Method for preparing graphical sapphire substrate for nitrifier epitaxial growth

A sapphire substrate, epitaxial growth technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of sapphire substrate pollution, complicated process, high cost, etc. Etching damage, low dislocation density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] See again Figure 1-Figure 4 This embodiment is a method for fabricating a patterned c-plane sapphire substrate 1 for nitride epitaxial growth. The c-plane sapphire substrate 1 is currently one of the most commonly used substrate materials for epitaxial growth of nitrides.

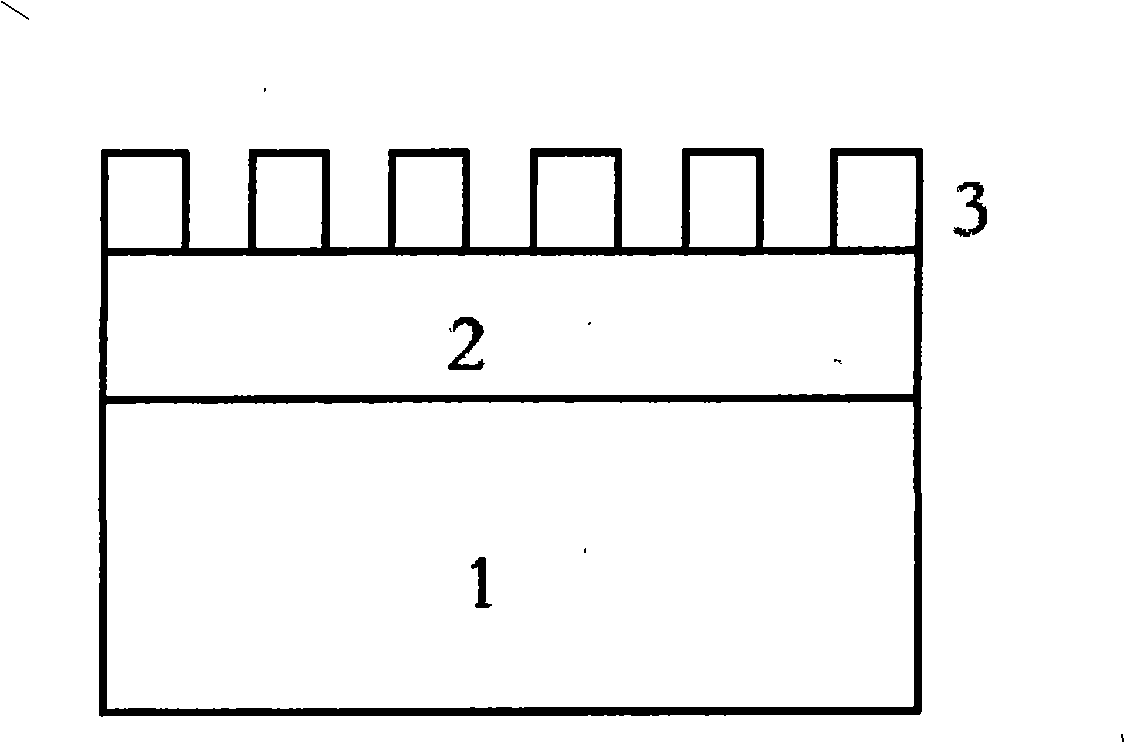

[0033] First, a 0.3 micron silicon dioxide film 2 is deposited on a 2-inch c-plane sapphire substrate 1 using plasma enhanced chemical vapor deposition (PECVD) technology, and a photoresist is coated on the silicon dioxide film 2 using conventional photolithography techniques Layer 3 is exposed and developed to form a circular array. The size and pitch of the circular array unit structure is 3 microns, and the structure section after photolithography is as follows figure 1 Shown

