Preparation of sodium monofluorophosphate

A technology of sodium monofluorophosphate and sodium metaphosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as low efficiency, long time required, fluorine loss, etc., achieve low energy consumption and reduce production costs , the effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

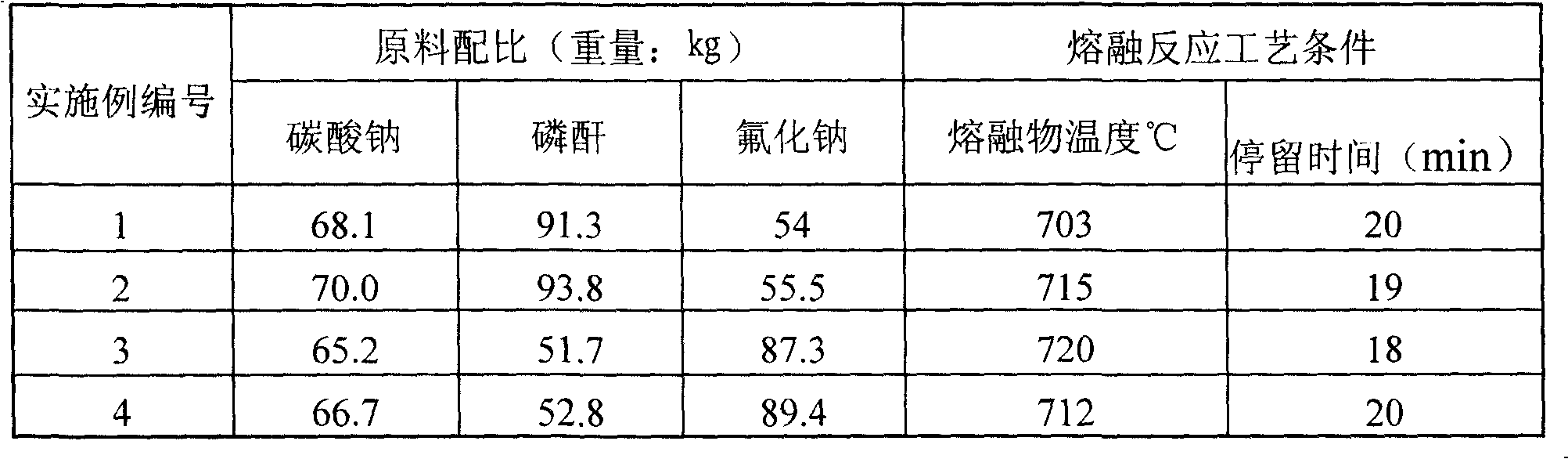

Embodiment 1、2、3、4

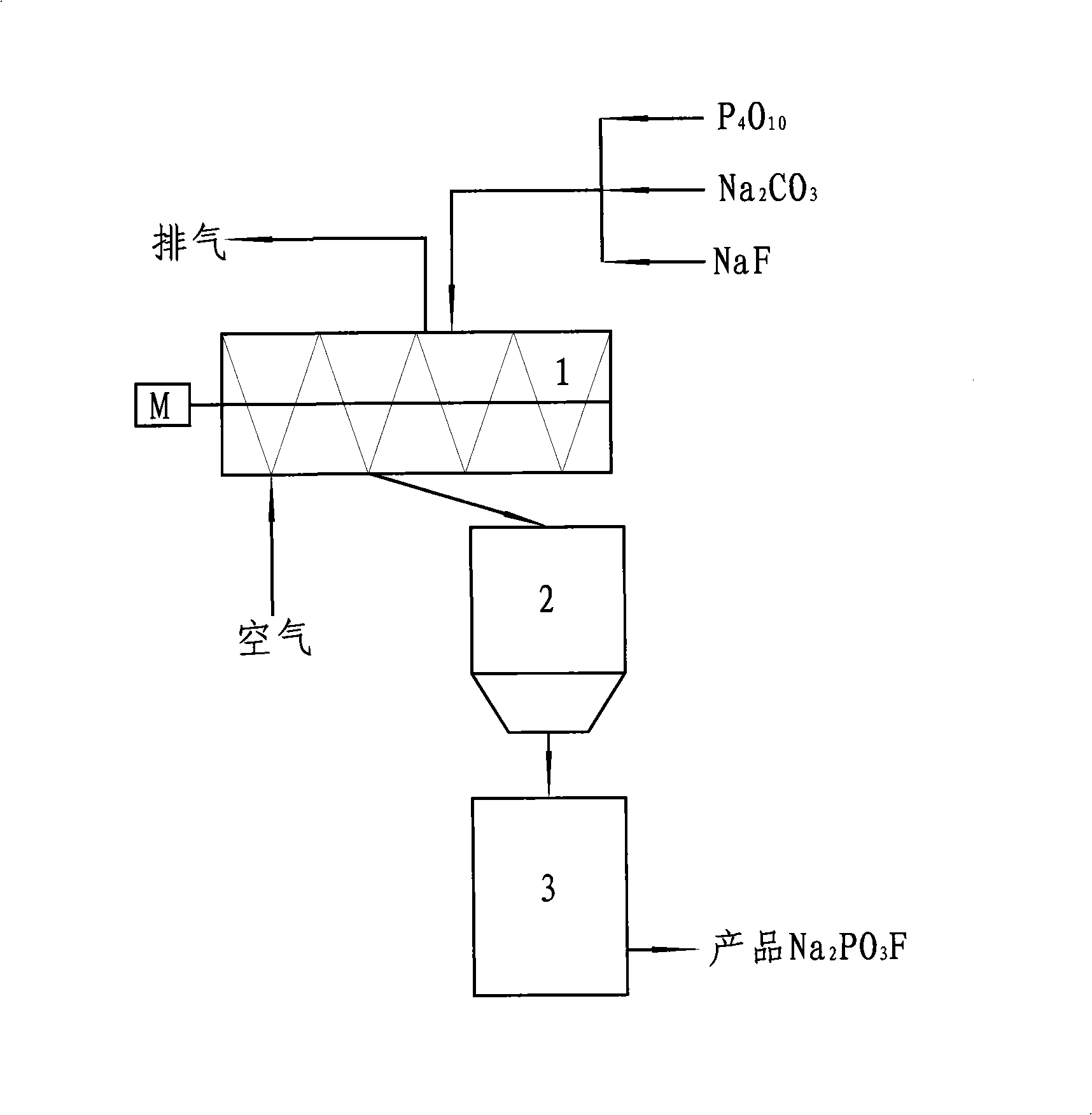

[0028] The preparation method of sodium monofluorophosphate as shown in the figure. First, add powdered phosphoric anhydride, sodium carbonate, and sodium fluoride into the mixer 1 with stirring according to the weight ratio of Table 1, and the temperature of the mixture slowly rises by itself. When the temperature of the mixed material rises to 250°C, air cooling is introduced into the reactor to control the temperature of the material between 250°C and 380°C, until the reaction is completed, the material temperature drops, and when the material temperature drops below 100°C, it is released The material enters the intermediate bin, and the material obtained is a mixture of sodium metaphosphate and sodium fluoride.

[0029] The mixture is fed from the mixing intermediate bin 2 into a vortex heating and melting reactor 3, the residence time of the melt is controlled by controlling the feeding rate, and the temperature of the melt is controlled by adjusting the heating power. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com