Method for producing high-quality polyphosphoric acid

A technology of polyphosphoric acid and production method, applied in directions such as phosphorus oxyacid, condensed phosphoric acid, etc., can solve problems such as not reporting arsenic content, not reporting polyphosphoric acid concentration, not reporting polyphosphoric acid production, and achieving high production efficiency , The effect of stable production system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

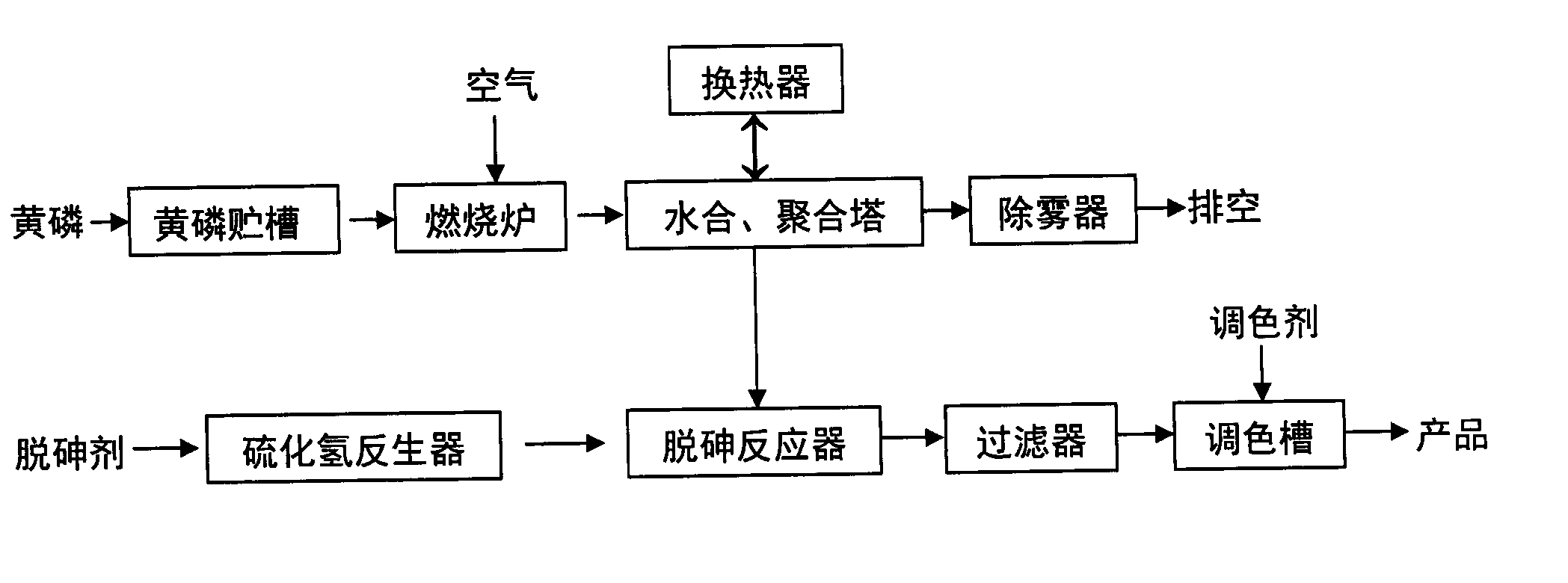

Image

Examples

Embodiment Construction

[0025] The implementation steps of the present invention will be further described in detail below in conjunction with specific examples, so as to facilitate a clearer understanding of the purpose, technical solutions and advantages of the present invention. It is necessary to point out here that the specific examples described below are only used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments, or replacement of some equipment with similar equipment, examples are as follows:

[0026] In the first step, the yellow phosphorus enters the combustion furnace stably from the yellow phosphorus storage tank at a rate of 80 kg / min, and the natural air also continuously and stably enters the combustion furnace under the action of the large fan installed at the rear of the production system. Phosphorus pentoxide flue gas is generated after the combustion reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com