Patents

Literature

47results about "Condensed phosphoric acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

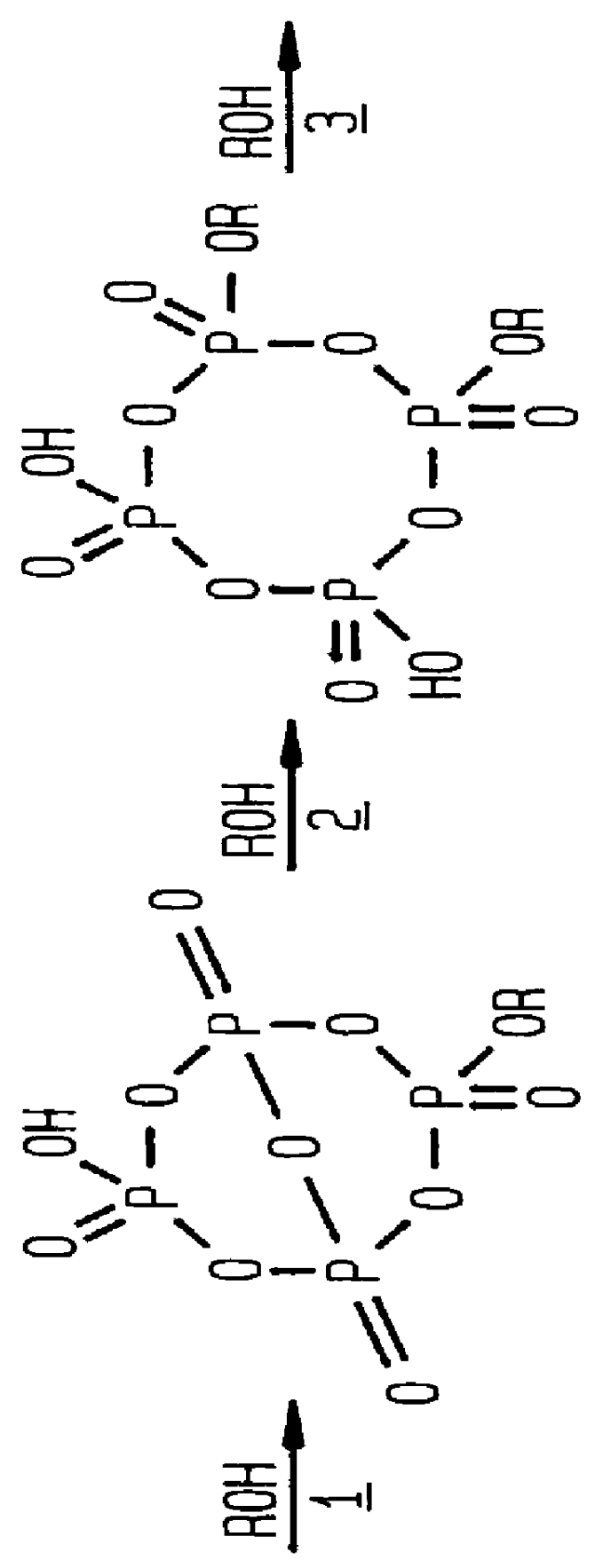

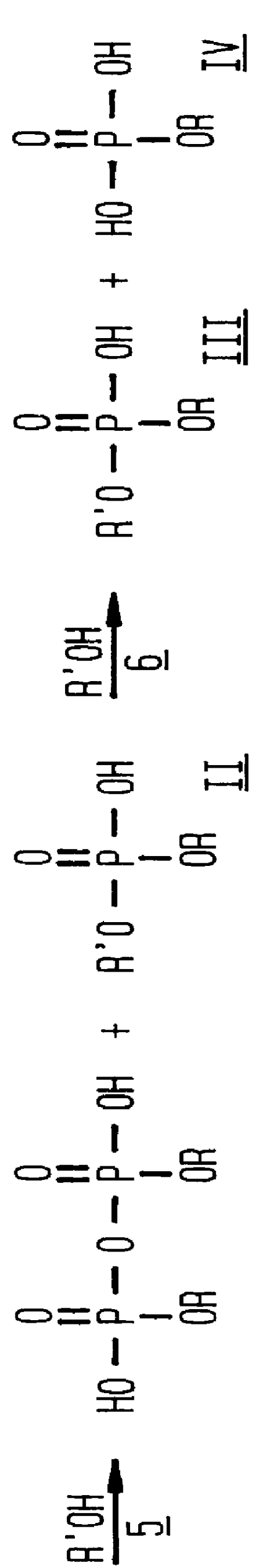

Phosphation reagent

The invention relates to a process for producing a unique phosphation reagent and to a simple, single-stage process utilizing is reagent to produce alkyl phosphate esters having high monoalkyl phosphate content in combination with low dialkyl phosphate, trialkyl phosphate, phosphoric acid and residual alcohol.

Owner:RHODIA OPERATIONS SAS

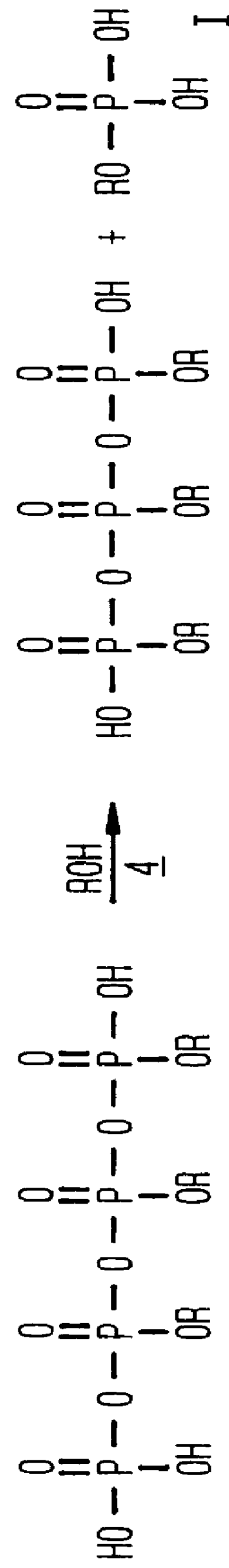

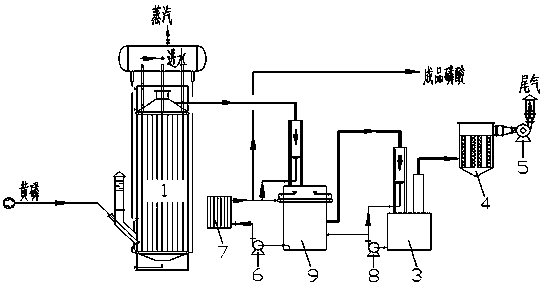

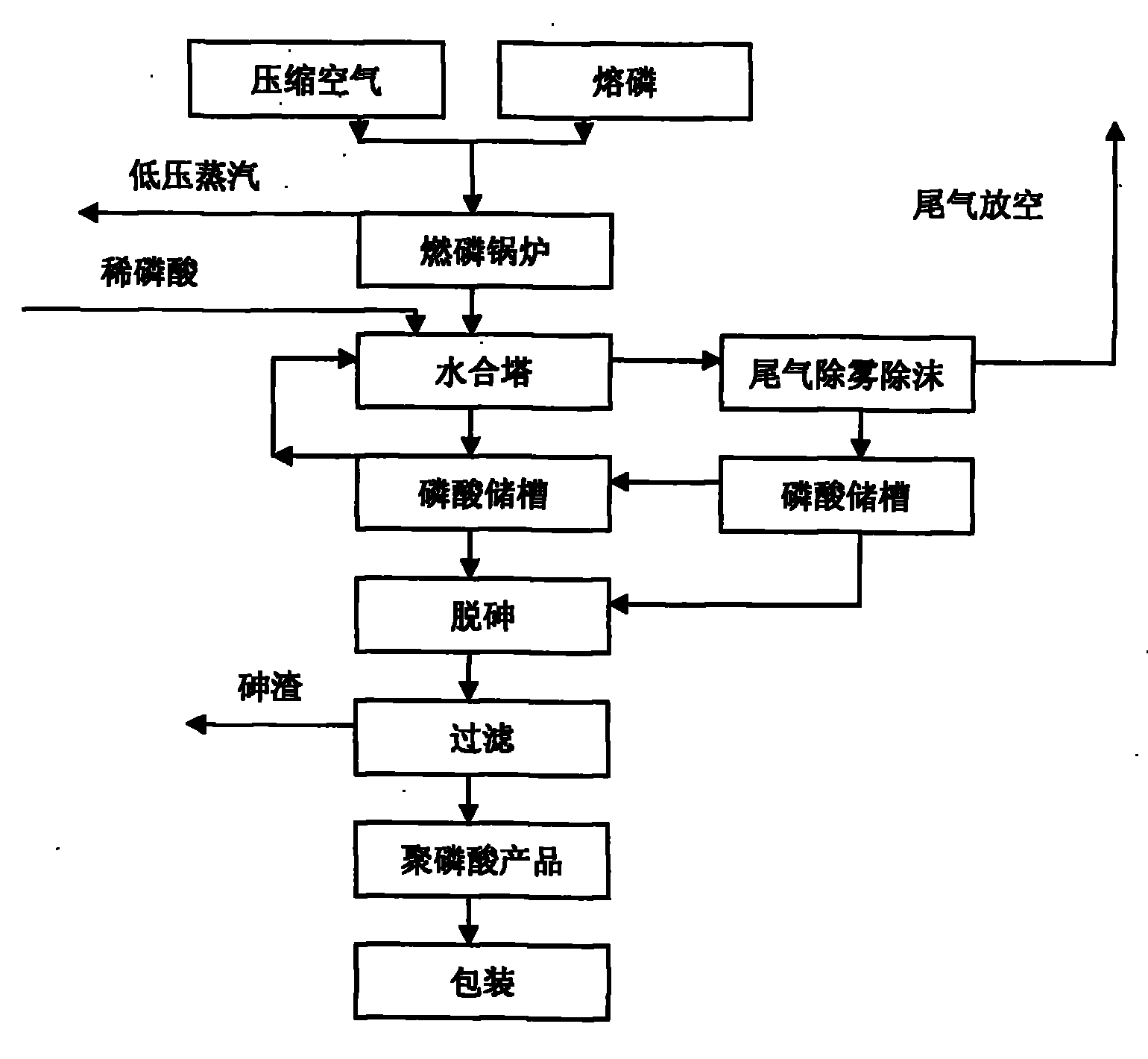

Method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid

ActiveCN101531354ALower packagingReduce logistics costsChemical industryCondensed phosphoric acidsO-Phosphoric AcidEconomic benefits

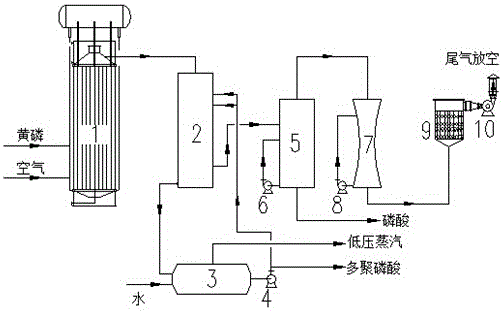

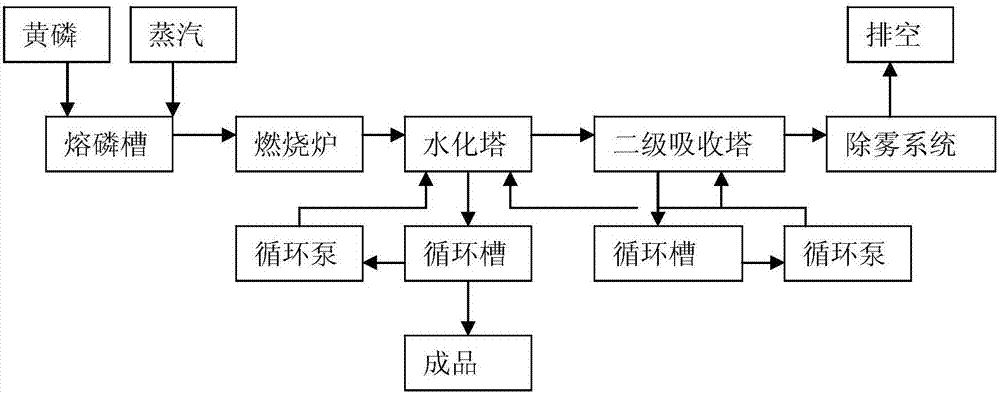

A method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid, including following steps: mixing yellow phosphorus and air with the proportion of 1kg yellow phosphorus to 6.3-6.6 m3, burning, absorbing the obtained P2O5 by diluted acid; applying the obtained phosphoric acid into a phosphoric acid groove; then using acid pump to send into a condenser to remove the heat; then sending the phosphoric acid into a hydration tower to circularly spray and absorb P2O5 to increase the concentrated phosphoric acid; cycling without stop to obtain the phosphoric acid having 82%-84% P2O5. The recovery coefficient of phosphorus is more than 98%. The obtained product reaches the standard of the food-level phosphoric acid. This invention may greatly reduce the cost of package and distribution of the phosphoric acid production enterprise via using the wet-method phosphoric acid or hot-method phosphoric acid of the concentrated content of the phosphoric acid anhydride of less than 100% obtained by yellow phosphorus burning. This invention does not need to consume the extra energy, and can fully use the burning heat and the hydration heat of the yellow phosphorus; the generated steam can be recycled. So this invention has the advantages of saving energy and greatly reducing the production cost of the polyphosphoric acid, with remarkable social and economic benefits.

Owner:WENGFU (GRP) CO LTD

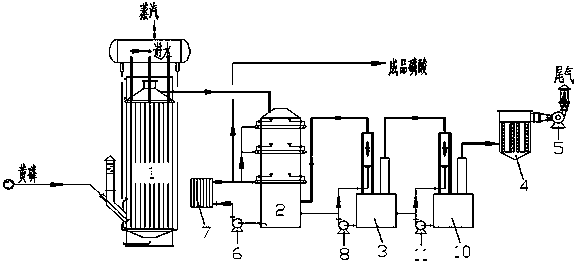

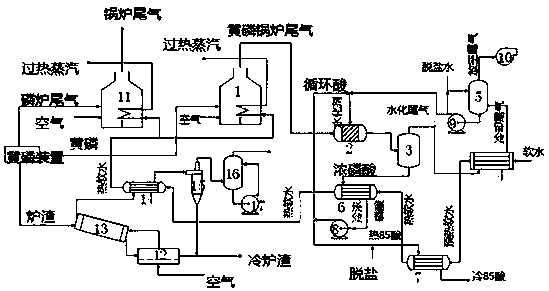

Hot-process phosphoric acid production device with low-temperature heat energy recovery

ActiveCN105731405AImprove absorption rateReduce wasteEnergy inputCondensed phosphoric acidsPhosphoric acidChemistry

The invention discloses a hot-process phosphoric acid production device with low-temperature heat energy recovery. The device comprises a combustion tower, a first-level absorption tower, a tube-shell boiler, a second-level absorption tower, a Venturi, a mesh mist eliminator and an induced draft fan, wherein the temperature of polyphosphoric acid in the first-level absorption tower is 150-200 DEG C. According to the hot-process phosphoric acid production device, the heat energy of polyphosphoric acid is converted into low-pressure steam for recovery by the tube-shell boiler; and the manufacturing cost of the low-temperature heat energy recovery device is low, 10-30% of the heat energy of the combustion heat of yellow phosphorus can be recycled, the water resource consumption and environmental pollution are reduced, and the device conforms to the production technology requirements of high efficiency, energy conservation, environmental protection and cleanness.

Owner:KUNMING UNIV OF SCI & TECH

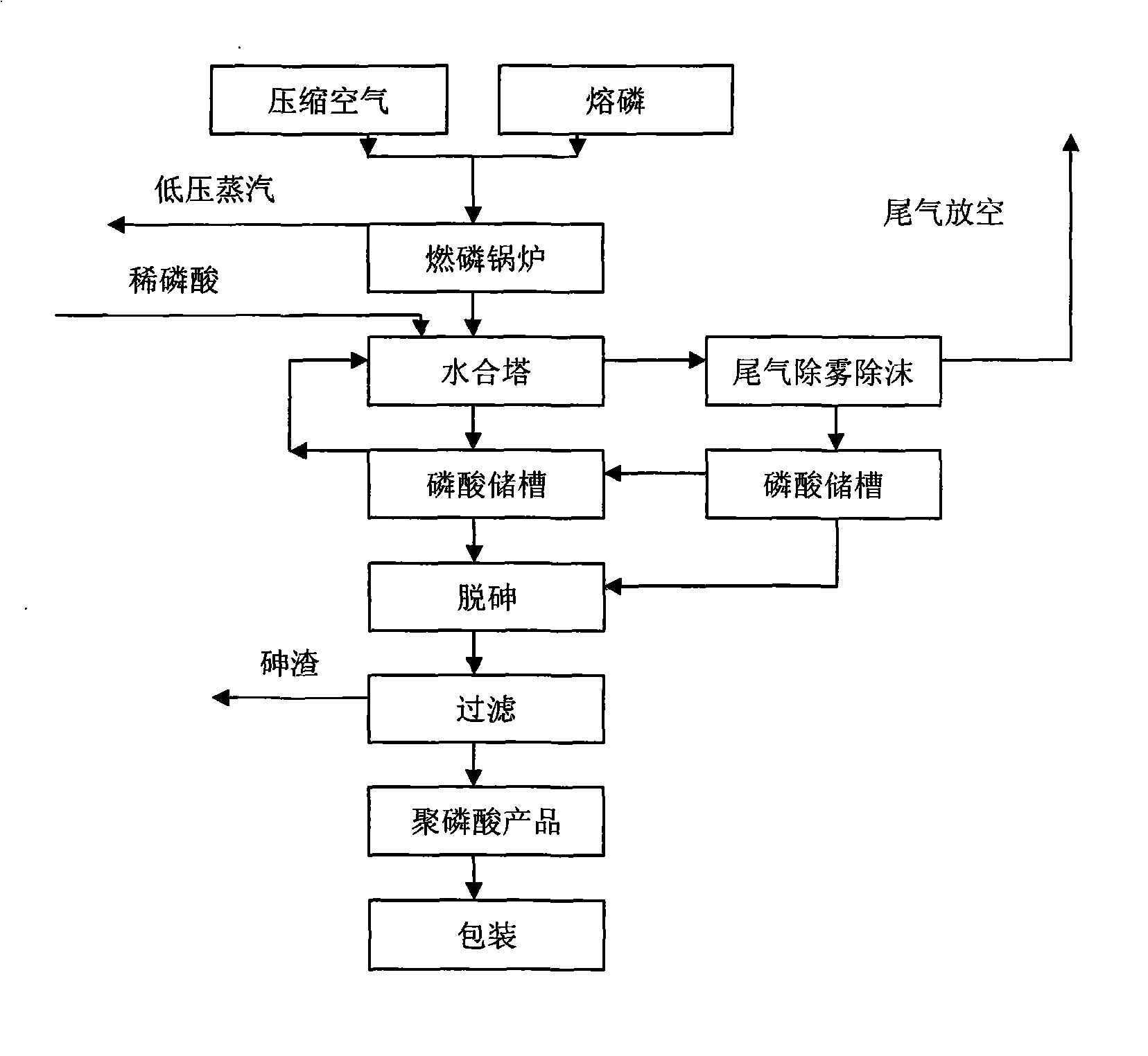

Method for producing high-quality polyphosphoric acid

ActiveCN103818890AProduction system is stableIncrease productivityCondensed phosphoric acidsCombustionInorganic Chemical

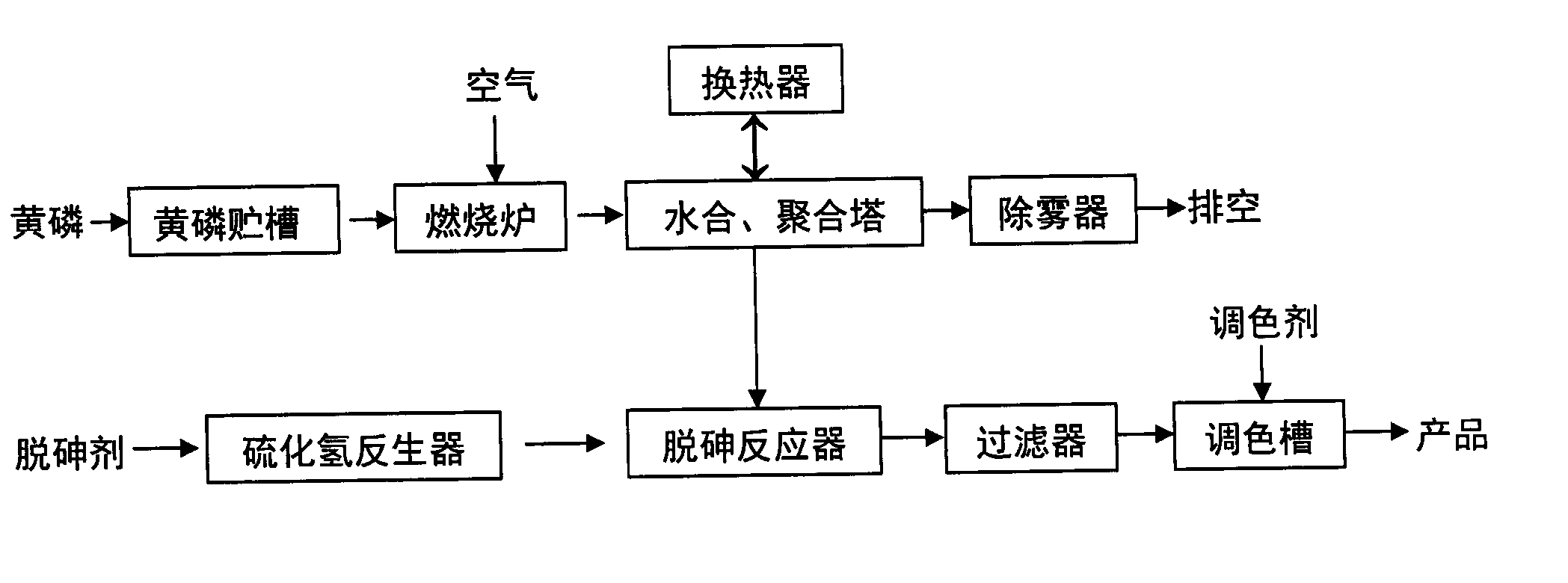

The invention belongs to the technical field of hot-process phosphoric acid production in the inorganic chemical industry and relates to a method for producing a high-quality polyphosphoric acid. The method is capable of further improving the advancement of the polyphosphoric acid production process and the quality of the obtained product, and as a result, the concentration of the obtained polyphosphoric acid product, converted into the content of orthophosphoric acid, ranges from 100% to 116%, and the content of arsenic in impurities contained in the obtained polyphosphoric acid product is low to the concentration range from 0.1ppm to 1.9ppm; in implementation, the production method comprises the major process steps of burning yellow phosphorus with air in a combustion furnace to generate phosphorus pentoxide flue gas, enabling the phosphorus pentoxide flue gas to enter a hydration-polymerization tower and react to generate the polyphosphoric acid, and carrying out arsenic removal and filtering by virtue of hydrogen sulfide gas, and then carrying out treatments such as color modulation on the polyphosphoric acid obtained through filtering to obtain the finished product.

