Patents

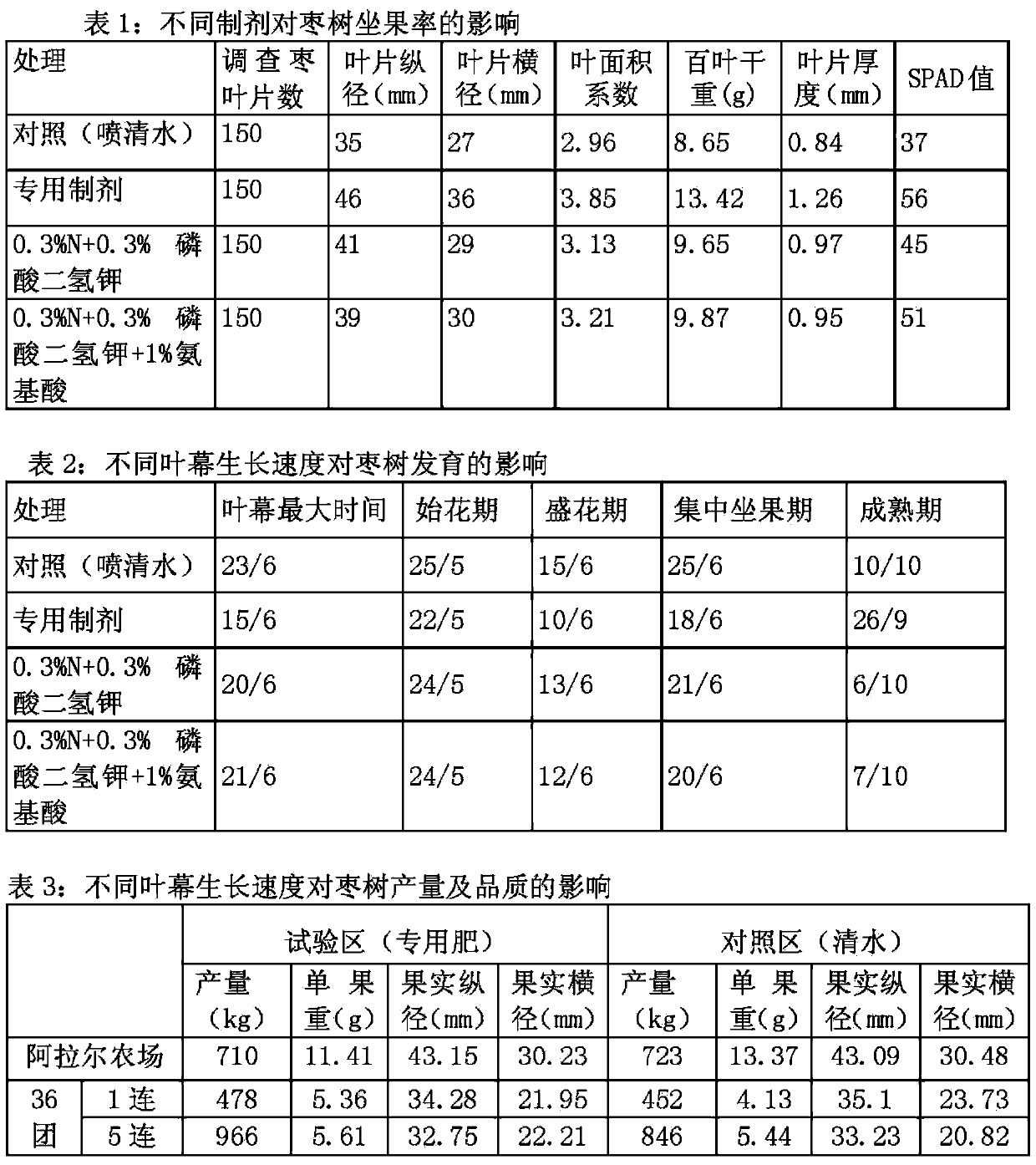

Literature

115 results about "Phosphoric anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

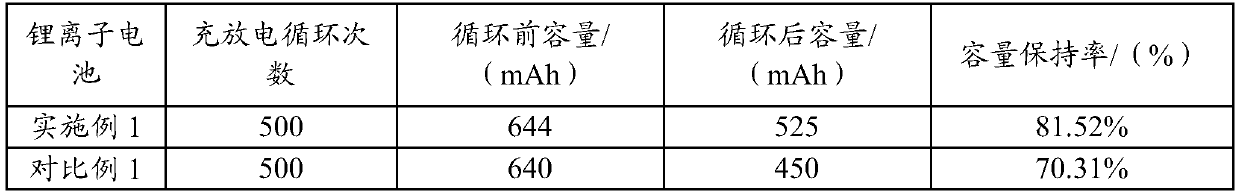

Electrolyte solution and lithium-ion secondary battery

ActiveCN103779607AImprove thermal stabilityIncreased high temperature capacity retentionSecondary cellsOrganic solventDecomposition

