Industrial-grade polyphosphoric acid production process and system

A production process and production system technology, applied in the field of industrial-grade polyphosphoric acid production process and its system, can solve the problems of high requirements for equipment corrosion resistance and pressure resistance, harsh and complex process conditions, low recovery rate, etc. Simple process, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

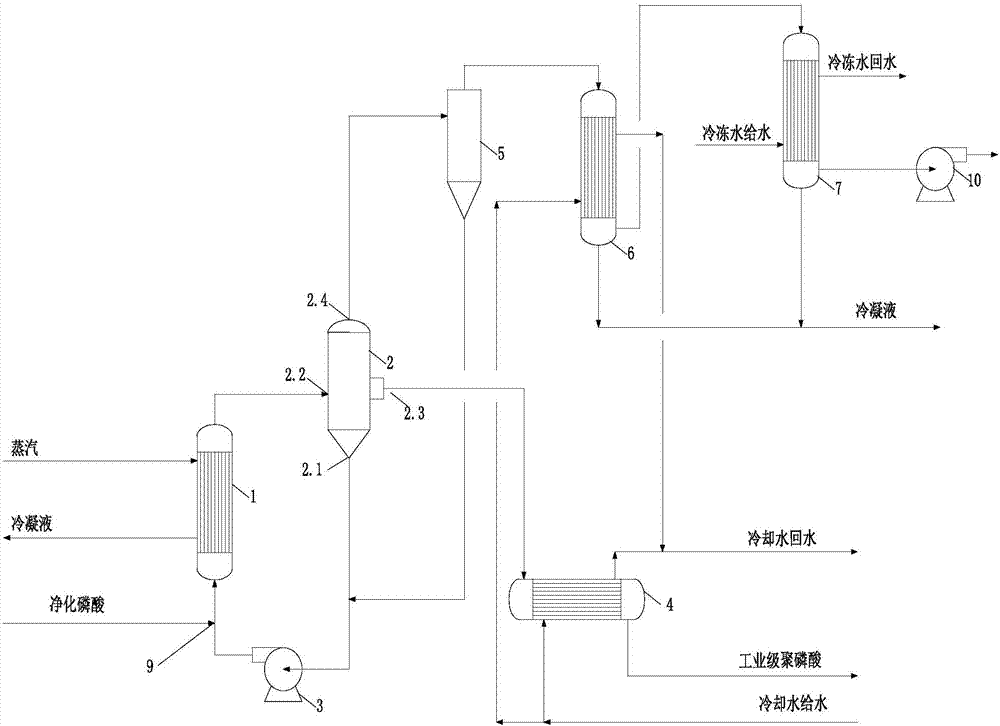

[0036] see figure 1 The system of the present invention includes a flash chamber 2, the circulating acid outlet 2.1 of the flash chamber 2 is connected to the circulating acid inlet 2.2 of the flash chamber 2 through an axial flow circulating pump 3, an acid heater 1, and the flash chamber The finished acid outlet 2.3 of 2 is connected to the finished acid cooler 4, and the pipeline connecting the flash chamber 2 and the acid heater 2 is provided with a purified phosphoric acid inlet 9. The steam outlet 2.4 of the flash chamber 2 is connected to the mist separator 5 , the precondenser 6 and the condenser 7 in sequence, and the liquid outlet at the bottom of the mist separator 5 is connected to the acid heater 1 .

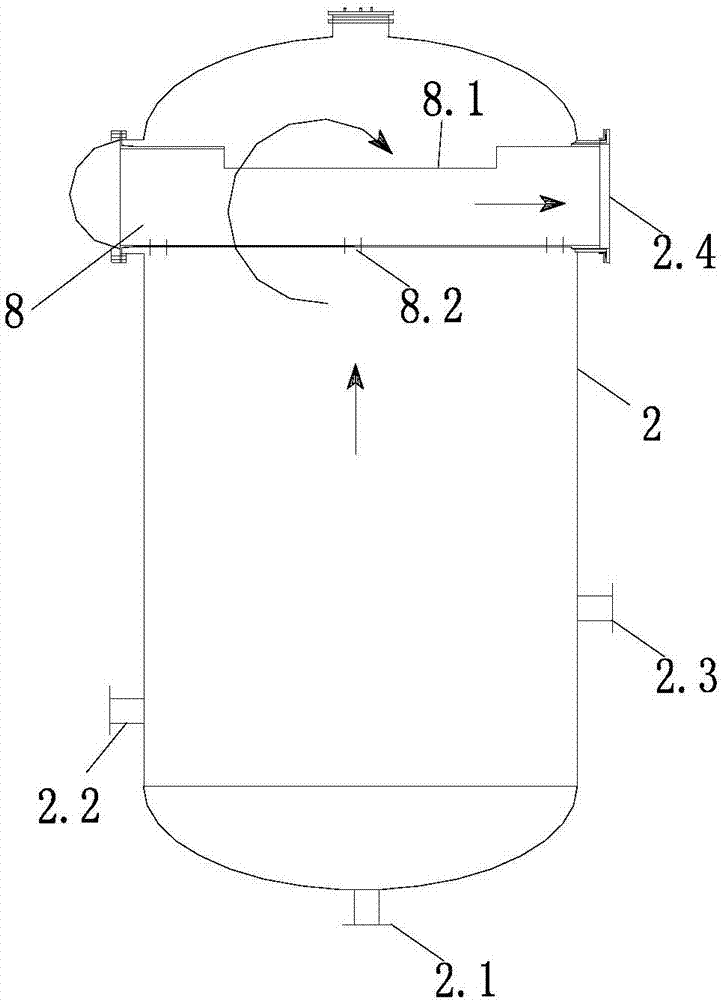

[0037] see figure 2 , the upper part of the flash chamber 2 is horizontally provided with an insertion pipe 8, one end of the insertion pipe 8 is closed, and the other end communicates with the steam outlet 2.4 of the flash chamber 2, and the top surface of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com