the front window is inside an inner end of the sealing material, to prevent the counter substrate of the liquid crystal display panel from being deformed by stress generated In the curing of the UV curable resin, thereby preventing yellow discoloration in the periphery of the display area.

Owner:JAPAN DISPLAY INC

Dye changing colour resulting from photo, acid, and its method of synthesis and dyeing

The present invention relates to a diarylvinyl yellow functional dye with photochromic and acid-induced chromatic properties and its synthesis and discoloration method. The functional dye is 3,4-bis(substituted five-membered heterocycle)-2,5- Diiminopyrroline compounds, which use 1,2-dicyano-1,2-bis(substituted five-membered heterocycle) vinyl compounds as raw materials, and under the action of catalysts and ammonia compounds in polar solvents Prepared by reaction. The prepared compound changes from colorless to yellow under the action of acid or light, and can undergo multiple reversible cycles. Taking advantage of this performance, this type of compound can be used as light-controlled rewritable full-color printing or full-color display, pH meter, light and chemical switch, light-controlled reversible discoloration device, and dual mode of acid-induced color and photochromic For high-density information recording, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for increasing high-temperature discoloration resistance of stainless steel workpiece

InactiveCN108716015AImprove the ability to resist high temperature discolorationSurface reaction electrolytic coatingOrganic acidElectrolysis

The invention relates to a method for increasing the high-temperature discoloration resistance of a stainless steel workpiece, and belongs to the technical field of stainless steel surface treatment.In order to solve the problem of yellow discoloration of an existing stainless steel workpiece at high temperature, the invention provides an electrolytic treatment method for increasing the high-temperature discoloration resistance of the stainless steel workpiece. The method is characterized by comprising the steps of immersing the stainless steel workpiece into a solution of oxygenated ligand organic acid for anode electrolytic treatment, wherein the oxygenated ligand organic acid and metal iron ions can form metal chelate, and cleaning after the anode electrolytic treatment, so that the high-temperature discoloration resistant stainless steel workpiece is obtained. According to the method, the mode that the oxygenated ligand organic acid and anode electrolysis are combined is adopted to treat the stainless steel surface, so that the electrolytic iron ions and the oxygenated ligand organic acid can effectively form the metal chelate, iron elements on the stainless steel surface areeffectively removed, the characteristics of chromium or chromated nickel are enriched, and the capability of increasing the high-temperature discoloration resistance is achieved.

Owner:ZHEJIANG SUPOR CO LTD

Manufacturing method of ambroid glass artware

ActiveCN105109262AModerates differences in thermal expansion and contractionSolve quality problemsSpecial ornamental structuresViscosityPolyresin

The invention provides a manufacturing method of ambroid glass artware. The manufacturing method comprises the following steps: preparing a glass container; preparing embedding resin of ambroid, which comprises a component A and a component B, wherein the component A is organic silicon resin of which the viscosity is 2,000-4,000 mPa*s at 25 DEG C, and the component B is an organic silicon resin curing agent; and placing a content into the glass container, mixing the component A and the component B to obtain a resin mixed solution in which the weight ratio of the component A to the component B is (1-10): 1, and injecting the resin mixed solution into the glass container for curing to obtain the ambroid glass artware. By the adoption of the technical scheme, the cold and heat shrinking percentages of resin and glass are approximate, so that the quality problems of layer separation between resin and glass and burst are solved, the original appearance can be kept after long-time placement, the phenomenon of yellowing discoloration is avoided, and layer separation between resin and glass or glass burst is prevented.

Owner:NANNING MILLENNIUM ARTS & CRAFTS

Polarizing plate and liquid crystal display device

InactiveCN106405711ASynthetic resin layered productsCellulosic plastic layered productsIn planeCellulose