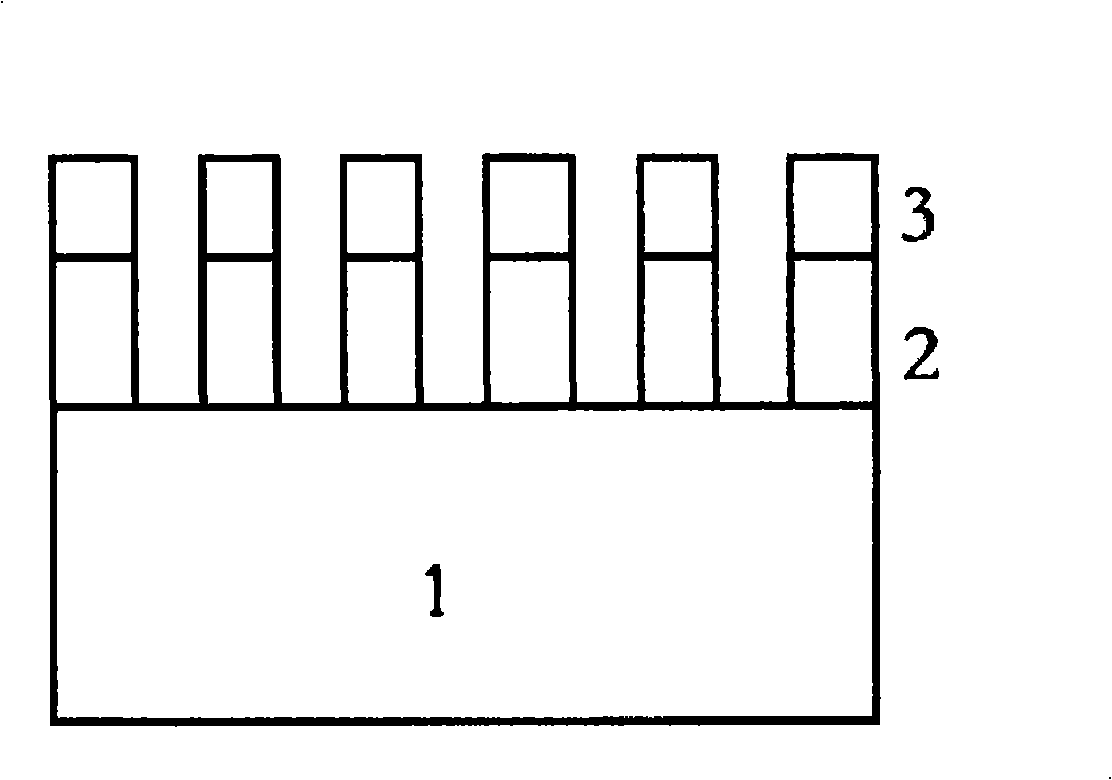

[0034] Then use the photoresist layer 3 as a pattern mask, using hydrofluoric acid (HF) + ammonia fluoride (NH 4 F)+H 2 O mixed solution, etch the photolithography pattern on the silicon dioxide film 2, and its structure secti...

Embodiment 2

[0039] This embodiment is a method for manufacturing a patterned r-plane sapphire substrate 1 for nitride epitaxial growth. The r-plane sapphire substrate 1 can be used for epitaxial growth of non-polar nitrides. Non-polar nitrides can avoid the built-in electric field caused by the strain effect in the vertical growth direction, thereby enhancing the probability of carrier radiation recombination and improving the performance of optoelectronic devices.

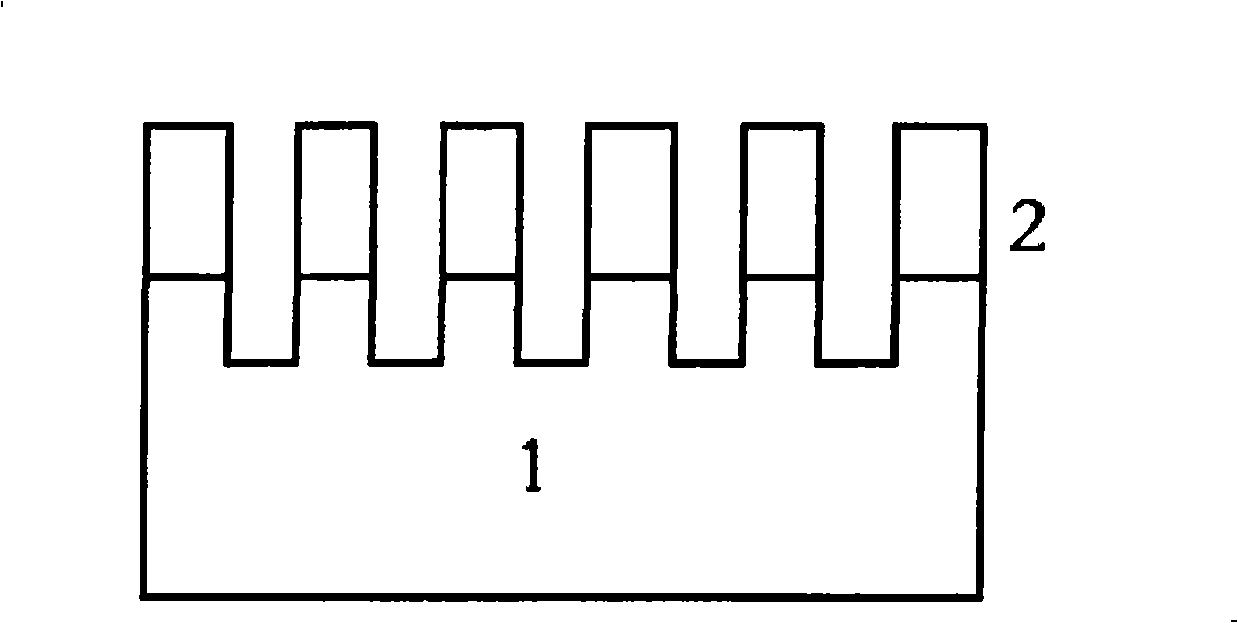

[0040]Using a process similar to that of Example 1, a silicon dioxide film is deposited on the r-plane sapphire substrate 1 using plasma-enhanced chemical vapor deposition (PECVD) technology. 2. Conventional lithography technology lithography patterns, hydrofluoric acid (HF )+Ammonia fluoride (NH 4 F)+H 2 The O mixed solution etches the silicon dioxide film 2. The sulfuric acid and phosphoric acid mixture is used to etch the r-face sapphire substrate 1 at 400°C. The etching time is 6 minutes. Finally, the remaining silicon dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com