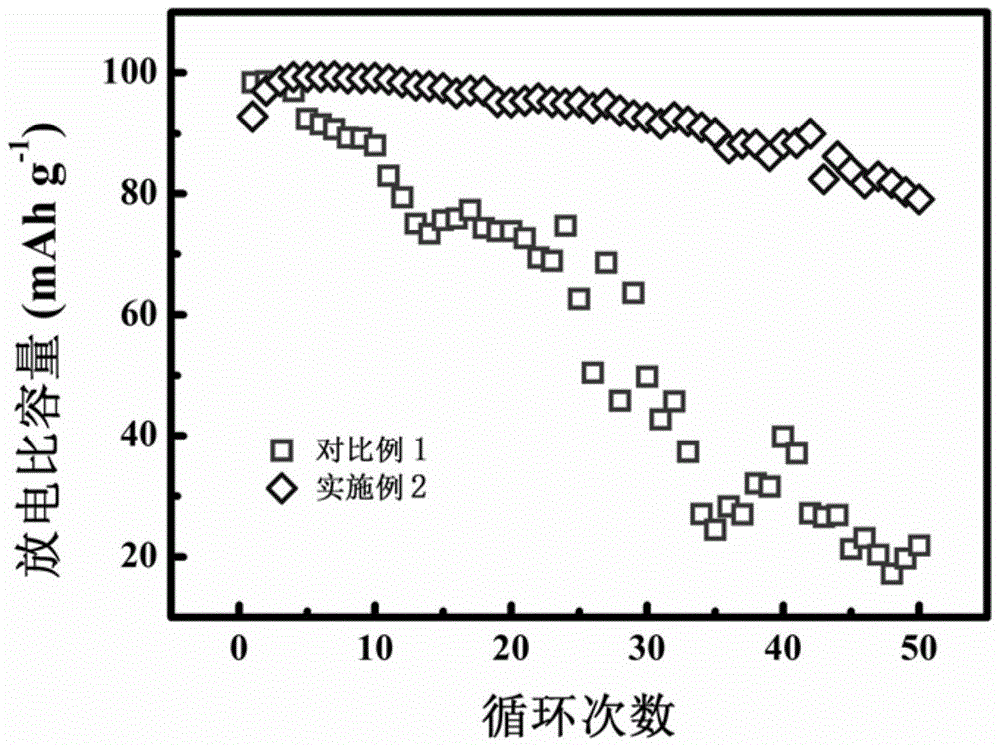

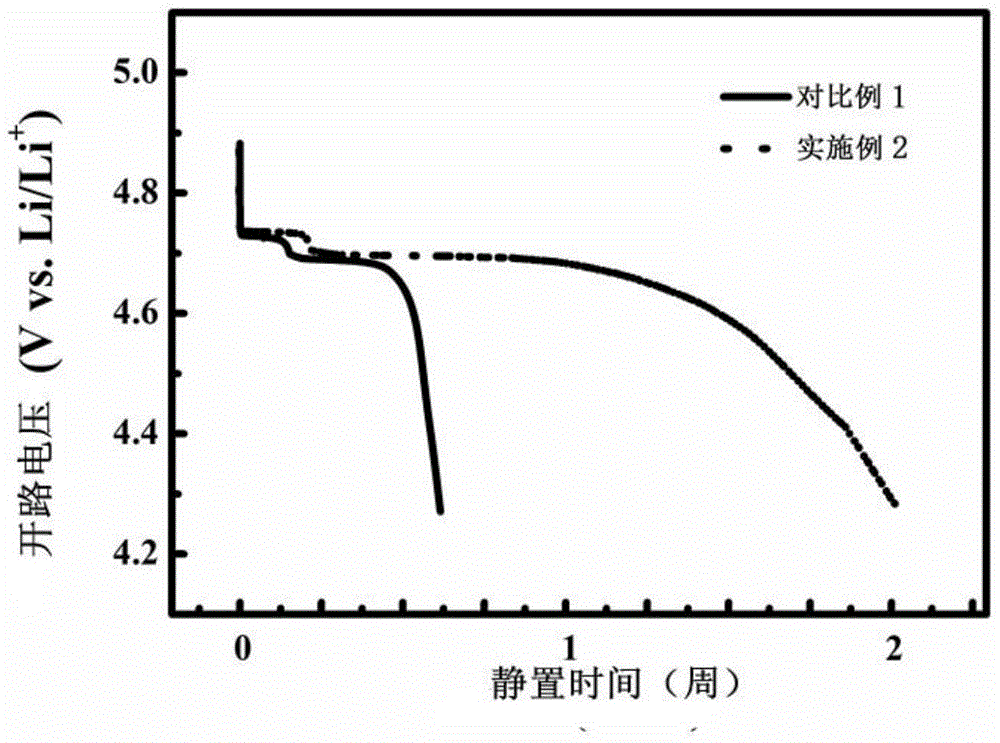

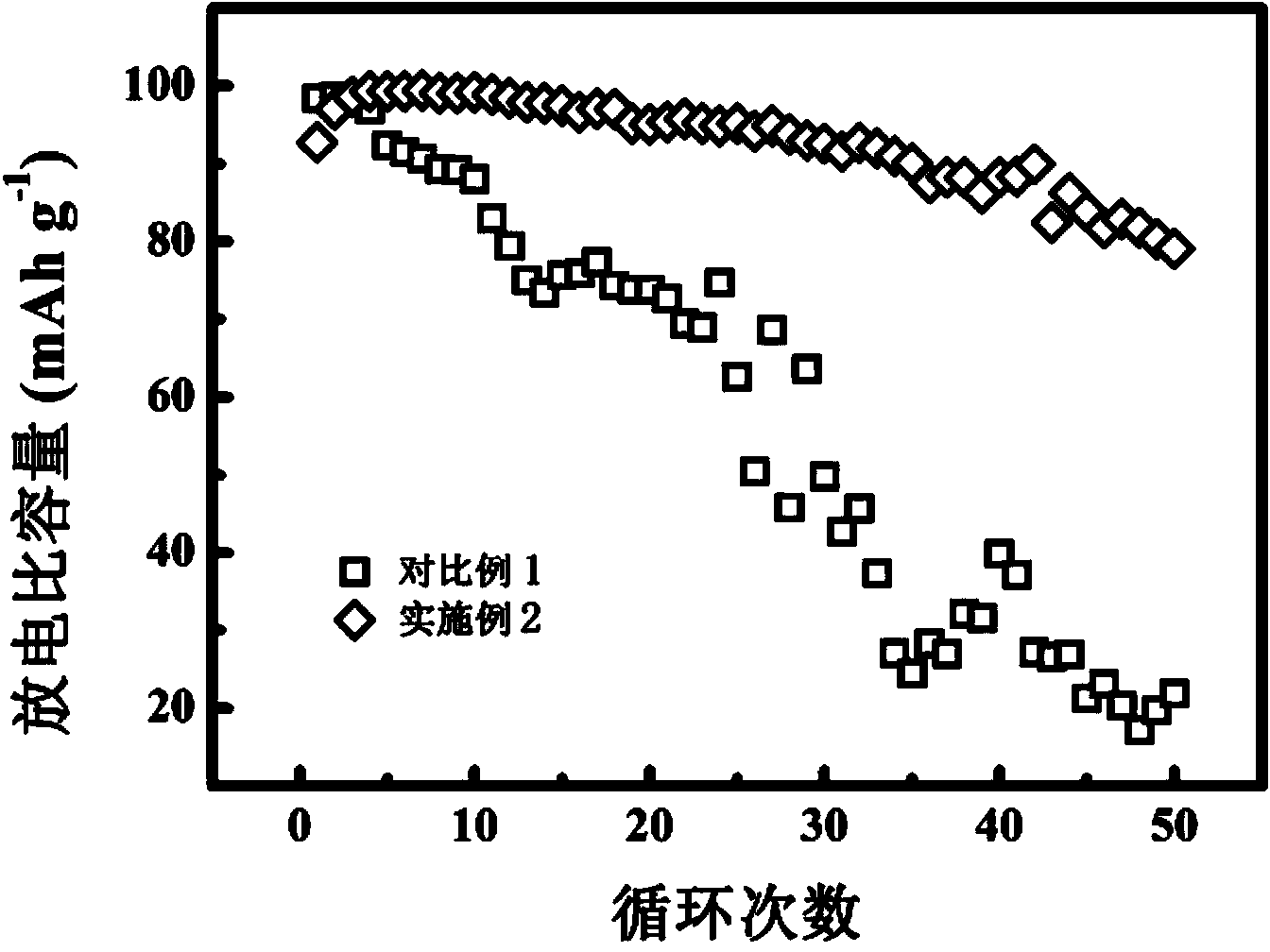

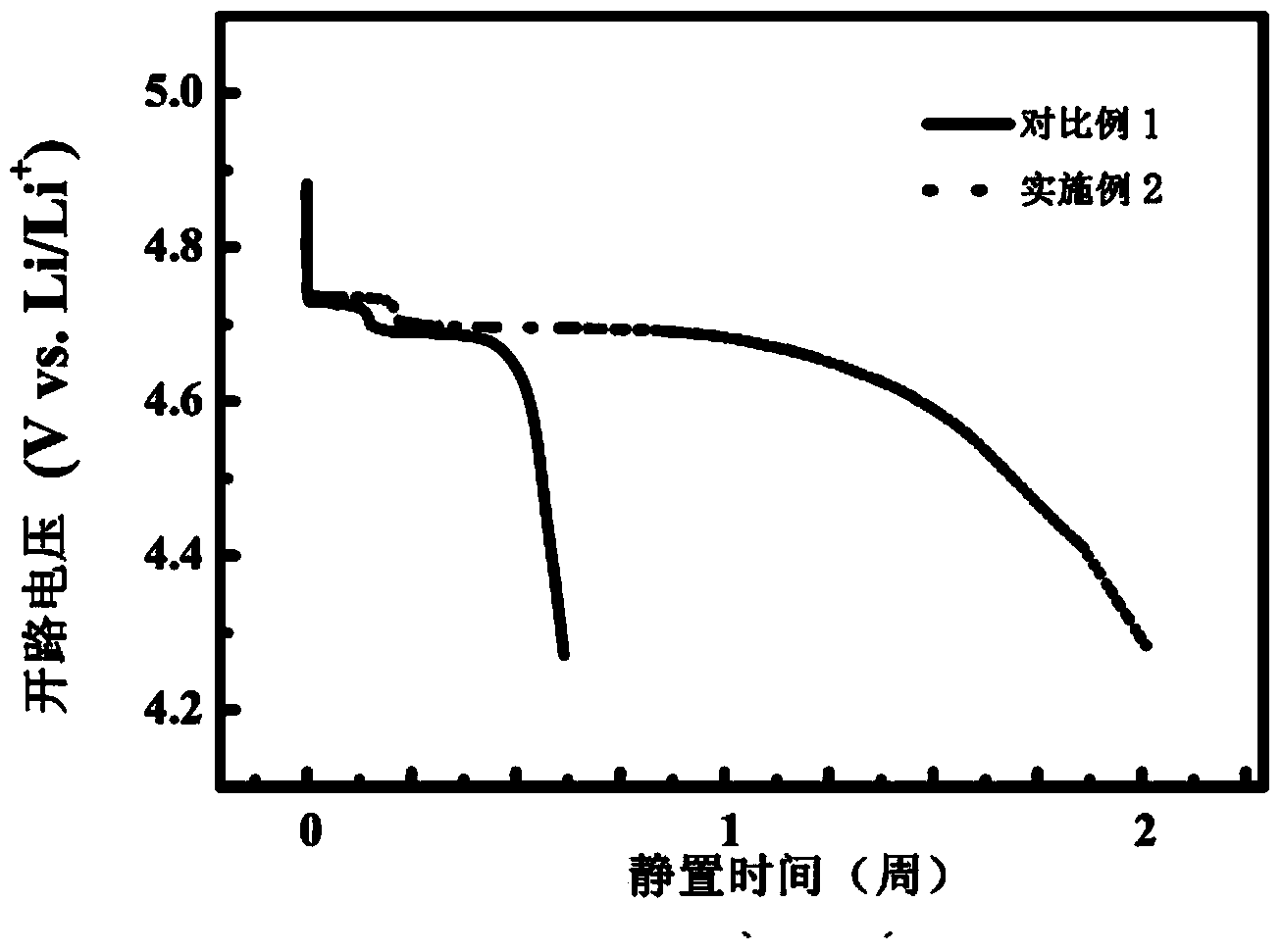

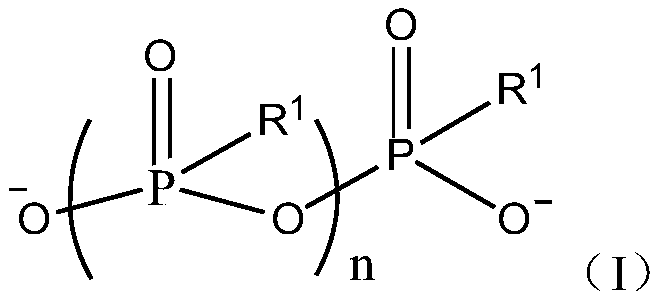

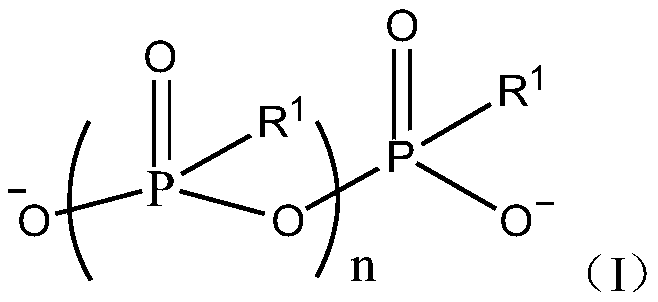

The invention discloses an electrolyte solution and a lithium-ion secondary battery. The electrolyte solution comprises an aprotic organic solvent, electrolyte lithium salt and an additive, wherein the additive is cyclic phosphoric anhydride; and the mass of the additive accounts for 0.01-10 percent of the total mass of the electrolyte solution. The lithium-ion secondary battery comprising the electrolyte solution can be subjected to electrochemical oxidation polymerization under the voltage of over 4.4V (vs.Li / Li+). By forming a polymer on the surface of a positive pole material, a good barrier is formed to cover strongly-oxidative active points of the positive pole material, and decomposition of a main solvent of the lithium-ion secondary battery is inhibited, so that the stability of the electrolyte solution under a high-voltage state and the high-voltage cycle and storage performances of a lithium-ion battery are improved.

Owner:CENT SOUTH UNIV

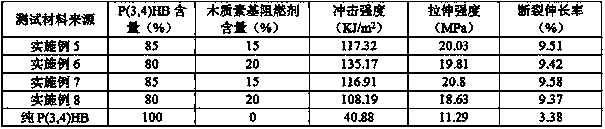

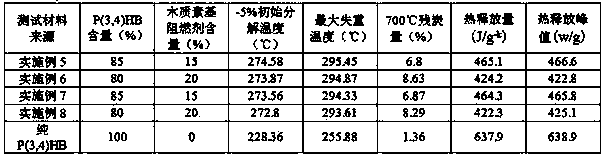

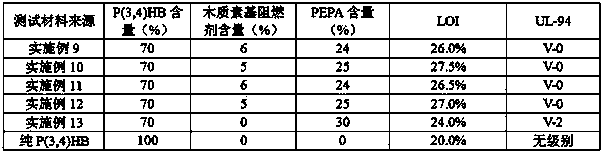

Preparation method and application of lignin-based intumescent flame retardant

ActiveCN104371116AIncrease char formationImprove flame retardant performancePolyesterPolymer science

The invention discloses a preparation method of a lignin-based intumescent flame retardant. The preparation method comprises the steps of carrying out esterification reaction on phosphoric anhydride and lignin through optimizing reaction temperature, reaction time, reactant ratio and solvent selecting ratio and other process conditions; then, enabling the reaction product to react with melamine to obtain the lignin-based intumescent flame retardant which is integrated with an acid source, a carbon source and an air source and is high in char formation quantity and good in flame retardance. When the lignin-based intumescent flame retardant is independently applied to a P(3,4)HB biopolyester material or is applied to the P(3,4)HB biopolyester material after being compounded with other flame retardants, the compatibility of the lignin-based intumescent flame retardant and a matrix is good, so that the flame retardance of the material can be remarkably improved, meanwhile, the mechanical property of the material can also be improved, and a P(3,4)HB flame-retardant composite material with excellent comprehensive properties can be prepared. By using the preparation method disclosed by the invention, the yield is high; a reactant is basically nontoxic; the process conditions are easy to control; the operation process is simple; the lignin serving as a main raw material is an abundant regenerative resource, so that the price is low; and therefore, the lignin-based intumescent flame retardant is favorable in application prospect.

Owner:NANJING FORESTRY UNIV

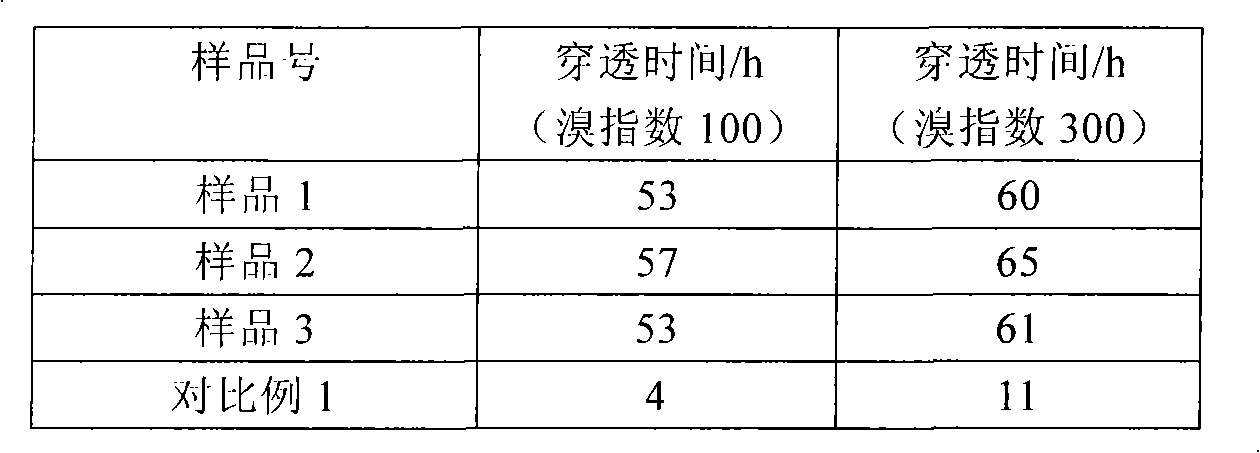

Preparation method of catalyst for removing trace amounts of alkenes in reformate

ActiveCN102029180AStrong ability to remove olefinsExtended service lifeMolecular sieve catalystsNaphtha reformingAir atmospherePhosphate

The invention relates to a preparation method of a catalyst for removing trace amounts of alkenes in reformate. The invention is characterized in that the catalyst comprises the following components in mass percent: (1) 60-90% of molecular sieve, (2) 2.0-10.0% of rare earth oxide, (3) 0.5-4.0% of alkaline earth oxide, (4) 1.0-6.0% of phosphoric anhydride and (5) balance of aluminum oxide. The preparation method comprises the following steps: (1) mixing the molecular sieve and deionized water, pulping, sequentially adding rare earth salts and phosphates, filtering, drying, evenly mixing with aluminum oxide, adding a dilute nitric acid solution for strip extrusion or ball molding, drying, and roasting in the air atmosphere to obtain a molecular sieve loaded with rare earth and phosphorus; (2) while stirring the salt solution of Mg or Ca at high speed, adding a surfactant to obtain a highly dispersed Mg or Ca solution; and (3) immersing the molecular sieve with the same volume obtained in the step (1) into the solution obtained in the step (2), drying the product, and roasting in the air atmosphere to obtain a finished catalyst product.

Owner:CHINA NAT OFFSHORE OIL CORP +2

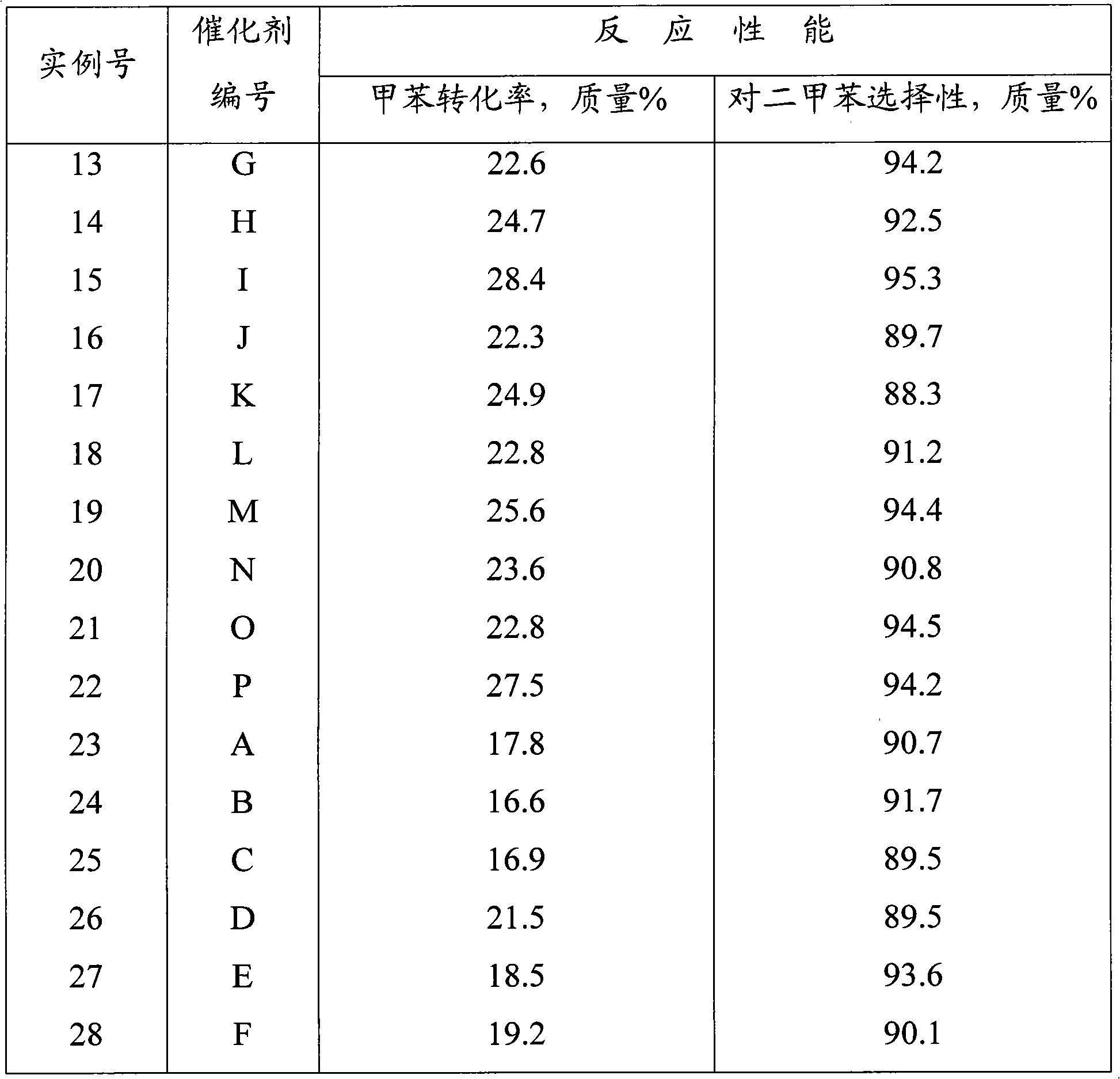

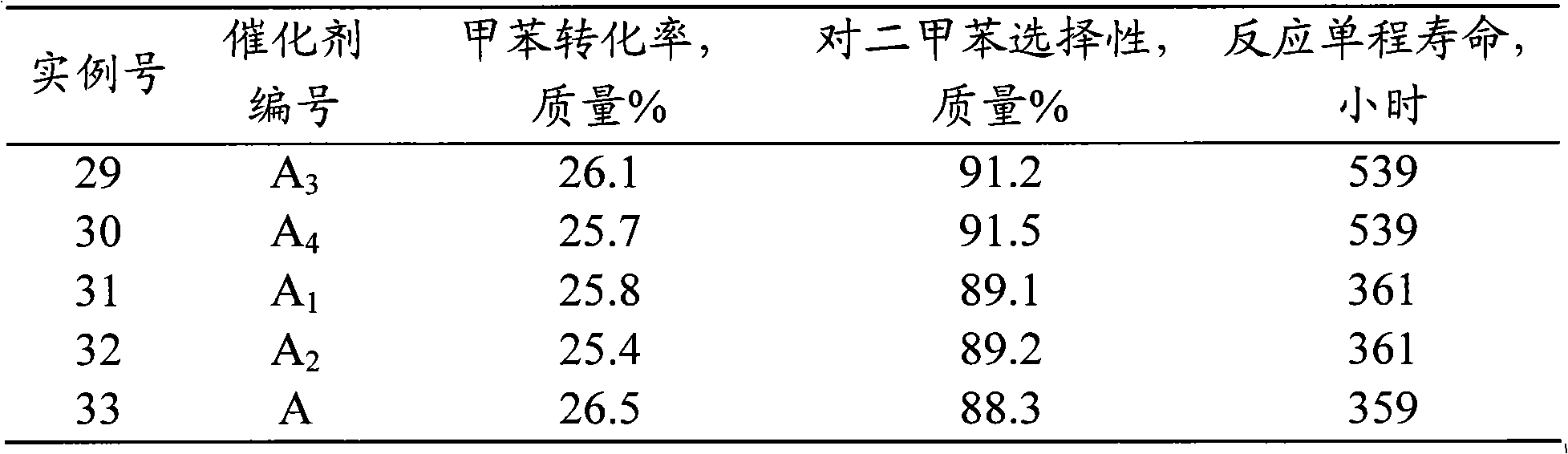

Catalyst for toluene alkylation reaction, and preparation method thereof

ActiveCN102335622AImprove activity stabilityLong reaction lifeMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationRare-earth elementMolecular sieve

The invention relates to a toluene alkylation reaction catalyst comprising components of, by mass: 10 to 70% of P-ZSM-5 / Silicalite-1 composite molecular sieve with rare earth elements loaded on the outer layer, and 30 to 90% of Silicalite-1 molecular sieve. The P-ZSM-5 / Silicalite-1 composite molecular sieve comprises, by mass: 3.0 to 21.0% of phosphorus expressed by phosphoric anhydride, and 1.0 to 9.0% of rare earth expressed by rare earth oxide. When the catalyst is used in the alkylation reaction between toluene with methanol, the activity stability is improved, the selectivity upon xyleneproducts is high, and the reaction life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

