Process and device for selectively producing phosphorus pentoxide

A kind of phosphorus pentoxide, selective technology, applied in the direction of phosphorus oxide, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of wasting energy, environmental thermal pollution, energy utilization, etc., to reduce water consumption and labor intensity , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

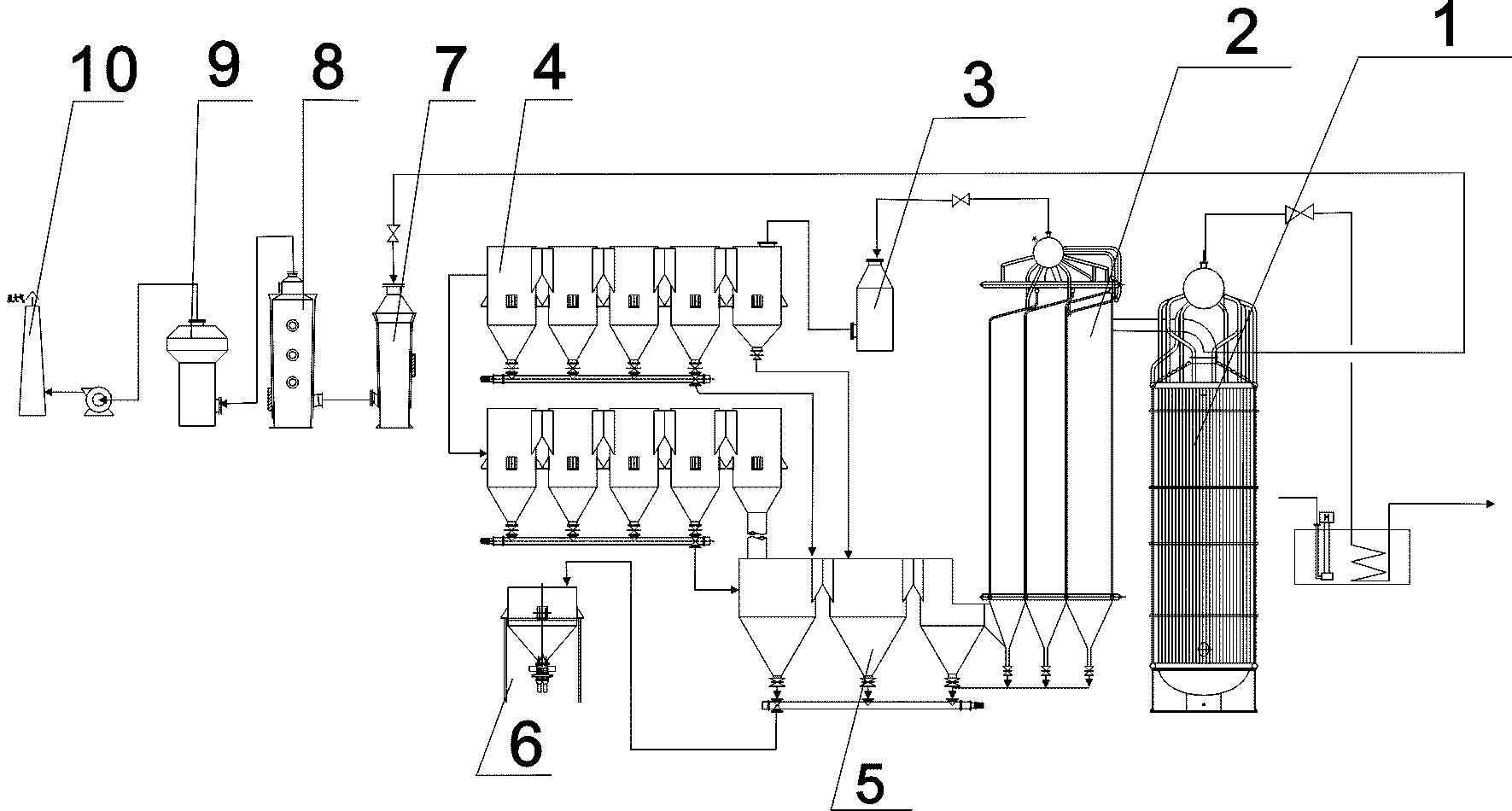

[0028] Put 10 tons (24 hours of phosphorus input) of yellow phosphorus into the phosphorus furnace 1 and burn it to produce phosphorus pentoxide flue gas, use sulfuric acid as a desiccant, open the valve, and send the phosphorus pentoxide flue gas through the flue gas pipeline. into the cooling tower 2, forcedly cooled to below 360°C by the water wall in the cooling tower 2, and the pressure is 1kpa, the cooled phosphorus pentoxide flue gas passes through the buffer tank 3 and then is sent to the 10-stage settling bin 4 to settle, so that the pentoxide The temperature of the phosphorus pentoxide flue gas is reduced to below 360°C, and the pressure is 1kpa. After cooling and sedimentation, the phosphorus pentoxide is sent to the phosphorus pentoxide silo 5 for absorption to produce 23.7 tons of phosphorus pentoxide with a purity higher than 99.5%, and the tail gas After purification, it is discharged through the exhaust gas discharge channel 7-1.

