Installation fixture of hot runner fastening lantern ring and application method thereof

A technology of fastening sleeves and jigs, which is applied in the manufacture of tools, workpiece clamping devices, metal processing, etc., can solve the problems of easy scattering, poor heat insulation effect of pads, fragile ceramic materials, etc., and achieve long-term stable production system , better heat insulation effect and increased competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

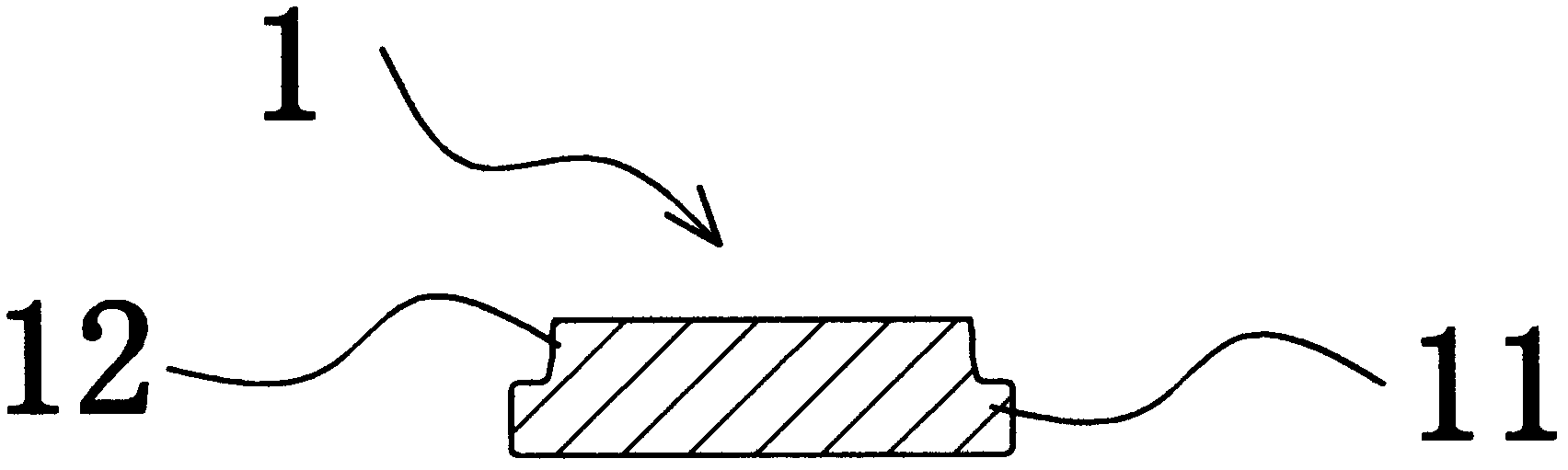

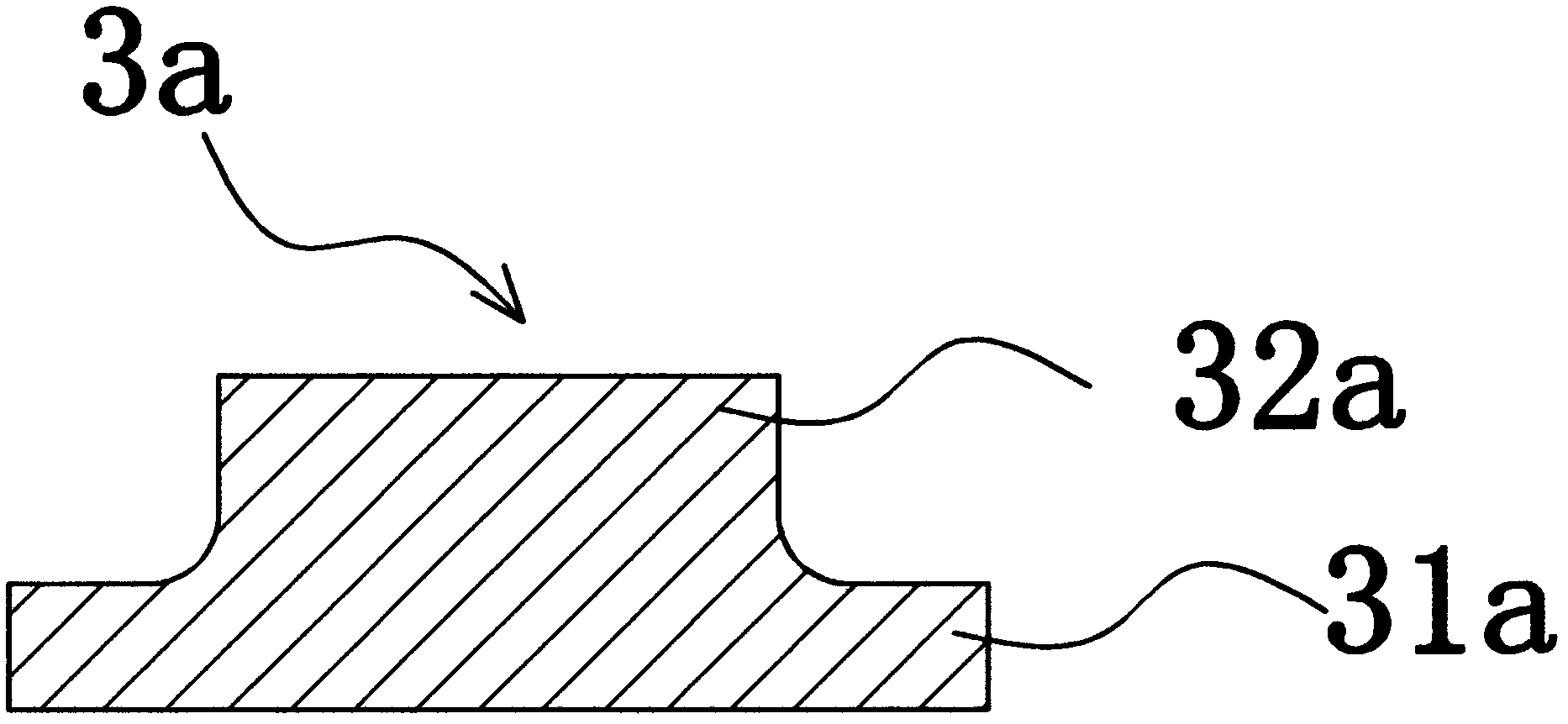

[0038] A fixture for installing a fastening collar in a hot runner has a first fixture A for pressing the fastening collar; and a second fixture B for installing the fastening collar on a ceramic gasket; wherein, The first fixture includes: see figure 1 , the fastening collar base 1 placed on the workbench T, which consists of a columnar bottom-11 and a cylindrical convex part-12 arranged on the columnar bottom and used to set the fastening collar, the convex part-arrangement At the center of the bottom one, the outer diameter of the cylindrical convex part one is smaller than the outer diameter of the columnar bottom one, and the convex part one is used to cover the fastening collar, and the outer diameter of the convex part one is determined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com