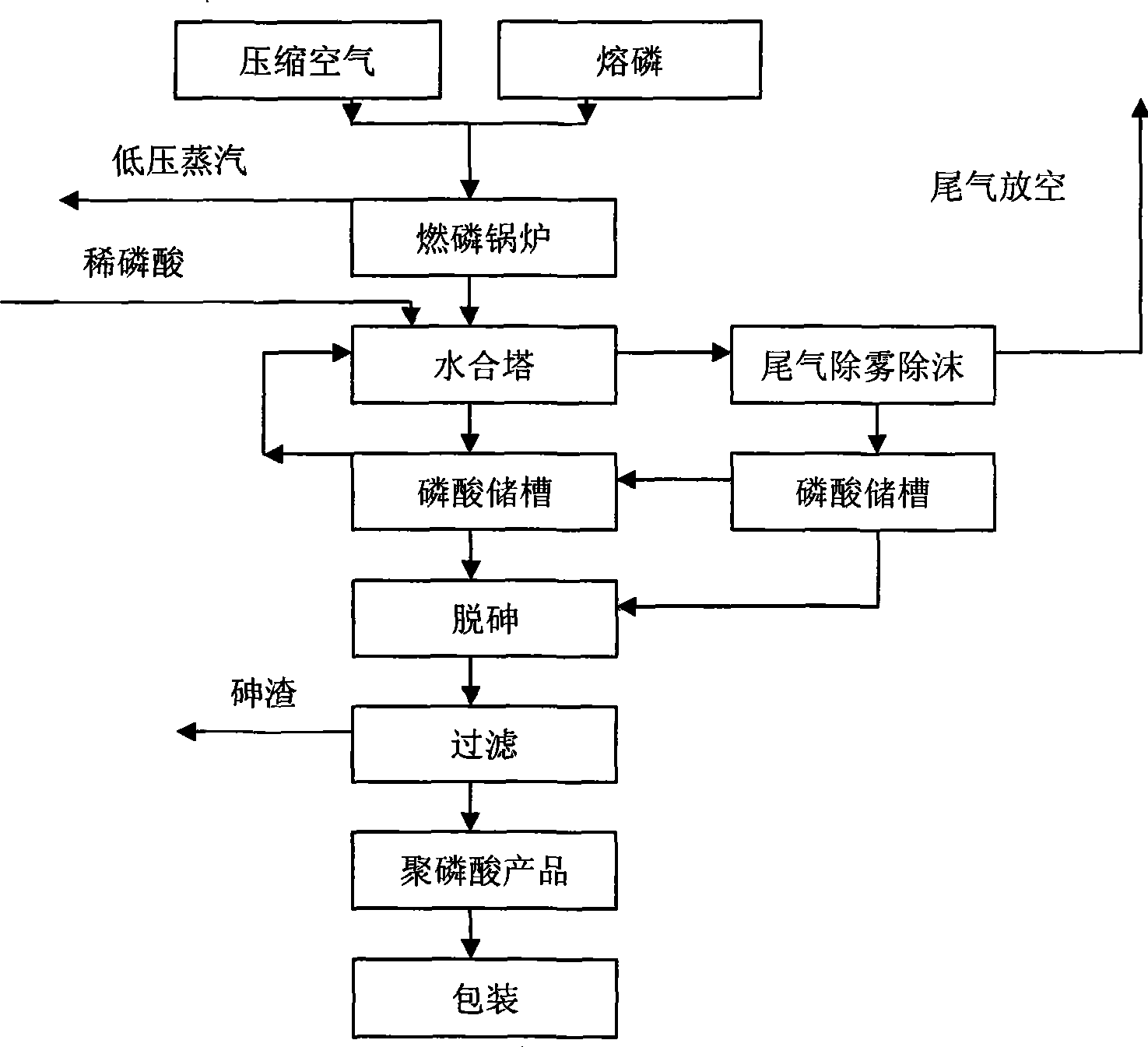

Method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid

ActiveCN101531354ALower packagingReduce logistics costsChemical industryCondensed phosphoric acidsO-Phosphoric AcidEconomic benefits

A method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid, including following steps: mixing yellow phosphorus and air with the proportion of 1kg yellow phosphorus to 6.3-6.6 m3, burning, absorbing the obtained P2O5 by diluted acid; applying the obtained phosphoric acid into a phosphoric acid groove; then using acid pump to send into a condenser to remove the heat; then sending the phosphoric acid into a hydration tower to circularly spray and absorb P2O5 to increase the concentrated phosphoric acid; cycling without stop to obtain the phosphoric acid having 82%-84% P2O5. The recovery coefficient of phosphorus is more than 98%. The obtained product reaches the standard of the food-level phosphoric acid. This invention may greatly reduce the cost of package and distribution of the phosphoric acid production enterprise via using the wet-method phosphoric acid or hot-method phosphoric acid of the concentrated content of the phosphoric acid anhydride of less than 100% obtained by yellow phosphorus burning. This invention does not need to consume the extra energy, and can fully use the burning heat and the hydration heat of the yellow phosphorus; the generated steam can be recycled. So this invention has the advantages of saving energy and greatly reducing the production cost of the polyphosphoric acid, with remarkable social and economic benefits.

Owner:WENGFU (GRP) CO LTD

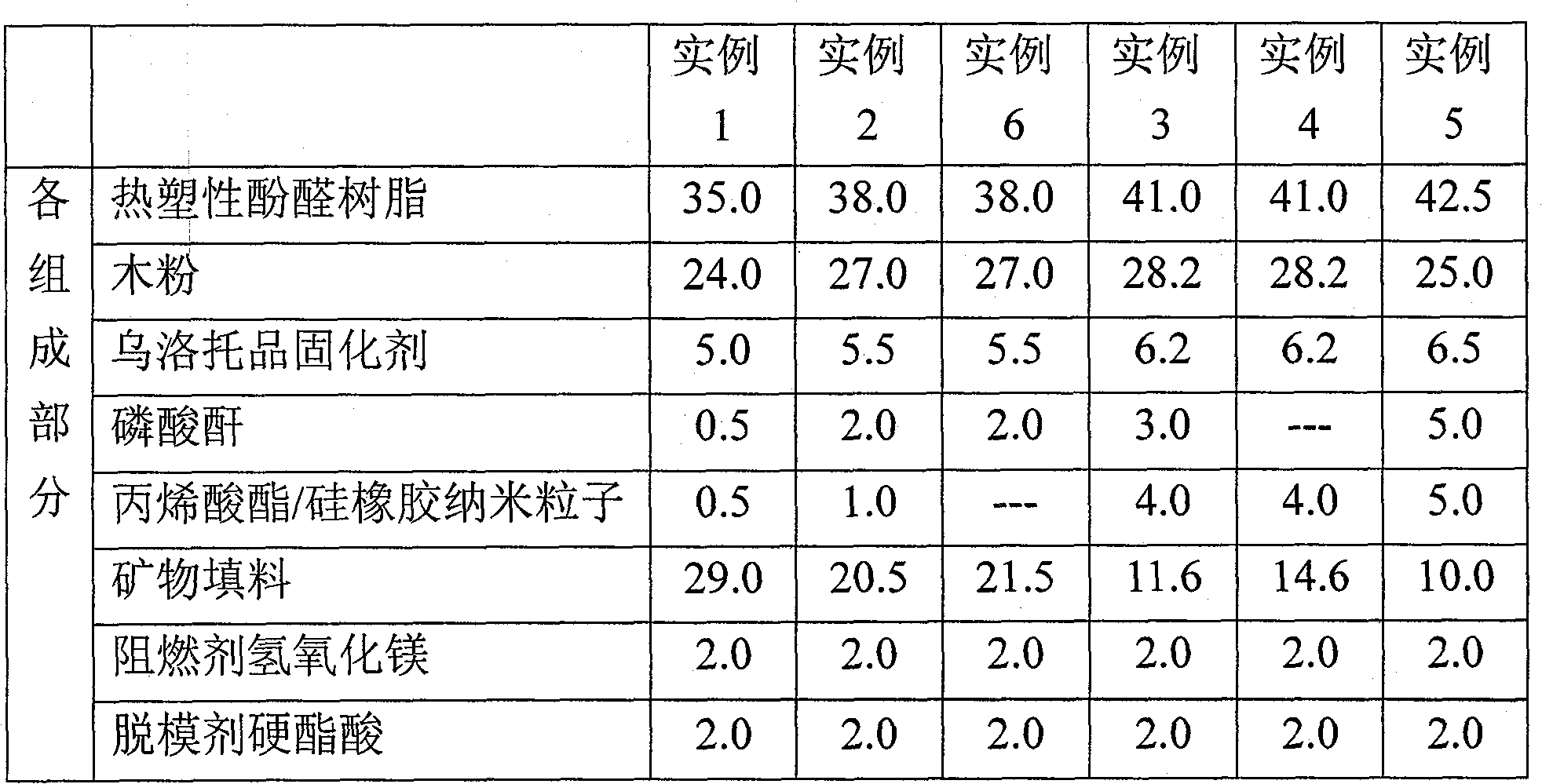

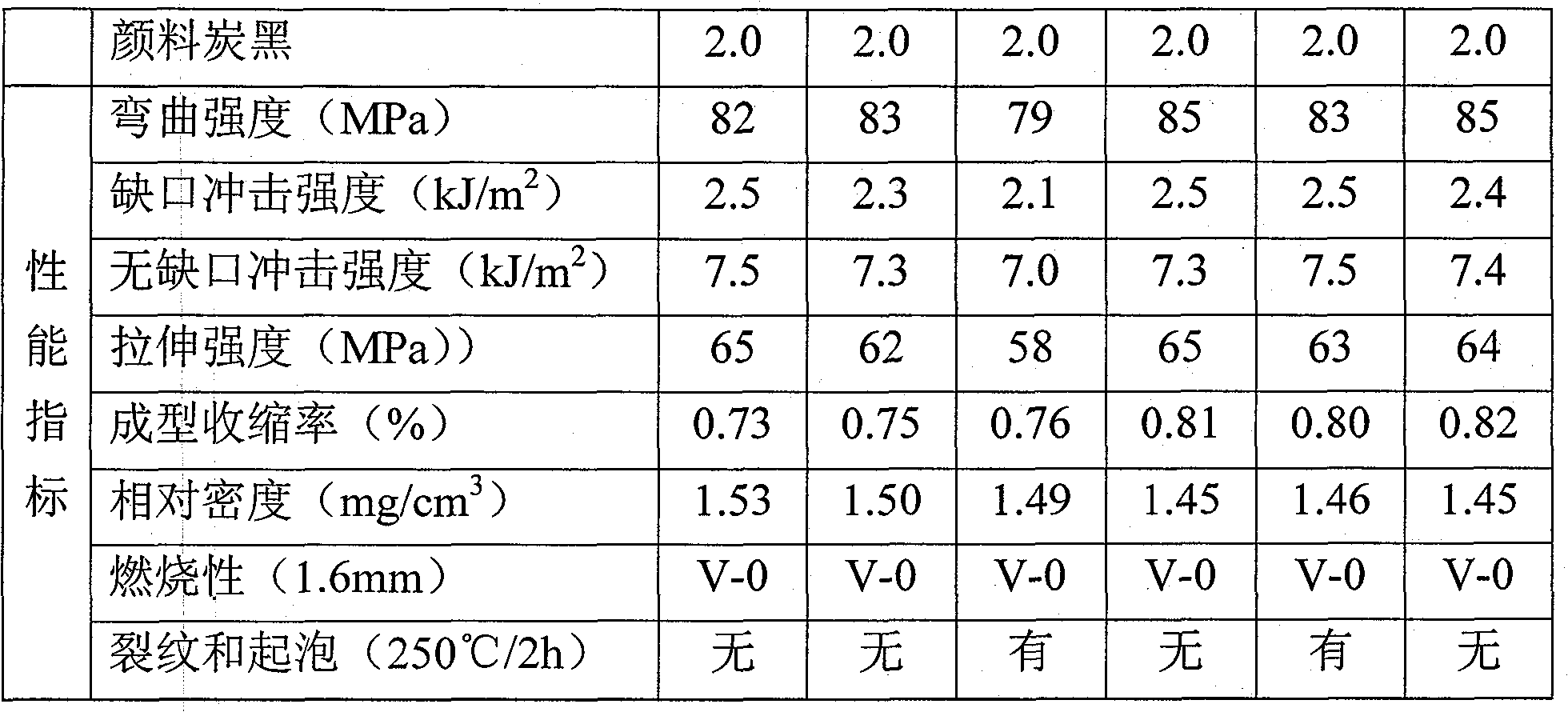

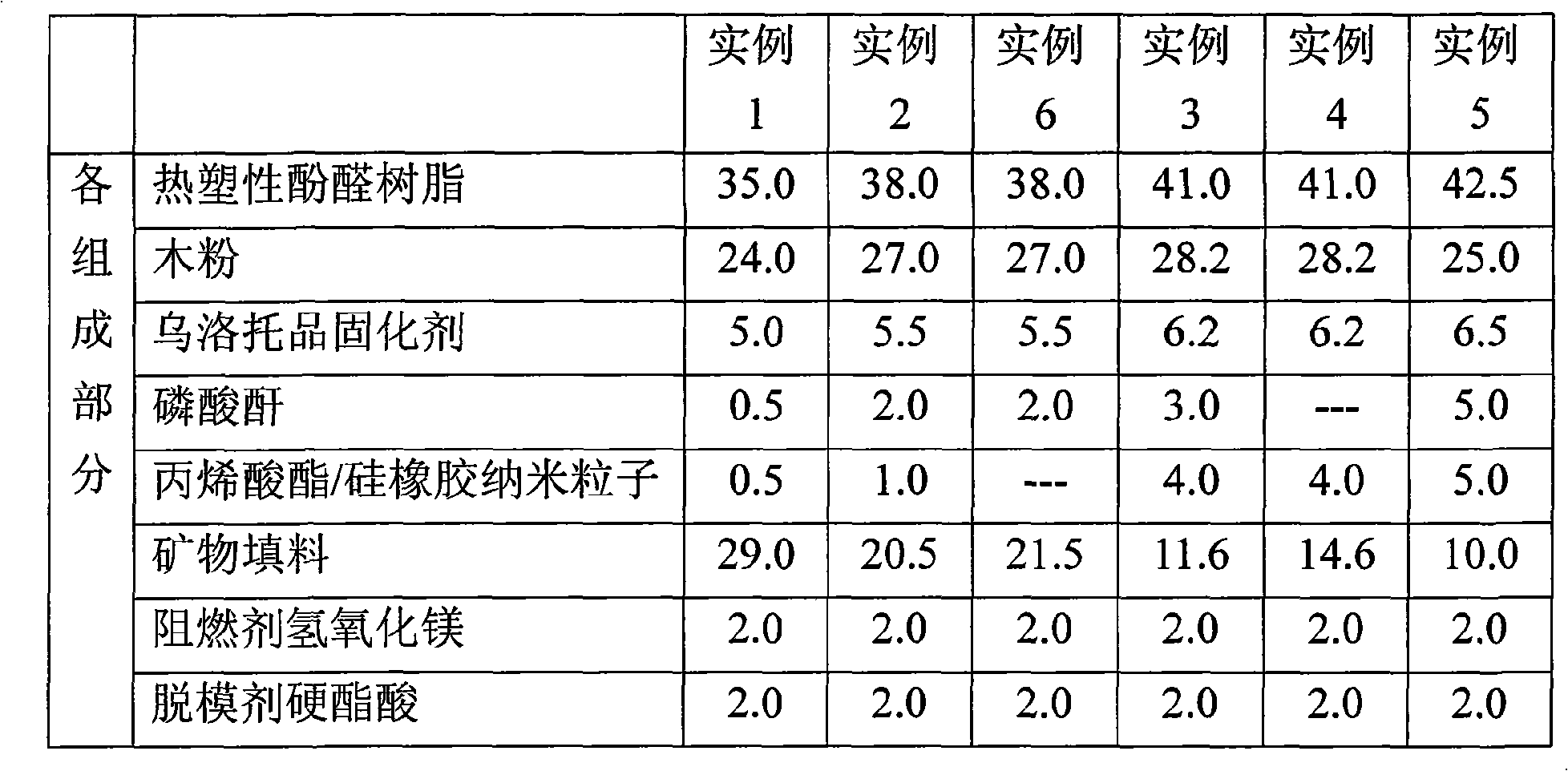

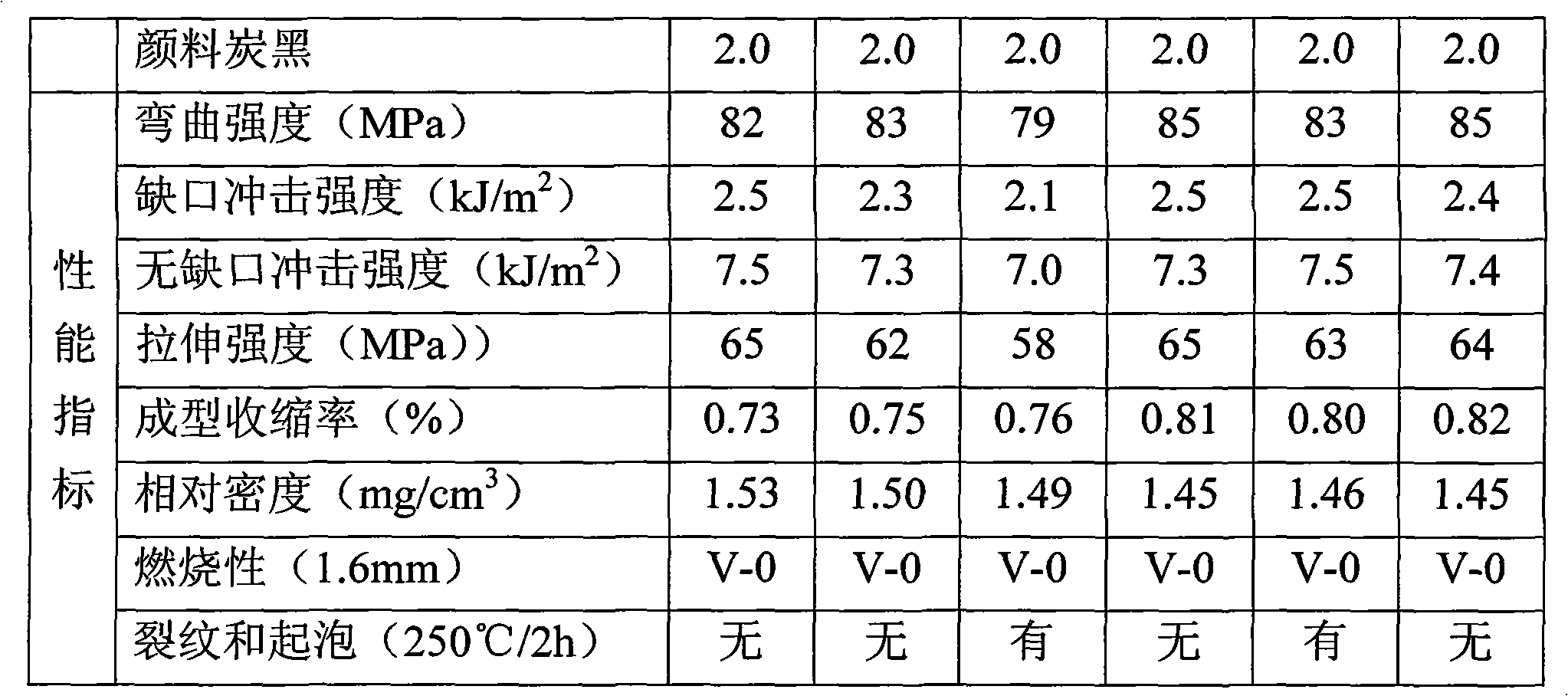

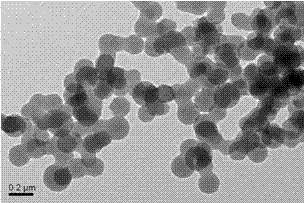

High-temperature baking resistant phenolic molding compound and preparation method thereof