[0029] 10 tons (24 hours of p...

Embodiment 2

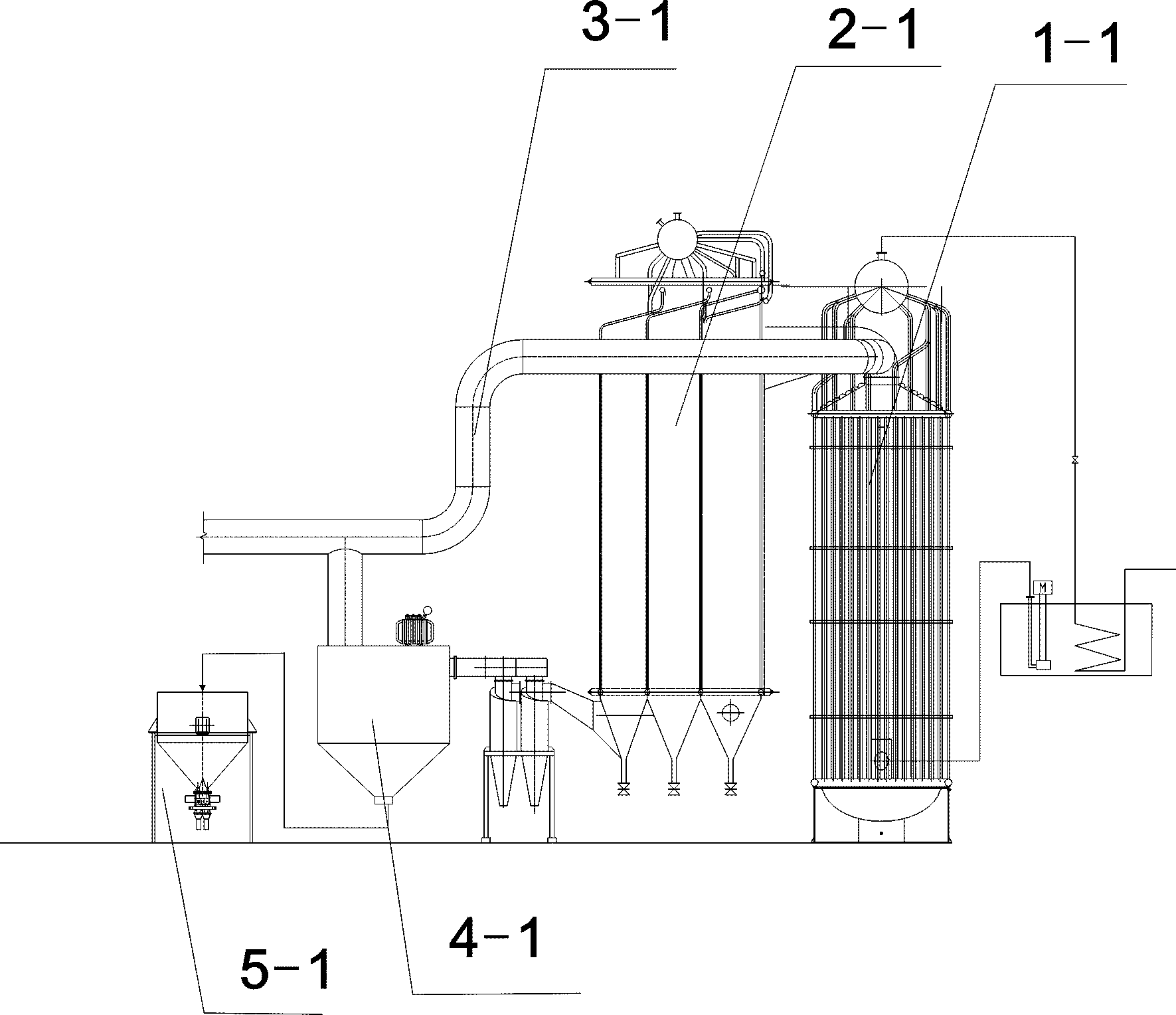

[0032] A new type of phosphorus pentoxide production equipment, the phosphorus furnace 1 is connected to the cooling tower 2 through the flue gas pipeline controlled by the valve, the cooling tower 2 is connected to the buffer tank 3, and the multi-stage settlement chamber 4 is set behind the buffer tank 3, and the multi-stage settlement The multi-stage settling bin 4 is connected to the packaging hopper 6 through the collection bin 5; the flue gas pipeline controlled by the valve of the phosphorus furnace 1 is connected to the polyphosphoric acid absorption tower 7 and the phosphoric acid absorption tower 8 in turn, and the phosphoric acid absorption tower 8 is absorbed by ammonia The tower 9 is connected with a fiber demister 10 .