Owner:BLACK P2 USA INC

Method for producing polyphosphoric acid

ActiveCN101269805AAvoid high temperature overheatingReduce dosageCondensed phosphoric acidsPhosphoric acidReaction temperaturePhosphoric acid

The invention discloses a manufacturing method of polyphosphoric acid, which comprises the following steps: 500g of wet phosphoric acid purification acid or thermal phosphoric acid of which the quality percentage concentration is 75-85percent is taken to be added into a vacuum distillation unit, the temperature rises to 160-300 DEG C in a speed of 5 DEG C / min, and the vacuum distillation unit is decompressed and distilled for 1-2h under the conditions that the vacuity is 0.0-0.085Mpa and the stirring speed is 100-300rpm; the phosphoric acid after water elimination is placed into a polymerization reactor which can control reaction temperature and is provided with an electric agitator, the quantity of the added phosphorus pentoxide is 41.4-49.2percent of raw material acid quantity and peroxide is 0.0032-0.0007percent of the raw material acid quantity under the conditions that the temperature is 80-150 DEG C and the stirring speed is 200-500rpm, and the polymerization is performed for 3-6h; when the reaction is over, the temperature of products is reduced to the normal temperature to obtain the polyphosphoric acid. The manufacturing method has the advantages of simple technics, easy industrialization, low cost, good quality, moderate operating conditions, low investment, cleaning and no pollution.

Owner:WENGFU (GRP) CO LTD

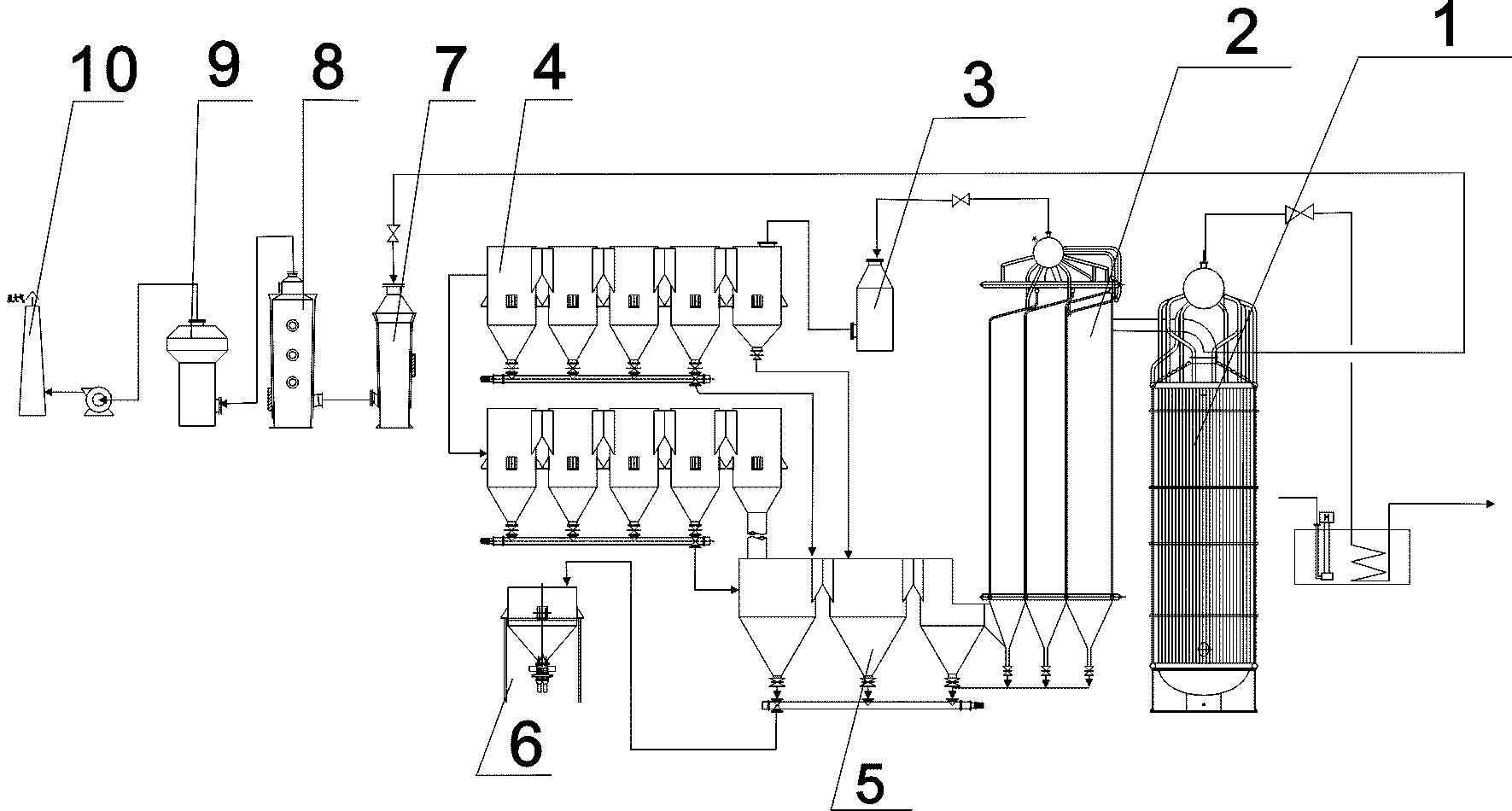

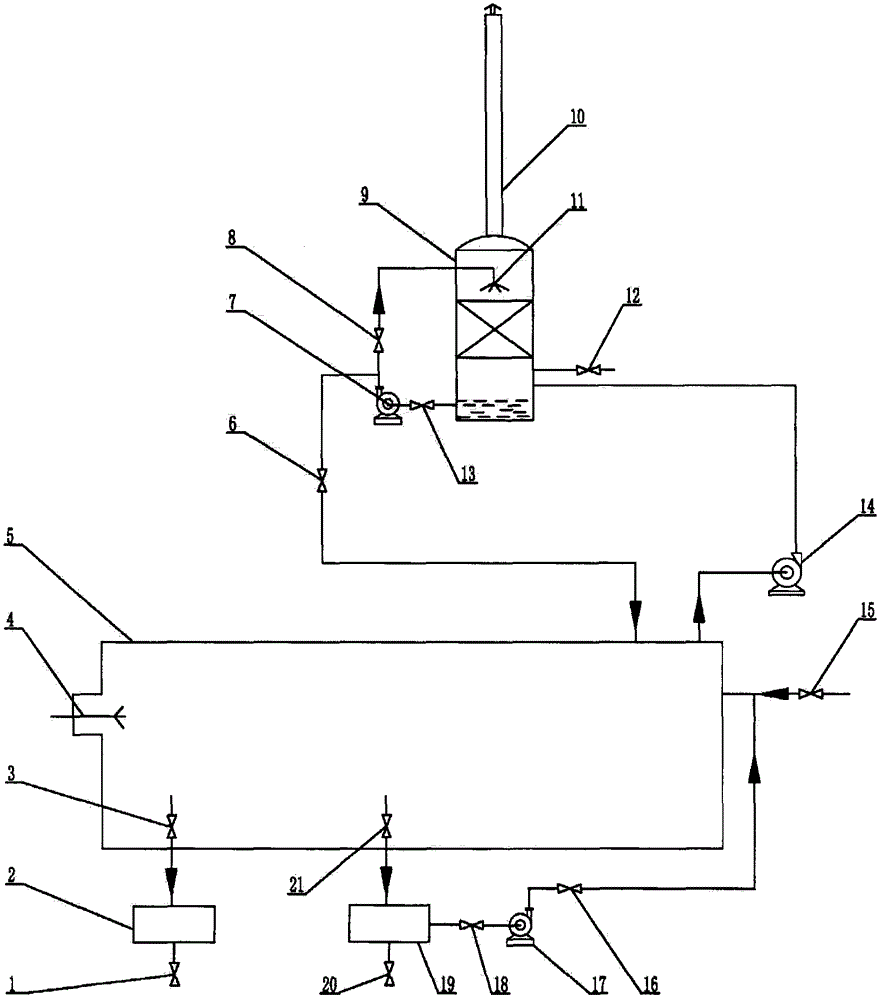

Phosphoric acid production device by employing hot method

ActiveCN104261370AReduce resistanceEmission reductionChemical industryCondensed phosphoric acidsVapor–liquid separatorCombustion

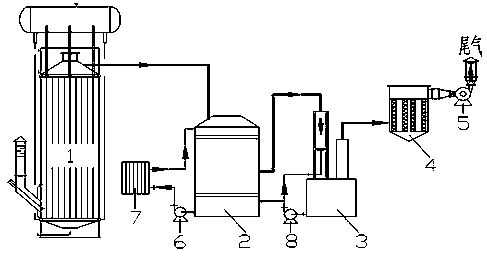

The invention discloses a phosphoric acid production device by employing a hot method, and belongs to the technical field of energy-saving technologies of phosphoric acid production by employing a hot method. The device comprises a combustion tower, an absorption tower, a dynamic wave demister, a gas-liquid separator and an induced draft fan, wherein the combustion tower is communicated with the inlet in the top of the absorption tower; the absorption tower is connected with the dynamic wave demister; the dynamic wave demister is communicated with the induced draft fan through the gas-liquid separator; meanwhile, the absorption tower is connected with a heat exchanger through an absorption tower circulating pump; the heat exchanger is communicated with the absorption tower to form a loop through a pipeline; and the dynamic wave demister and a demister circulating pump form a loop through a pipeline. According to the device, the resistance of the system is reduced, the dosage of circulating acid and circulating water is lowered, the installed capacity of the system is greatly lowered, energy conservation and consumption reduction are achieved, the production capacity of the system is improved, and the device has the characteristics of low investment cost, small floor area, low power consumption, low production cost, and low coal resource and water resource consumption.

Owner:KUNMING UNIV OF SCI & TECH

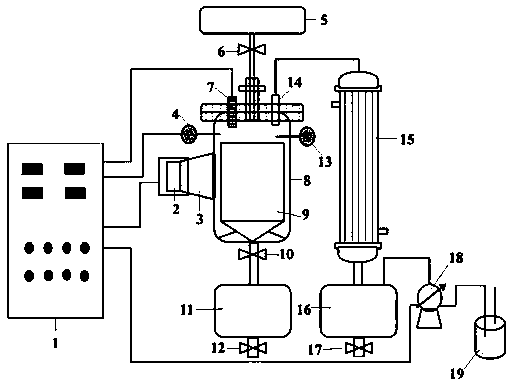

Method and equipment for preparing polyphosphoric acid by phosphoric acid microwave flash evaporation

PendingCN109264687AAvoid lostReduce energy consumptionChemical industryCondensed phosphoric acidsInlet valvePhosphoric acid

The invention discloses a method and equipment for preparing polyphosphoric acid by phosphoric acid microwave flash evaporation. The method comprises the following steps of heating by microwaves undera vacuum condition; performing flash evaporation on raw liquid of phosphoric acid, concentrating and polymerizing, so as to obtain the polyphosphoric acid; condensing tail gas of flash evaporation, and recycling. The equipment comprises a microwave generator, a microwave waveguide, a pressure transmitter, an overhead tank, a liquid intake valve, an infrared temperature sensor, a flash evaporationtank, a reaction tank, a liquid outlet valve, a concentrated liquid collecting tank, a valve, a condensing tower, a condensate collecting tank, a collecting tank valve, a vacuum pump, and a tail gasabsorbing device. The equipment has the advantages that the equipment is simple, the heat efficiency is high, the energy consumption is low, the technological process is short, and the treatment speedis quick; compared with the traditional method, the chroma, purity and the like of the produced polyphosphoric acid are better; a continuous, semi-continuous or discontinuous independent manner can be adopted for production, and the production manners are diversified; the problems of easiness in corrosion of a heat exchange surface and a forced circulating pump, high electric consumption, low product purity and the like in the traditional evaporation process are solved, and the purpose of high-efficiency preparation of the polyphosphoric acid with high polymerizing degree can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Process and device for selectively producing phosphorus pentoxide

InactiveCN103723695AReduce labor intensityEnter in timePhosphorus oxidesCondensed phosphoric acidsCombustionDesiccant

The invention discloses a process for selectively producing phosphorus pentoxide. By using yellow phosphorus as a basic material and sulfuric acid as a drying agent, the phosphorus pentoxide is prepared by combustion in a phosphorus combusting furnace, phosphorus pentoxide smoke prepared by combustion of the yellow phosphorus is introduced into a multistage sedimentation system after being cooled through a cooling system, and sent to a material collecting bin after being further cooled by the multistage sedimentation system to prepare phosphorus pentoxide powder, and a tail gas is exhausted after being purified; or the phosphorus pentoxide smoke prepared by combustion of the yellow phosphorus combustion is sequentially introduced into a polyphosphoric acid absorbing tower and a phosphoric acid absorbing tower for being absorbed after being cooled by the cooling system so that polyphosphoric acid and phosphoric acid are respectively obtained, and the tail gas is exhausted after being absorbed through a foam absorbing tower, an ammonia absorbing tower and a fiber demister. According to the process, equipment is capable of reasonably optimizing a structure of production equipment; the purity of the produced phosphorus pentoxide reaches above 99.5 percent, and the phosphorus pentoxide can be largely produced.

Owner:HUBEI LIUSHUGOU CHEM TECH

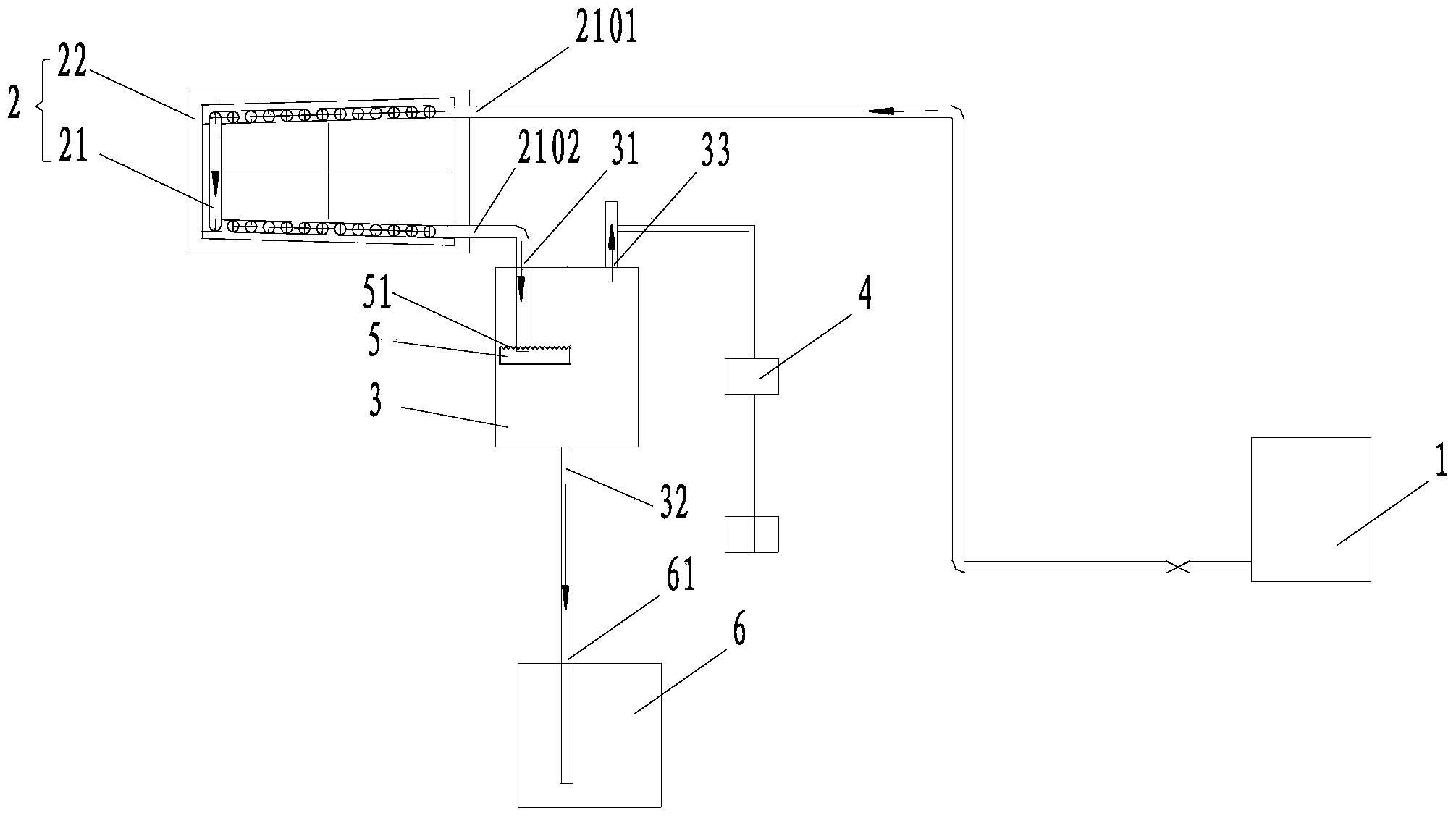

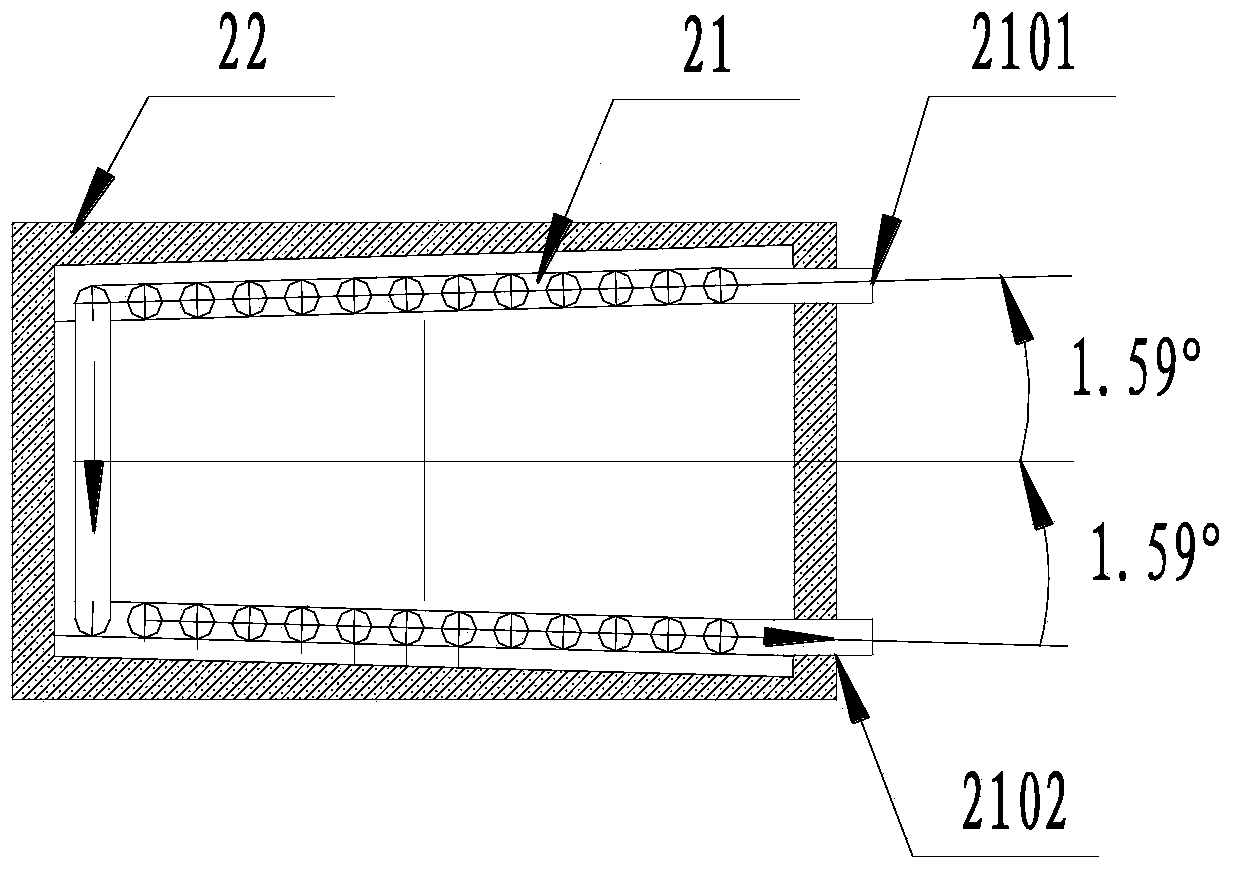

Preparation method for polyphosphoric acid

ActiveCN103832986AReduce manufacturing costComponent distribution is evenCondensed phosphoric acidsChemical industryHigh concentration

