Surface-treating agent comprising crystalline layered inorganic compound dispersed in nanosheet form

A surface treatment agent and inorganic compound technology, applied in the direction of niobium compounds, inorganic chemistry, phosphorus compounds, etc., to achieve the effect of improving corrosion resistance or coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

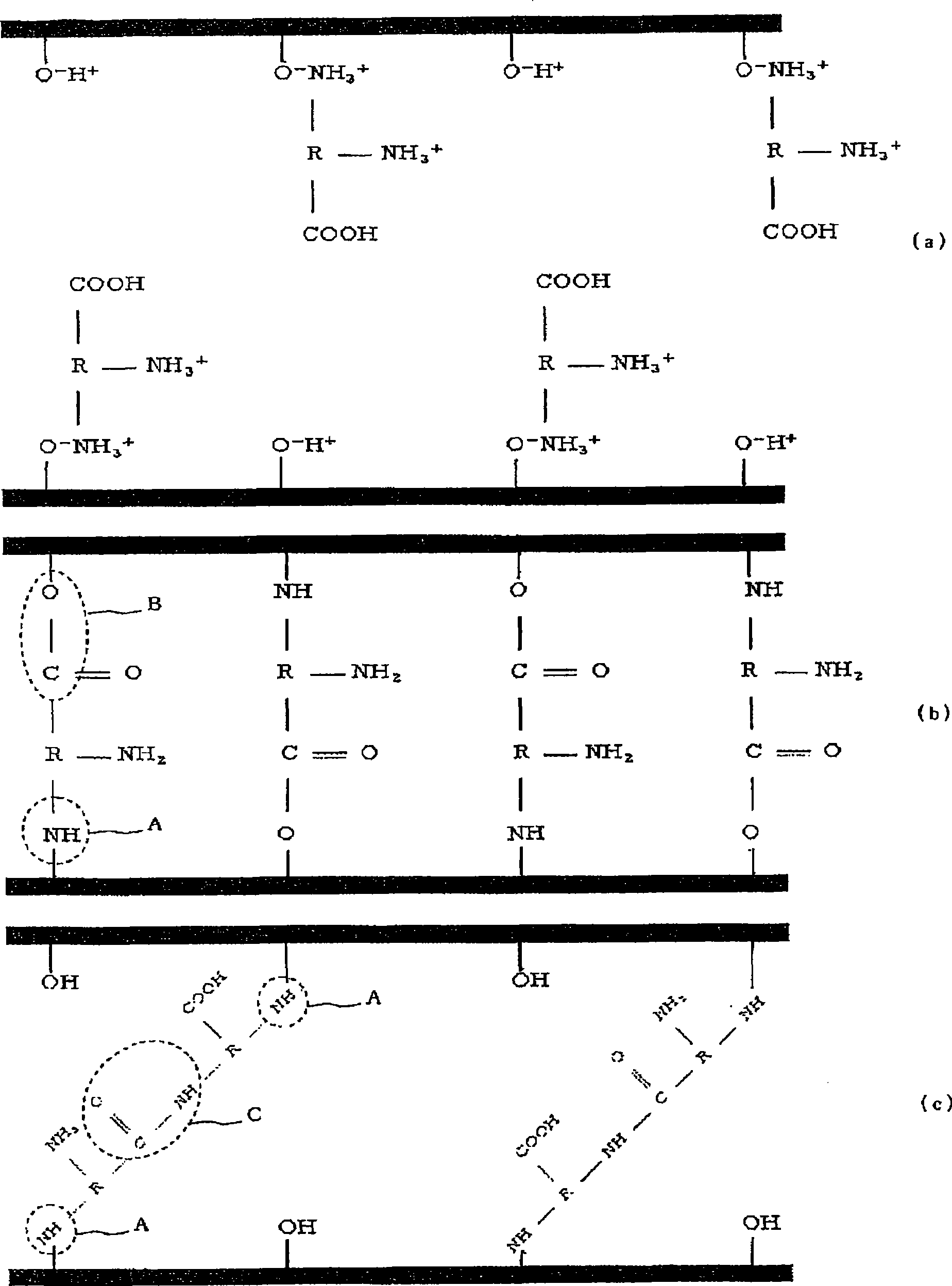

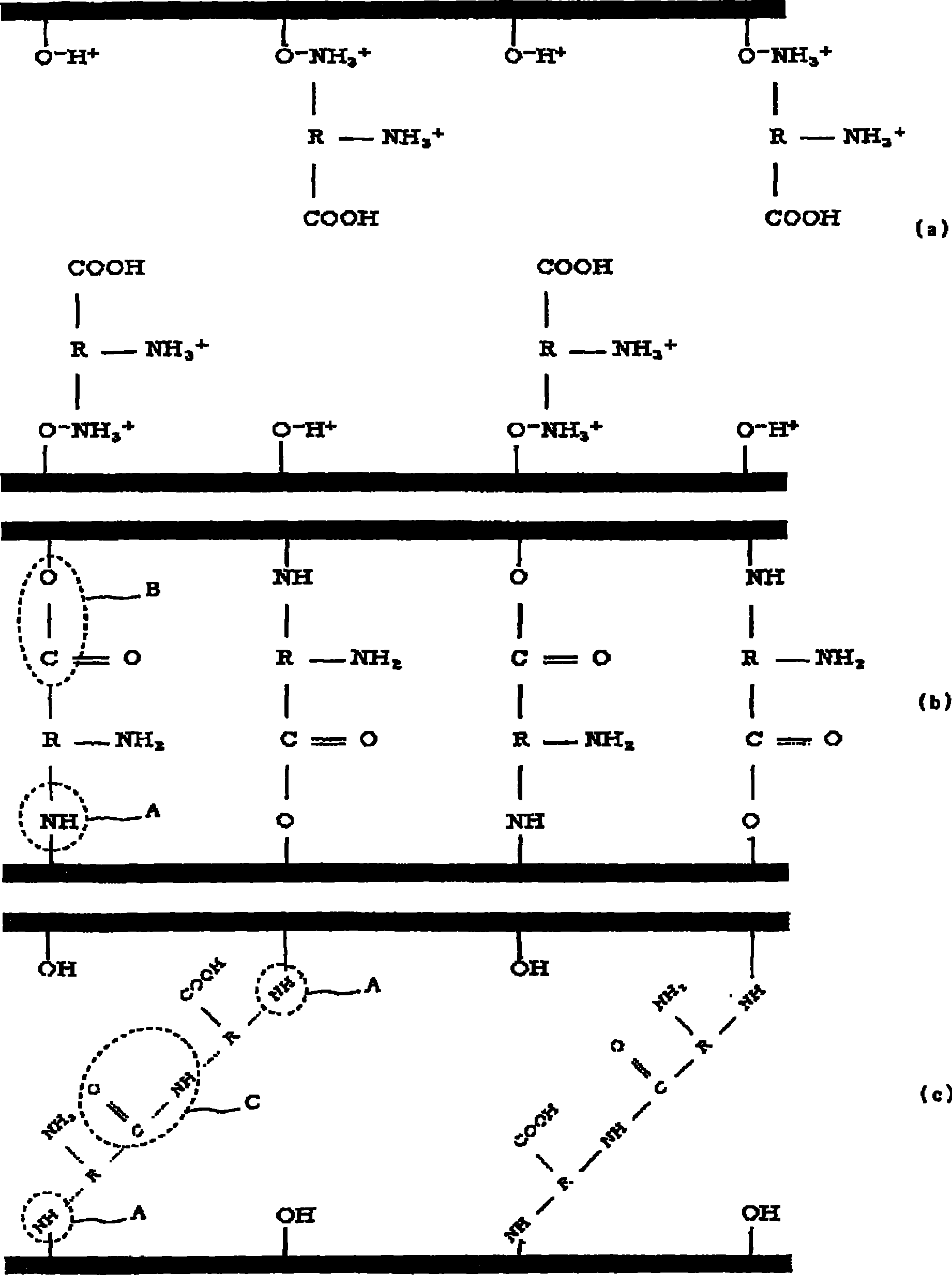

Method used

Image

Examples

Embodiment 1~69、 comparative example 1~24

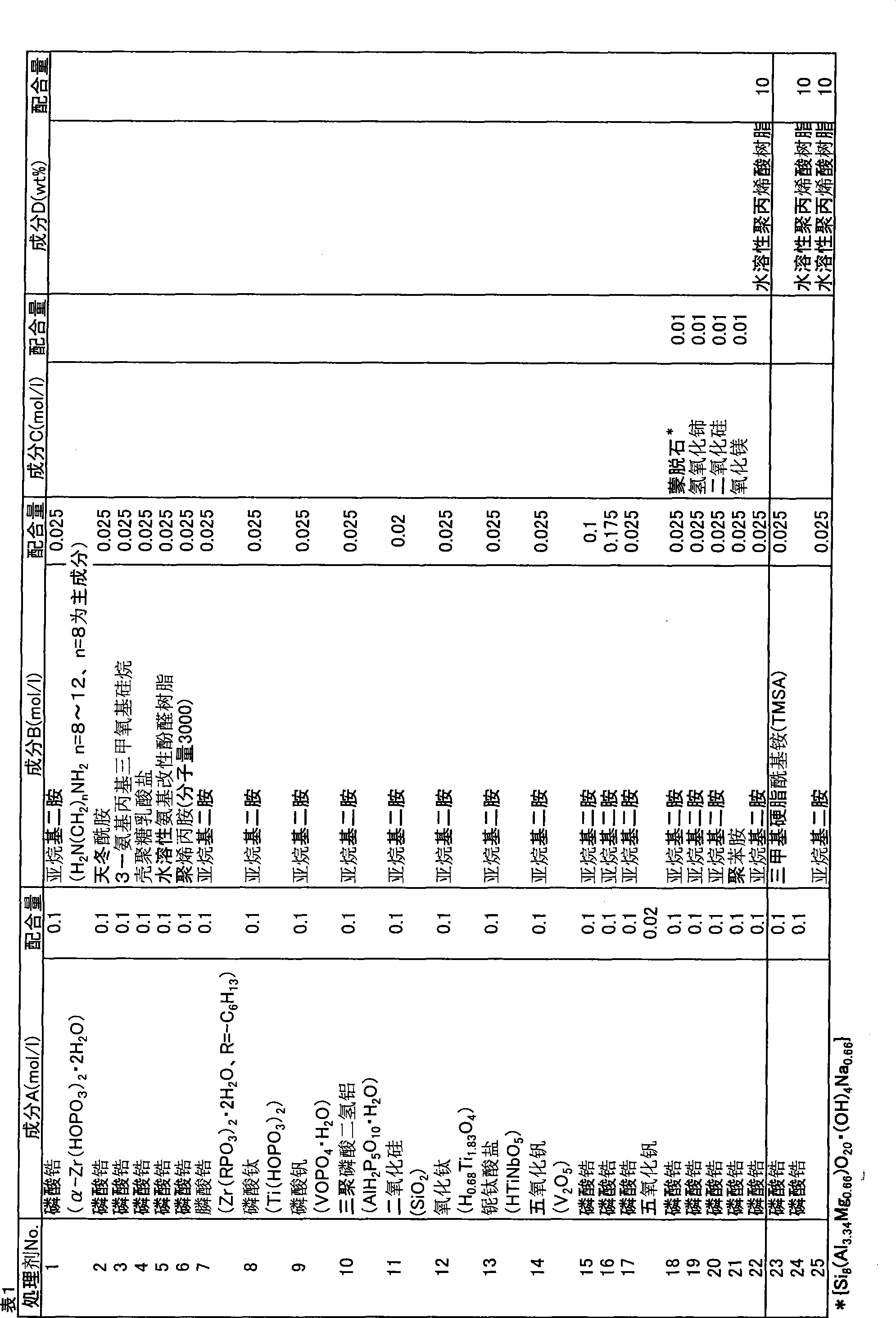

[0068] For SPCC material, GA material, EG material, GI material, GL material or AL material, use the surface treatment agent with the composition shown in Table 1, and apply it by bar coating to form a specified film thickness, and use it as a temporary rust preventive agent. The used bare board (before painting) and / or the bottom treatment film of the general painted board and the bottom treatment film of the pre-coated board are dried in a drying oven at a maximum temperature (PMT) of 120°C. For the AL material, use the surface treatment agent with the composition shown in Table 1, and apply it by bar coating to form a specified film thickness, and use it as the bottom treatment film of the hydrophilic coating plate, and dry it in a drying oven at PMT180°C . Here, the crystalline layered zirconium phosphate [Zr(HPO 4 ) 2 ·H 2 O] As an example, production examples of the crystalline layered inorganic compounds used in the present examples and comparative examples will be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stripping area | aaaaa | aaaaa |

| stripping area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com