The invention provides a high-temperature baking resistant phenolic molding compound containing additive, which comprises the following components by weight percent: 30-48% of phenolic resin; (2) 10-40% of wood powder; (3) 10-30% of mineral filler; (4) 4.0-9.0% of hexamine; (5) 0.5-5.0% of phosphoric anhydride and (6) 0.5-5.0% of acrylic ester nano particles or silicon rubber nano particles. The invention also discloses a method for preparing the high-temperature baking resistant phenolic molding compound. The phenolic molding compound can be baked for 2h at the temperature of 250 DEG C, and does not crack, foam or deform; and compared with the common bakelite, the cost of the invention is not obviously increased.

Owner:上海欧亚合成材料股份有限公司

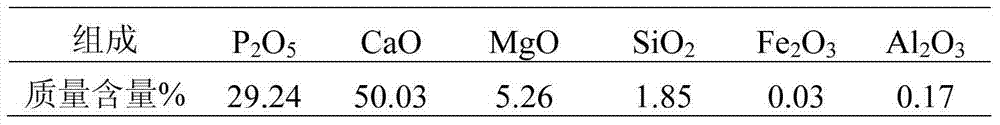

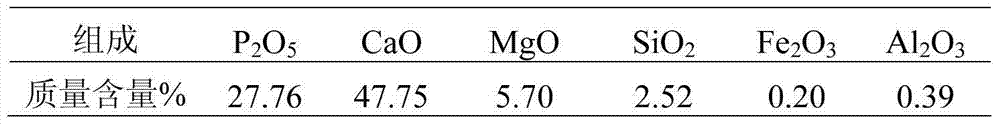

Soil conditioner and preparation thereof

InactiveCN101280193AFull of nutritionReduce planting costsAgriculture tools and machinesOrganic fertilisersSlagOrganic matter

The invention relates to soil conditioner which can improve the acidity of the soil; while the soil conditioner improves the acidity of the soil, the soil conditioner can provide a plurality of nutrient elements for the soil to guarantee the major, medium and microelements for the growth of the plants; the soil conditioner and the preparation method include that the soil conditioner is prepared through the steps as the followings: calcium magnesium phosphate, blast furnace slag and humic acid are grinded respectively; and then the grinding materials are mixed evenly, granulated and dried sequentially according to certain weight ratio; the soil conditioner is composed of 3%-4% of phosphoric anhydride, 20%-30% of silicon dioxide, 3%-5% of magnesia and 8%-10% of organic matter; when the soil conditioner in the invention is adopted, not only the acidity of the soil is improved, but also the content of the soil nutrient is increased.

Owner:朱庆然

Mesoporous bioactive glass material with apatite nanocrystallines and method for producing mesoporous bioactive glass material with apatite nanocrystallines

The invention relates to an ordered mesoporous bioactive glass material with apatite nanocrystallines and a method for producing the ordered mesoporous bioactive glass material with apatite nanocrystallines. The molar ratio of the main ingredients of the mesoporous bioactive glass material is that silicon dioxide to calcium oxide to phosphoric anhydride is (60-90):(6-36):(4-5), and an apatite nanocrystalline structure is a nanocrystal with nanopore clustered hydroxyapatite. The material adopts a double-template technology, carbon microspheres are taken as hard templates, a structure-directing agent is taken as a mesoporous template, and a sol-gel method is combined so as to synthesize the material under moderate conditions. The components of the novel mesoporous bioactive glass can be adjusted, a mesostructure is ordered and controllable, the pore diameter can be controlled within the range between 2 nanometers and 20 nanometers, the specific surface area can reach 600square meters / gram, and the pore volume can reach 0.8cubic centimeter / gram. The ordered mesoporous bioactive glass material can be used a support material for bone substituent or repair materials, drug release and tissue engineering.

Owner:ZHEJIANG SCI-TECH UNIV +1

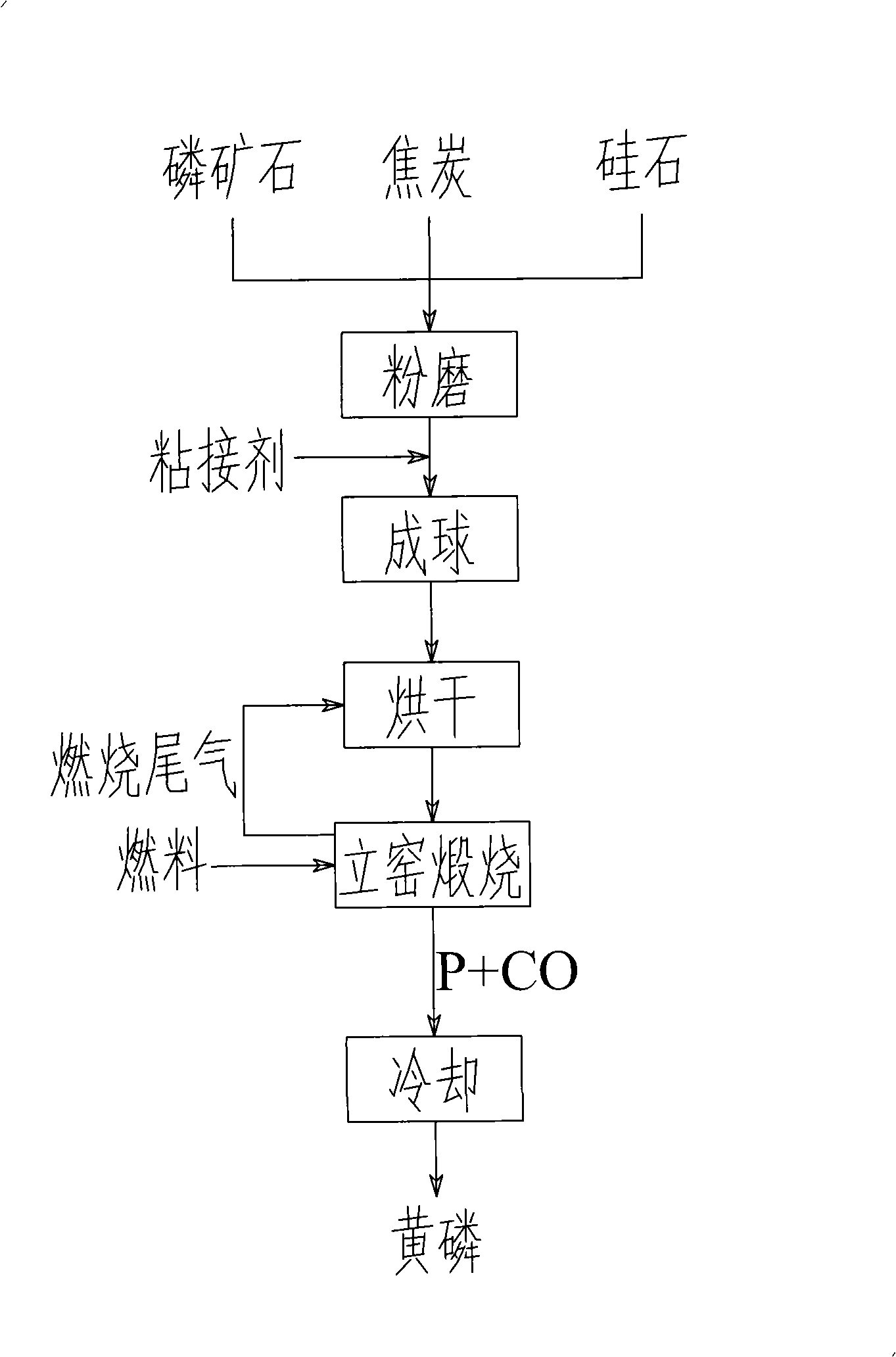

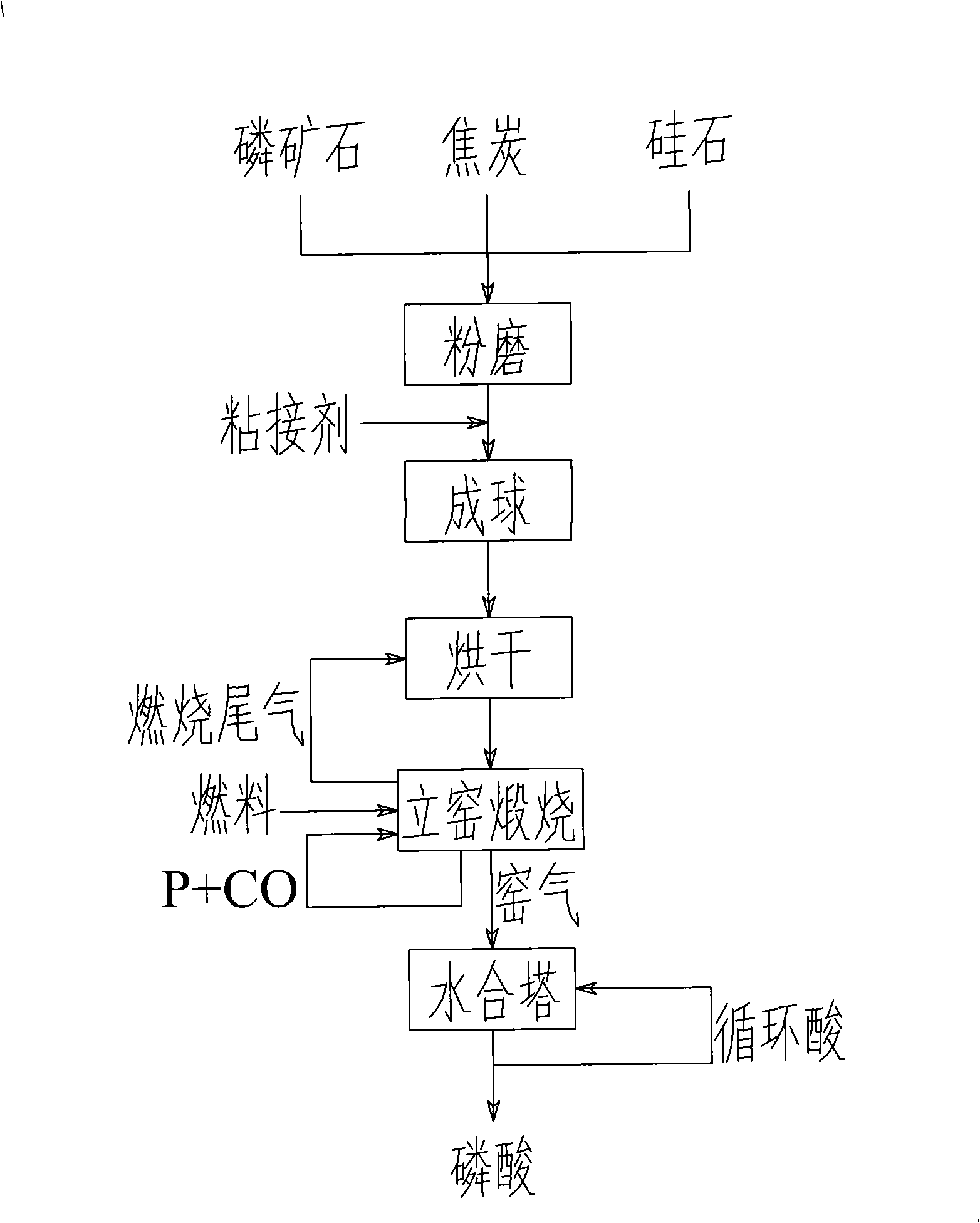

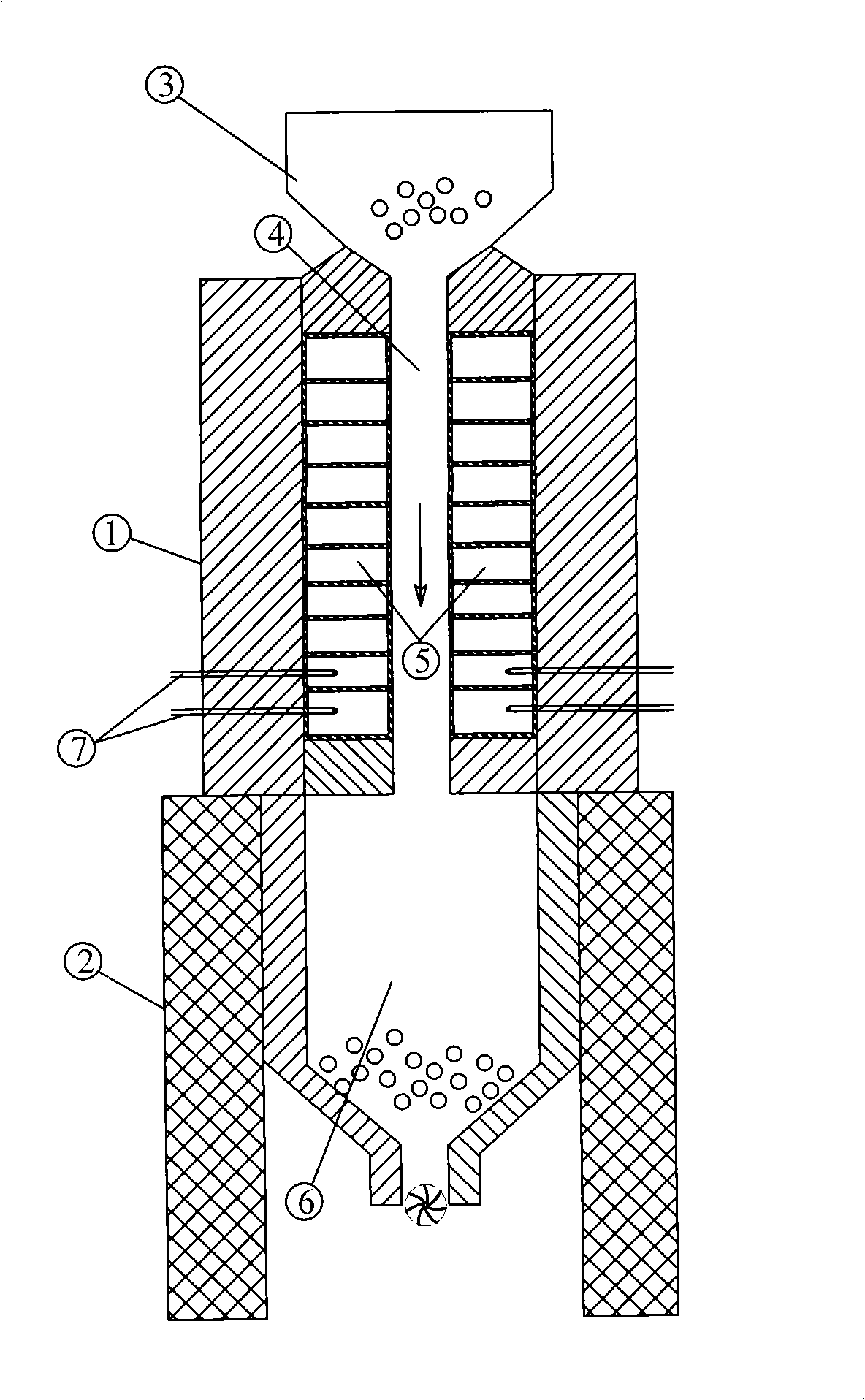

Method and equipment for preparing yellow phosphorus or phosphoric acid with vertical enclosed tobacco-partition kiln

InactiveCN101343050AFlexible adjustmentRealize the core ideaPhosphoric acidHigh concentrationUnit mass

Discloses are a method and a device which adopt the vertical closed smoke separate kiln furnace to produce yellow phosphorus or phosphoric acid. The prepared ball material is added to the vertical closed smoke separate kiln furnace from the upper part; the ball material moves downwards due to the gravity of the ball material in the continuous discharge process on the lower part of the kiln furnace while the temperature is increased gradually; the reaction is processed to generate phosphor vapor and carbon dioxide; the kiln gas contains phosphoric anhydride is absorbed by the circulation acid spraying to obtain the high concentration phosphoric acid. The method and a device which adopt the vertical closed smoke separate kiln furnace to produce yellow phosphorus or phosphoric acid have the advantages that no wrapping agent is needed on the surface of the material, so as to simplify the process, reduce the cost and eliminate the weight of the wrapping agent which accounts on the ball material so that the phosphor yield rate of the ball material in unit weight; the reduction ambience and oxidation ambience of the vertical closed smoke separate kiln furnace is separated by the heating area of the smoke separate combustion; the problem that the carbon substance of the mixture ball material is oxidized in advance in the temperature increasing process is solved; the dosage of carbon reducing agent in the composite pellet is reduced; the production efficiency is improved.