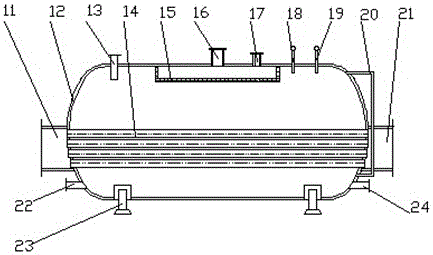

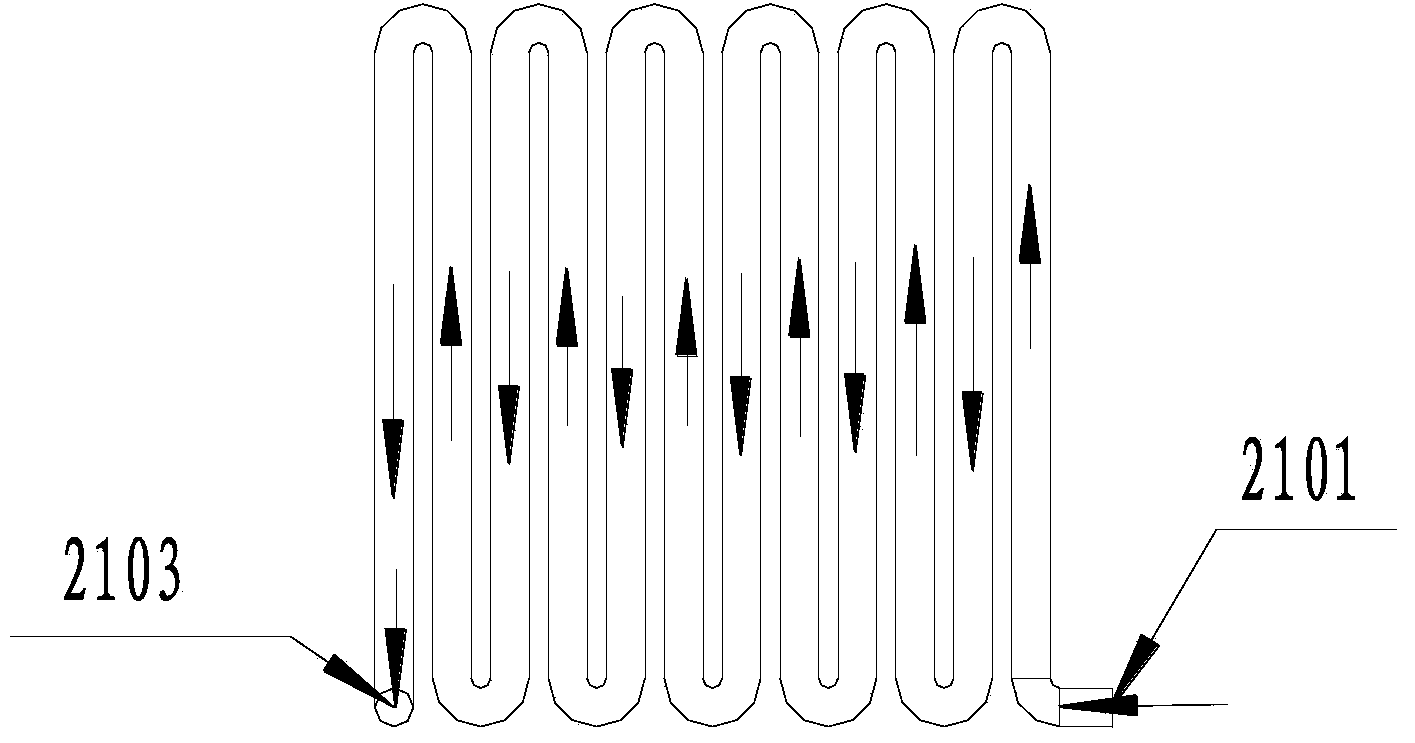

The invention relates to the field of phosphorus chemical industry, in particular to a preparation method for polyphosphoric acid. The method for preparing polyphosphoric acid includes: letting dilute phosphoric acid enter a heater through a heat exchange tube acid inlet to be heated to 185DEG C-230DEG C, then discharging the dilute phosphoric acid out of the heater from a heat exchange tube acid outlet, and making the dilute phosphoric acid enter a separator to undergo flash concentration, keeping the vacuum degree in the separator ranging from -500 to -700mmHg, discharging the concentrated acid liquor out of the separator through an acid outlet tube at the lower end of the separator, and leading the concentrated acid liquor into a concentrated acid tank through a concentrated acid tank acid inlet to undergo cooling and storage. The heat exchange tube is coiled in an S shape in the heater, from the heat exchange tube acid inlet to the heat exchange tube acid outlet, the heat exchange tube tilts downward at an angle of 1-3 degrees. The preparation method for polyphosphoric acid provided by the invention has a simple process, can prepare high concentration polyphosphoric acid from dilute phosphoric acid by one-step polymerization. By taking dilute phosphoric acid as the raw material, the acid liquor cannot adhere to the heat exchange tube wall, thus avoiding blocking of the heat exchange tube. Further, the prepared polyphosphoric acid product has uniformly distributed components.

Owner:绵阳启明星磷化工有限公司

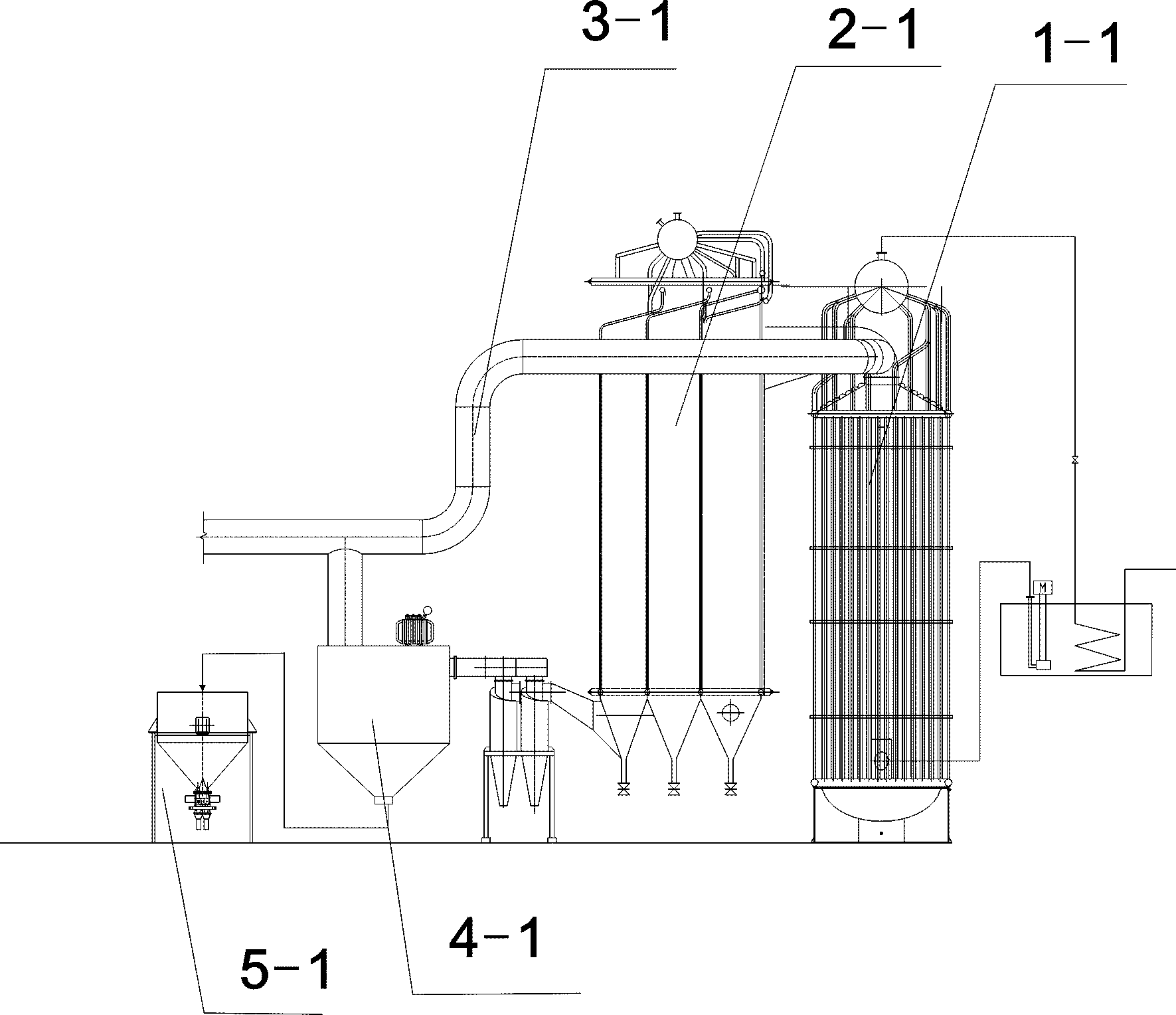

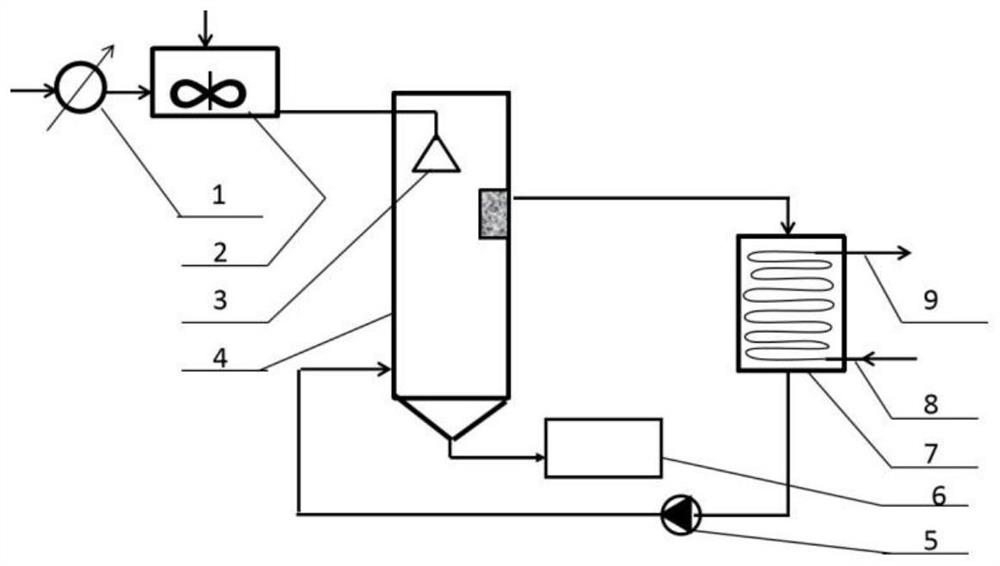

Industrial-grade polyphosphoric acid production process and system

PendingCN107128888AQuality improvementSimple processChemical industryCondensed phosphoric acidsEvaporationPhosphoric acid

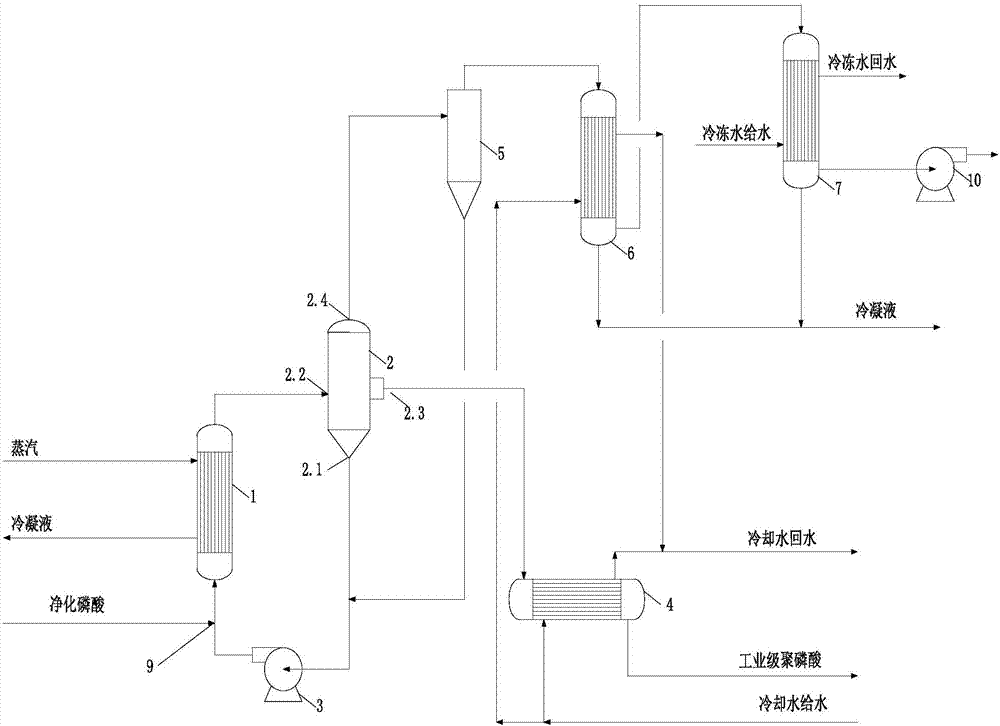

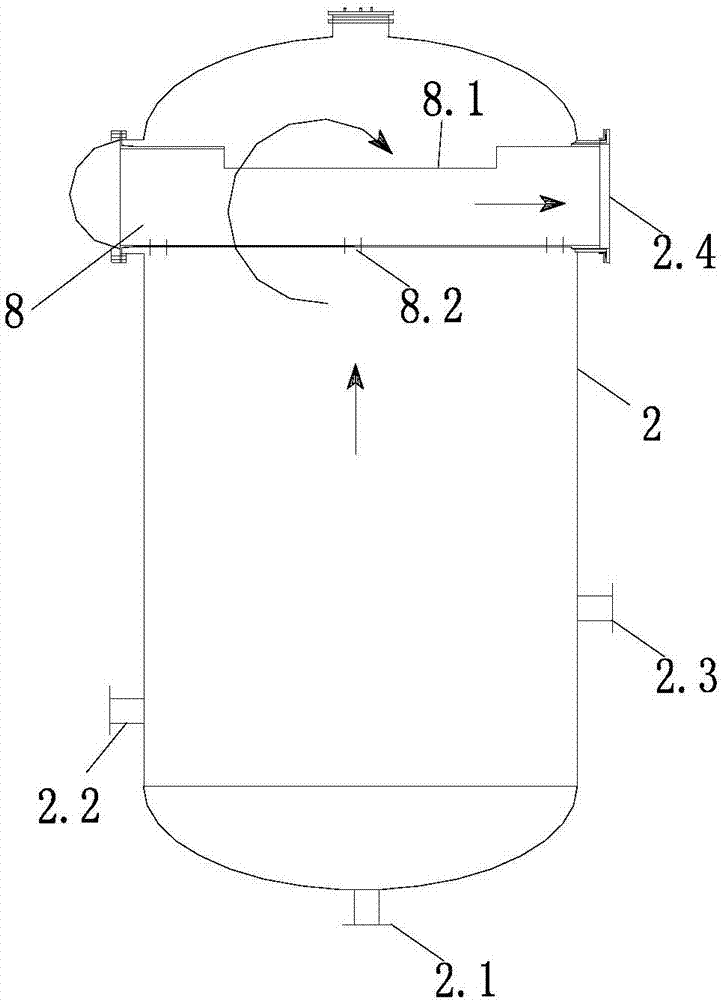

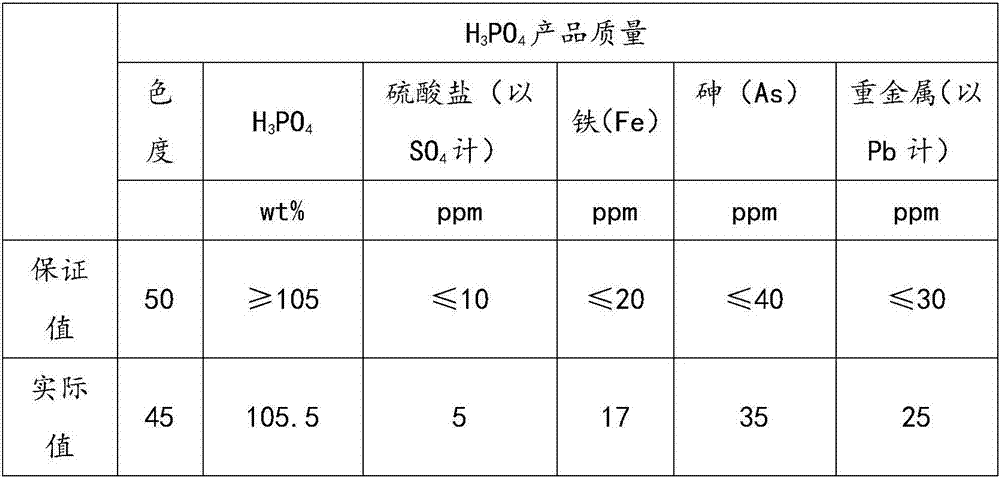

The invention discloses an industrial-grade polyphosphoric acid production process and system and solves the problem that existing methods for producing industrial-grade polyphosphoric acid through wet-process purifying of phosphoric acid are harsh and complex in process condition and low in recovery rate and concentration. The technical scheme includes: feeding circulating acid into an acid heater for heating, feeding the same into a flashing chamber for flashing evaporation, and feeding obtained circulating acid back into the acid heater through a circulating pump for cyclic heating; when concentration of phosphoric acid after being flash-evaporated and concentrated in the flashing chamber is 68-76%P2O5, guiding out part of the circulating acid as finished product acid to be fed into a finished product acid cooler for cooling, and supplementing purified phosphoric acid into the rest of the circulating acid as circulating acid to be sequentially fed into the acid heater for cyclic heating and into the flashing chamber for cyclic flashing evaporation, wherein inlet temperature of the acid heater is controlled to 190-195 DEG C while outlet temperature of the same is controlled to 195-200 DEG C. The process is simple, easy in condition control, high in P2O5 yield and capable of saving energy and lowering consumption. The system is reliable and low in equipment investment and running cost.

