Method for recycling residual solutions comprising phosphorus and device for such a method

a technology of phosphoric acid and residual solution, which is applied in the direction of phosphorus oxyacids, chemical/physical/physico-chemical processes, chemical apparatus and processes, etc., can solve the problems of inability to use such residual solution in the purification process of phosphoric acid or ppa as described, and achieve the effect of ep2411325 b1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

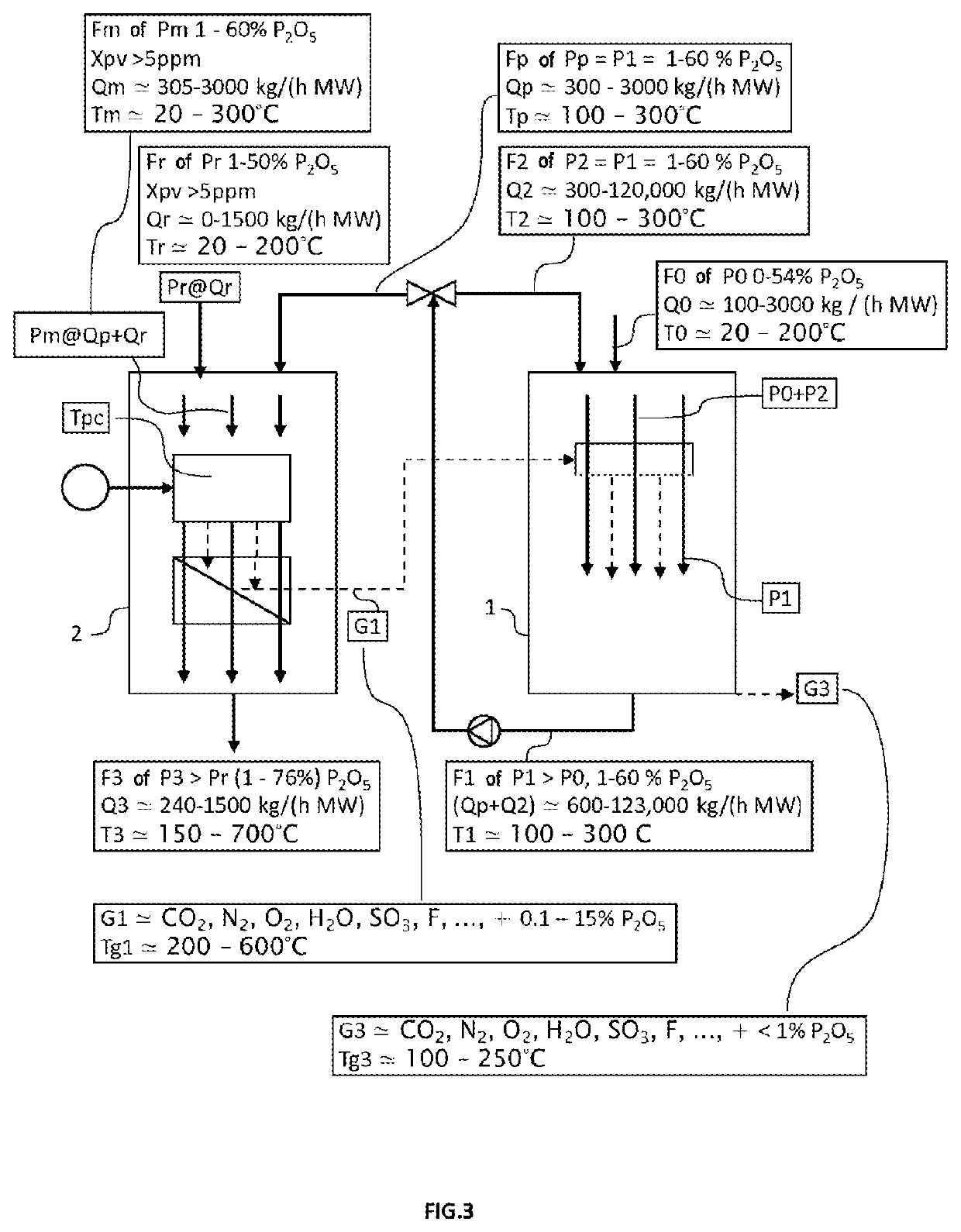

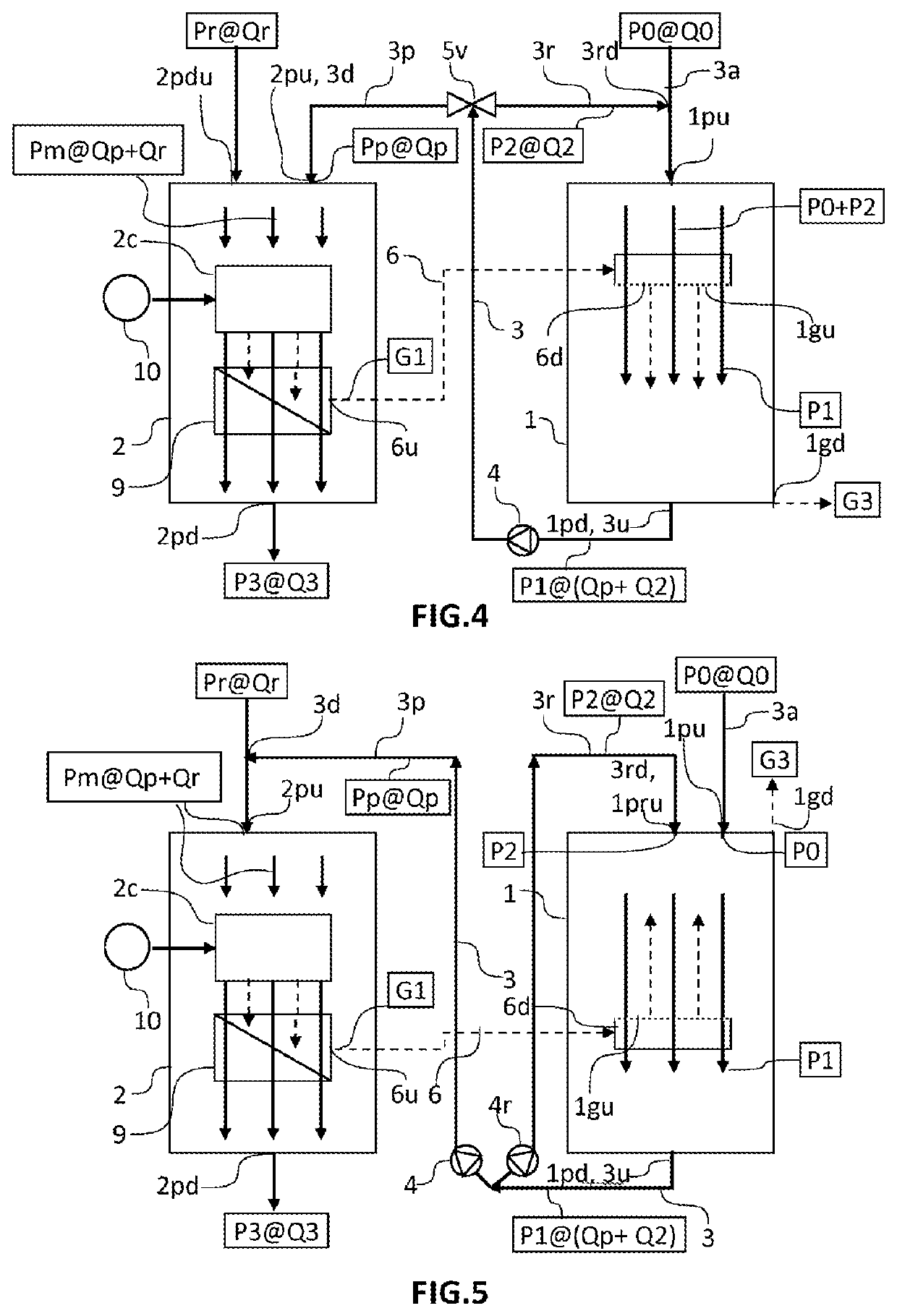

[0079]FIGS. 2 to 5 illustrate the process and nonexhaustive variants of devices for forming said process. Hereinbelow, the term “stream” represented by the letter “F” is used in its commonly accepted interpretation as simply a flow of a fluid. Only FIG. 3 indicates the streams by the letter “F”. The other figures illustrating devices indicate flow rates “Q” corresponding to the streams “F” of FIG. 3. The term “flow rate” represented by the letter “Q” characterizes the mass of the stream per unit time and is expressed in [kg / s] or [kg / h]). The term “flow rate”, even used alone, thus defines a mass flow rate. In order to express the flow rates as a function of the nominal power of the combustion chamber, the mass flow rates of the various streams will be reported hereinbelow in units of [kg / (h MW)], which represents a flow rate per unit of nominal power [MW−1] of the combustion chamber.

[0080]Since the combustion solution P3 derived from the combustion of the mixing solution Pm obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com