Owner:HUBEI SANXIN PHOSPHORIC ACID

Electrochemical device and electronic device including same

The invention relates to an electrochemical device. The electrochemical device of the present application includes a positive electrode, a negative electrode, and an electrolyte solution, wherein theelectrolyte solution includes anions having a phosphoric anhydride functional group of a specific structure. By adding the anions into the electrolyte solution, the low-temperature discharge performance and the high-temperature storage performance of the electrochemical device can be improved and achieved at the same time, and the cycling stability of the electrochemical device at normal temperature and high temperature is improved.

Owner:NINGDE AMPEREX TECH

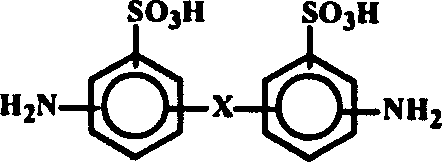

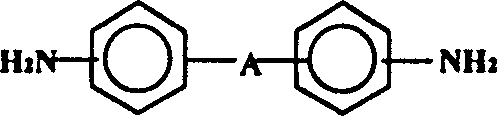

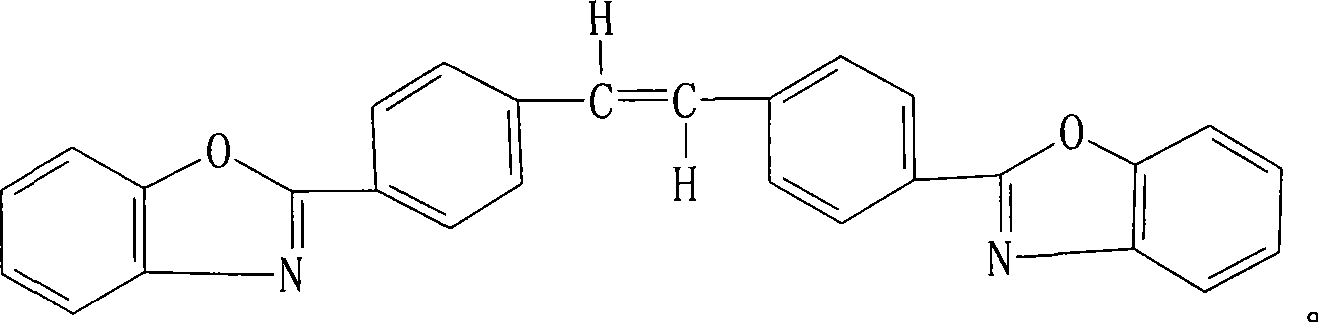

Method for preparing anti-ultraviolet ageing poly-p-phenylene-benzobisoxazole (PBO) fiber

InactiveCN101397696AImproves UV resistanceDoes not affect mechanical propertiesMonocomponent synthetic polymer artificial filamentSpinning solutions preparationFiberUltraviolet

The invention relates to a preparation method of an ultraviolet and aging resistant poly (p-phenylenebenzobisoxazole) (PBO) fiber, which comprises the steps that: DAR question mark 2HCl (DAR), terephthalic acid (TA), phosphoric anhydride (P2O5) and polyphosphoric acid (PPA) (wherein, the mole ratio between the DAR and the TA is 1 to 1) are heated for dissolving under the protection of inert gases, added with an ultraviolet resisting agent, TM, for reaction for 5 hours to 7 hours under the pressure of 0.2MPa to 1.0MPa and the temperature of 110 DEG C to 120 DEG C; the pressure in a reaction kettle is eliminated and reaction is carried out for 6 hours to 7 hours in vacuum; then reaction materials are extruded by adopting a two-screw or single-screw extruder, and the dry jet-wet spinning technique is adopted. The PBO fiber obtained by the method has better ultraviolet resisting performance without affecting the mechanical property of the PBO fiber and the preparation method improves and promotes the light stability of the PBO fiber as well as composite materials thereof.

Owner:DONGHUA UNIV

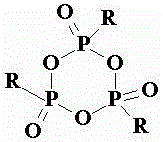

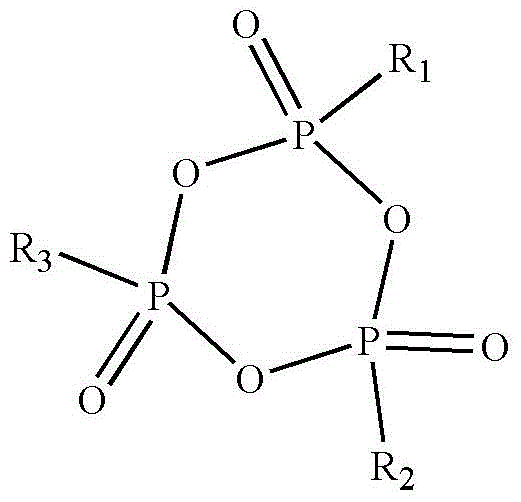

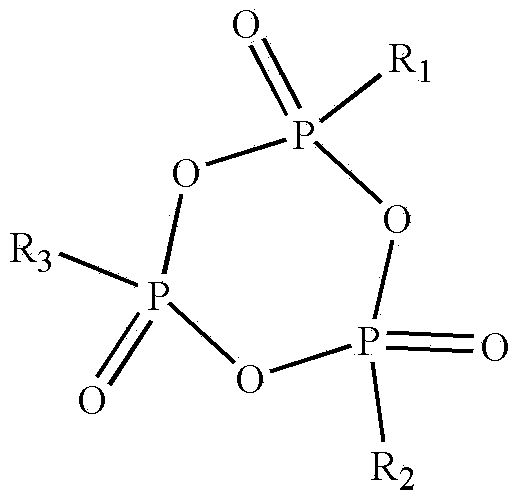

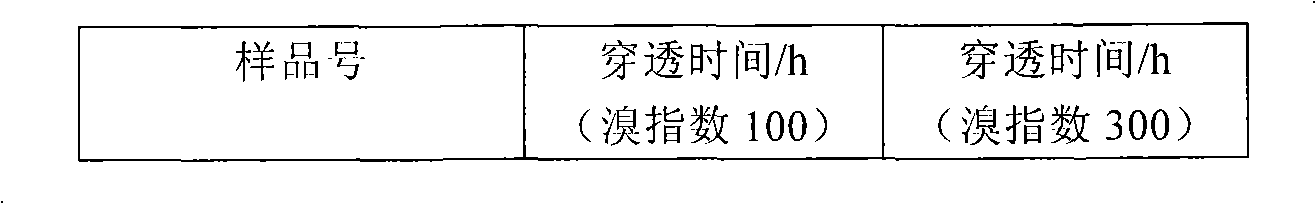

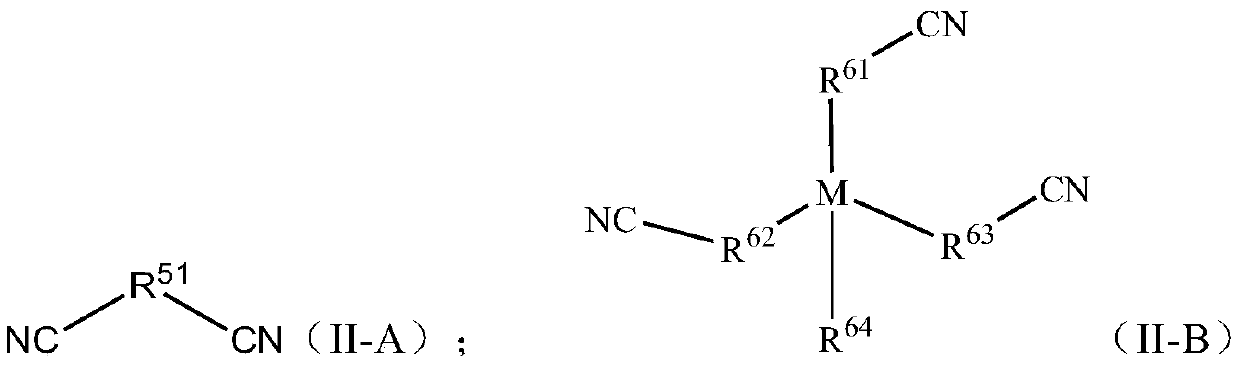

Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate

ActiveCN106008596AOvercoming the problem of instability and easy decompositionHigh feasibilityGroup 5/15 element organic compoundsSolubilityDecomposition

The invention discloses a preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as a glufosinate intermediate. The method comprises the following steps: 1) proper organic solvent, alkaline substance and phase-transfer catalyst are added to cyclic phosphoric anhydride at the temperature of subzero 30 DEG C, stirred, heated to 25-50 DEG C, subjected to a reaction with diethyl oxalate at the room temperature and stirred, and a product is obtained through direct precipitation and filtration from the solvent; 2) water is added to the product, hydrogen chloride is introduced slowly, the pH is controlled, heating is performed, water is removed through rotary evaporation after the reaction is performed for 16 h, and a final product is obtained through vacuum drying. The method has the advantages that the problems of poor solubility and high probability of precipitation of cyclic phosphoric anhydride at a low temperature as well as high probability of ring opening of anhydride and high probability of decomposition of phosphate groups of cyclic phosphoric anhydride under an alkaline condition due to temperature increasing are solved, and the feasibility for preparing 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as the glufosinate intermediate from cyclic phosphoric anhydride is realized successfully.

Owner:ANHUI COSTAR BIOCHEM CO LTD

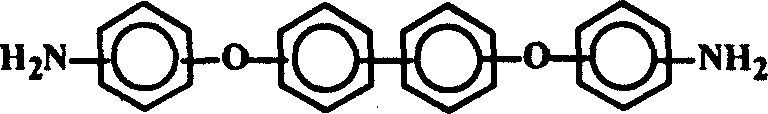

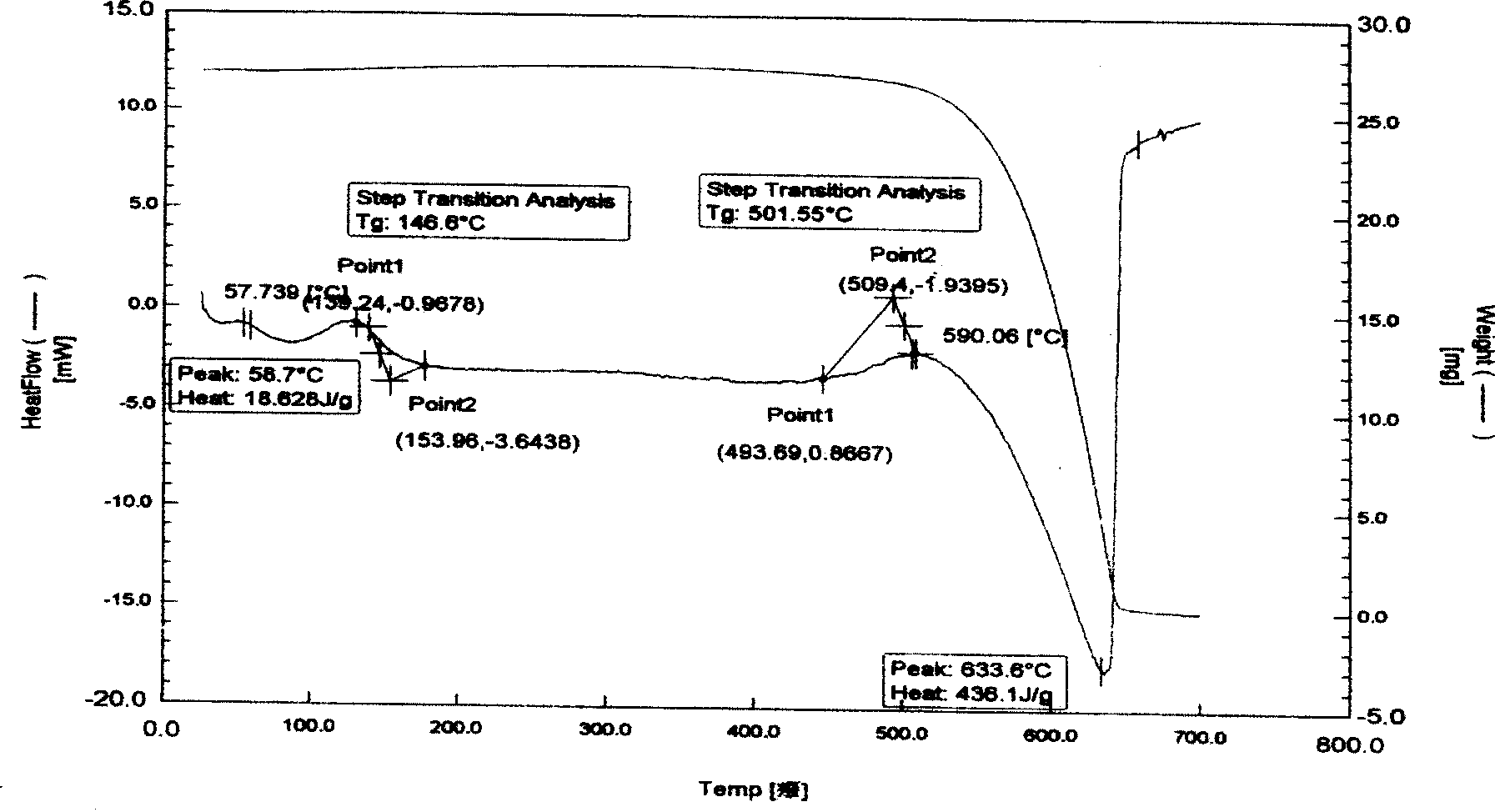

Method for preparing cross-linked polyimide membrane

The invention relates to a new method to prepare crosslinking polysulfonimides membrane, which comprises: dissolving the material in organic solvent with phosphoric anhydride, film forming with liquid moulding, drying for 2~20h at 60~200Deg; then, drying in vacuum for 1~30h at 100~200Deg; dipping the membrane in deionized water, clearing to neutrality, and drying in vacuum. This method is simple and economical. This product has well water resistance and high proton conductivity and wide application in fuel cell, ion exchange resin and sensor.

Owner:SHANGHAI CHLOR ALKALI CHEM +1

High temperature anticorrosive method by using self-reaction products

InactiveCN101456544AAvoid corrosionStable structurePhosphorus oxidesPhosphoric acidHigh-temperature corrosion

The invention relates to a method for high-temperature corrosion protection by utilizing self reaction products, in particular to anticorrosive technology for a combustion tower in production technology for preparing phosphoric anhydride or thermal phosphoric acid by combustion of yellow phosphorus. The method is to utilize the reaction products generated in the production process of preparing the phosphoric anhydride by combustion of the yellow phosphorus to realize high-temperature corrosion protection. The method is characterized by comprising: a, air pumped into the combustion tower at normal temperature and pressure is non-dried air at normal temperature and pressure; b, the wall surface of the combustion tower is cooled to reduce the temperature of the wall surface of the combustion tower during production of the phosphoric anhydride by combustion of the yellow phosphorus, and the temperature of the wall surface of the combustion tower is controlled to be less than 490 DEG C; and c, conjunctival matters are formed on the tower wall during combustion of the yellow phosphorus. Various technological conditions required by the method are easy to realize, and the actual control difficulty is small. Moreover, the method can also reduce the energy consumption and the production cost, is suitable to be applied in mass industrial production, and has great promotion value.