[0033]The length of the flue gas pipeline from the phosphorus burning furnace 1 to the polyphosphoric acid absorption tower 7 is 28-35m. The side wall of the cooling tower 2 is provided with a circulating water channel,

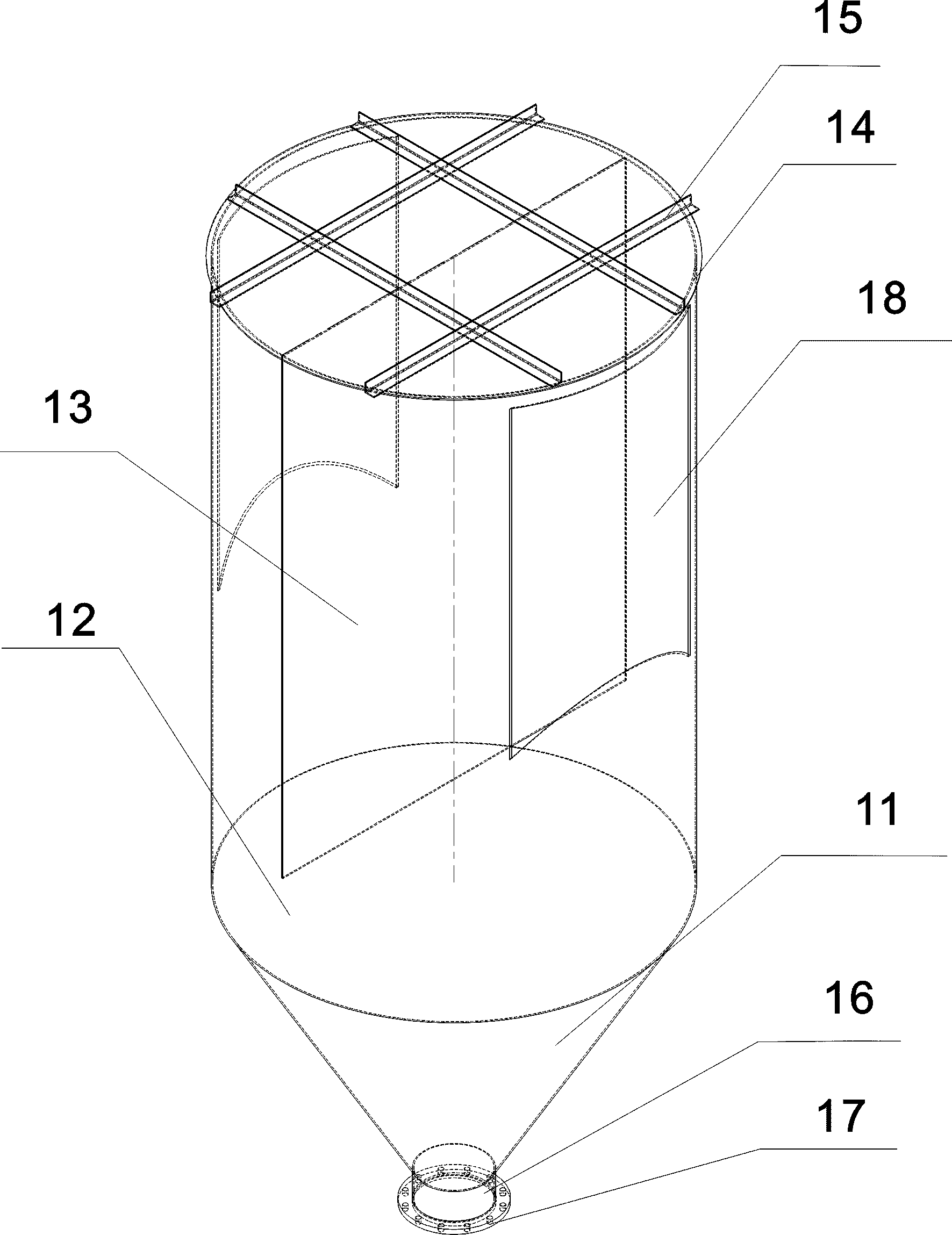

[0034] The multi-level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com