Phosphoric acid production device by employing hot method

A production device and technology of thermal phosphoric acid, applied in the field of thermal phosphoric acid production and energy saving, can solve the problems of increased power configuration of circulating pump and induced draft fan motor, large volume of hydration tower equipment, large amount of circulating acid in empty tower, etc. The effect of absorption rate and demisting rate, reduction of thermal pollution and harmful emissions, and reduction of installed capacity of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

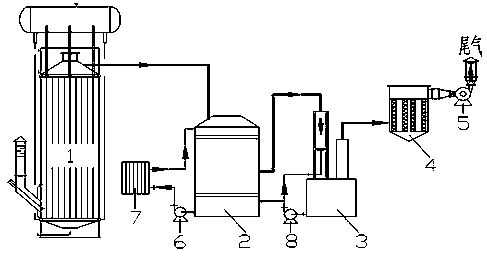

[0031] Embodiment 1: as figure 1 , 6 As shown, the thermal phosphoric acid production device includes a combustion tower 1, an absorption tower 2, a power wave demister 3, a gas-liquid separator 4, and an induced draft fan 5. The combustion tower 1 communicates with the entrance at the top of the absorption tower 2, and the absorption tower 2 and The power wave demister 3 is connected, and the power wave demister 3 is connected with the induced draft fan 5 through the gas-liquid separator 4. At the same time, the absorption tower 2 is connected with the heat exchanger 7 through the absorption tower circulation pump 6, and the heat exchanger 7 is connected to the absorption tower through a pipeline. The tower 2 forms a circuit, and the power wave demister 3 and the demister circulation pump 8 form a circuit through the pipeline; the absorption tower is a hollow absorption tower with three layers of nozzles, and the power wave demister 3 includes a demister cylinder 22, a power ...

Embodiment 2

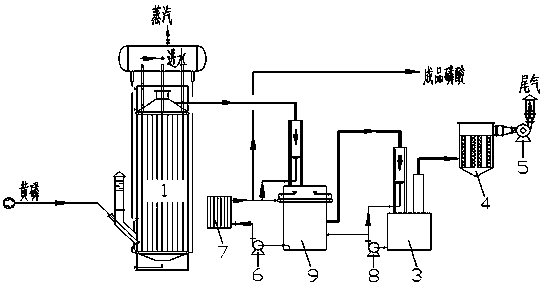

[0035] Embodiment 2: as figure 2 , 5 , shown in 6, this thermal phosphoric acid production device comprises combustion tower 1, power wave absorption tower 9, power wave demister 3, gas-liquid separator 4, induced draft fan 5, the entrance of combustion tower 1 and power wave absorption tower 9 tops Connected, the dynamic wave absorption tower 9 is connected with the dynamic wave demister 3, the dynamic wave demister 3 is connected with the induced draft fan 5 through the gas-liquid separator 4, and the dynamic wave absorption tower 9 is connected with the heat exchanger 7 through the absorption tower circulation pump 6 , the heat exchanger 7 is connected to the power wave absorption tower 9 to form a circuit through pipelines, and the power wave demister 3 and the demister circulation pump 8 form a circuit through pipelines; wherein the power wave absorption tower is composed of a power wave absorber 12 and a closed spray tower 13, the dynamic wave absorber is set on the u...

Embodiment 3

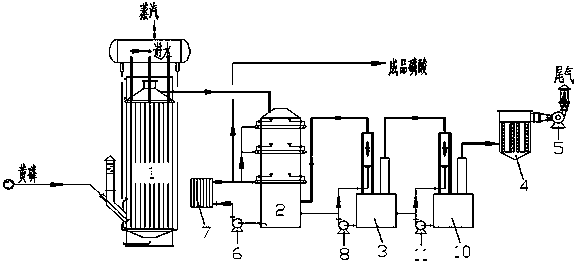

[0043] Embodiment 3: as image 3 , 5 , shown in 6, this thermal phosphoric acid production device comprises combustion tower 1, absorption tower 2, dynamic wave demister 3, secondary dynamic wave demister 10, gas-liquid separator 4, induced draft fan 5, combustion tower 1 and absorption tower 2 The entrance at the top is connected, the absorption tower 2 is connected with the power wave demister 3, the power wave demister 3 is connected with the secondary power wave demister 10, and the secondary power wave demister 10 is connected with the induced draft fan 5 through the gas-liquid separator 4 At the same time, the absorption tower 2 is connected to the heat exchanger 7 through the absorption tower circulation pump 6, and the heat exchanger 7 is connected to the absorption tower 2 to form a loop through the pipeline, and the power wave demister 3 and the demister circulation pump 8 form a loop through the pipeline. The primary power wave demister 10 and the secondary demiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com