Owner:YUNNAN CHEM RES INST

Preparation method of high-heat-conductivity graphite radiating fin

ActiveCN103476226AReduce pollutionReduce sulfur contentGraphiteCooling/ventilation/heating modificationsAmmonium peroxydisulfateReducing agent

The invention discloses a preparation method of a high-heat-conductivity graphite radiating fin. Natural flake graphite is used as a raw material, ammonium peroxydisulfate is used as an oxidant, nitric acid phosphoric anhydride are used as intercalators, and a small amount of oxalic acid is used as a reducer to prepare low-sulfur highly-expanded graphite; and a water washing method and an expansion method are improved to finally prepare the high-heat-conductivity graphite radiating fin, wherein the sulfur content of the prepared expanded graphite is less than 1%. The method has the advantages of simple preparation technique, mild reaction conditions, small environmental pollution, accessible raw materials, low cost and the like, and is easy to master and convenient for popularization.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Bioactive glass ceramic and preparation method thereof

The invention discloses a bioactive glass ceramic and a preparation method thereof. The ceramic comprises the following raw materials in parts by weight: 80-100 parts of sodium oxide, 10-20 parts of calcium oxide, 4-10 parts of phosphoric anhydride, 5-15 parts of potassium fluoride, 10-15 parts of potassium oxide, 20-30 parts of silicon dioxide, 10-40 parts of zinc oxide and 5-9 parts of polybutylene succinate. The preparation method comprises the following steps: putting sodium oxide, calcium oxide, phosphoric anhydride, potassium fluoride, potassium oxide, silicon dioxide, zinc oxide and polybutylene succinate in a crucible and maintaining the temperature at 1400-1800 DEG C for 1-2 hours; drastically cooling the crucible to form a fusion cake and crushing the fusion cake into glass powder; melting the glass powder at 1000-1200 DEG C in the crucible and naturally cooling the melted glass powder so that the bioactive glass ceramic is obtained. The bioactive glass ceramic is capable of actively participating in biological reactions so as to induce the contacted bone tissues to grow around the bioactive glass ceramic, so that a continuous bone material is formed.

Owner:SUZHOU VIVOTIDE BIOTECH

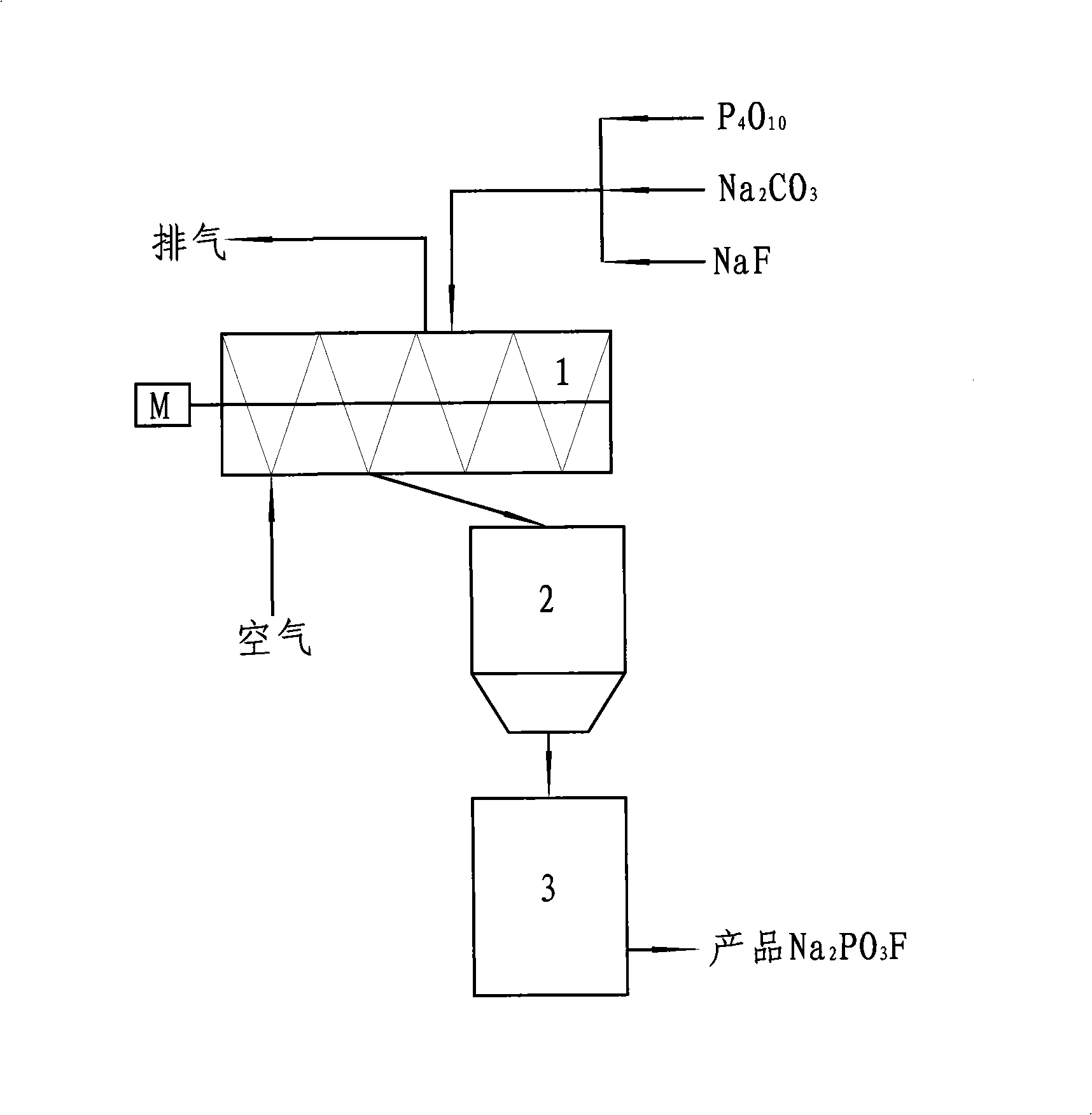

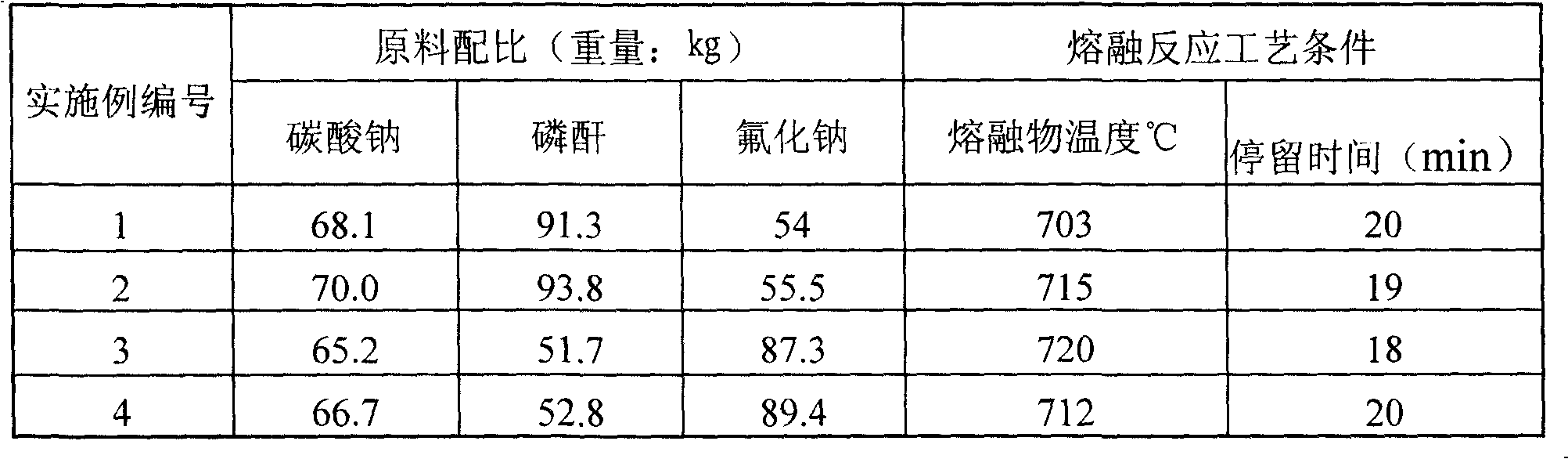

Preparation of sodium monofluorophosphate

InactiveCN101327923AReduce manufacturing costSimple production processPhosphorus compoundsSODIUM METAPHOSPHATESodium phosphates

The invention relates to a preparation method of sodium monofluorophosphate which comprises the steps of: mixing and reacting phosphoric anhydride and sodium carbonate to obtain sodium metaphosphate, then mixing and heating the sodium metaphosphate and sodium fluoride to a melting state. The sodium monofluorophosphate is obtained through reacting the mixture of sodium phosphate and sodium fluoride in the melting state. The art of the invention has advantages of simply technology, low energy consumption and low content of product impurity.

Owner:YUNNAN JIANGLIN GROUP

Fertilizer as well as preparation method and application thereof

InactiveCN103755416APromote healthy growthCorrect deficienciesFertilising methodsFertilizer mixturesBiotechnologyTotal nitrogen

The invention discloses a fertilizer. The fertilizer contains total nitrogen, water-soluble phosphoric anhydride, water-soluble potassium oxide, water-soluble magnesium and trace elements, wherein the mass ratio of the total nitrogen to the water-soluble phosphoric anhydride to the water-soluble potassium oxide is 3: 1: 1. The invention also provides a preparation method of the fertilizer and an application of the fertilizer in rectifying yellowing of plants. The fertilizer provided by the invention has the beneficial effects that a certain amount of magnesium (MgSO4) and a micro element fertilizer (STEM) are added to the fertilizer so that plants can absorb various elements and nutrients, and therefore, the nutritional deficiency problem of the plants can be rectified fundamentally so that the plants can turn to green quickly and safely, and healthy growth of plants is promoted. One week later after the fertilizer is irrigated to the roots of the yellowing plants or sprayed to the leaves of the plants, the leaves of the yellowing plants begin to turn to green, half a month later, the leaves turn to strong green and have luster, and one month later, the plants can grow healthily.

Owner:GUANGXI SENXIANYUAN BIOLOGICAL SCI & TECH

Electrolyte for lithium titanate battery and battery product prepared from electrolyte

InactiveCN106299474AImprove high temperature cycle lifeEasy to implementSecondary cellsOrganic electrolytesProduction rateHigh temperature storage

The invention discloses an electrolyte for a lithium titanate battery and a battery product prepared from the electrolyte. The electrolyte is prepared from solutes, a solvent and an additive through mixing, wherein the additive is alkyl phosphoric anhydride, and alkyl phosphoric anhydride accounts for 0.1%-10% of the electrolyte for the lithium titanate battery in percentage by mass. The formula of the electrolyte for the lithium titanate battery is ingenious in design, alkyl phosphoric anhydride is added reasonably, the content of alkyl phosphoric anhydride is set scientifically, alkyl phosphoric anhydride can react with water of a lithium titanate pole piece to consume water, furthermore, acidity of produced alkyl phosphonic acid is low, positive and negative poles of the battery cannot be damaged, so that the gas production rate is reduced, expansion of the battery during high-temperature storage is greatly reduced, the high-temperature cycle life of the lithium titanate battery is prolonged, and better high-temperature storage property and cycle performance are realized; the battery product prepared from the electrolyte for the lithium titanate battery is simple in structure and easy to produce and has the better high-temperature storage property and cycle performance and good combination property, and wide popularization and application are facilitated.