Owner:WUHUAN ENG

Method and equipment for producing polyphosphoric acid with wet process phosphoric acid

ActiveCN106672931ASolve the problem of easy fouling and difficult to deal withEasy to operate and controlChemical industryCharge manipulationChemical industryEvaporation

The invention belongs to the technical field of phosphoric acid production in the inorganic chemical industry, and relates to a novel production method and equipment for producing polyphosphoric acid with wet process phosphoric acid. According to the method, a reverberatory furnace is mainly adopted innovatively, the equipment such as a burner nozzle, a polyphosphoric acid tank, a low polyphosphoric acid circulating pump, a fume extractor, a filler washing tower and a plurality of control valves is additionally arranged, and the wet process phosphoric acid is used as a raw material for concentrated polymerization production of the polyphosphoric acid. The reaction equipment is reliable and stable, and easy and convenient to operate and control, and solves the problem that scales easily deposit on tubes of a tubular heat exchanger in single-stage or multi-stage evaporation of the wet process phosphoric acid and are stubborn at home and abroad at present. Temperature control is moderate, and the phenomenon that a large number of acid particles are carried away due to local overheating and excessively high temperatures is avoided. No vacuum mode is required, and energy is saved. Two-stage product output is adopted, thereby facilitating the improvement on the production efficiency. Tail gas is recycled by a cleaning solution which then is used as a raw material, the product yield is increased, exhaust emission is reduced, and the environmental protection is facilitated.

Owner:广西越洋生物技术有限公司

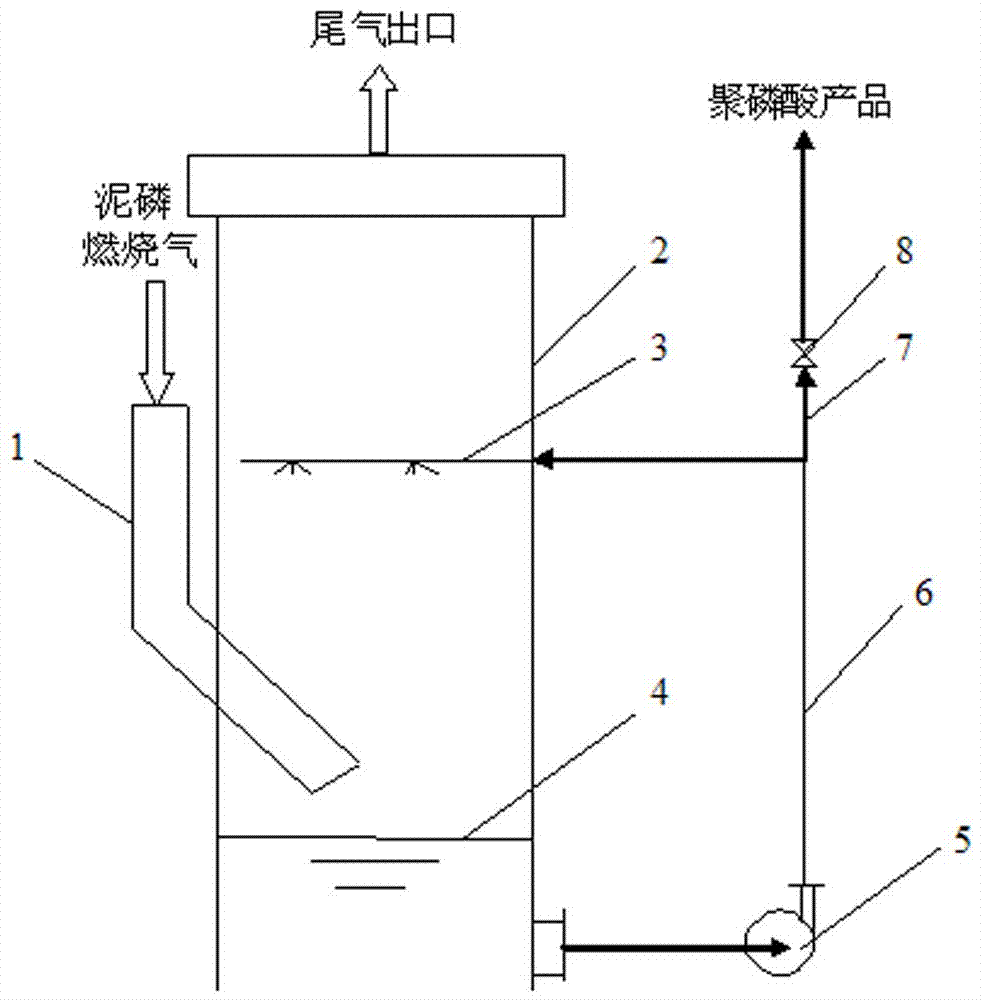

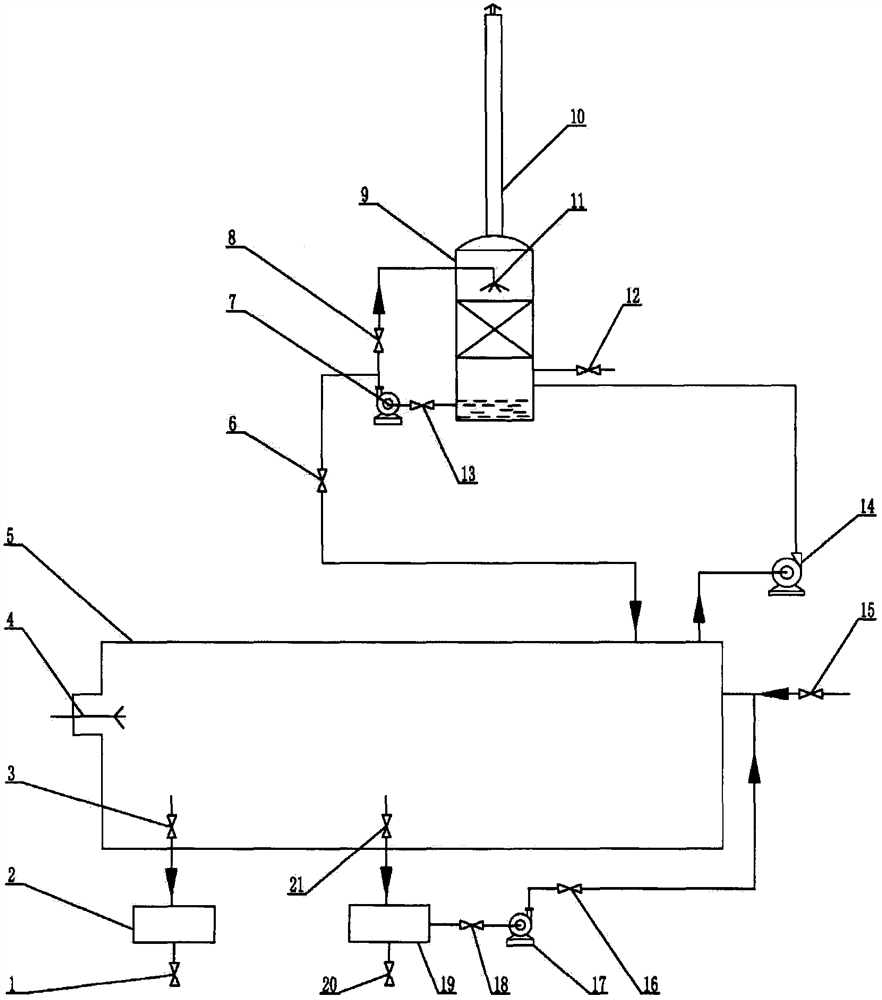

Polyphosphoric acid production method using device for making acid from phosphorous slurry

InactiveCN106865515AGuaranteed uptimeOvercome the loopholesCondensed phosphoric acidsHydration reactionCounter flow

The invention provides a polyphosphoric acid production method using a device for making an acid from phosphorous slurry. The polyphosphoric acid production method using the device for making an acid from phosphorous slurry includes the steps: adding a phosphorous slurry byproduct from yellow phosphorous production to a phosphorous slurry groove, heating the phosphorous slurry to 70-80 DEG C, stirring and mixing the phosphorous slurry uniformly, and pumping the uniformly stirred and mixed phosphorous slurry into a nozzle in a combustion tower; atomizing the phosphorous slurry by compressed air, oxidizing the atomized phosphorous slurry with excessive 2.0 to 2.5 times of combustion-supporting air in the combustion tower to generate phosphorous slurry high temperature combustion gas containing P2O5 and water vapor, controlling the temperature at 1100-1200 DEG C, sending the phosphorous slurry high temperature combustion gas into a lower part of a hydration tower, and conducting a hydration reaction on the phosphorous slurry high temperature combustion gas and circularly sprayed phosphoric acid in a counter-flow manner, wherein the temperature of the circularly sprayed phosphoric acid is controlled at 80-100 DEG C, and heights of a circulating phosphoric acid liquid level and a phosphorous slurry high temperature combustion gas inlet tube are controlled to 400-600 millimeters; and controlling tail gas temperature at 90 DEG C or below, and directly discharging the phosphoric acid with the concentration in percentage by weight of 95%-105% from a circulating acid tube. According to the polyphosphoric acid production method using the device for making an acid from phosphorous slurry, the existing process and equipment for making an acid from phosphorous slurry are fully used for producing polyphosphoric acid; a lot of equipment investments are saved; the technological process is simplified; the energy consumption is reduced; and the method is especially suitable for the optimization and efficient utilization of the existing device for making an acid from phosphorous slurry, so that products produced by the existing device are increased dramatically in value, the scope of market application is wide, and economic benefits are significant.

Owner:YUNNAN TIANAN CHEM CO LTD

Method for purification of phosphoric acid high purity polyphosphoric acid

InactiveUS6861039B1Good effectEfficient removalCondensed phosphoric acidsHigh concentrationHydrogen halide

The present invention provides a purification method of phosphoric acid, which includes bringing phosphoric acid containing arsenic into contact with hydrogen halide, thereby to remove the arsenic from the phosphoric acid, and a purification method of phosphoric acid, which includes bringing phosphoric acid containing arsenic into contact with hydrogen halide in the presence of a compound capable of generating hydrogen halide under acidic conditions. According to the method for purifying phosphoric acid of the present invention, a completely new method for removing arsenic in phosphoric acid is provided, which does not require a filtration or deaeration step or shows a great amount of residual sodium, unlike a sulfide coagulation method. This method is applicable to high concentration phosphoric acid, particularly polyphosphoric acid, and can be practiced at a low cost. In addition, a conventionally nonexistent high purity polyphosphoric acid having an arsenic (As) content of not more than 1 ppm and low contents of heavy metal, silica, sodium and the like can be provided.

Owner:TOYOBO CO LTD

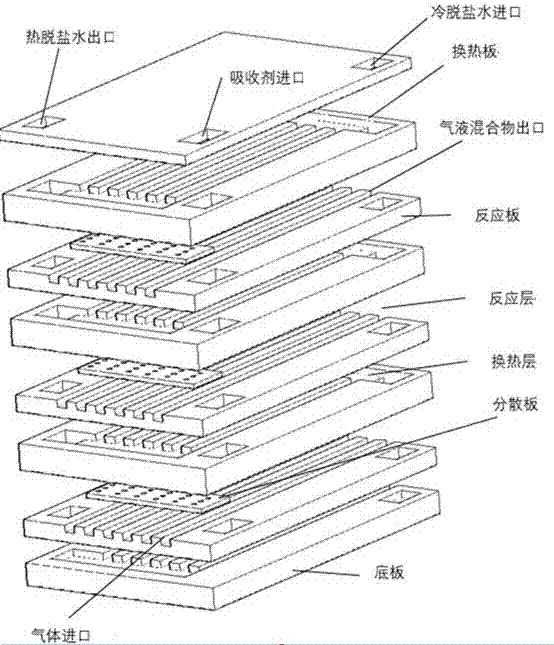

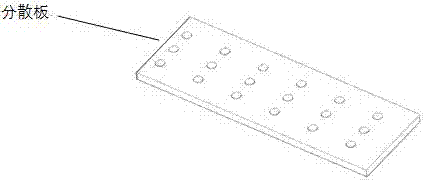

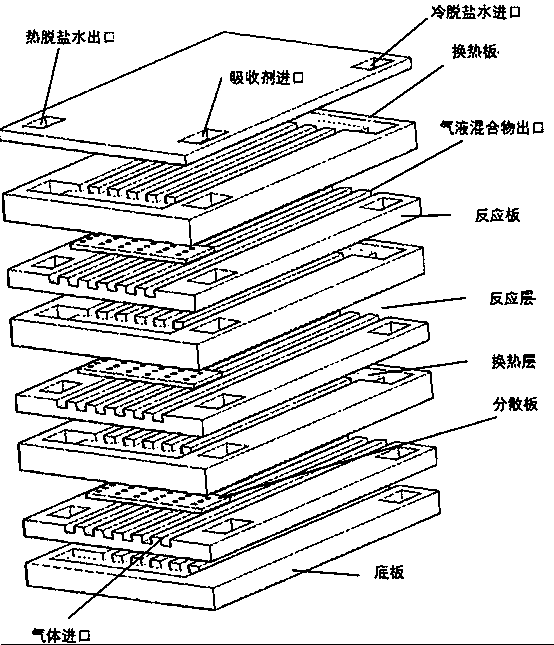

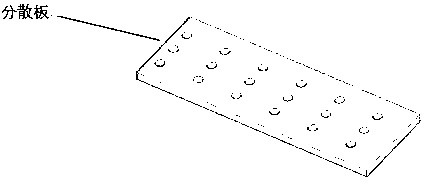

Heat energy recovery method for combining heat-process phosphoric acid and polyphosphoric acid micro absorption and device thereof

ActiveCN107200314AEfficient recyclingReduce manufacturing costEnergy inputCombustion technology mitigationThermal energyRecovery method

The invention discloses a heat energy recovery method for combining heat-process phosphoric acid and polyphosphoric acid micro absorption and a device thereof. According to the method, a micro absorption heat exchanger is used for recovering heat of reaction heat of phosphorus pentoxide and water; the heat of furnace slag is recovered through a furnace slag heat recovery device; the recovered heat of the reaction heat and the heat of the furnace slag are simultaneously connected into an air heat exchanger to prepare hot soft water; the hot soft ware is conveyed to a yellow phosphorus furnace and a phosphorus furnace tail gas boiler through pipelines for overheating steam; through combining the reaction heat, the furnace slag heat, the byproduct tail gas combustion heat and the yellow phosphorus combustion heat, the efficient recovery and utilization of the heat energy is realized. The goals of producing heat-process phosphoric acid or polyphosphoric acid by low energy consumption and recovering the combustion heat of the byproduct tail gas of the yellow phosphorus, the combustion heat of the yellow phosphorus, the reaction heat of phosphorus pentoxide and water, the solidification heat and the sensible heat of the furnace slag at the same time can be achieved; the recovery efficiency is high; the energy sources can be favorably saved; the production cost is effectively reduced.

Owner:贵州东晟捷能科技有限公司

Process for preparing polyphosphoric acid by utilizing wet-process phosphate purified acid

InactiveCN108439359ASmall particle sizeReduce usageCondensed phosphoric acidsPhosphatePhosphoric acid

The invention provides a process for preparing polyphosphoric acid by utilizing wet-process phosphate purified acid. The process comprises the following steps: (1), adding the wet-process phosphate purified acid into a reaction kettle, heating the wet-process phosphate purified acid to 85 to 95 DEG C while stirring, and then stirring at a constant temperature; (2), directly heating phosphorus pentoxide to 575 to 590 DEG C and ensuring that the phosphorus pentoxide is melted; regulating stirring speed in the reaction kettle to 700 to 900r / min, subsequently, centrifugally atomizing the melted phosphorus pentoxide into phosphorus pentoxide fog droplets with the thickness of 30 to 50 micrometers, and then spraying the phosphorus pentoxide fog droplets into the wet-process phosphate purified acid in the reaction kettle; continuously stirring for 100 to 150 minutes after the spraying is ended to ensure that a reactant becomes transparent liquid; stopping stirring to obtain the polyphosphoricacid. The process disclosed by the invention has the advantages of simple steps, short production time and low production cost; moreover, the prepared polyphosphoric acid can reach the food-grade requirement.

Owner:FARMASINO PHARMA ANHUI

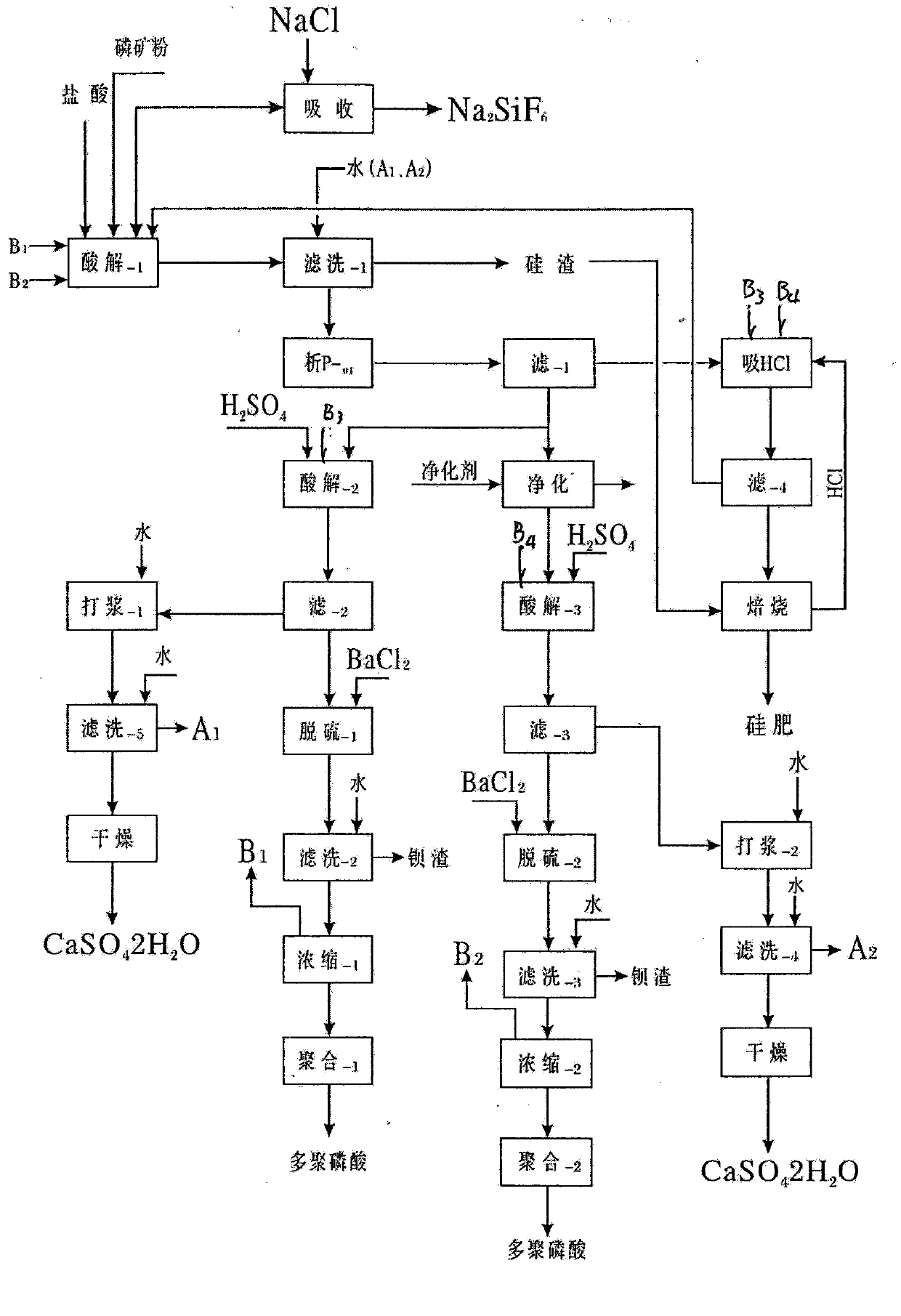

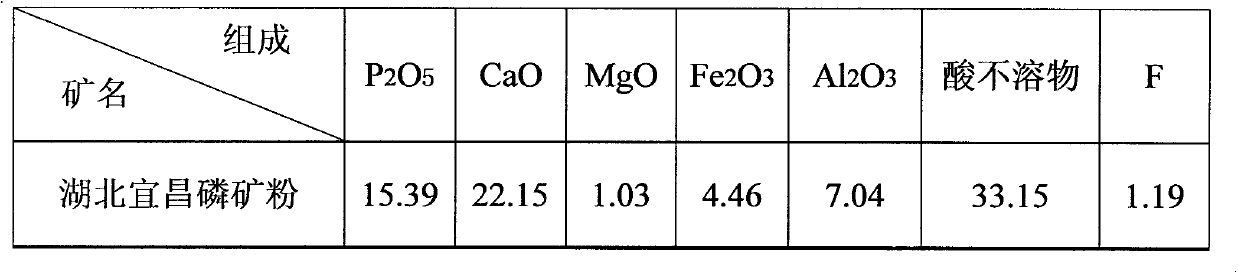

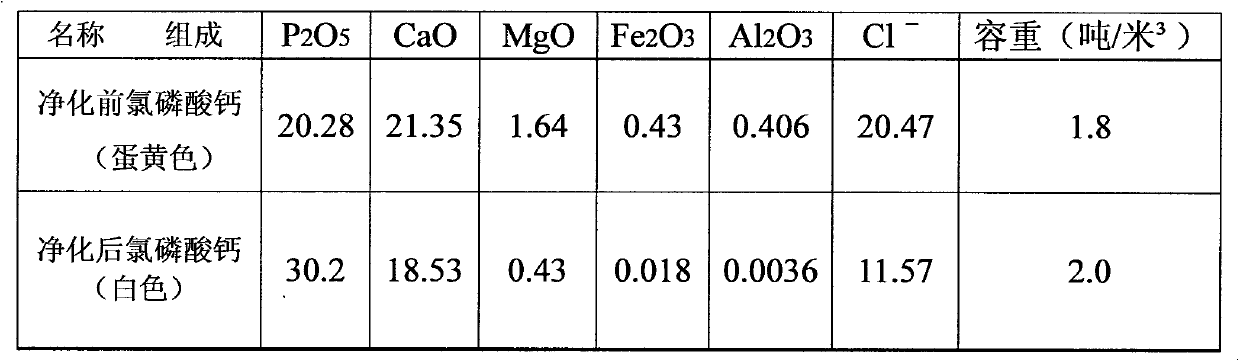

Methods of decomposing middle- and low-grade phosphate ore with double acids to produce polyphosphoric acid

A method of decomposing any phosphate ore with hydrochloric acid and sulfuric acid to produce polyphosphoric acid is provided. The method includes: decomposing the phosphate ore with the hydrochloric acid to produce calcium chlorophosphate, decomposing the calcium chlorophosphate with the sulfuric acid by utilization of a hemihydrate-dihydrate method or a dihydrate method to produce phosphoric acid with a high concentration, desulfurizing, concentrating and polymerizing to obtain industrial polyphosphoric acid. Another method includes purifying the calcium chlorophosphate, decomposing with the sulfuric acid by utilization of a hemihydrate-dihydrate method or a dihydrate method, producing the phosphoric acid with a high concentration, desulfurizing, concentrating and polymerizing to obtain low-arsenic polyphosphoric acid. Calcium chlorophosphate mother liquor is salted out to obtain chloride through feeding HCl, and is returned to the e phosphate ore decomposing step. Rare earth, iodine, uranium, and other useful elements in the phosphate ore is enriched and extracted. The chloride and silicon slag are prepared into a high-activity silicon fertilizer by intermediate-temperature calcination. A byproduct HCl gas is fed into calcium chlorophosphate mother liquor of the next cycle to salt out the chloride, thus forming a closed cycle process. Water is added into phosphogypsum, pulped, and washed to obtain high-quality gypsum.