Owner:NITTO DENKO CORP

Method for producing negative ion silk quilt

Owner:LIAONING YIXING FLOSS SILK

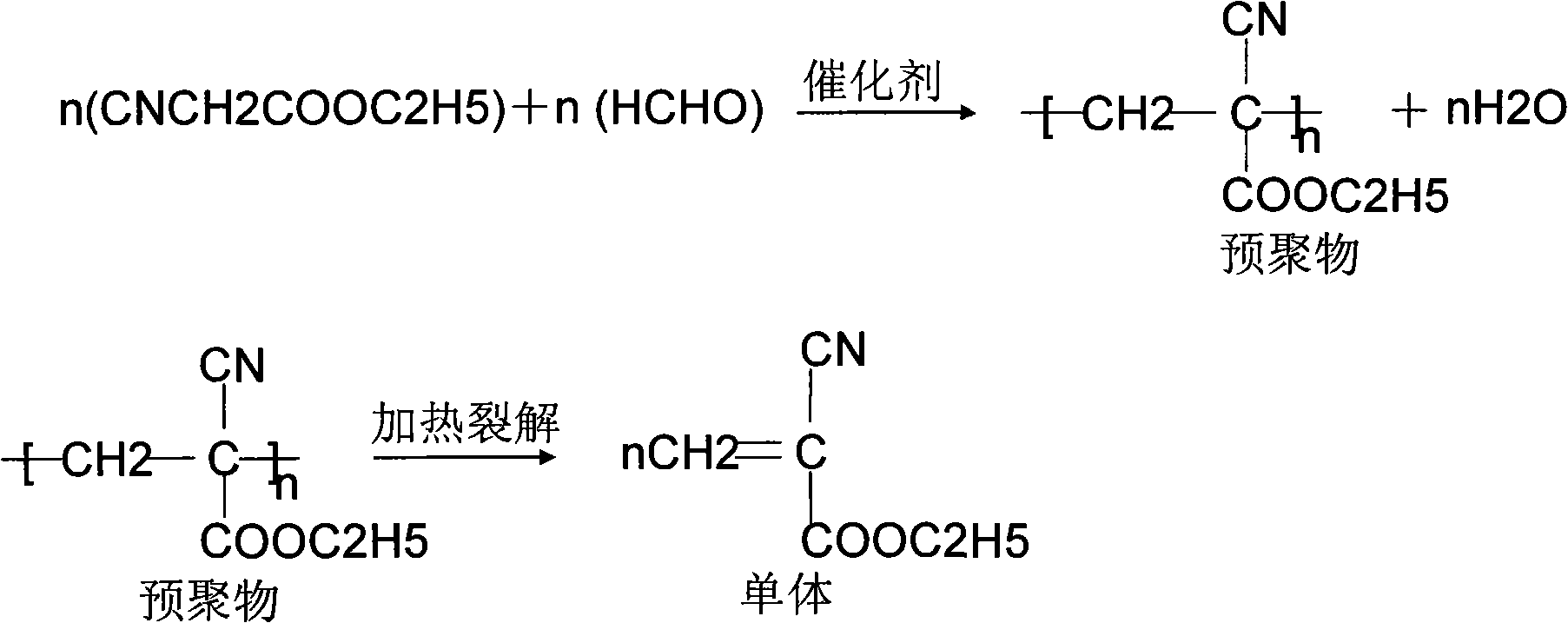

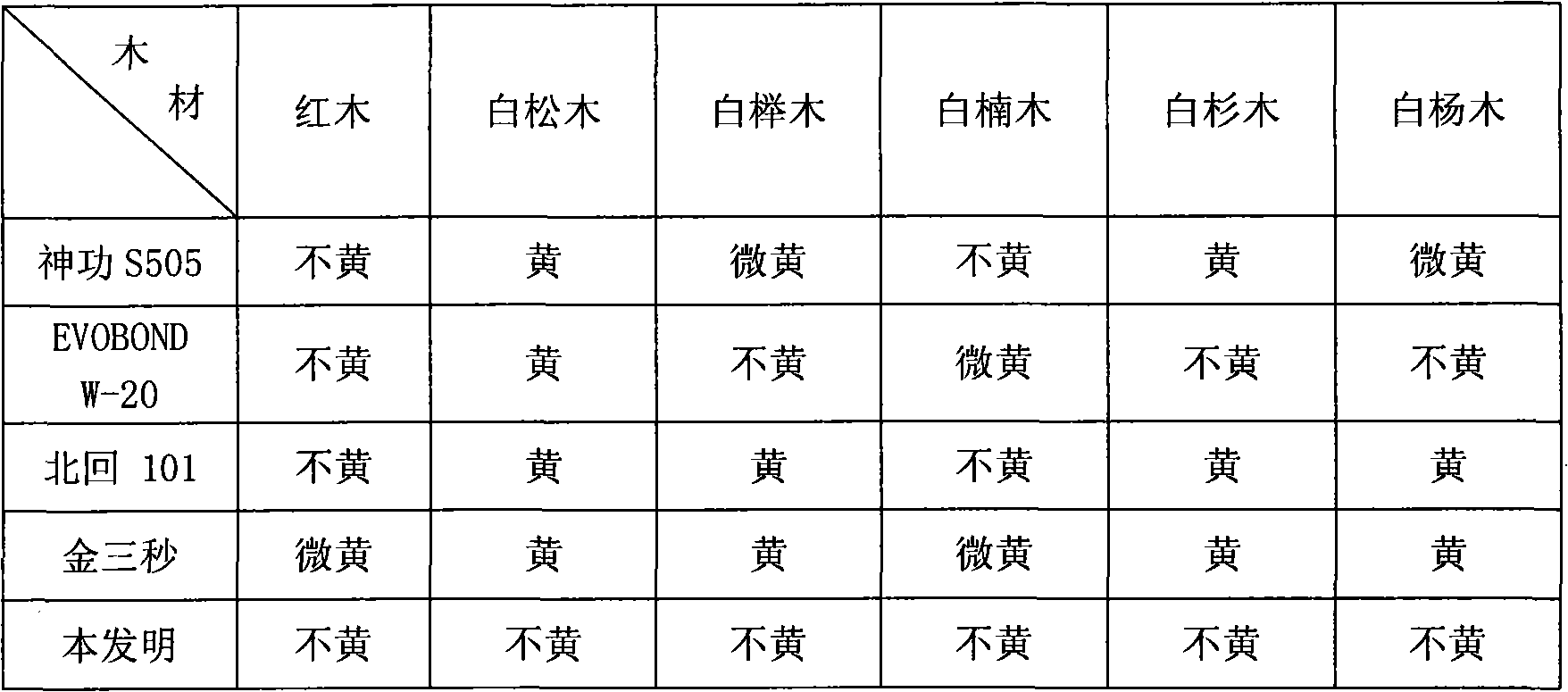

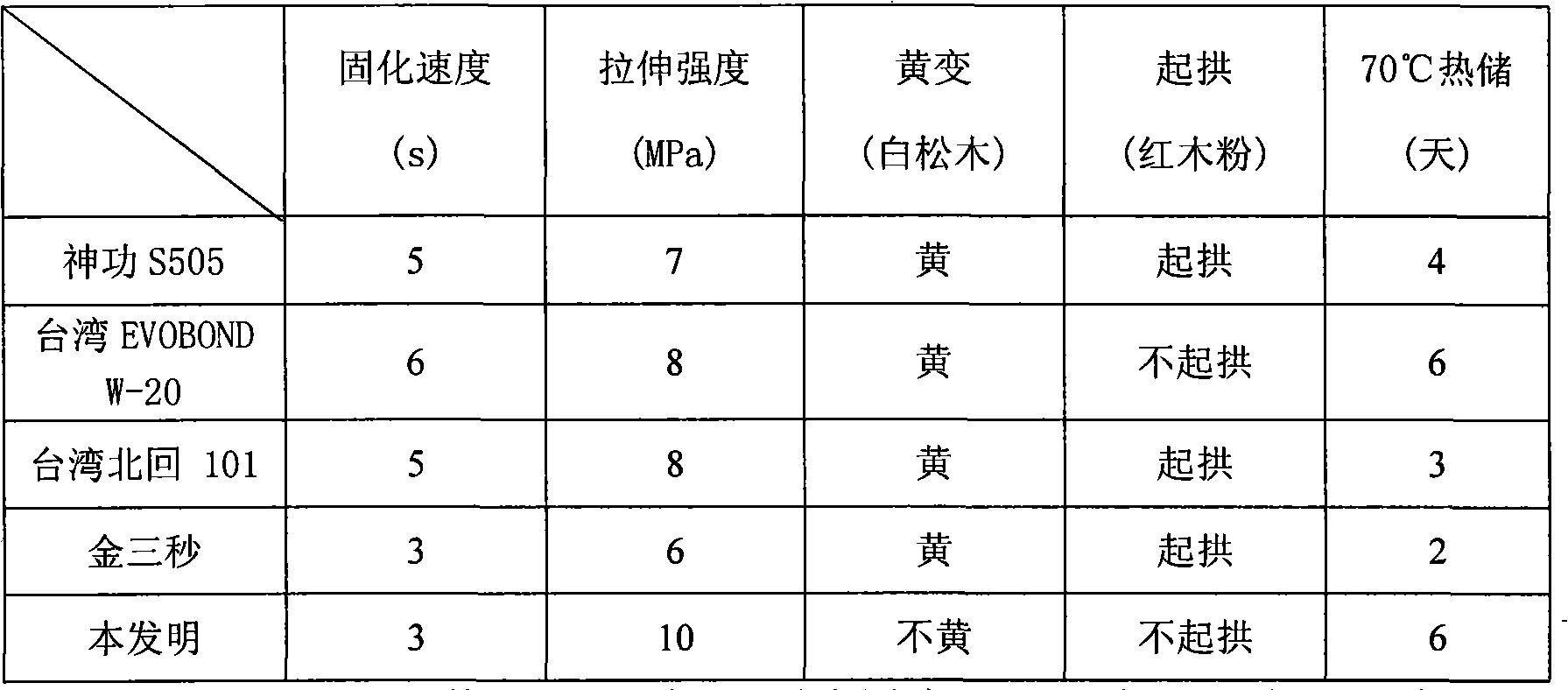

Wood industry adhesive and preparation thereof

InactiveCN101298544ALess side effectsHigh purityAldehyde/ketone condensation polymer adhesivesDepolymerizationAdhesive

The invention discloses a wood adhesive which consists of following components by weight portion: 1 portion of paraformaldehyde; 2 to 4.6 portions of ethylene dichloride; 3 to 4 portions of ethyl ester and / or 10 to 15 portions of hexahydropyridine; 0.03 to 0.54 portion of phosphoric anhydride and / or 0.022 to 0.514 portion of hydroquinone; 0.003 to 0.018 portion of paratoluenesulfonic acid; and less than 0.1 portion of additive; the preparation method includes the steps of preparing the finished product after a polymerization step, a pyrolysis step, a distillation step and a rectification step according to the components. The whole reaction system is always in back flow state during the preparation process, by methods of adding inhibitor and improving technical conditions etc. at the depolymerization stage of the reaction, the occurrence of side reaction is reduced, and properties such as purity etc. of the product is enhanced, thus allowing the invention to have the advantages of high adhesion speed, super penetrability, free from yellow discoloration and arching, as well as short curing time.