Owner:东莞市航盛新能源材料有限公司

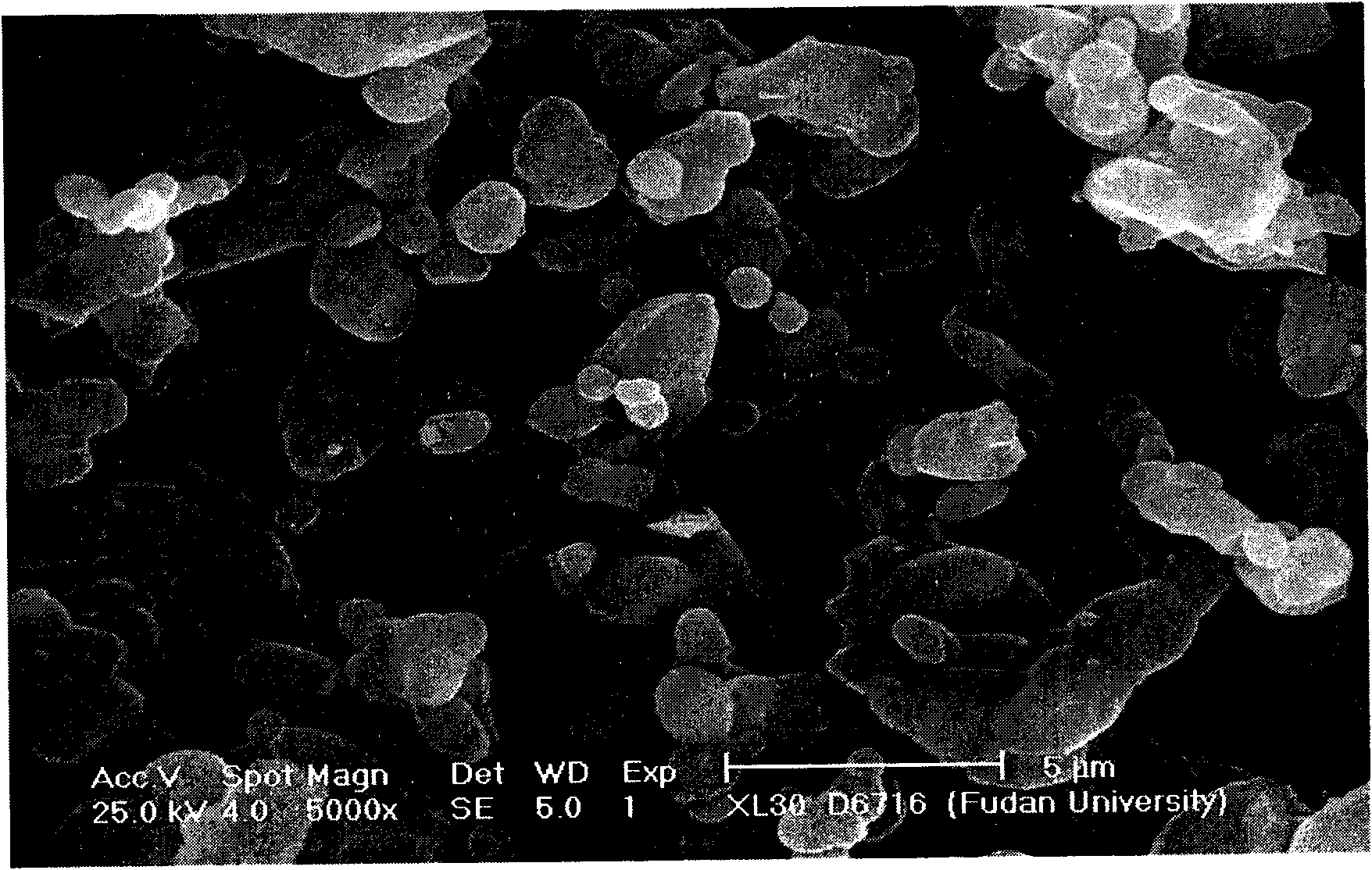

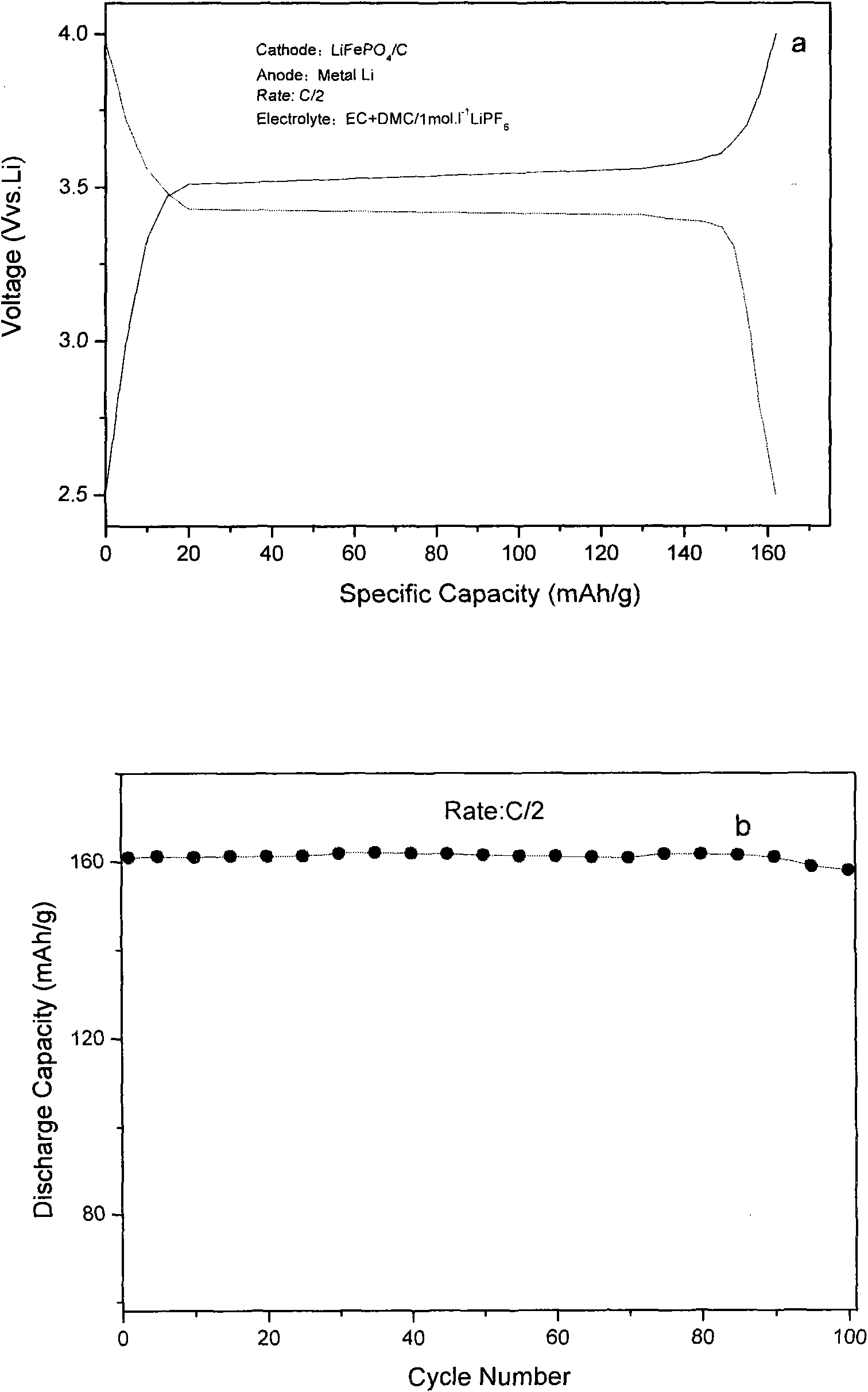

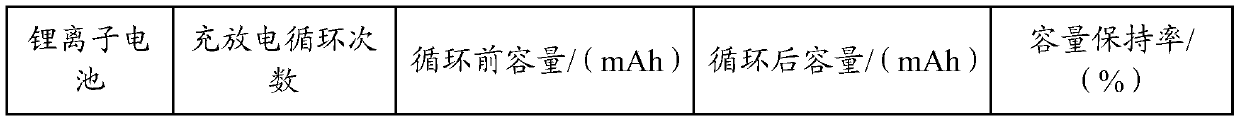

Method for improving electric conductivity of lithium iron phosphate battery anode material

InactiveCN101604749AImprove conductivityNo attenuationElectrode manufacturing processesLithium iron phosphateLithium-ion battery

The invention belongs to the technical field of electrochemistry, and specifically discloses a method for improving electric conductivity of lithium iron phosphate battery anode material. Based on synthesizing lithium iron phosphate material by a conventional method, the method removes residual moisture in the lithium iron phosphate material by methods of injecting gas capable of dehydrating, pumping with a vacuum pump and absorbing water with phosphoric anhydride when calcining at high temperature so that the electric conductivity of the material is greatly improved. The lithium iron phosphate anode material treated by the method is used for preparing the lithium battery with the properties of high specific capacity, good safety, long cycle period and the like. The lithium / lithium ion battery prepared with the anode material is charged or discharges at a speed of 0.5C and the capacity thereof is up to 160mAh / g; the first charging / discharging effect thereof is near 100%; and the battery can be circularly charged or discharge above 100 times and substantially has no attenuate phenomenon.

Owner:FUDAN UNIV

Electrolyte and lithium ion battery

ActiveCN111162315ALow melting pointImprove high temperature stabilitySecondary cellsComposite electrolytesPropanoic acidHigh energy

The invention relates to the field of lithium ion batteries, and discloses an electrolyte which comprises a high-temperature organic solvent, a positive and negative electrode protection additive andan electrolyte lithium salt, wherein the high-temperature organic solvent comprises the following components in parts by weight of 5-30 parts of ethylene carbonate, 5-30 parts of propylene carbonate,5-30 parts of diethyl carbonate, 5-50 parts of propyl propionate and 1-10 parts of fluorobenzene; the positive and negative electrode protection additive comprises the following components in parts byweight of 0.2 to 5 parts of ethylene sulfate, 0.2 to 5 parts of fluoroethylene carbonate, 0.2 to 5 parts of difluoroethylene carbonate, 0.2 to 5 parts of a dinitrile organic matter, 0.2 to 3 parts oflithium difluorophosphate, 0.2 to 5 parts of diethylene glycol dipropionitrile ether, 0.2 to 3 parts of lithium fluorosulfonyl imide, 0.1 to 2 parts of 1-propyl phosphoric anhydride, 0.5 to 20 partsof 1, 1, 2, 2-tetrafluoroethyl-2, 2, 3, 3-tetrafluoropropyl ether, 0.1 to 2 parts of lithium oxalyldifluoroborate and 0.1 to 1 part of methylene methanedisulfonate. The electrolyte is excellent in high-temperature resistance, enables the lithium ion battery with high energy density to normally work at the temperature of 70 DEG C or above, and can keep the relatively better endurance.

Owner:EVE ENERGY CO LTD

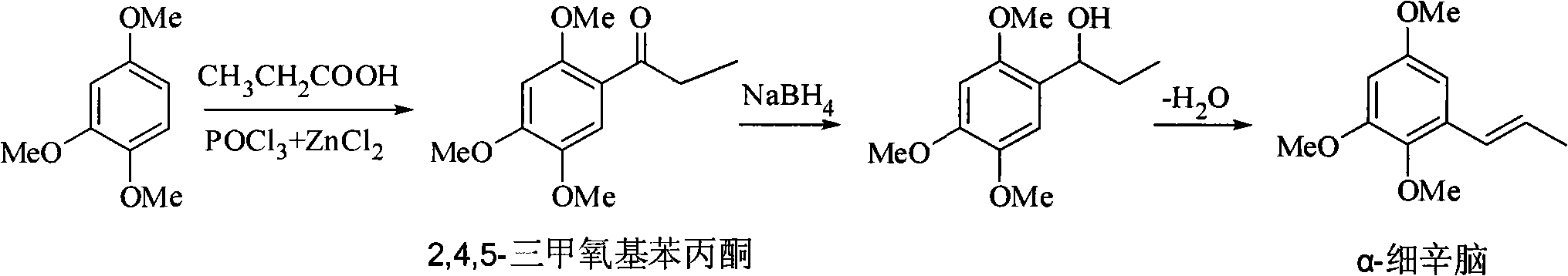

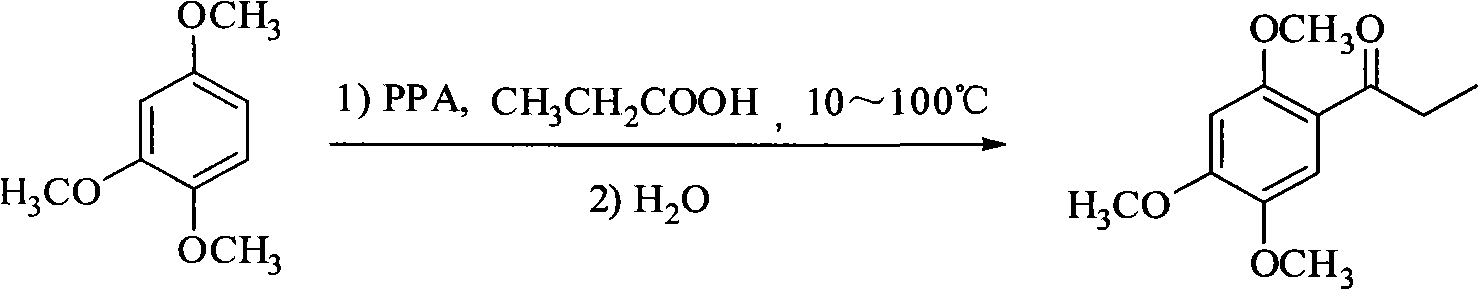

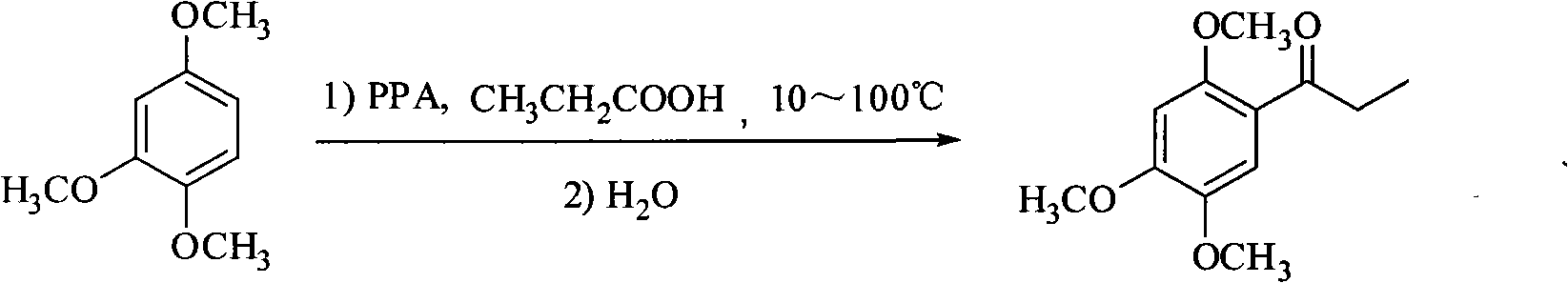

Method for synthesizing 2,4,5-trimethoxyethylphenylketone intermediate of alpha-asarin

InactiveCN101891604ASimple processLow costCarbonyl compound preparation by condensationPropanoic acidPropionic anhydride

The invention discloses a method for synthesizing a 2,4,5-trimethoxyethylphenylketone intermediate of alpha-asarin, which is characterized by comprising the following steps of: directly reacting 2,4,5-trimethoxybenzene, which servers as a raw material, with propanoic acid or propionic anhydride under the action of polyphosphoric acid, or a mixture of phosphoric acid and phosphoric anhydride, or a mixture of the polyphosphoric acid, the phosphoric acid and the phosphoric anhydride; and performing hydrolysis to obtain the 2,4,5-trimethoxyethylphenylketone. The product can be used as the raw material or the intermediate of the alpha-asarin or the raw material for synthesizing other medicaments, and also can be used as spices. The method of the invention has the advantages of simple process, low cost, high product quality, high yield and the like and is safe and reliable in operation and suitable for industrial production. The method can effectively solve the problems of complicated operation and the like of the synthesis of the 2,4,5-trimethoxyethylphenylketone intermediate of the alpha-asarin.

Owner:广西中医学院

Method for quickly constructing leaf curtain for date trees and special leaf fertilizer

ActiveCN104211522AImprove nutritional conditionsConducive to build and maintainFertilizer mixturesSoil scienceNutrition

The invention relates to a method for quickly constructing a leaf curtain for date trees and a special leaf fertilizer. The method is characterized in that the special fertilizer mainly comprising allantoin, DA-6, hypersensitive protein, BR, urea, water-soluble phosphoric anhydride, K2SO4, HBO3, FeSO4, CuSO4, ZnSO4, MnSO4 and ammonium molybdate is used as a spraying solution to spray the date trees so as to realize quick construction of the leaf curtain for the date trees. Compared with the prior art, the method and the special leaf fertilizer have the advantages that a remixing preparation is adopted, and meanwhile, the special leaf fertilizer contains plant growth substances, inorganic nutrients (major and trace elements) and organic nutrients, are complete in nutrients, convenient to use and stable in effect; by the synergistic effect of multiple substances, the plant growth hormone is supplemented from outside, and the condition that inorganic or organic nutrients are independently used, but the internal growth power is poor is avoided, so that the condition of unobvious effect is avoided, the nutritional condition of development of leaves of the date trees is effectively improved, the quick development of the leaves is enhanced to construct the leaf curtain in advance, and the basic condition for high yield of dates is guaranteed, especially the need for photothermal resources; due to strong sources, the benefit for construction and maintenance of warehouses is achieved; when the sources and the warehouses are developed in a coordination manner, organic coordination of high yield and quality can be obtained.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