Owner:武汉凌派化工科技有限公司

A method and device for combined thermal energy recovery of thermal phosphoric acid and polyphosphoric acid micro-absorption

ActiveCN107200314BEfficient recyclingReduce manufacturing costEnergy inputCombustion technology mitigationRecovery methodSlag

The invention discloses a heat energy recovery method for combining heat-process phosphoric acid and polyphosphoric acid micro absorption and a device thereof. According to the method, a micro absorption heat exchanger is used for recovering heat of reaction heat of phosphorus pentoxide and water; the heat of furnace slag is recovered through a furnace slag heat recovery device; the recovered heat of the reaction heat and the heat of the furnace slag are simultaneously connected into an air heat exchanger to prepare hot soft water; the hot soft ware is conveyed to a yellow phosphorus furnace and a phosphorus furnace tail gas boiler through pipelines for overheating steam; through combining the reaction heat, the furnace slag heat, the byproduct tail gas combustion heat and the yellow phosphorus combustion heat, the efficient recovery and utilization of the heat energy is realized. The goals of producing heat-process phosphoric acid or polyphosphoric acid by low energy consumption and recovering the combustion heat of the byproduct tail gas of the yellow phosphorus, the combustion heat of the yellow phosphorus, the reaction heat of phosphorus pentoxide and water, the solidification heat and the sensible heat of the furnace slag at the same time can be achieved; the recovery efficiency is high; the energy sources can be favorably saved; the production cost is effectively reduced.

Owner:贵州东晟捷能科技有限公司

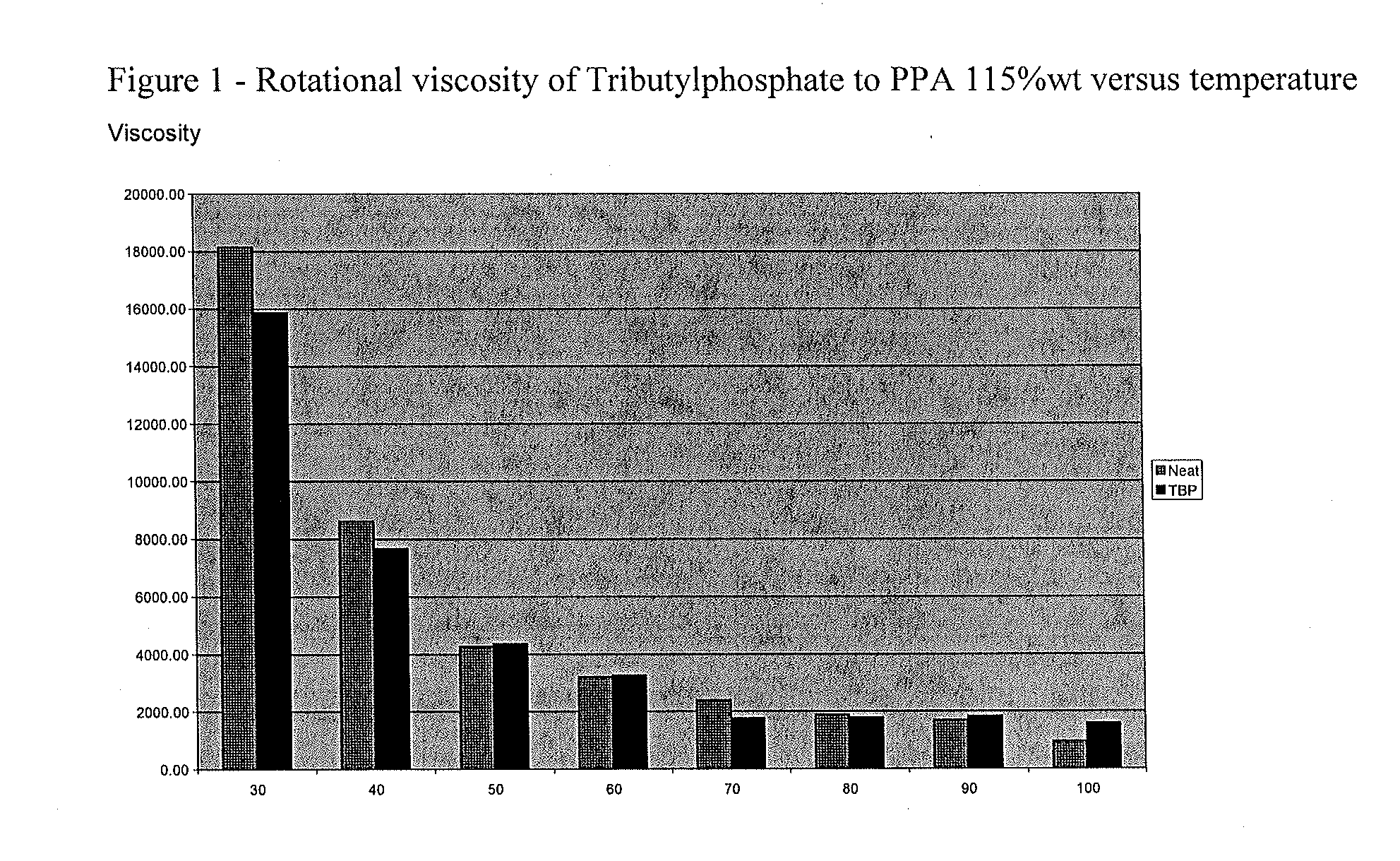

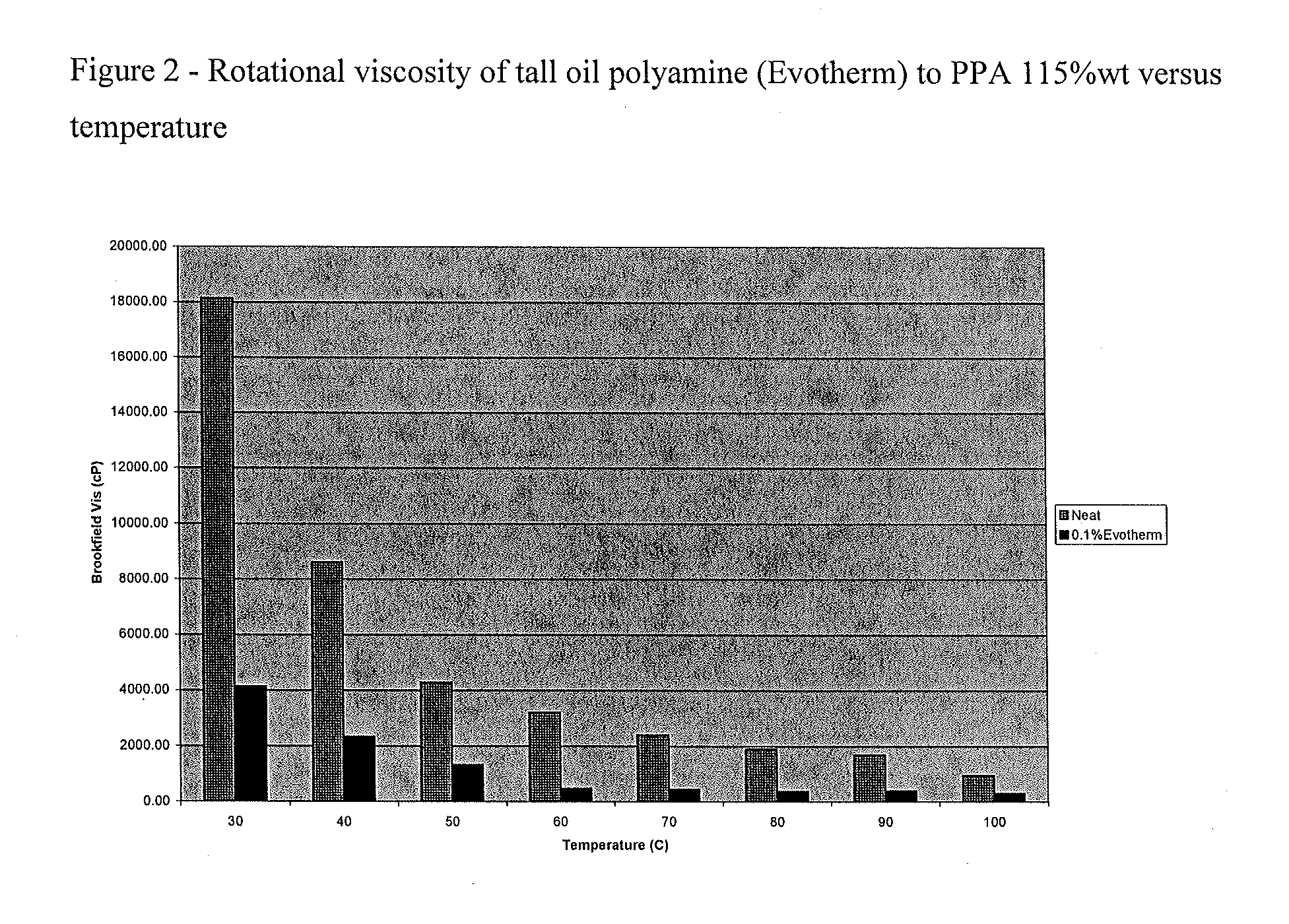

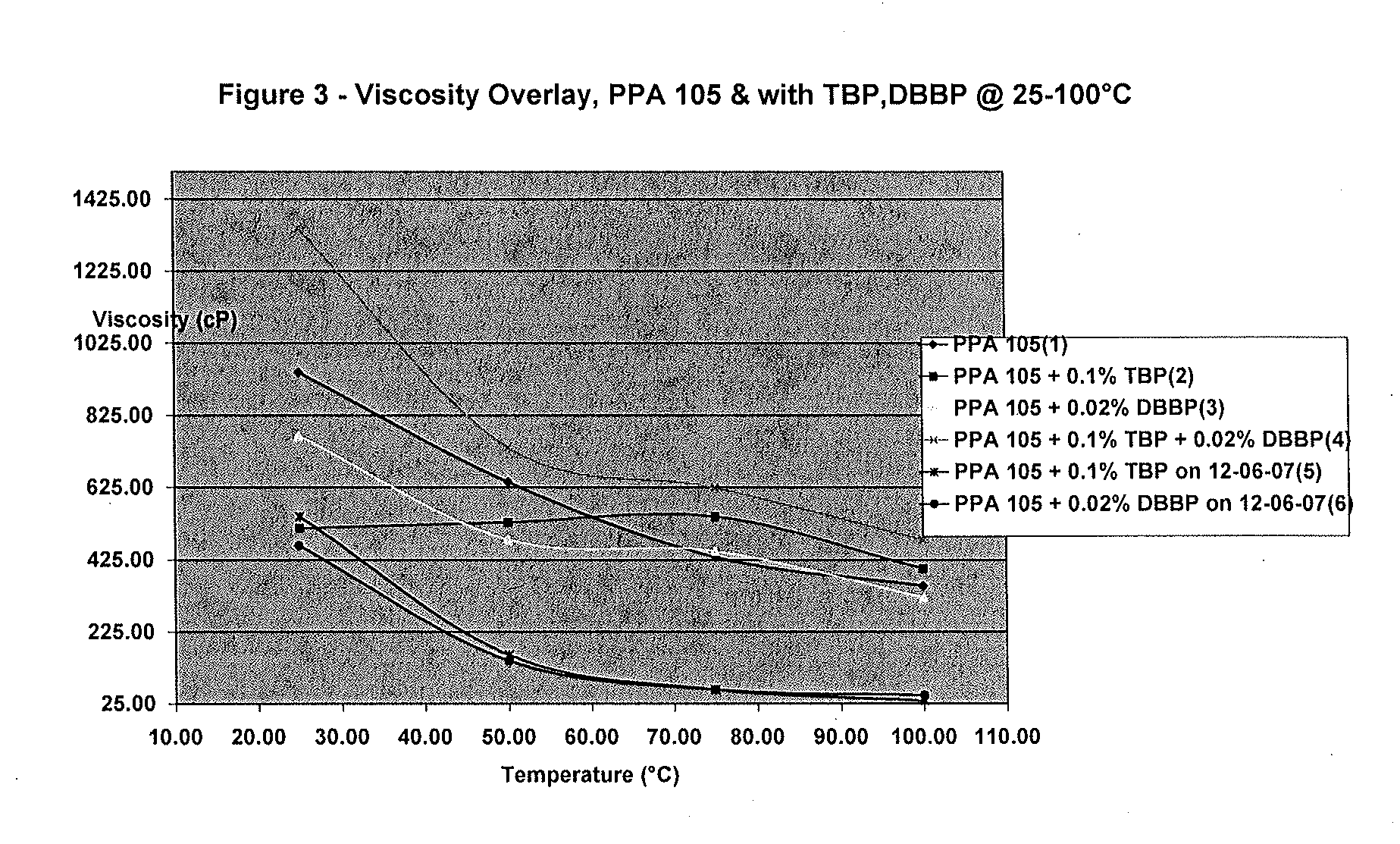

Polyphosphoric acid compositions having a reduced viscosity

Polyphosphoric acid compositions having a reduced viscosity compared to neat polyphosphoric acid. The viscosity of the polyphosphoric acid is reduced by combining the polyphosphoric acid with an additive that reduces the viscosity of the polyphosphoric acid composition. In one embodiment, additives that can cause solvation and / or partial neutralization of the polyphosphoric acid without the addition of water may be used. The reduced viscosity polyphosphoric acid may be used, for example, as an additive in asphalts used in road pavements.

Owner:INNOPHOS INC

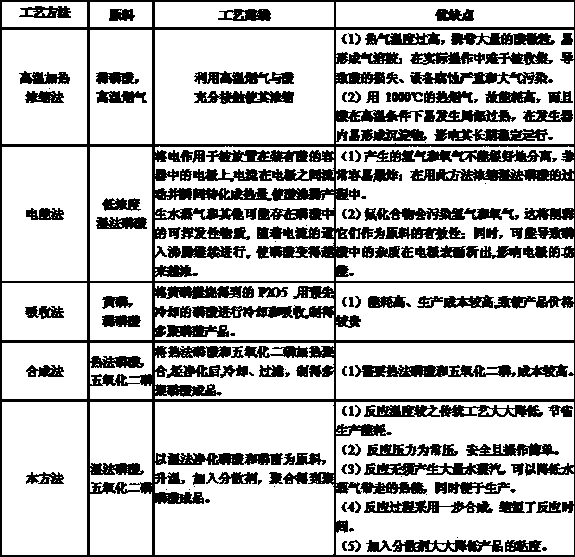

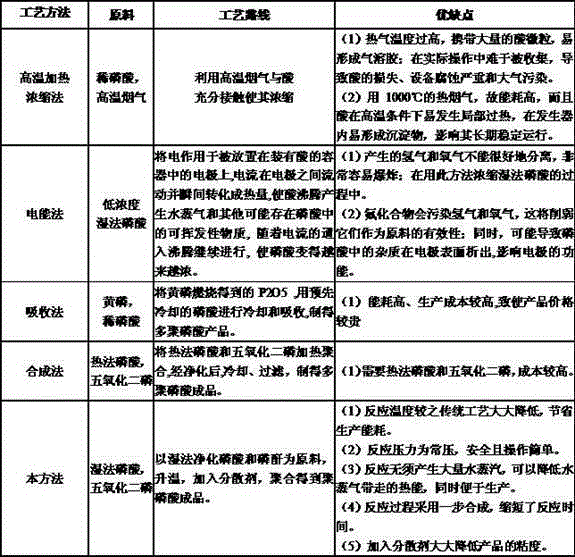

Method for synthesizing polyphosphoric acid by taking wet-process purified phosphoric acid and phosphoric acid anhydride as raw materials

ActiveCN103641092ALow reaction temperatureSave heatCondensed phosphoric acidsChemical industryO-Phosphoric Acid

The invention relates to a method for synthesizing polyphosphoric acid by taking wet-process purified phosphoric acid and phosphoric acid anhydride as raw materials, belonging to the technical field of phosphorous chemical industry. The method is characterized by comprising the following steps: placing phosphorus pentoxide into a three-neck flask at one time, slowly adding the wet-process purified phosphoric acid, continuously stirring to ensure that the phosphorus pentoxide is dissolved as much as possible, and setting the temperature and the rotating speed of a heat-collection type constant temperature heating magnetic stirrer so as to sufficiently mix materials; and after the materials are uniformly mixed, heating to a reset temperature, adding a dispersant, and carrying out polymerization reaction at constant temperature for 2-6 hours to obtain the colorless flowing transparent polyphosphoric acid of which the mass concentration of the phosphoric acid 114-120 percent. The method disclosed by the invention has the advantages that the production energy consumption of the polyphosphoric acid is greatly reduced as the wet-process purified acid is used as a raw material; the method is safe and simple to operate and has good generalization practicability.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

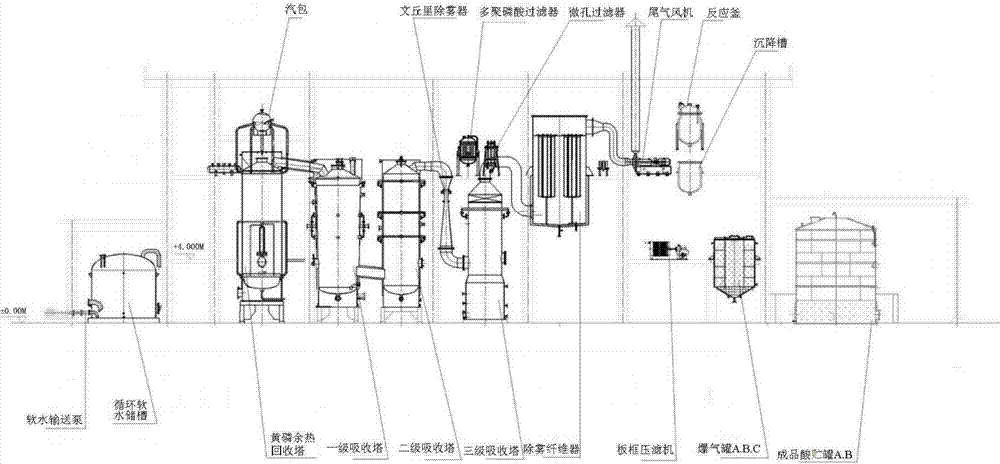

Novel phosphoric acid and polyphosphoric acid production technological method

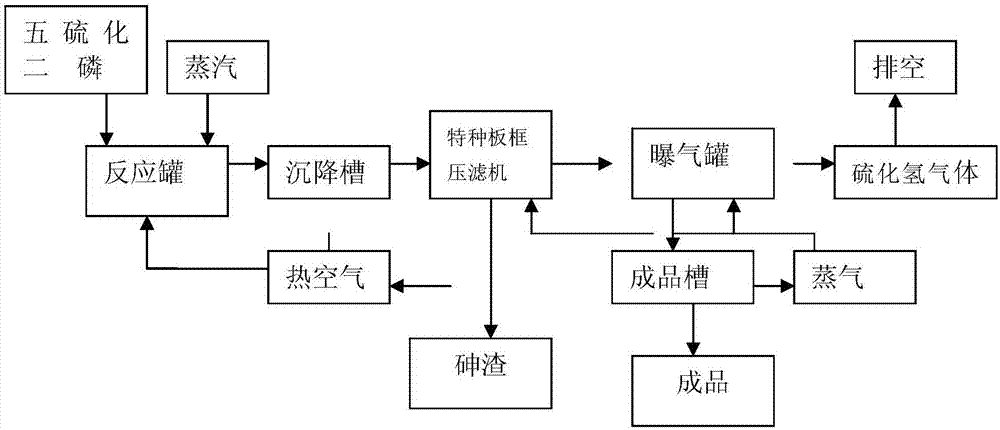

InactiveCN107055499AOvercome difficultyOvercome PurificationCondensed phosphoric acidsPhosphoric acidThree levelCombustion

The invention relates to a novel phosphoric acid and polyphosphoric acid production technological method which is characterized by comprising the following two steps: combustion absorption and purification and arsenic removal; a directly connected spray gun of a phosphorus supply pump is changed to a plate-and-frame press filter by adopting the traditional production technological one-step method combustion absorption and hydration one-step method, different products adopt different structures and materials, a material 316L stainless steel jacket is adopted, an air stirrer is arranged, replacement is not needed, long-term operation can be ensured, and a transmission device for stirring is not needed; and by adopting the principle of being high in technical content, low in production cost, fewer in three wastes and easy in treatment, the invention provides a two-step technological method of combustion-hydration three-level absorption acid mist capturing and production of polyphosphoric acid.

