Novel phosphoric acid and polyphosphoric acid production technological method

A technology of polyphosphoric acid and production process, applied in the field of phosphorus chemical industry, can solve the problems of waste of a large amount of combustion heat energy, difficulty in further utilization, etc., and achieve the effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

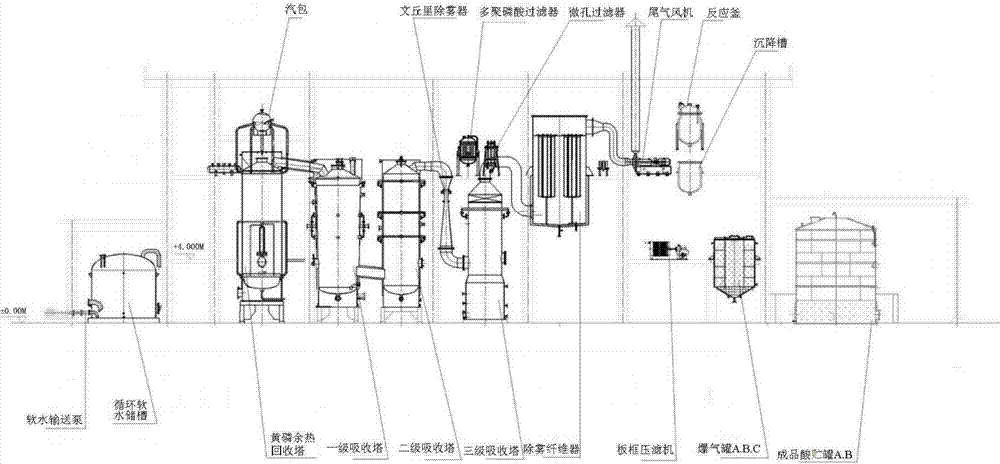

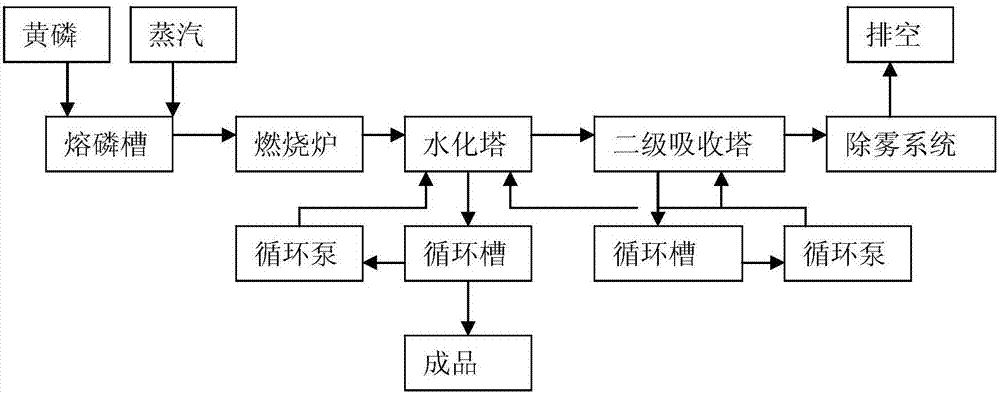

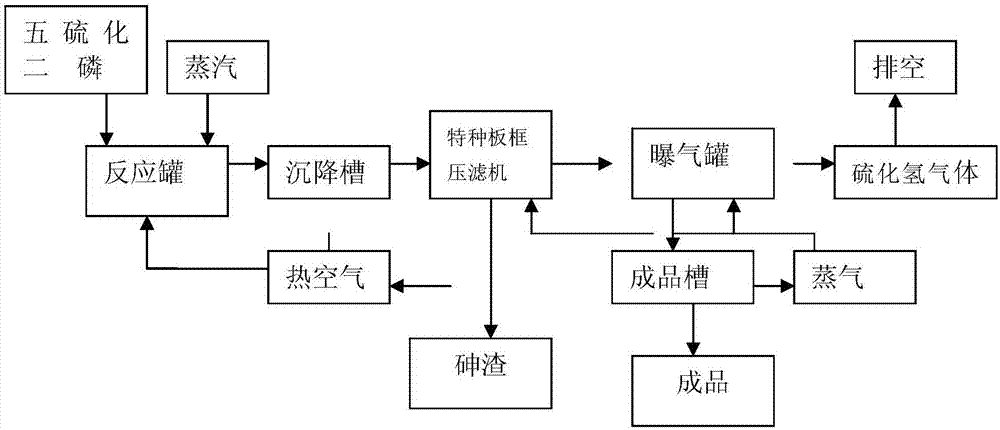

[0016] See figure 1 , Novel phosphoric acid, polyphosphoric acid production process, the present invention is characterized in that, be divided into two steps: (1) combustion absorption

[0017] Melt the yellow phosphorus that meets the specified quality indicators into a liquid state with hot water, atomize the yellow phosphorus with the primary compressed air, and burn it together with the secondary air in the combustion tower. After the combustion is complete, the phosphorus containing 2 o 5 (P 4 o 10 ) mixed process gas is gradually absorbed by the circulating dilute phosphoric acid in the hydration tower and the first-level absorption tower, and the circulating dilute phosphoric acid in the second-level absorption tower gradually circulates dilute phosphoric acid. Phosphoric acid with a specified concentration is filtered, cooled, measured and packaged into the warehouse; the remaining tail gas is discharged into the atmosphere after being treated by Venturi and fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com