Method for preparing cross-linked polyimide membrane

A sulfonated polyimide membrane and a technology of sulfonated polyimide are applied in the field of preparation of functional polymer materials to achieve the effects of low cost, improved service life and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

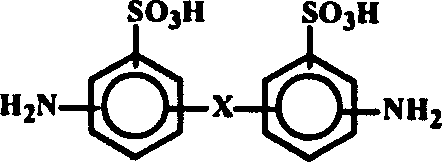

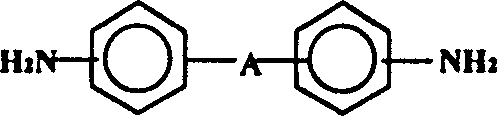

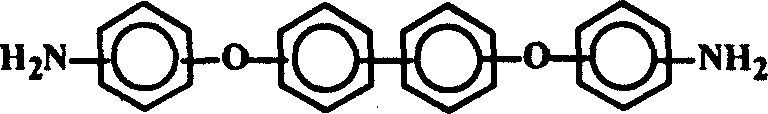

[0038] The preparation of embodiment 1 sulfonated polyimide NTDA-ODADS / BAPF (5 / 1):

[0039] NTDA refers to 1,4,5,8-naphthalic anhydride, ODADS refers to 4,4'-diaminodiphenyl ether-2,2'-disulfonic acid, BAPF refers to 9,9-bis(4-aminophenyl) fluorene;

[0040] Add 0.7200 g (2.0 mmol) of ODADS, 0.1392 g (0.4 mmol) of BAPF, 10 mL of m-cresol and 0.68 mL of triethylamine into a dry 100 mL three-necked flask equipped with a condenser and a nitrogen inlet and outlet. After the diamine monomer was completely dissolved, 0.6432 g (2.4 mmol) of NTDA and 0.42 g of benzoic acid were added. The reaction mixture was stirred at room temperature for 0.5 hours, then heated to 80°C for 4 hours, and then heated to 180°C for 20 hours. After the reaction, the resulting highly viscous polymer solution was diluted with 10 mL of m-cresol, and then slowly poured into 200 mL of methanol / hydrochloric acid solution with a volume ratio of 3:1 to obtain a fibrous precipitate, which was filtered and used ...

Embodiment 2

[0041] Preparation of embodiment 2 cross-linked sulfonated polyimide NTDA-ODADS / BAPF (5 / 1) membrane:

[0042] 1.8 grams of dry sulfonated polyimides obtained in Example 1 were dissolved in 20 mL of dimethyl sulfoxide containing 10 wt % phosphorus pentoxide, and the resulting solution was poured onto a glass plate at 80 ° C and 150 ° C. °C for 2 hours and 10 hours, respectively, and then dried at 150 °C for 20 hours under vacuum. The sulfonated polyimide was peeled off from the pouring glass plate, washed with deionized water to neutrality, and then dried under vacuum to obtain a sulfonated polyimide NTDA-ODADS / BAPF (5 / 1) film with a thickness of is 40 μm.

Embodiment 3

[0043] The performance of embodiment 3 cross-linked sulfonated polyimide NTDA-ODADS / BAPF (5 / 1) film:

[0044] The cross-linked sulfonated polyimide NTDA-ODADS / BAPF (5 / 1) film obtained in Example 2 was put into dimethyl sulfoxide for a solubility test, and it was found that the film was completely insoluble in dimethyl sulfoxide , indicating that crosslinking has occurred. The membrane was soaked in deionized water at 100°C for one month (720 hours), and it was found that the membrane still had good mechanical strength. The proton conductivity of the membrane was 0.13 S / cm at 60°C and 100% relative humidity, and 0.20 S / cm at 130°C and 100% relative humidity.

[0045] The tensile strength of the film soaked in deionized water at 100° C. for one month was immediately measured, and the measured tensile strength was 10-12 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com