Owner:昆明风动新技术集团发展有限公司

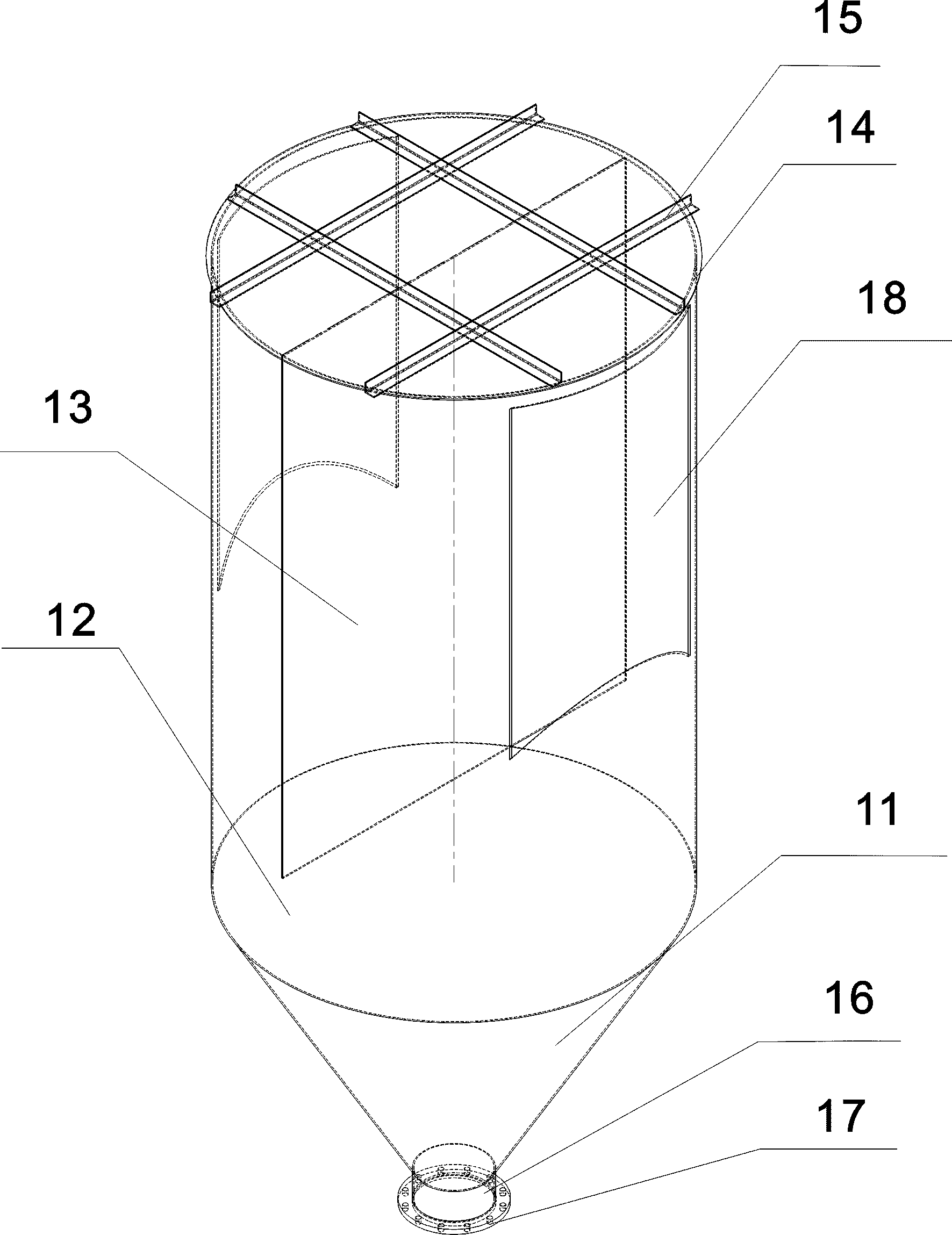

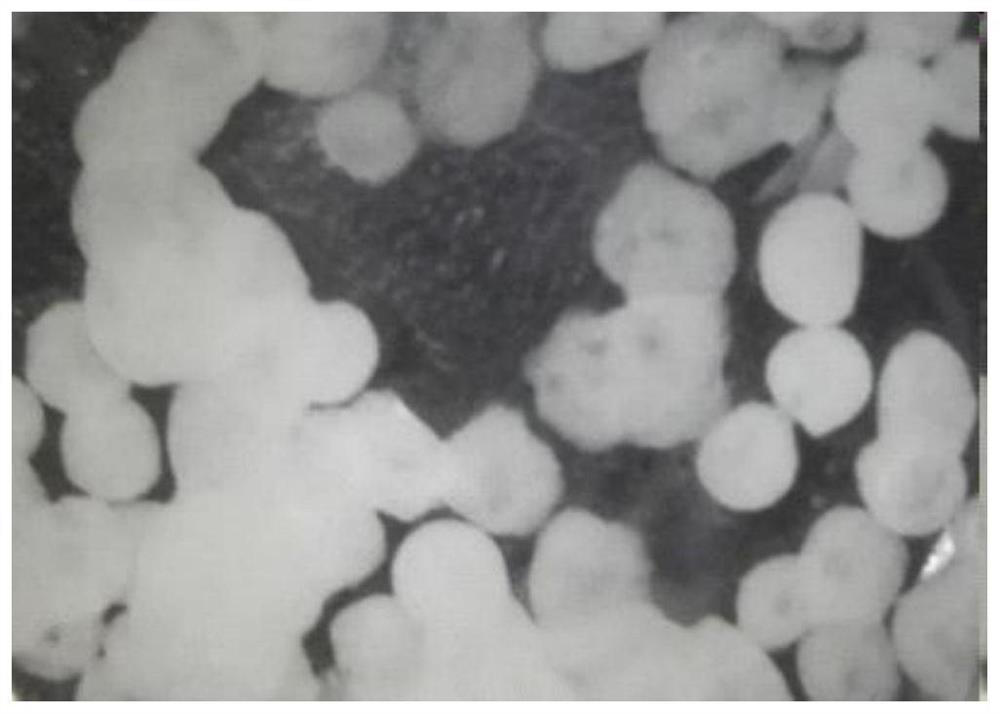

A kind of preparation device and preparation method of spherical solid phosphoric acid

ActiveCN110171808BAdjust particle sizeUniform particle sizeCondensed phosphoric acidsPhosphoric acidO-Phosphoric AcidPhosphate

The invention belongs to the technical field of chemical industry, and in particular relates to a preparation device and a preparation method of spherical solid phosphoric acid. Aiming at the problems of poor granularity of solid phosphoric acid particles and liquid attached to the surface of solid phosphoric acid in the production of solid phosphoric acid in the prior art, the technical solution of the present invention is: suspending small particles of solid phosphoric acid in liquid phosphoric acid to form a crystal slurry, and using the crystal slurry The small particle solid phosphoric acid in the medium is used as the crystal seed, and the inert liquid without water is used as the cooling medium. The crystal slurry is dispersed into droplets by using the drip tray and dropped into the inert liquid in the cooling and solidification tower. During the process of sinking, it is cooled by the inert liquid and condensed into a solid. The solid is taken out from the bottom of the cooling and solidification tower, separated from the solid and liquid, and the volatile cooling medium on the surface of the solid is removed to obtain spherical solid phosphoric acid.

Owner:LESHAN NORMAL UNIV

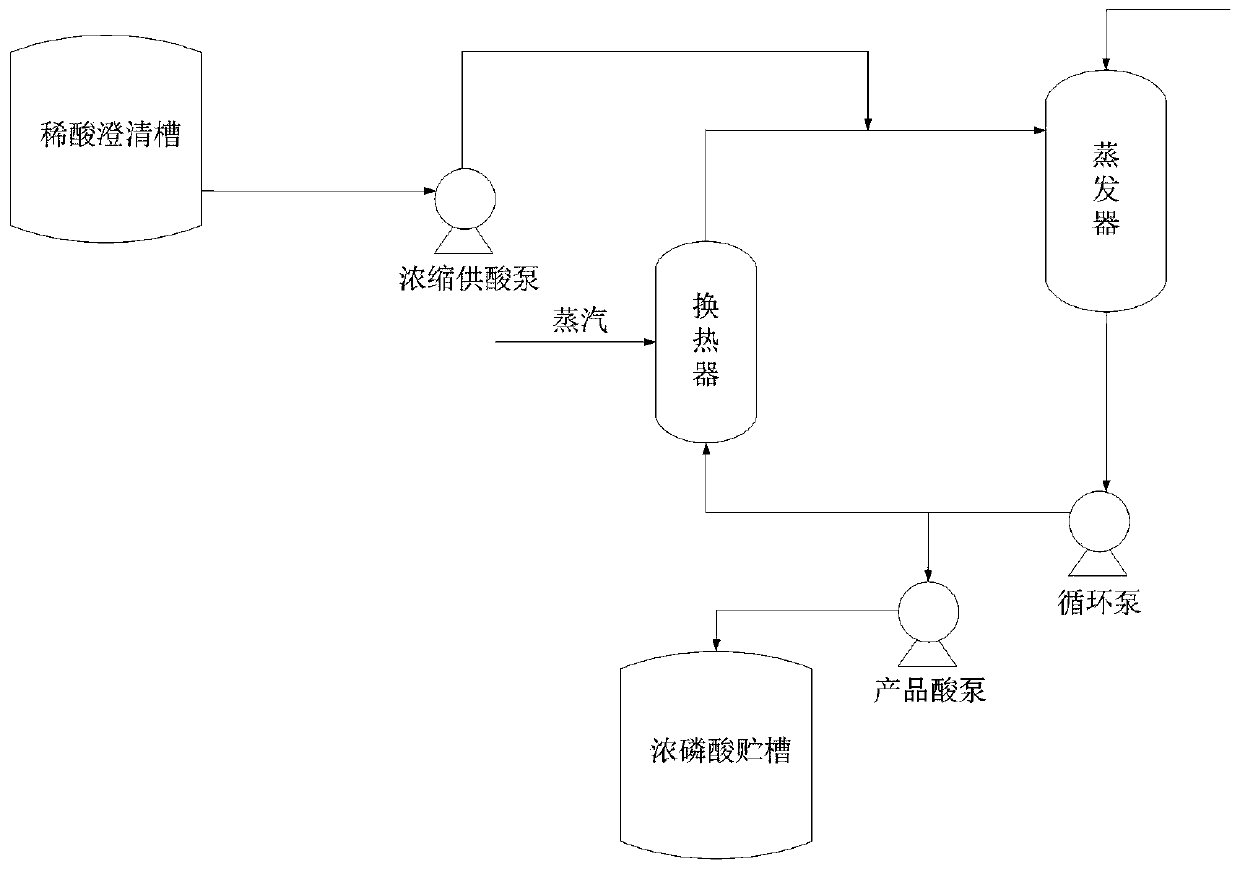

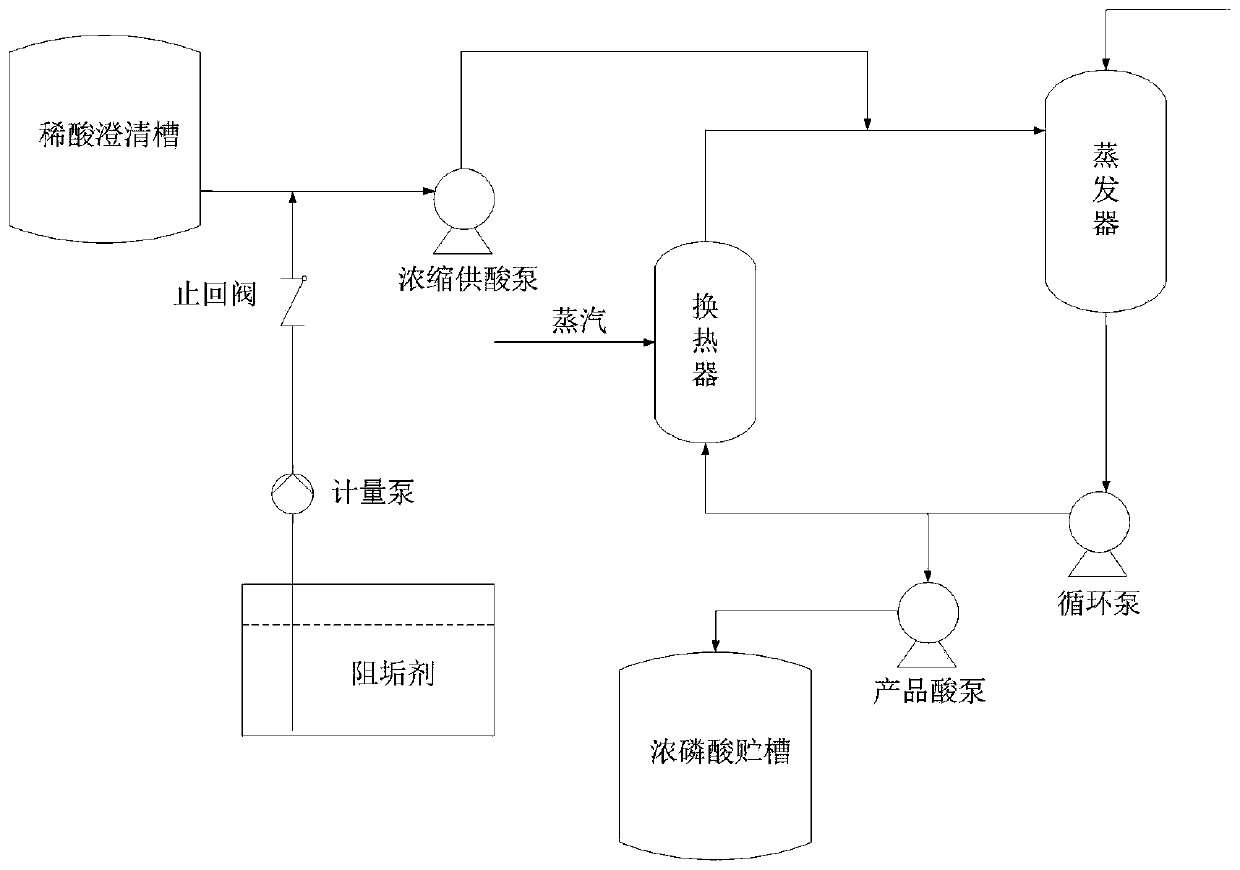

Efficient wet-process phosphoric acid graphite heat exchanger scale inhibitor, preparation method and application

The invention provides an efficient wet-process phosphoric acid graphite heat exchanger scale inhibitor which comprises, by weight, 28-38 parts of dodecyl polyoxypropylene ether sulfonate, 27-32 partsof succinic acid and 35-50 parts of cosolvents. The scale inhibitor is fed into an inlet and outlet port of a concentrated graphite tube array, the scale inhibitor and diluted phosphoric acid are mixed and then enter the concentrated graphite tube array, scaling of the graphite tube array is stopped and delayed under the action of chelation, solubilizing, lattice distortion and dispersion, original scale of the graphite tube array can be stripped and cleaned, the corrosion rate of an acid side pipeline is reduced, so that the start-up cycle of wet-process phosphoric acid production is prolonged, the heat exchange efficiency of the graphite tube array is improved, energy is saved, consumption is reduced, output is improved, and production cost is reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