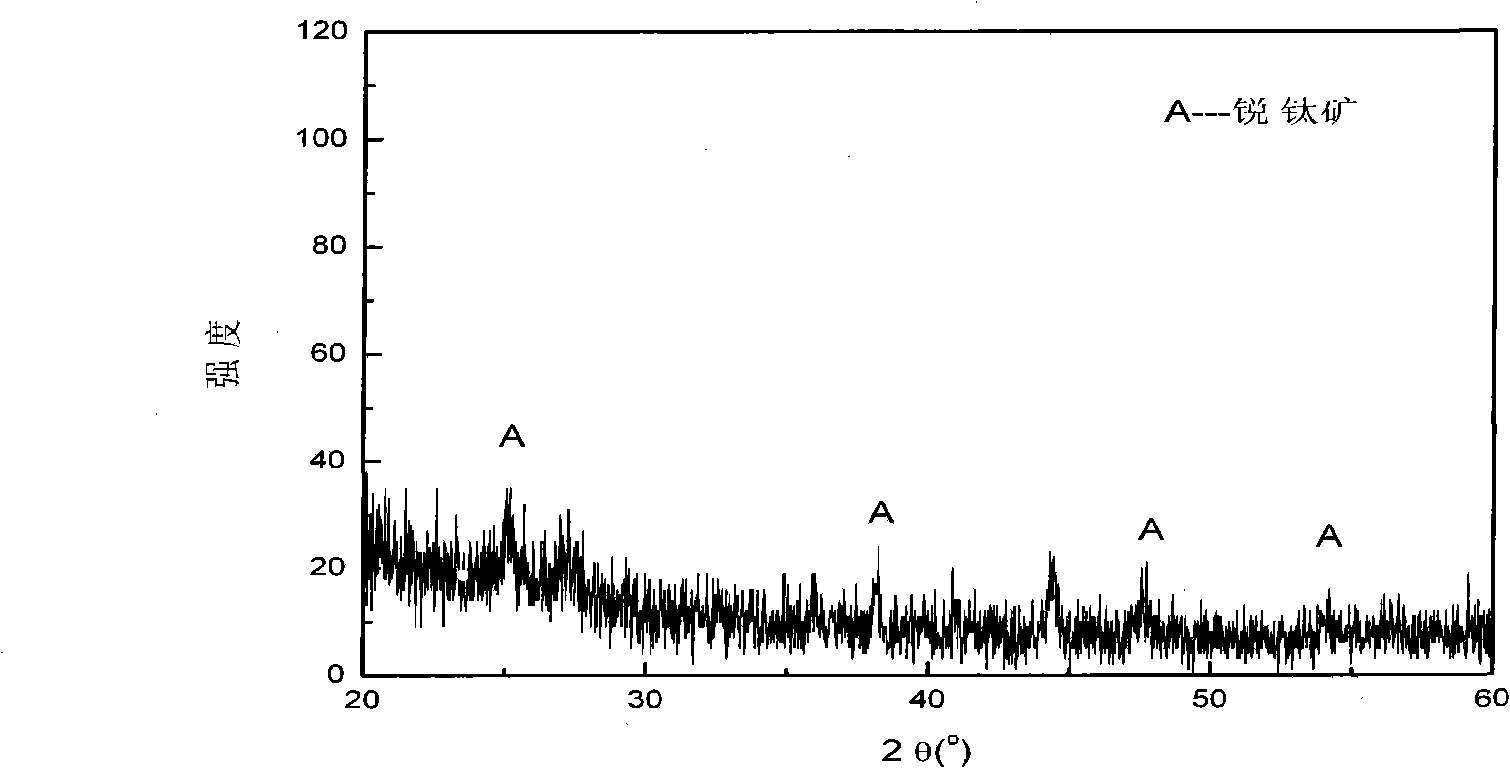

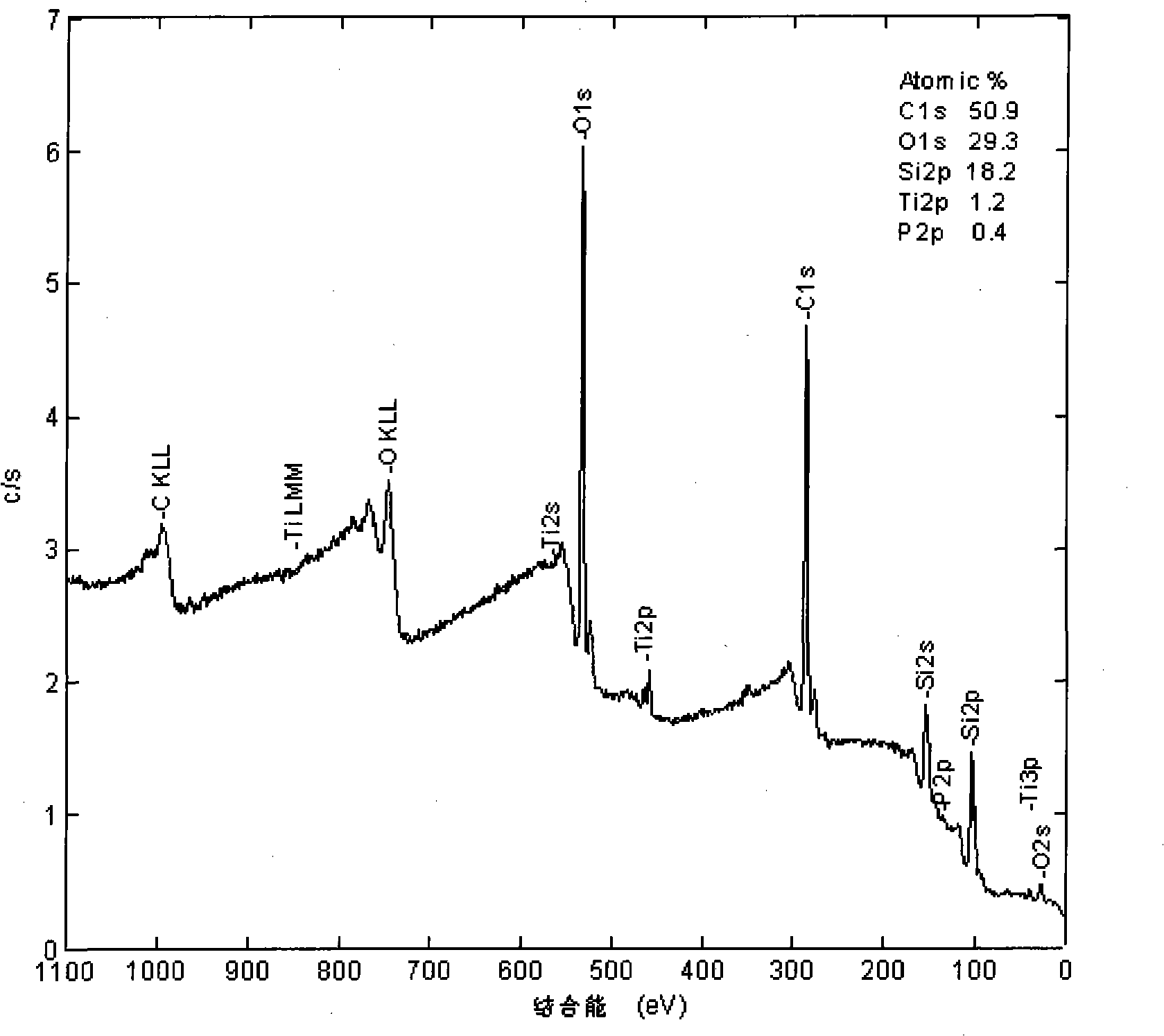

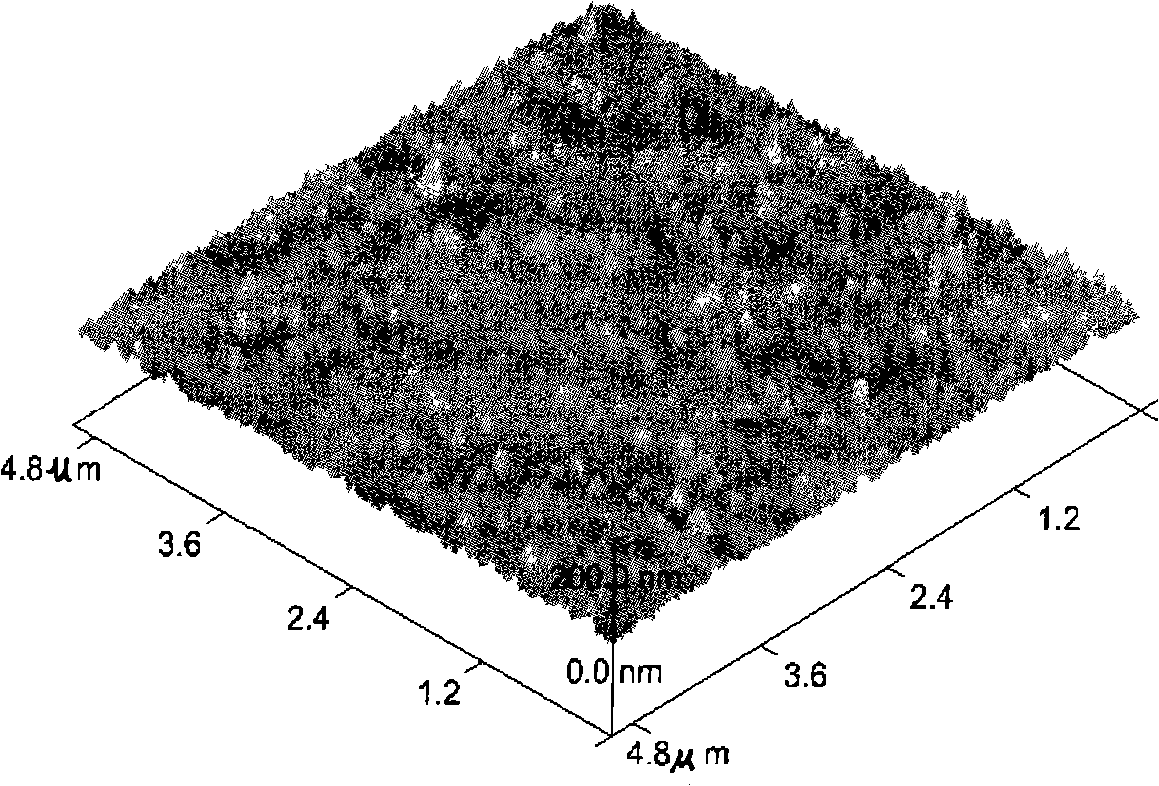

Method for preparing titanium dioxide crystalline state film at low-temperature

InactiveCN101314481ANo pollution in the processEasy to prepareTitanium dioxideCoatingsSurface bindingCalcination

The present invention discloses a method for preparing a crystalline titanium dioxide film at a low temperature, which comprises the steps of:(1) cleaning and drying a substrate;(2) immerging the substrate into an organic solvent solution of X(CH2)nSi(OCH3)3 for soaking, and taking out the substrate for cleaning and drying, wherein the X in the X(CH2)nSi(OCH3)3 is -SH or -CH3 or -Cl or -NH2, n is one of 1 to 16;(3) soaking the substrate in a supersaturation methanol solution of phosphoric anhydride, and taking out the substrate for cleaning and drying;(4) soaking the substrate in an aqueous solution of TiCl4 which contains hydrochloric acid to carry out nano titanium dioxide film deposition and growth, and thus the crystalline titanium dioxide film is made. The method is simple and causes no pollution to environment. The order assembly of phosphosilane on the surface of the substrate is realized, and the substrate is used as a template to direct the assembly and growth of the nanometer titanium dioxide at a low temperature without the need of high temperature calcination. The film has a certain crystal structure, but also fixedly bonded with the surface of the substrate.

Owner:TIANJIN UNIV

Method for preventing and treating calathea rotundifolia cv.fasciata leaf spot

The invention relates to a method for preventing and treating calathea rotundifolia cv.fasciata leaf spot, which is characterized in that turfy soil Klasmann No. 414 is used as a culture substrate; the temperature is controlled at 22-28 DEG C in the day and 20-25 DEG C in the night, and the humidity is controlled at 75-85 percent in the day and 80-95 percent in the night; solution prepared by dissolving 0.2-0.4 gram of urea, 0.2-0.4 gram of monopotassium phosphate and 0.1-0.2 gram of micronasole into 100 L of water is sprayed at the time before sunlight irradiates plants in the morning once a month from plantlet introduction to sale; when an EC (earth current) value of soil is more than 0.12, clear water is sprayed, and when the EC value of the soil is less than 0.25, 1-1.2 g / L of a water solution containing peters professional 20-20-20 or 0.8-0.9 g / L of a KNO3 water solution is sprayed alternatively, wherein the peters professional 20-20-20 comprises the following components in percentage by weight: 20% of total nitrogen, 8.04% of ammonium nitrogen, 11.96% of nitrate nitrogen, 0.02% of boron, 0.01% of chelate copper, 0.10% of chelate iron, 20% of water-soluble phosphoric anhydride, 0.056% of chelate manganese, 20% of water-soluble potassium oxide, 0.01% of molybdenum, 0.25% of water-soluble magnesium oxide, 0.0162% of chelate zinc, and the balance of water.

Owner:DASHUN INT FLOWER

Special fertilizer for cotton

The invention relates to a compound fertilizer for agricultural production, particularly a special fertilizer for cotton. The invention is characterized in that the special fertilizer for cotton is prepared by proportionally mixing rotten chicken manure, ammonium chloride, diammonium phosphate, potassium chloride, borax and ammonium molybdate. The special fertilizer comprises the following raw materials in percentage by weight: 67-70% of rotten chicken manure, 5-10% of ammonium chloride, 9-17% of diammonium phosphate, 7-13% of potassium chloride, 1% of borax and 0.04% of ammonium molybdate. The total nutrient content of the special fertilizer is 16%, wherein the content of nitrogen is 4%, the content of phosphoric anhydride is 4-8%, and the content of potassium oxide is 4-8%; and besides, the content of borax is 1%, the content of ammonium molybdate is 0.04%, and the content of organic substance is 20%. The special fertilizer for cotton can satisfy the demands of cotton growth and development for several main nutrient elements, and has the effects of strongly activating soil, removing hardening, increasing fertility, retaining water to resist drought and improving continuous cropping; and the special fertilizer for cotton can effectively prevent and treat the symptoms of budding without flowering and flowering without fruiting of cotton as well as the symptom of hard blooms, increase both yield and income, and improve the quality.

Owner:陆凯

Docetaxel conjugate preparation method based on mesoporous material self-assembly system

InactiveCN108514641ASimple processMild reaction conditionsOrganic active ingredientsOrganic-compounds/hydrides/coordination-complexes catalystsDocetaxelMesoporous silica

The invention provides a method for preparing a docetaxel conjugate under a carboxyl-modified mesoporous silica self-assembly system. The method comprises the following steps: preparing carboxyl-modified mesoporous silica particles; preparing a docetaxel ester-mesoporous silica self-assembly body; in the presence of a catalyst PyBOP and a reaction assistant n-propyl phosphoric anhydride, adding acondensating agent, enabling the prepared docetaxel ester-mesoporous silica self-assembly body and a coupling component to perform an esterification reaction in a dimethylsulfoxide solvent, and generating the docetaxel conjugate. The method is capable of, through using the combination of the modification mesoporous material and a catalyst / promoter system, forming a reaction interface on the surface of the mesoporous material, promoting a coupled reaction to be performed, and greatly improving the reaction efficiency.

Owner:张海英

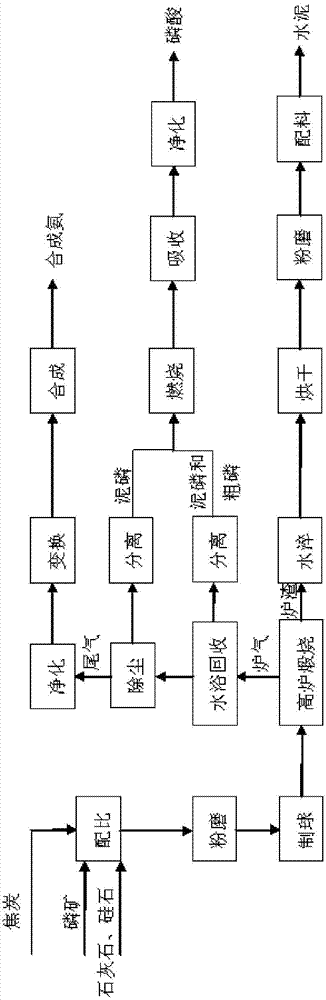

Method for producing phosphoric acid and jointly producing cement and synthetic ammonia by using phosphorus ores, limestone and silica

The invention relates to a method for producing phosphoric acid and jointly producing cement and synthetic ammonia by using phosphorus ores, limestone and silica. The method comprises the following steps of that the phosphorus ores, the limestone and the silica are blended, ground, pelletized and subjected to blast furnace roasting to obtain solid furnace slag and a furnace gas, the furnace gas is firstly cooled through a water bath to recover rough phosphorus and phosphorus sludge, and the furnace gas cooled through the water bath is dedusted to recover the phosphorus sludge; the rough phosphorus and the phosphorus sludge are oxidized and combusted and then a phosphoric anhydride gas is absorbed through water to prepare phosphoric acid; an obtained furnace tail gas is desulfurized and transformed to form a feed gas used for synthetic ammonia and then the feed gas is desulfurized, decarburized and subjected to gas purification to produce synthetic ammonia. The method disclosed by the invention opens a new way for the resource integrated utilization of the blast furnace process phosphoric acid tail gas by directly purifying the blast furnace process phosphoric acid tail gas obtained after the phosphorus sludge is recovered to be used as a raw material used for synthetic ammonia, ingeniously carries out integrated utilization on various raw materials and enhances the integral value of a process.

Owner:KINGENTA NORSTERRA CHEM CO LTD

High-temperature baking resistant phenolic molding plastic

The invention provides a high-temperature baking resistant phenolic molding compound containing additive, which comprises the following components by weight percent: 30-48% of phenolic resin; (2) 10-40% of wood powder; (3) 10-30% of mineral filler; (4) 4.0-9.0% of hexamine; (5) 0.5-5.0% of phosphoric anhydride and (6) 0.5-5.0% of acrylic ester nano particles or silicon rubber nano particles. The invention also discloses a method for preparing the high-temperature baking resistant phenolic molding compound. The phenolic molding compound can be baked for 2h at the temperature of 250 DEG C, and does not crack, foam or deform; and compared with the common bakelite, the cost of the invention is not obviously increased.

Owner:上海欧亚合成材料股份有限公司

A kind of electrolyte solution and lithium ion secondary battery

ActiveCN103779607BImprove thermal stabilityIncreased high temperature capacity retentionSecondary cellsOrganic solventDecomposition

The invention discloses an electrolyte solution and a lithium-ion secondary battery. The electrolyte solution comprises an aprotic organic solvent, electrolyte lithium salt and an additive, wherein the additive is cyclic phosphoric anhydride; and the mass of the additive accounts for 0.01-10 percent of the total mass of the electrolyte solution. The lithium-ion secondary battery comprising the electrolyte solution can be subjected to electrochemical oxidation polymerization under the voltage of over 4.4V (vs.Li / Li+). By forming a polymer on the surface of a positive pole material, a good barrier is formed to cover strongly-oxidative active points of the positive pole material, and decomposition of a main solvent of the lithium-ion secondary battery is inhibited, so that the stability of the electrolyte solution under a high-voltage state and the high-voltage cycle and storage performances of a lithium-ion battery are improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate](https://images-eureka.patsnap.com/patent_img/612c6417-1bb1-4030-911a-20a36fce8964/BDA0000992003570000021.PNG)

![Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate](https://images-eureka.patsnap.com/patent_img/612c6417-1bb1-4030-911a-20a36fce8964/BDA0000992003570000022.PNG)

![Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate](https://images-eureka.patsnap.com/patent_img/612c6417-1bb1-4030-911a-20a36fce8964/FDA0000992003560000011.PNG)