Polyphosphoric acid preparation technology and production control method thereof

A preparation process and technology of polyphosphoric acid, applied in the field of phosphorus chemical industry, can solve problems such as low production efficiency and low temperature of feed liquid, and achieve the effects of improving production efficiency and device life, improving production efficiency, and stable and reliable process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

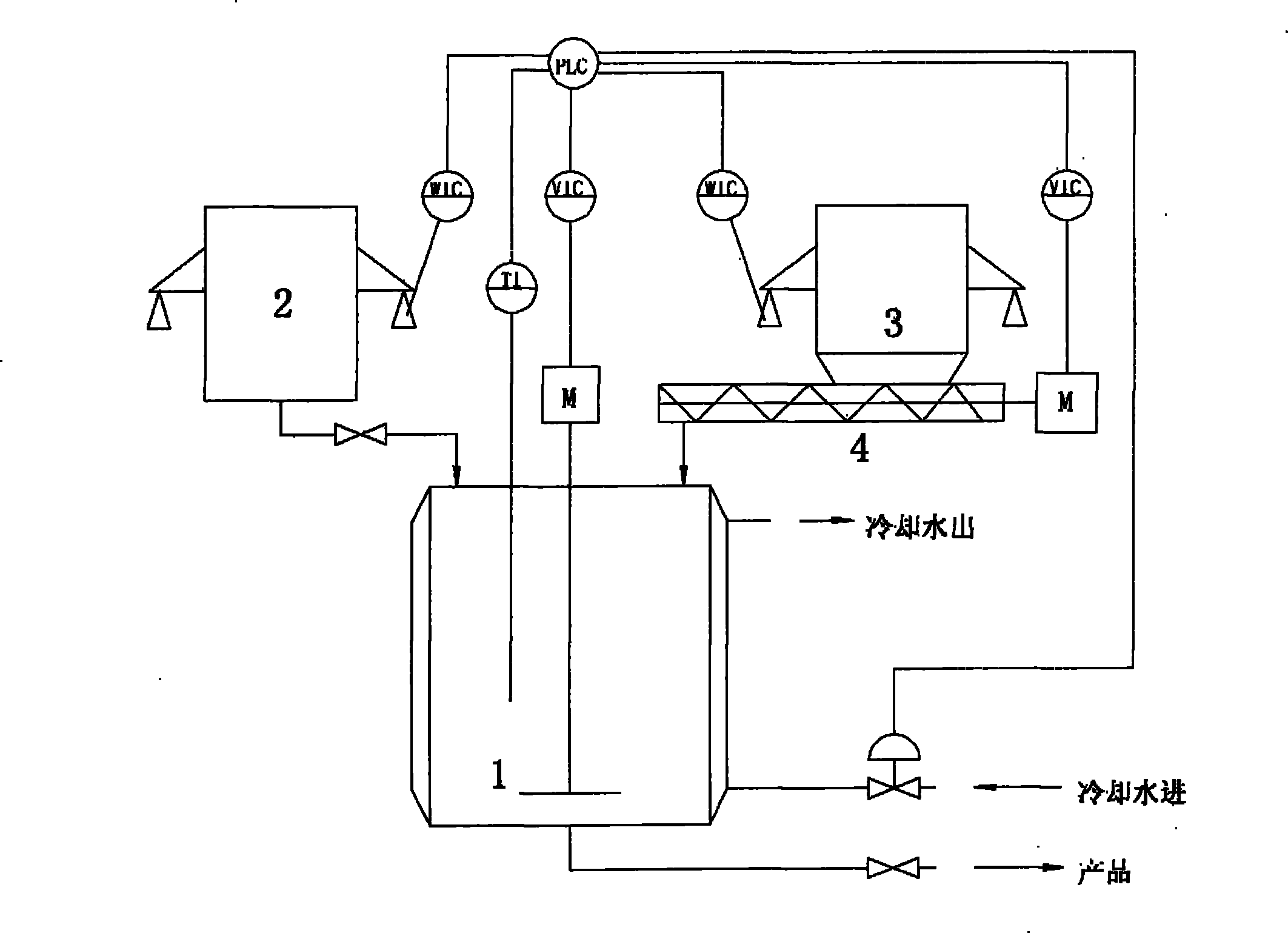

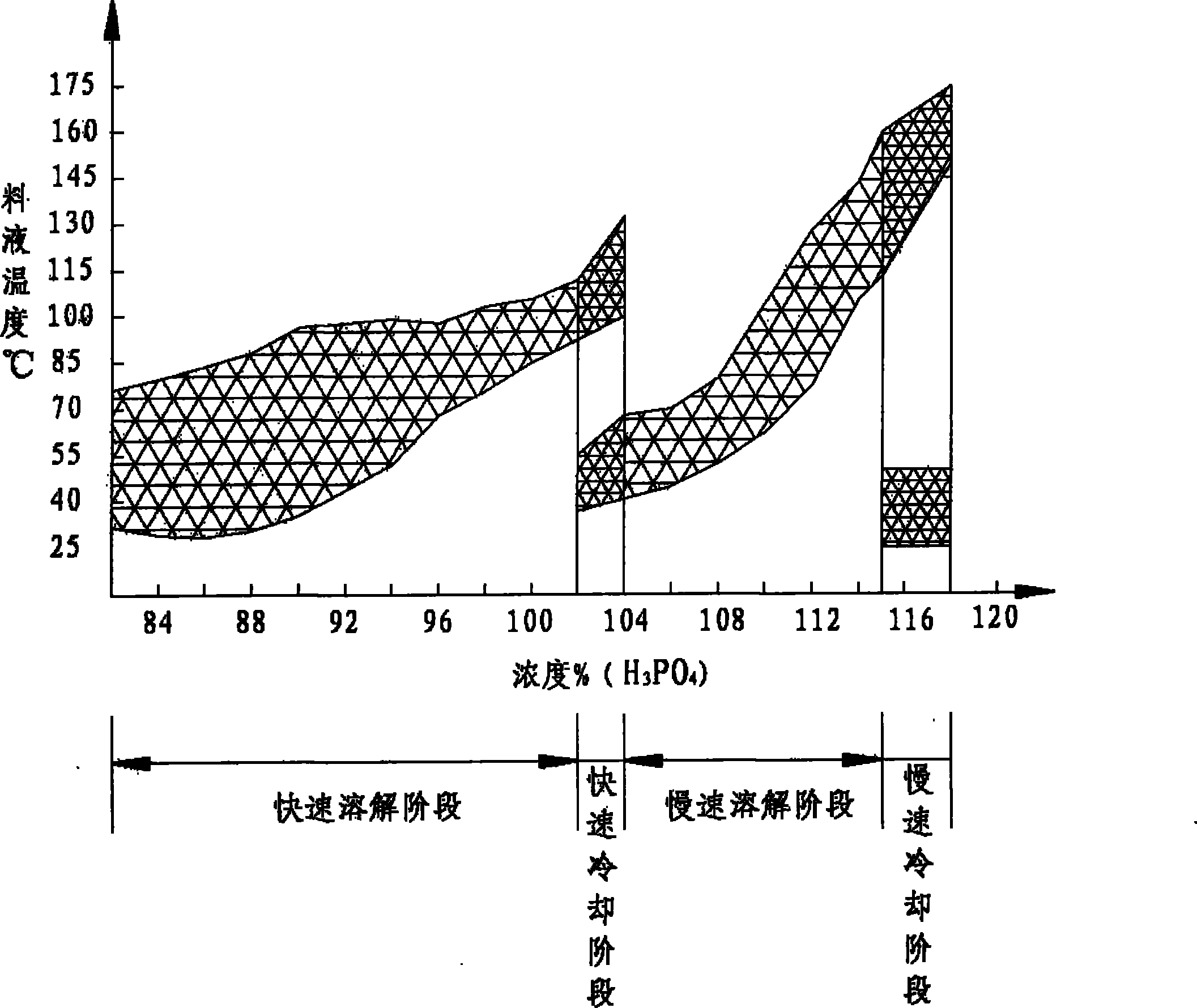

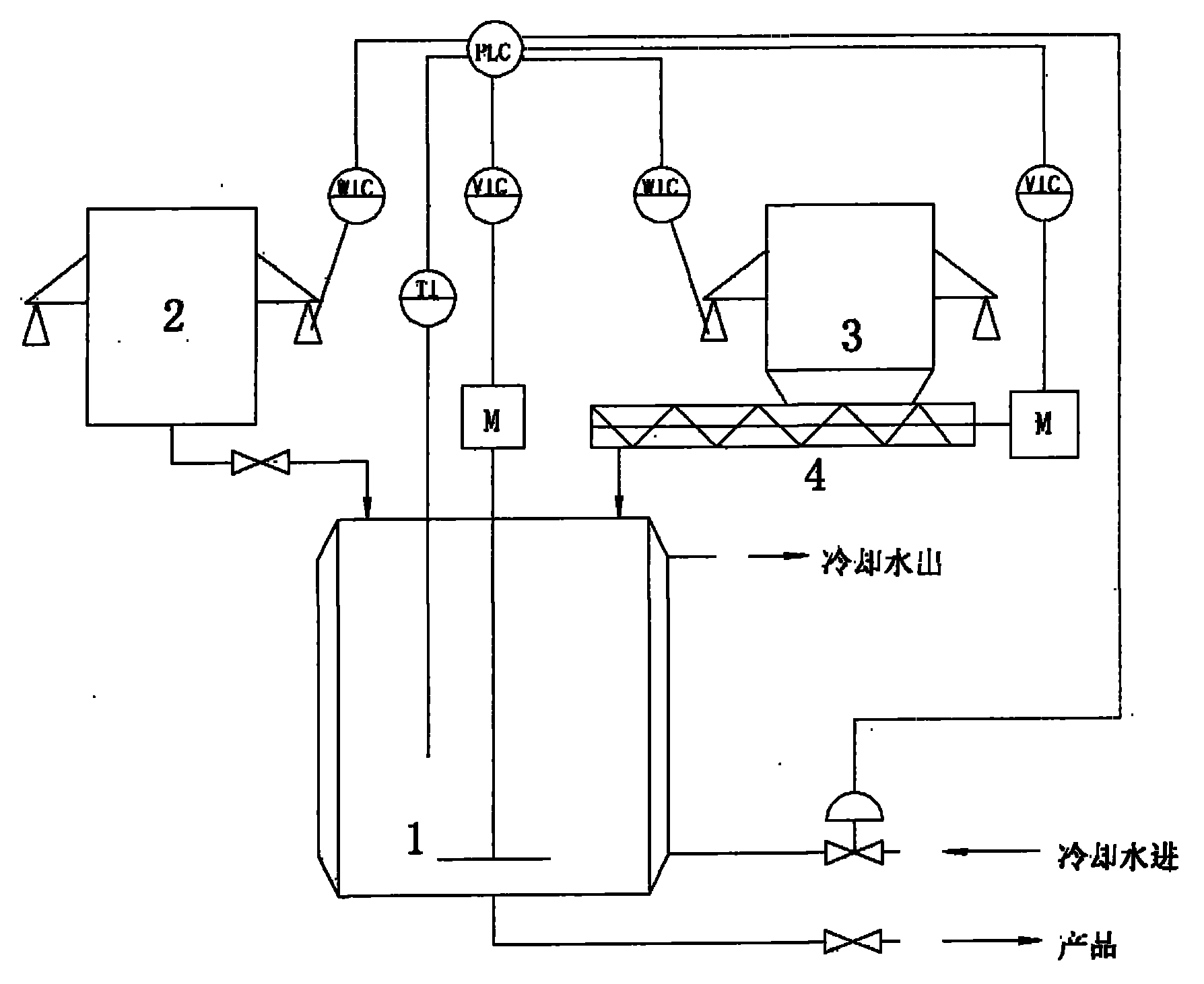

[0050] (i) fast dissolution stage of phosphoric anhydride: figure 1 In the shown preparation equipment, first add 690 kilograms of 85.1% industrial grade phosphoric acid to be the mother liquor, and add phosphoric anhydride under the condition that cooling water is passed into the cooling jacket for cooling, according to the present invention figure 2 The control area shown adjusts the rate of phosphoric anhydride addition;

[0051] (ii) rapid cooling stage of feed liquid: after adding 340 kg of phosphoric anhydride and dissolving, calculate the concentration of feed liquid at this time to be about 103%, and the temperature of feed liquid is shown as 104°C, stop adding phosphoric anhydride, increase the cooling water flow, Increase the stirring speed to cool the feed liquid to 58°C within 2-3 minutes, then stop the cooling water in the cooling jacket and drain the remaining cooling water in the cooling jacket;

[0052] (iii) slow dissolving stage of phosphoric anhydride: con...

Embodiment 2

[0054] Embodiment 2: In embodiment 1, replace 85.1% technical grade phosphoric acid with 85.12% food grade phosphoric acid as mother liquor, all the other situations are identical with embodiment 1.

[0055] Table 1. Analytical test results of polyphosphoric acid products

[0056]

[0057] For further illustrating the present invention's advantage under the control reaction, provide two examples here, the situation of the comparative experiment outside the control reaction situation:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com