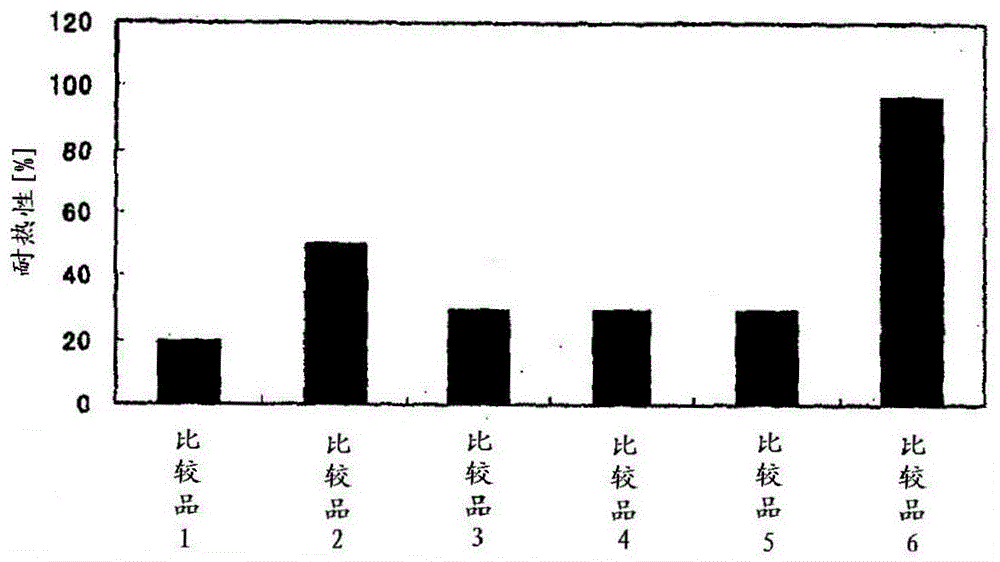

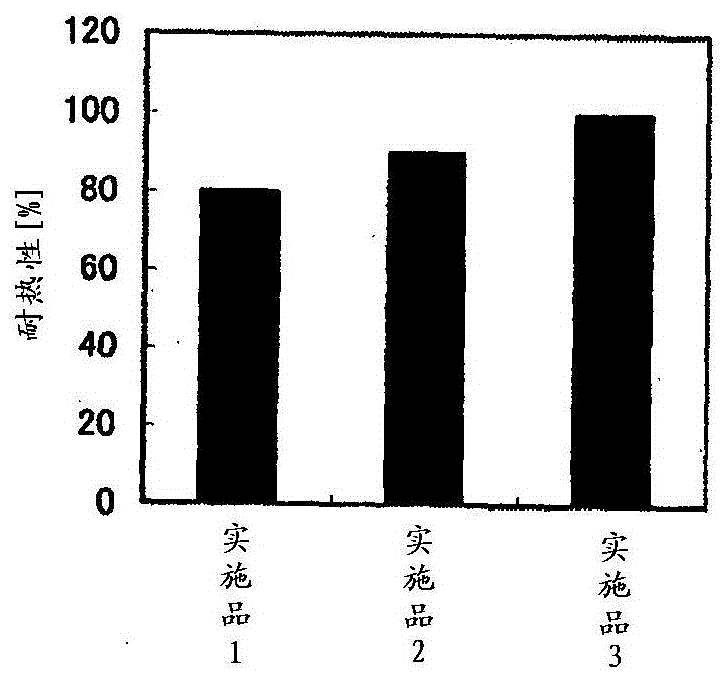

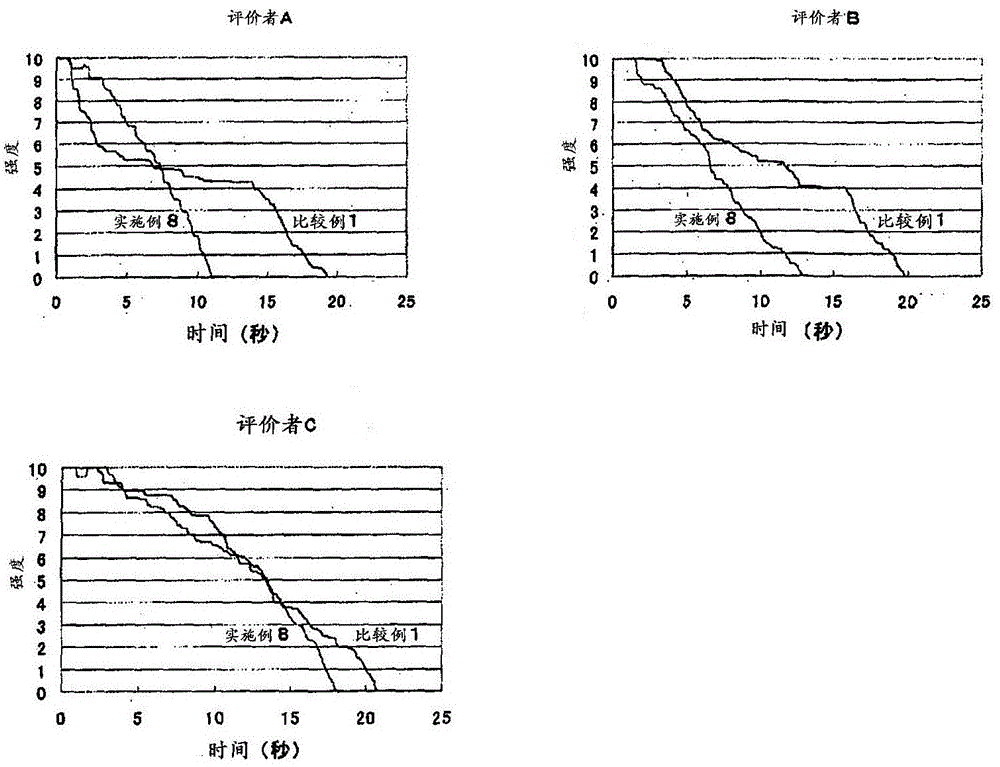

Processed cheese and its production method

ActiveCN104684402BImprove heat resistanceAdd flavorCheese manufactureCondensed phosphoric acidsCITRATE ESTERHeat resistance

The present invention relates to heat-resistant processed cheeses and a method for producing the same. The present invention further relates to processed cheeses in which the feeling of "sticky stickiness" is reduced and the feeling of "melting in the mouth" is improved, and a method for producing the same. By blending the condensed phosphate having a turbidity of 2.0 or more in a 1.0% aqueous solution adjusted to pH 6.0, excellent heat resistance can be imparted to processed cheeses without providing a special process. In addition, by blending any one or more molten salts of water-soluble polyphosphate, diphosphate, monophosphate, and citrate in addition to the above-mentioned condensed phosphate, or a maturity index of 30% or more Natural cheeses can be processed cheeses in which the feeling of "stickiness" is reduced and the feeling of "melting in the mouth" is improved.

Owner:SNOW BRAND MILK PROD CO LTD

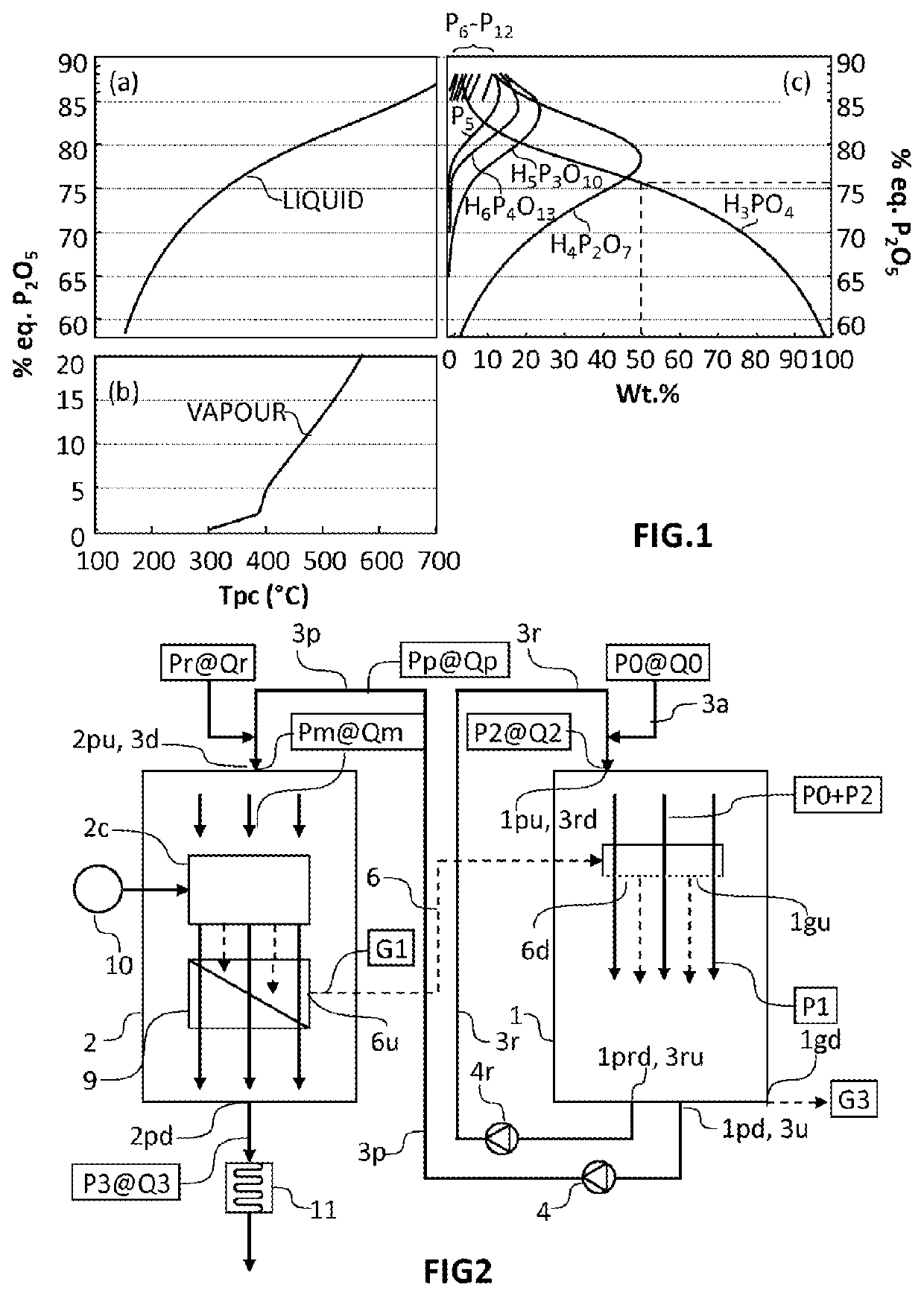

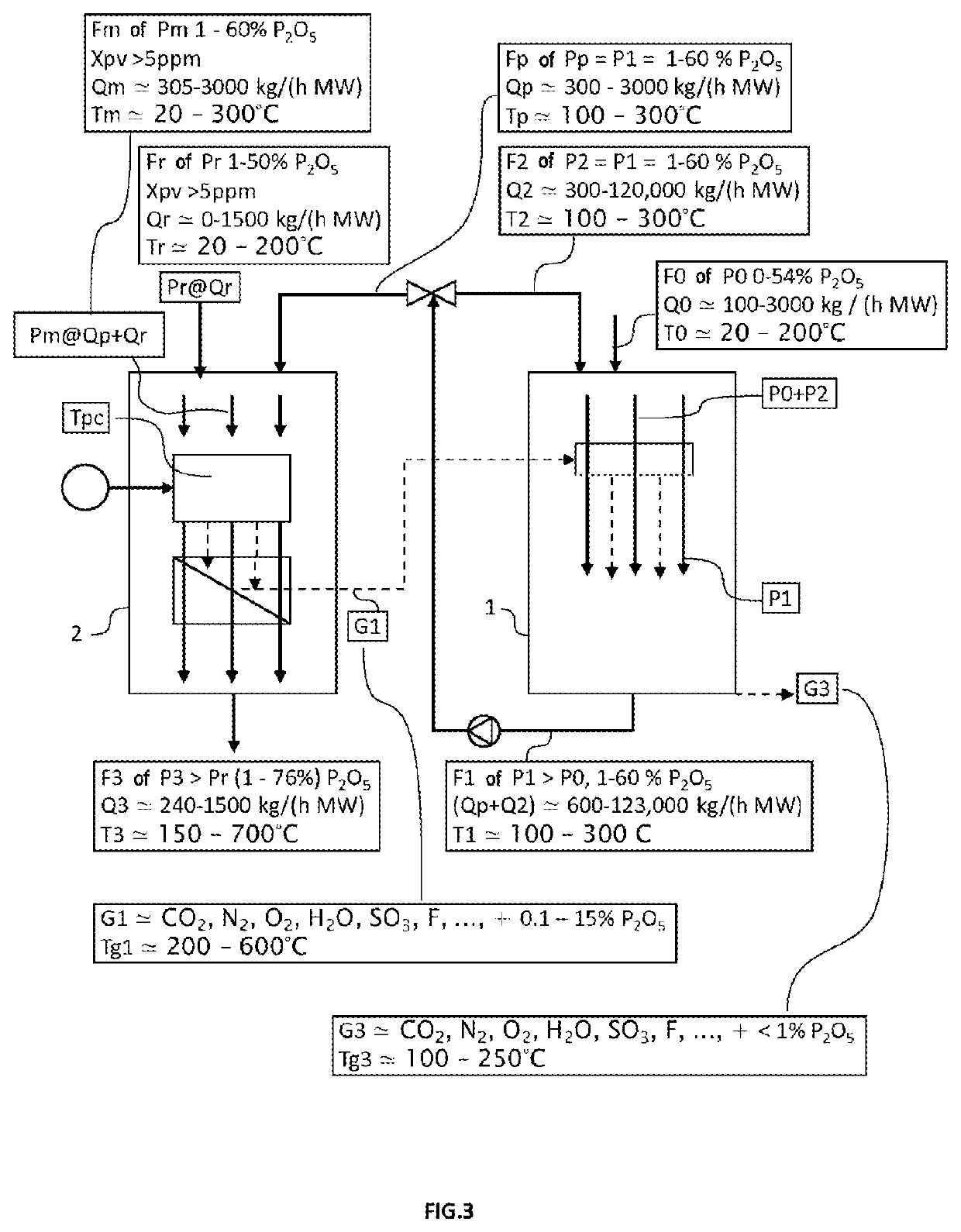

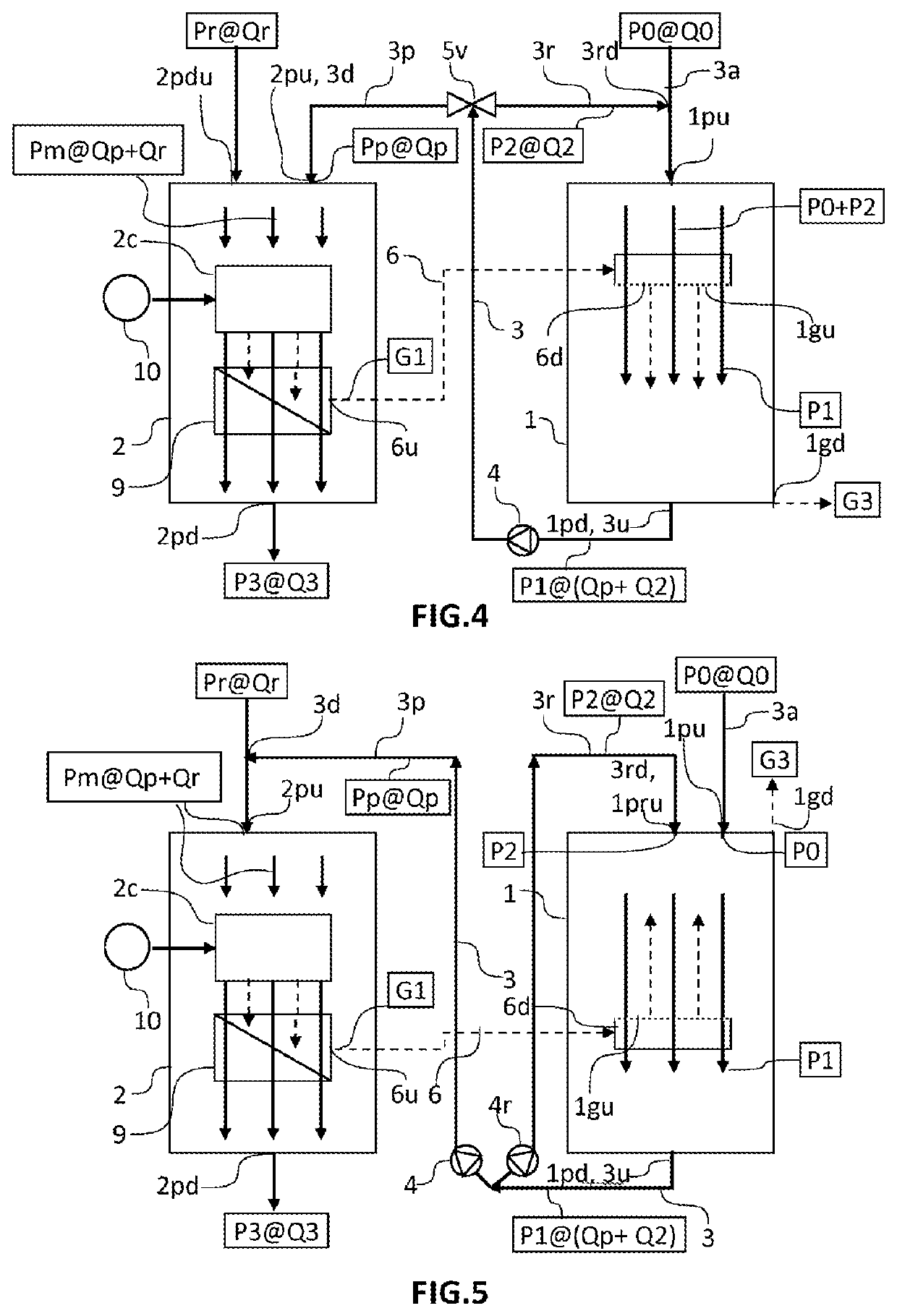

Method for recycling residual solutions comprising phosphorus and device for such a method

InactiveUS20210130171A1Heat treatmentsChemical/physical/physico-chemical stationary reactorsO-Phosphoric AcidCombustion chamber

A method and device for the purification of phosphoric acid contained in a residual solution is provided that includes undesirable volatilizable materials. The residual solution is mixed with a solution of enriched phosphoric acid and is sprayed into a flame of a combustion chamber in order to form a combustion solution P3 of phosphoric acid purified of the undesirable volatilizable materials. The combustion gases resulting from the combustion chamber are contacted with a feed solution in a gas-acid contactor in order to increase the temperature and concentration of P2O5 and thus to form the solution of enriched phosphoric acid. A portion of this solution is conveyed at a flow rate Qp into the combustion chamber. The remainder of the solution is conveyed into a recycle loop in order to be reintroduced into the gas / acid contactor at a flow rate Q2. The ratio of the flow rates, Qp / (Qp+Q2) is controlled at a predefined value.