Owner:浙江久而久化学有限公司

Method for reducing processing temperature of calcium carbonate granule filling ultra-high molecular polyethylene composite material

A method for reducing the processing temperature of calcium carbonate particles in filling ultra-high molecular weight polyethylene material is characterized in that the following steps are included: (1) the calcium carbonate particles with two different particle sizes are mixed according to specific particle size and mass ratio; (2) the mixture is used for filling the ultra-high molecular weight polyethylene material according to the mass ratio of 20-50 percent; wherein the calcium carbonate particles with two different particle sizes are: calcium carbonate I: 200 meshes to 600 meshes; calcium carbonate II: 800 meshes to 2500 meshes; and the mass ratio of the calcium carbonate I and the calcium carbonate II stuffing is 30: 70 to 70: 30. The calcium carbonate stuffing with two different particle sizes in the optimal proposal undergoes surface treatment by 1-3 percent stearic acid. The method can remarkably reduce the processing temperature of polymer composite material (around 30 DEG C), ensure the color and luster of the composite material not to have yellow discoloration, improve the mechanical performance of the composite material by more than 25 percent and achieve the purposes of reducing energy consumption and lowering cost.

Owner:NANJING NORMAL UNIVERSITY

PC/ABS material composition for relieving yellow discoloration

ActiveCN101759979BReduce color differenceMeet the requirements of color differenceYELLOW DYEPolycarbonate

The invention discloses a PC / ABS material composition for relieving the yellow discoloration, which is prepared from the following ingredients in percentage by weight: 10 to 60 parts of acrylonitrile-butadiene-styrene graft copolymers, 30 to 85 parts of polycarbonate, 0 to 10 parts of acrylics graft rubber, 0.25 to 0.88 parts of coloring agents, 0 to 1 part of antioxidizers and 0 to 1 part of light stabilizers. Yellow dyes without light illumination resistance performance exist in a dye system, and the dyes can not influence the whole coloring process of plastics in the plastic coloring process, but in the light illumination process, the dyes gradually fade, the PC / ABS materials carry out yellow discoloration in the light illumination process, so the two mutually inconsistent processes have the mutual counteraction effect, and the color aberration of the whole PC / ABS composition is reduced after the light illumination. At the same time, the mechanical property of the composition material is not obviously reduced.

Owner:CHONGQNG PRET NEW MATERIAL +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com