Owner:PRAYON SA

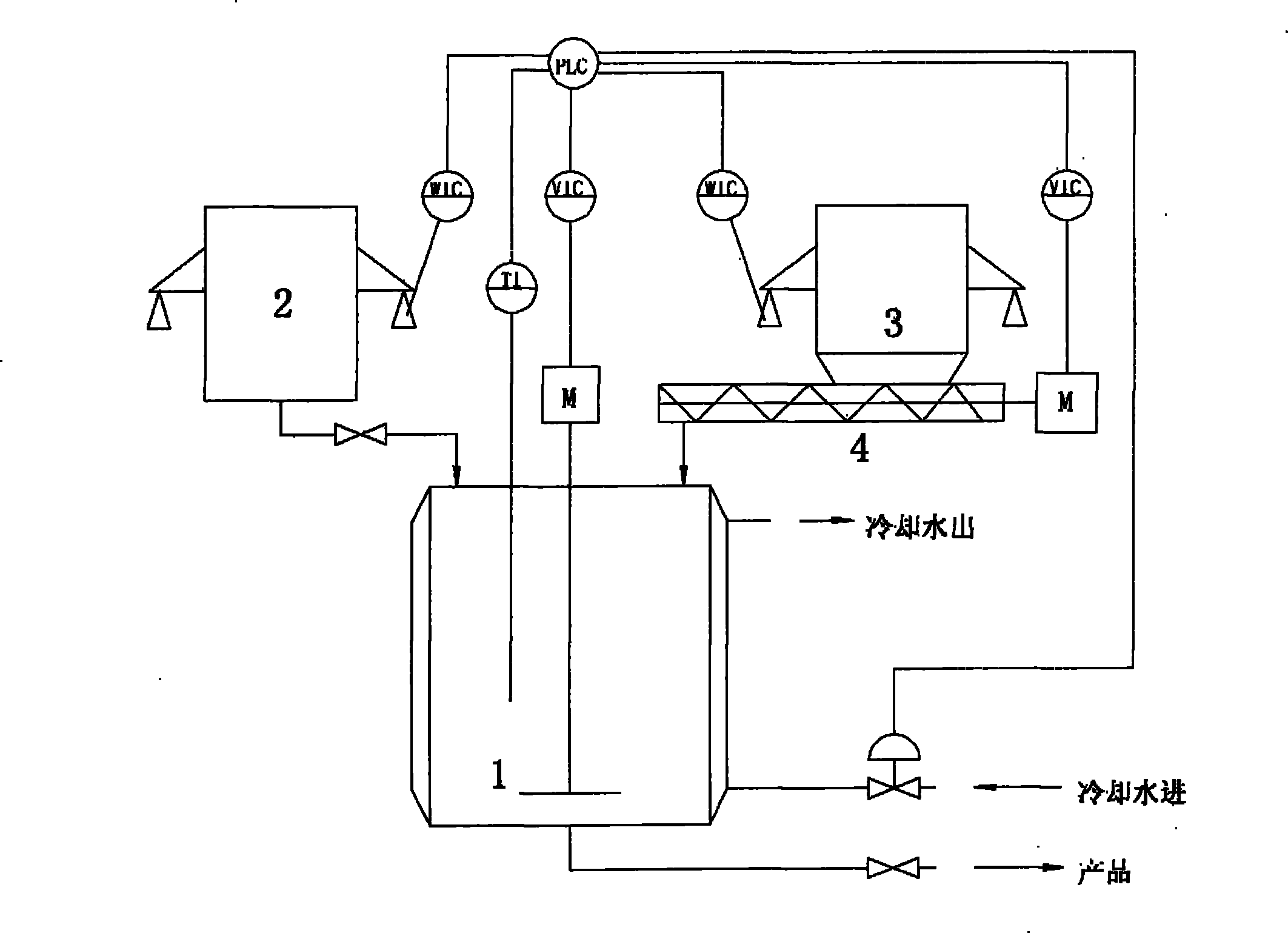

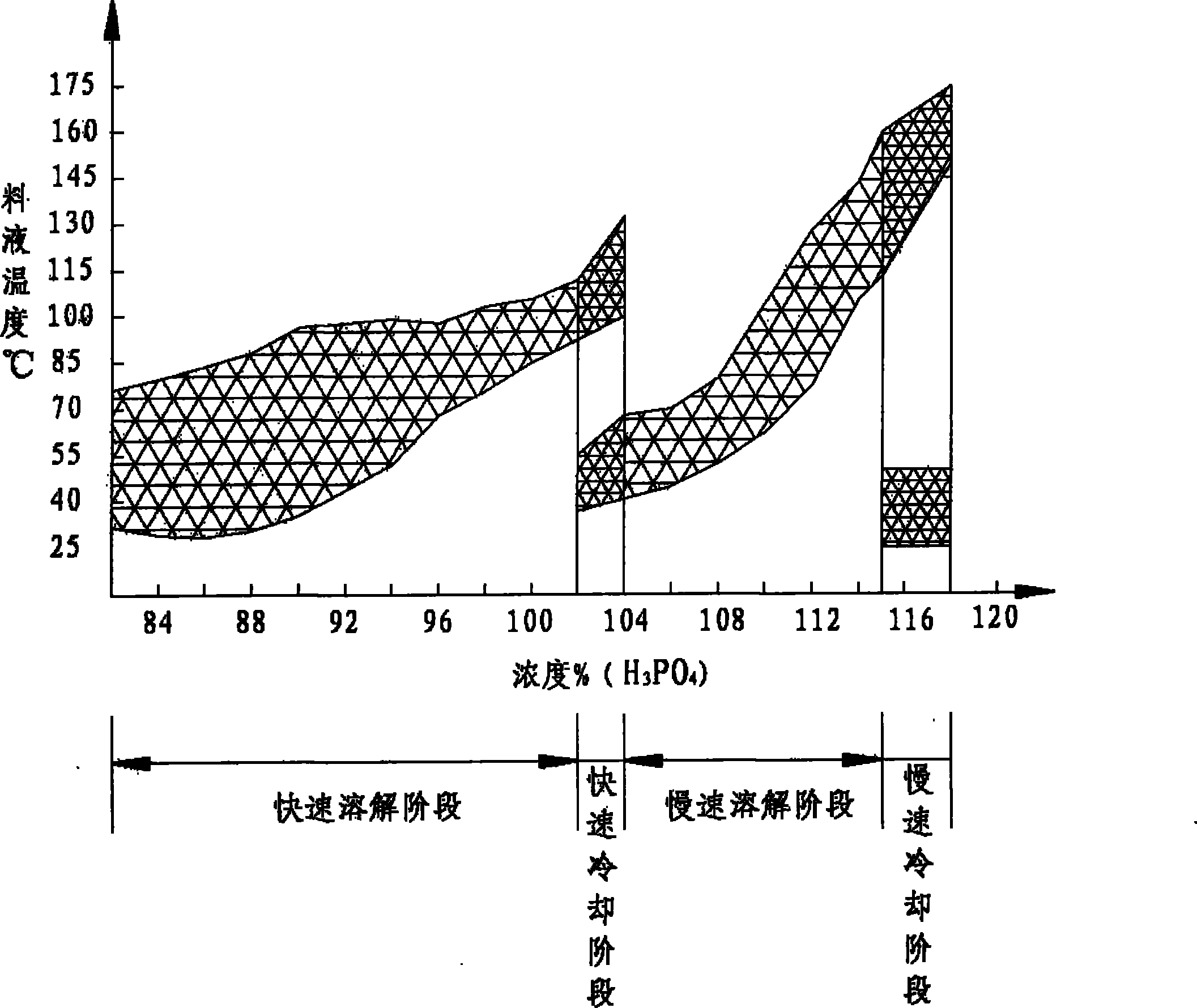

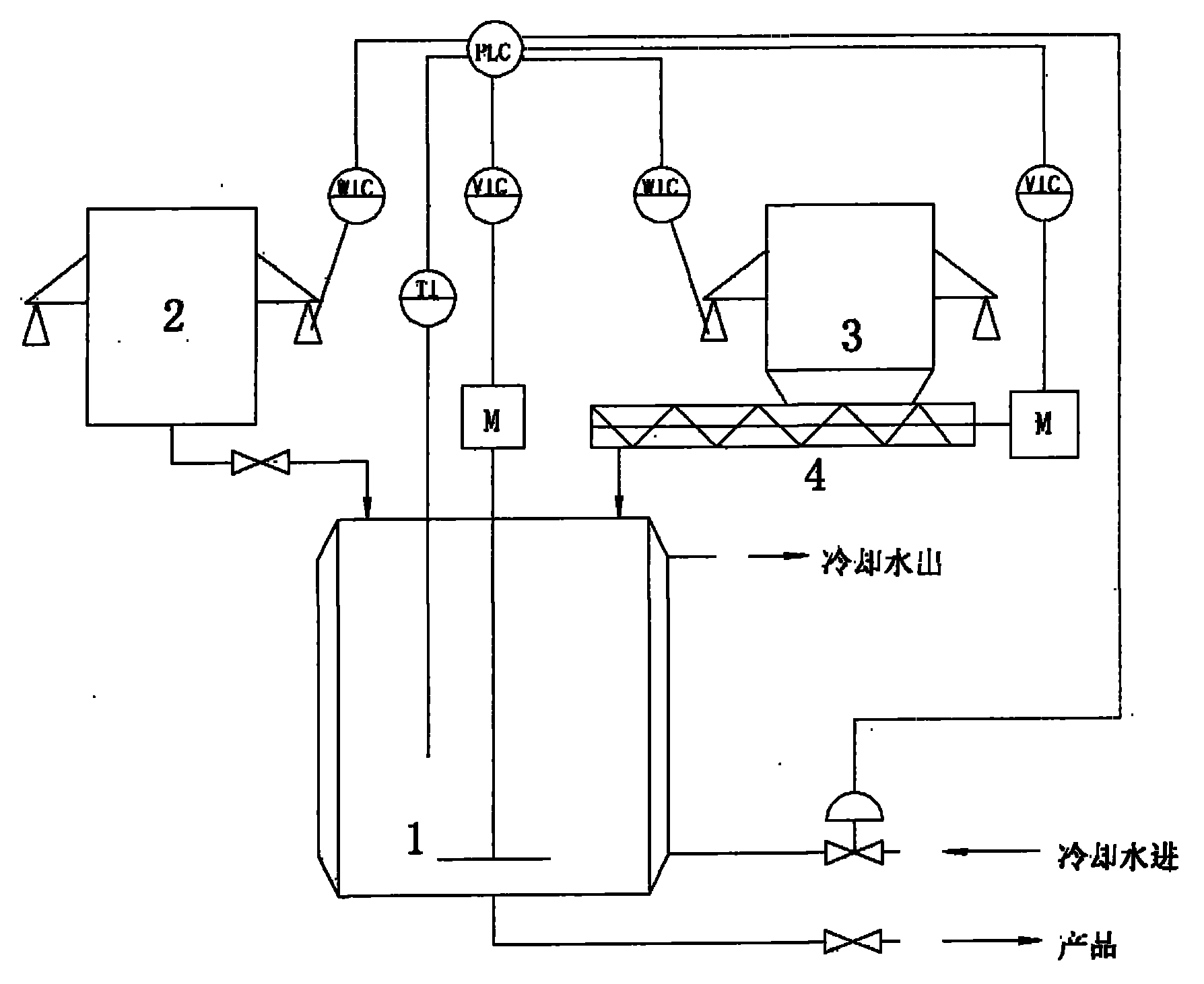

Polyphosphoric acid preparation technology and production control method thereof

ActiveCN101445227BProcess control is stable and reliableIncrease productivityCondensed phosphoric acidsLower limitManufacturing technology

Owner:YUNNAN JIANGLIN GROUP

Method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid

ActiveCN101531354BLower packagingReduce logistics costsChemical industryCondensed phosphoric acidsO-Phosphoric AcidEconomic benefits

A method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid, including following steps: mixing yellow phosphorus and air with the proportion of 1kg yellow phosphorus to 6.3-6.6 m3, burning, absorbing the obtained P2O5 by diluted acid; applying the obtained phosphoric acid into a phosphoric acid groove; then using acid pump to send into a condenser to remove the heat; then sending the phosphoric acid into a hydration tower to circularly spray and absorb P2O5 to increase the concentrated phosphoric acid; cycling without stop to obtain the phosphoricacid having 82%-84% P2O5. The recovery coefficient of phosphorus is more than 98%. The obtained product reaches the standard of the food-level phosphoric acid. This invention may greatly reduce the cost of package and distribution of the phosphoric acid production enterprise via using the wet-method phosphoric acid or hot-method phosphoric acid of the concentrated content of the phosphoric acid anhydride of less than 100% obtained by yellow phosphorus burning. This invention does not need to consume the extra energy, and can fully use the burning heat and the hydration heat of the yellow phosphorus; the generated steam can be recycled. So this invention has the advantages of saving energy and greatly reducing the production cost of the polyphosphoric acid, with remarkable social and economic benefits.

Owner:WENGFU (GRP) CO LTD

A method for synthesizing polyphosphoric acid with wet purification of phosphoric acid and phosphoric anhydride as raw material

ActiveCN103641092BLow reaction temperatureSave heatCondensed phosphoric acidsChemical industryO-Phosphoric Acid

The invention discloses a method for synthesizing polyphosphoric acid by using wet-purified phosphoric acid and phosphoric anhydride as raw materials, belonging to the technical field of phosphorus chemical industry. Its characteristic is to place phosphorus pentoxide in a three-necked flask at one time, slowly add wet-purified phosphoric acid, and keep stirring to dissolve the phosphorus pentoxide powder as much as possible, and set the temperature and speed of the collector type constant temperature heating magnetic stirrer To fully mix. After the mixture is evenly mixed, the temperature is raised to the set temperature, and a dispersant is added. After constant temperature polymerization for 2-6 hours, a colorless and flowing transparent polyphosphoric acid with a phosphoric acid mass concentration of 114-120% is obtained. The invention has the advantages of adopting wet-process purification acid as raw material, greatly reducing the energy consumption of polyphosphoric acid production, safe and simple operation, and good popularization and practicability.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Arsenic-removing filtering method for high-concentration polyphosphoric acid

ActiveCN102515125AReduce arsenic levelsReduce heavy metal contentCondensed phosphoric acidsHigh concentrationPhosphorus pentasulfide

The invention provides an arsenic-removing filtering method for high-concentration polyphosphoric acid, which includes: using industrial polyphosphoric acid as the raw material, adding water-soluble phosphorus pentasulfide emulsion used as arsenic-removing agent to enable arsenic contained in the polyphosphoric acid to form sulfide precipitate under the acidic condition, and purifying and refining the polyphosphoric acid by means of filtering, aerating and the like to produce low-arsenic polyphosphoric acid. By the low-arsenic polyphosphoric acid production method that filter cakes are formed on filter media from the dilute polyphosphoric acid containing arsenic residue first, and then the polyphosphoric acid with added arsenic-removing agent is filtered, the technical problem of filtering in the low-arsenic polyphosphoric acid preparation process is solved, and low-arsenic polyphosphoric acid production can be industrialized. Further, the arsenic-removing filtering method for high-concentration polyphosphoric acid is low in operating cost and simple in operating process, and low-arsenic polyphosphoric acid products, which cannot be obtained by conventional methods and are 105%-118% in concentration, namely percentage composition of P2O5 ranges from 76.1% to 85.5%, and arsenic content is no more than 10ppm, can be obtained by the arsenic-removing filtering method.

Owner:YUNNAN CHEM RES INST

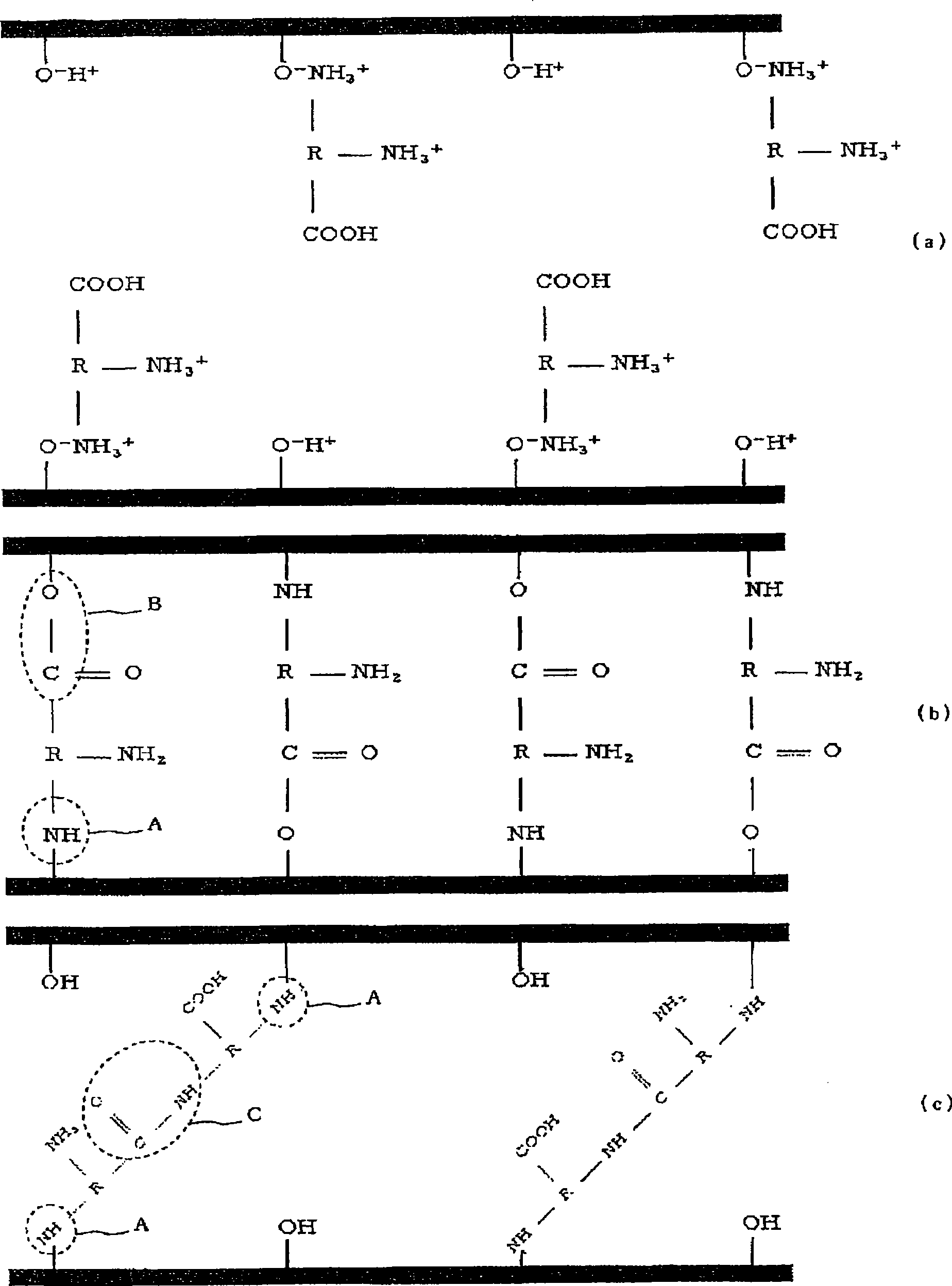

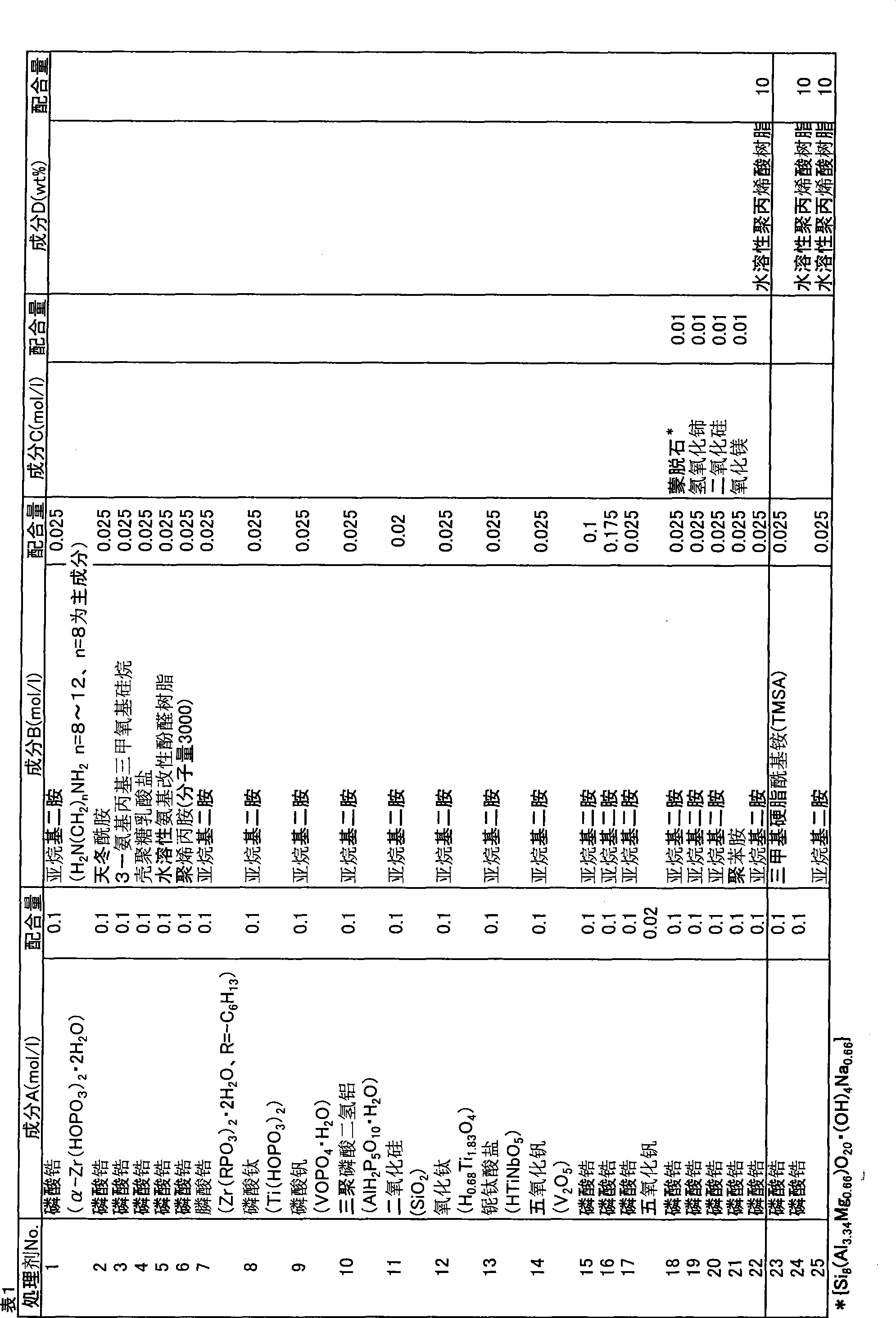

Surface-treating agent comprising crystalline layered inorganic compound dispersed in nanosheet form

InactiveCN101370964BEffect of water resistanceAccelerated corrosionPigmenting treatmentMaterial nanotechnologyChromium freeAutomotive product

Disclosed is a surface-treating agent comprising a crystalline layered inorganic compound formed with an organic amine or an organic ammonium into a nanosheet, wherein the organic amine or organic ammonium is a polyfucntional organic amine or polyfunctional organic ammonium. The surface-treating agent is a nanosheet-dispersed sol-type non-chromate surface-treating agent which shows excellent corrosion resistance and coating-adhesiveness at a processed part and can form a stiff film even used in the manufacture of a precoated metal plate which is applicable to an electric appliance, an automotive product or the like which is required to have a strictly machined shape.

Owner:NIHON PARKERIZING

A method and equipment for producing polyphosphoric acid from wet-process phosphoric acid

ActiveCN106672931BSolve the problem of easy fouling and difficult to deal withEasy to operate and controlChemical industryCharge manipulationTemperature controlO-Phosphoric Acid

The invention belongs to the technical field of phosphoric acid production in the inorganic chemical industry, and relates to a new production method and equipment for producing polyphosphoric acid from wet-process phosphoric acid. The innovation of this method mainly adopts a reverberatory furnace, plus burners, polyphosphoric acid tanks, oligophosphoric acid circulation pumps, smoke exhaust fans, packing washing towers, multiple control valves and other equipment, and uses wet-process phosphoric acid as raw material to concentrate and polymerize to produce polyphosphoric acid. phosphoric acid. The reaction equipment is reliable and stable, and the operation and control are simple and convenient, which solves the problem that the tubes and tubes of the tube and tube heat exchanger in the single-stage or multi-stage evaporation of wet-process phosphoric acid at home and abroad are easy to foul and difficult to deal with; the temperature control is moderate, avoiding local overheating and When the temperature is too high, the acid particles are carried away in large quantities; there is no need to use vacuum, which saves energy; the use of two-stage product output facilitates the improvement of production efficiency; the exhaust gas is recycled and used as raw materials after the washing liquid is recycled, which improves the product yield and reduces It reduces exhaust emissions and is conducive to environmental protection.

Owner:广西越洋生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com